3D vlog # 5: Makers in Russia - 3D printing and cosplay. Interview with the creator of 3DToday

Hello friends! With you, Vasily Kiselev and this issue of our video blog we shot in St. Petersburg, with which I have a lot of warm memories, because here I was born, grew up and founded my company Top 3D Shop in 2013, and only in 2015 we decided to open an office in Moscow. A full-fledged back office with a staff of about 30 people is still working in St. Petersburg.

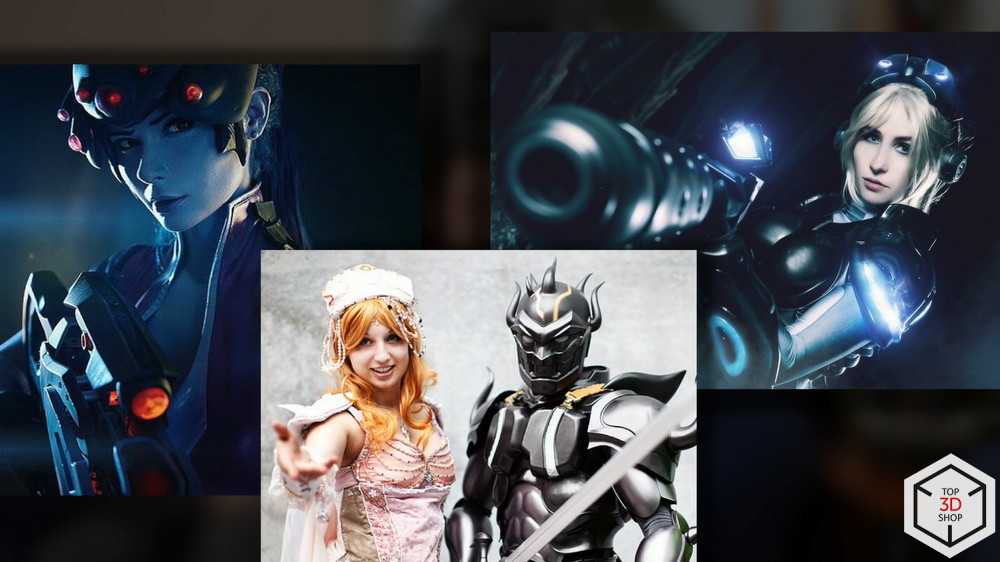

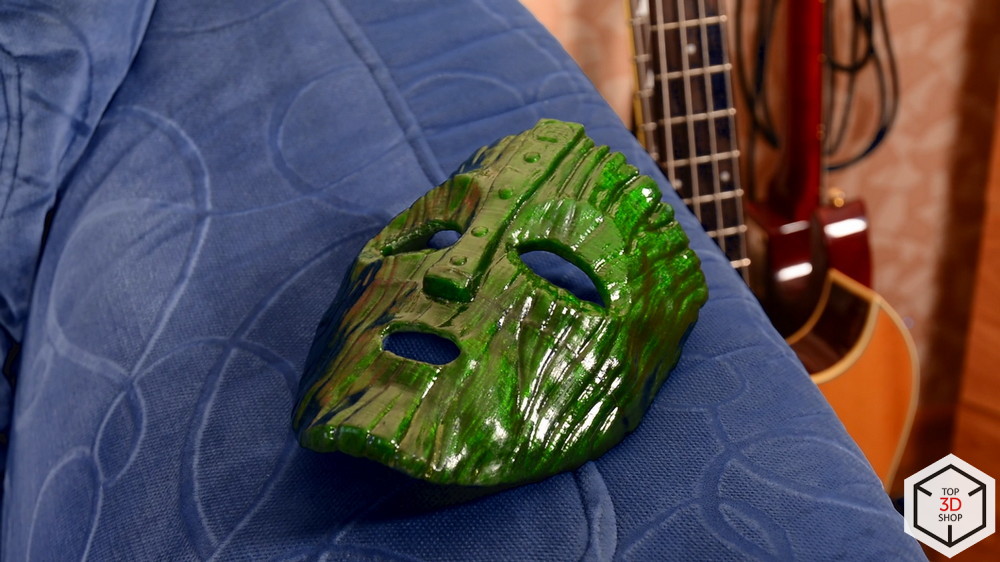

In this issue, we will meet with Ilya Nikonov, a man seriously involved in cosplay and using 3D printing to make costumes and paraphernalia, and with Sergey Pushkin, the permanent manager and founder of the 3DToday portal, we have a number of questions about his project and future .

