Disc Grinding Machine

Before starting work, I studied in detail the constructions of such machines, looked through articles and videos on this topic. One time I was thinking about buying, but I decided to make the device myself all the same. I set the goals as follows: on the one hand, to get a machine for grinding small parts from soft materials (wood, textolite, plywood); on the other hand, learn to develop and design such products (practical experience in design).

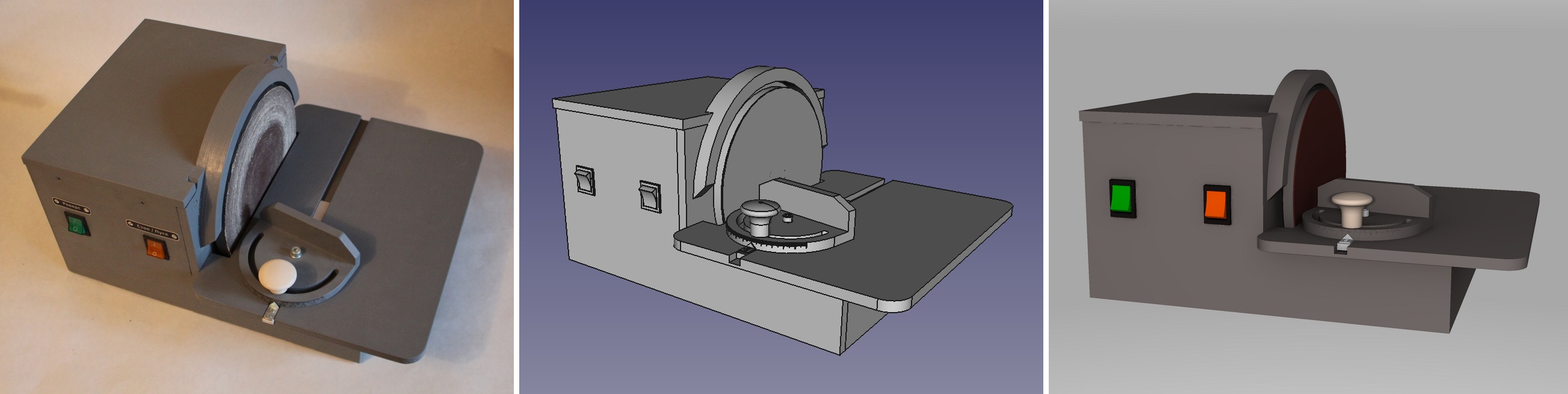

Stages of development

I would single out four stages in my work on this machine:

- Build the first model, the prototype. Then I thought that I was doing the final version, "the first time." Everything was drawn by hand, it was going to be “in place,” with a fitting file. The result was ugly, cumbersome, inconvenient in work.

- Refinement and adjustment. The second model. On the basis of the initial drawings, based on the experience of test operation, a second version of the machine was assembled with an adjustment to the design. She presented in the photographs and is described in the current review.

- Improvement and modernization. A useful option was completed: an angular stop. Revision well laid down, came to the place, organically combined with the very body of the machine.

- Creating a parametric model of the machine in the CAD program. In theory, this stage should be the first, but it was the last, since initially there was no understanding and experience in this matter.

Machine Specifications

- weight: 8.5 kg

- overall dimensions (LWH): 460270240 mm

- engine power: 180 W (50 Hz, 220 V)

- angular velocity (at the edge of the disc) - 14-15 m / s

- reversing the direction of rotation of the grinding wheel

- quick change of emery wheel on disk

- table tilt angle fixed (90 degrees)

- the possibility of dust removal is realized (the diameter of the inlet is 40 mm)

Characteristics of an angular emphasis

- footboard length 120 mm

- adjustment range (on scale) ± 60 degrees

')

"Dolgostroy"

At all stages: the implementation of ideas and ideas, improvements took me about four years of life (meaning calendar years - between the stages there were breaks, external circumstances, other projects, etc.).