')

Ilya Nikonov

In the first release of the 3D vloga, I said that we will communicate with the makers, and today this day has come.

We are in Ilya, this is a maker-cosplayer, and when we arrived here we were pleasantly surprised to find a whole family of makers instead of Ilya — Ilya and his wife Nastya.

- How did you come to this?

- We visited StarCon 2015 and saw several booths in fantastic universes that we like.

They made a very big impression on us, literally shocked.

It was overwhelming - only yesterday I played a game or watched anime, and today I see all these characters, in those same costumes and with the same weapon.

There we met one of the teams of cosplayers and asked to accept us because we wanted to study the whole process from the inside.

Even before that, we made to order some small props and jewelry with their own hands.

- How did you come to 3D printing?

- There is such a moment: when you are engaged in make-up, different materials are required for everything.

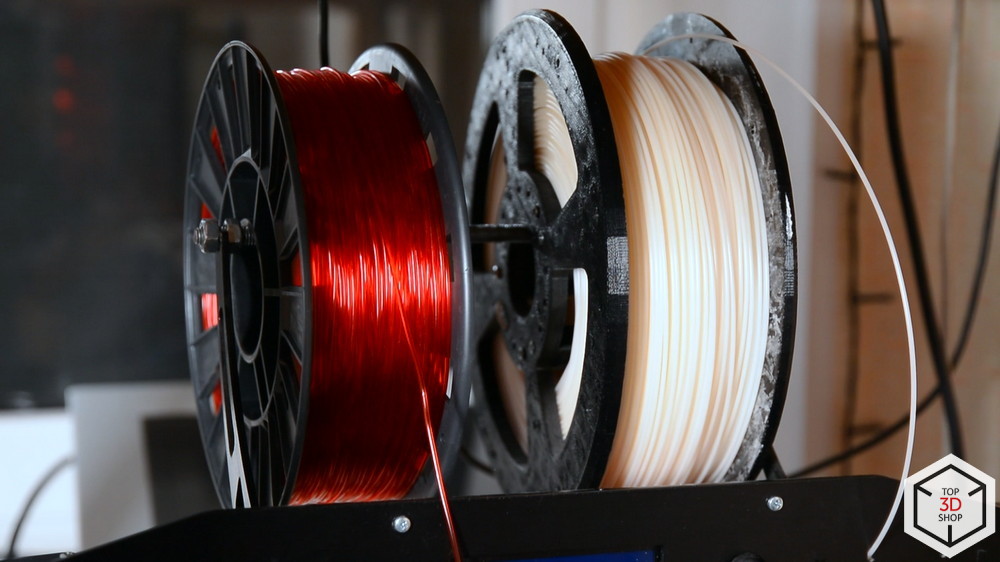

Sheet material, all sorts of tubes, gears and so on. It does not matter when you do one thing, another, third. But when you constantly make something, materials and components accumulate and tend to capture all the volume available to them in the room. This becomes a serious problem when doing this in your residential apartment. And in any workshop all this requires some kind of accounting, ordering, etc. Excessive headache.

With the advent of the 3D printer, this problem disappears - no need to store anything. It took a gear - took and printed. This saves a lot of space and now we can create our costumes at home. For 3D printing we need, from materials, only reels with plastic, and they are much more compact than all the junk that we had piled everywhere before.

- When working at home, there are no problems with evaporation from the printer, smells of meltable plastic, acetone during post-processing?

- There are certain problems, but these are mainly problems with noise.

There is no strong odor - we use such plastics that do not particularly smell. And if you want to print something ABS or process the surface with a solvent - just open the window and everything goes there. Acetone, which scares so many, is a relatively harmless thing, because even the human body releases similar compounds, and if you do not create a large concentration, air it, then the risk is minimal.