When I used to read that personal technical projects can last several years, it surprised me. It seemed to me that why take so long? He invented, drew, put everything together for a couple of months - the finish. But, having worked on a new and complex (for me) project on my own, I begin to understand why it happens this way: you get distracted by something else, look for a “good” solution, study analogs for a long time, wait for delivery of components, design everything in detail (mastering new knowledge and technology), etc.

Sometimes, already during the implementation of the current project, there are ideas about modernization and improvement, which are obvious, but do not fit into the existing structure. In general, welcome to project management and product release.

Design

The general scheme was formed in the head rather quickly. Initially, I did not make drawings (I just ordered a transition flange on the motor shaft), assembled and customized the parts “in place”. Later (during the modifications and upgrades) - I looked at every detail, its shape, place, size, manufacturing methods, installation and replacement. Not all the ideas were implemented, but in general, the design is efficient and usable.

The cover above the engine is made removable to give access to the interior: wiring, capacitors, etc. Rubber legs are provided so that the machine does not “drive” on the table while working. The table is removable, unregulated; has a fixed installation angle of 90 degrees (the inclination of the table relative to the grinding disc is not provided).

The power of the existing engine is completely enough for hobby needs (even with a small margin). Eating on a decent tree, even if the contact area is large. Of course, if you press the workpiece very hard against the disk, the rotation of the engine will slow down.

Assembly

The assembly was made with the help of glue - this is a fast and reliable way to connect plywood parts. Used PVA glue (water resistance class - D2). The basis of the design was two 40x50 mm bars on which were attached a supporting platform for the engine and table fasteners. From above fastened a protective and power framework from plywood 10 mm thick.

Dust removal

Dust removal is present as an option. The gap in the volume under the desktop, I tried to eliminate as much as possible (to effectively suck the dust). Grinding without dust removal is not very good for employee health and cleanliness in the room. On the side of the case opposite to the buttons, under the table, in the case, there is an inlet for connecting the dust removal system. Through a standard sanitary adapter 40/32, you can connect the hose of a household vacuum cleaner. Tests have shown that with a working dust removal system, you can even grind in the apartment. Almost all the small sawdust are sucked, nothing flies away (the main thing is to choose the right direction of rotation of the disc and place the workpiece in the right place).

Grinding wheel

Disc diameter: 200 mm. This size was not chosen by chance, it is the width of standard sandpaper in rolls, which is sold in any market. You can buy a piece of any grain and cut the desired number of removable disks. The circle itself is made of plywood. He is bolted to the flange with six M6 bolts. After installation, the circle is machined in place with a chisel (to ensure flatness). Grinding speed (at the edge of the disc) is obtained in the region of 14–15 m / s. which is enough for woodworking. Emery circle is fixed on the double-sided tape. I tried to change the sandpaper - this is done quickly and easily, the mount is strong.

Electrician

There is no "collective farm" and twisting: all electrical connections are made at the terminals, clamps or soldering. The correct reverse phase of a single-phase motor has been implemented (and not through a change in the working and start winding, as shown on one video on YouTube). I give a schematic diagram of electricians connecting the engine.

Painting

As for painting and puttying, I studied the experience of those craftsmen who restore metal machines (but there mostly epoxy putties are used). I did not have a utility room for work - I chose paint, which can be painted in a residential area, which is safe from an environmental point of view. He stopped at the water-emulsion acrylic paint. Pigment picked up and stirred separately (the paint was originally white).

If there was a workshop, I would now more responsibly approach the processing and painting of the hull: I would seal all the cracks and defects of plywood with putty, grind more and more carefully, paint it in several layers. If you apply several layers of putty or paint (with intermediate sanding and embedding all the irregularities and shortcomings of plywood), you will get a very smooth and smooth surface. With due diligence, you can not even understand what kind of material (it will be like plastic, metal).

Angle stop

The last step was the corner stop for the machine. This is my first stop (which I made and used in my work). Prior to that, I sharpened everything “by sight”, but the result was, to put it mildly, not very. Work without a stop, conductor or guides - get mediocre and unpredictable result at the exit.

The accuracy of the “scale”, of course, does not reach the factory, but it allows you to pre-set the angle - and then, the adjustment and more accurate measurements, the adjustment. I also recommend that the axis of rotation of the stop be pushed as close as possible to the thrust pad. This is not obvious when designing, but it is already clear during operation.