- What can be said about monetization, can this hobby bring in money?

- It already does it. But this cannot be perceived as the main income, this is exactly a hobby, which in parallel brings some money in the season of festivals. This is not a permanent income, so to speak.

- Is the number of festivals, conventions, cosplay-related audience growing?

- There are quite a few festivals in St. Petersburg alone. only 2-3 large annually pass, plus many small, many people visit each of them.

The industry is growing, especially in the last couple of years.

- Nevertheless, it is not yet possible to make this your main job?

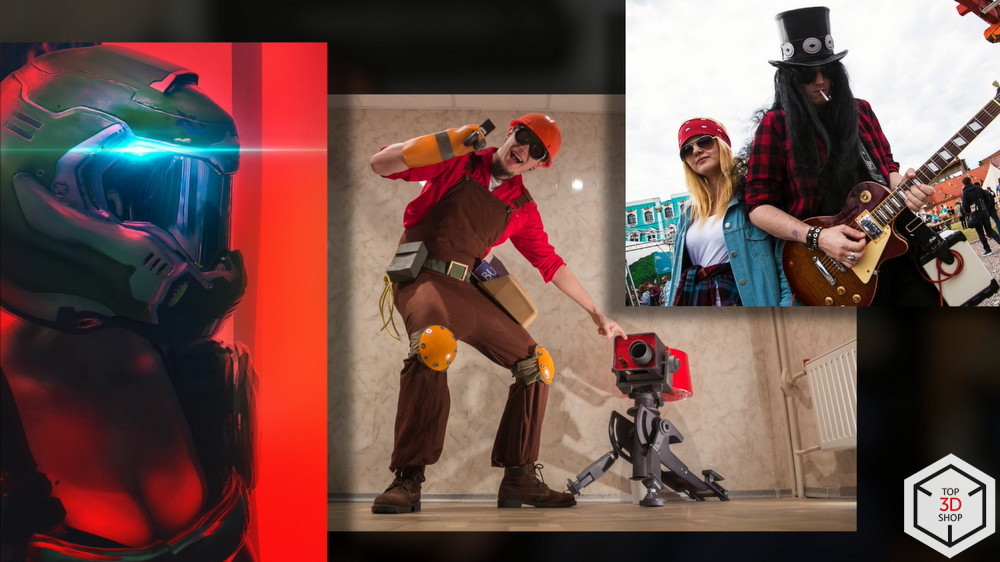

- People here love to save. They prefer to do something on their own from scrap materials, which often does not look the best way. Or order a cheap analogue on Ali-express - Chinese sites sell the fierce horror of the cheapest materials, in violation of design and color, crooked seams and other true-Chinese quality charms, in the best traditions of things from the markets of the 90s. It looks wild. Laughing over “Ali-cosplay” is deserved. Most of the things that can be printed on a 3D printer can be made manually for too long and laborious, and it is almost impossible to buy. It is necessary to simulate, print, postprocess. All this takes time and effort, the price tag turns out quite decent.

- Do cosplayers know about 3D printing?

- Of course, cosplayers are very advanced people who follow the achievements of science and technology.

Most of them believe that 3D printing is “pressed the button and done”. They do not remember that the model should be modeled, a suitable plastic should be selected, and processed and painted after printing.

They do not understand the fact that a 3D printer is a CNC machine, with which you also need to know how to work and adjust it. From the side of much is not visible and everything seems very simple, therefore, prices surprise many. Many people perceive 3D printing as cheating, they think that things for cosplay should be done by all means with your own hands - to cut, plane, cut.

- Tell me about some of his works, which are proud.