He began to focus on "from scratch", without knowing at all what it is and how it would have to be exploited. Initially, there was not enough understanding of what the length of the stop pad should be. Therefore, I made two blanks: 100 and 120 mm. Stopped at a length of 120 mm. Now I would additionally provide holes for fixing external devices.

Details for assembling the draft version of the stop, the handle is made of furniture fittings, an aluminum strip was bought for the guide (a bit wider than necessary). The reason for the duplication of holes - could not drill a perpendicular hole the first time (everything was going to crooked).

In the table of the machine we mill the groove under the guide. The reinforcing strip of plywood is glued underneath. The height of the guide is 6 mm, the depth of the groove is 7 mm, plywood is 10 mm thick.

Initially (for one installation, for one pass of the router), we get a groove of the same width along the entire length of the table. If you make several passes, the groove will be of different widths at the beginning and end (I did not think up, as in my conditions, with the available tools and skills to make it the same width). The guide is less in length, and can be fitted to the groove in width without much difficulty.

Ideally, we get a smooth course of the corner stop (without backlash) along the entire length of the table.

In reality, of course, there will be small gaps (due to the negligence of performance, errors and omissions of technology, etc.).

Close-up. Numerous hand marking flaws are visible. In the future, it would be nice to engrave (laser-apply) them directly on the support or to make the scale as a separate part and install it on the product.

I tested a little corner support: I tried to grind the cubes, and also - to make the connection at 45 degrees. The cubes did not work out (there was little time and you need to make a device for grinding 45-degree faces (with setting in three planes))

But the connection such as "frame for a picture" surprisingly turned out quite accurate. The planes fit perfectly together and form an angle very close to ninety degrees.

Disadvantages, errors:

- the design turned out to be partially non-separable (it is impossible to replace the engine without dismantling the body part)

- chose an unsuitable motor with a time limit for continuous operation and rotor imbalance

- at least the grinding disc itself is partially balanced, but during operation there are slight vibrations in the machine (due to the engine).

- Now I would redo the electrical circuit of the machine: I would add a large “Stop” button, I would connect the engine not directly, but through a relay (starter). Those. connection would do like an "adult" machine.

Advantages, advantages:

- the dust removal system works very well

- availability of assistive devices (corner stop, other additions in the future)

- low weight, compact size

- low price (if you count only materials and external works)

Creating a parametric model

The last stage of work for me was the creation of a parametric model of the machine in a CAD program.

Drawing in various versions of paper and electronic panels already in the past. Similar concepts come from the 80s. Now it is much more effective to model a parametrized solid body, and remove views and sections from it. Such an approach is not a substitute for drawings, it is conceptually different. The resulting models can be directly transferred to the CAM for production (cutting, milling, 3D printing, etc.).

It was very difficult for me to mentally move from the concept of development " thought, figured everything in my head and drew paper / electronic drawings , transferred to production " to " thought, created a solid-state model, corrected errors and inaccuracies, created drawings , transferred them to production ". It took a lot of effort (to change stereotypes), you always want to go "easy" and the usual way. I remember, I often read in the forums statements of more experienced comrades about which methods of work are most effective, but I missed it by; or could not understand; or understood, but there was no time and energy to acquire new skills.

In this project, I chose the FreeCAD program. There are a lot of lessons and training videos for it. Of course, there are many more complex and professional development packages, but the existing functionality for my level and range of tasks was enough. Even the rendering (visualization) of the model was able to be configured and run (although initially I wanted to study Blender 3D for this).

After the stage of getting used to the interface, working with model parameters and assembling all the details together brings pleasure and allows you to fully concentrate on the design, seeing the whole picture.

I remember how I tried to keep and correlate "in the head" several interdependent dimensions, transfer them to the drawings. Still, after long titanic efforts, I was mistaken and re-ordered the manufacture of individual parts in the assembly.

Conclusions and Conclusion

When practice and theory go side by side, with interest and determination one can master almost any area of human activity, solve a complex complex problem.

Source: https://habr.com/ru/post/374477/

All Articles