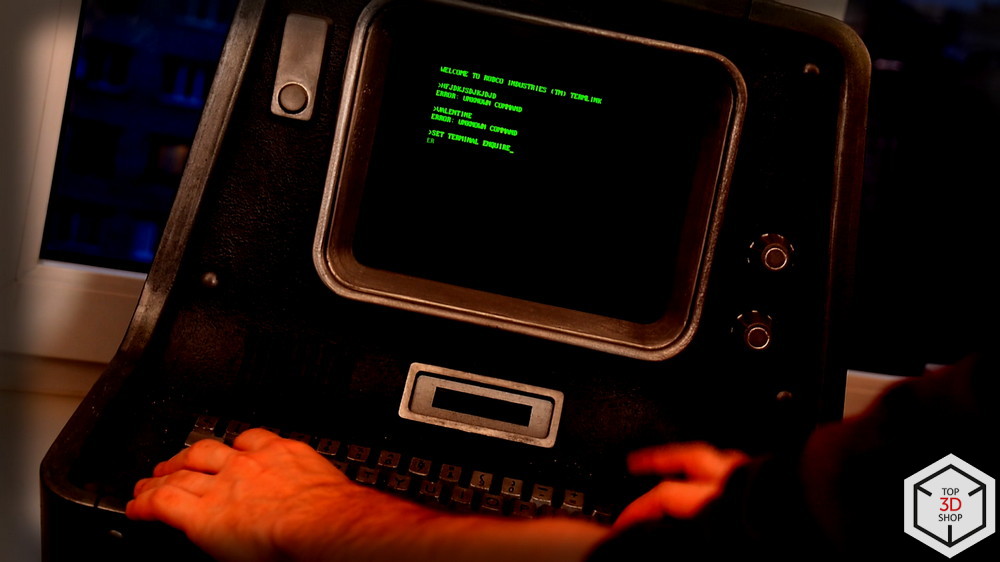

“In the fall of 2017, we prepared for the StarCon Halloween festival and created a booth for it in the DOOM universe.

The greatest difficulty was to create a suit for Nastya, or rather, to adapt a model of a men's suit, taking into account the graceful female figure and preserving the degree of authenticity sufficient to recognize the image.

It turned out a lightweight version, a sort of bikini-spacesuit - a helmet, a bib with shoulder pads, elements for a belt and legs.

It took about 1.5 months to make it, most of this time - to work out the concept, to create a digital model, which was based on the arts for the game and heavily reworked models from it.

It was not easy to individually fit the dimensions, introducing them into the model manually. A 3D scanner that we didn't have would be very useful.

- What could you advise our viewers?

- Pay attention to what other cosplayers and makers are doing. A lot has been done in creating cosplay items, most of which is available on the net - methods, methods, tricks. Do not neglect other people's experience, a lot has already been invented before you. This is especially true of foreign cosplay - there, this area is developing much longer, it is just a storehouse of useful information.

Other examples of 3D printed cosplay

Arkham Origins Batman Armor - Julian Checkley

Xenomorph Costume - XRobots

Reprinted from Ninjaflex .

Iron Man Suit - The Toolbox Armory

One of the most popular images for creating a 3D printed suit. Who just does not do it. For example, The Toolbox Armory.

And here is XRobots.

And this is the model of the Chinese master.

Sergey Pushkin and 3DToday.ru

In the office of 3DToday, the company’s founder and managing director Sergey Pushkin spoke with us. Sergey will tell us how this project started.

- In 2012, the boom of interest in 3D-printers, 3D-printing and all sorts of its application began, and we decided to create a resource that would tell about it.

Now on our portal there is not only a news feed, but also blogs, and many other interesting features. The site’s audience is growing, doubling each year. Every day there are 100-150 new registrations - people register, download models for printing, write to blogs to share information. Statistics show that 3DToday.ru is the second site in the world about additive technologies, in terms of attendance, and the first in the world to include everything together - blogs, news, technical information and a hub of 3D models.

First of all, we owe our success to our visitors, portal users - they themselves create most of the content, use it themselves, help each other and communicate on the site.

In the near future, we want to organize a stock exchange of orders for 3D printing, so that each maker can place his offer or respond to someone's order, execute it and get paid.

Perhaps we will organize a special section on the site - for CNC machines that are not directly related to 3D printing.

The average portrait of our Central Asia does not exist - the site is visited not only by registered users, but also by any interested persons, from schoolchildren engaged in self-education to directors of factories and other industrial enterprises. This is what the correspondence received tells us - many letters come with questions and requests for help.

The main essence of the project is to convey to people: what 3D technologies are, how and where they are applied; demonstrate capabilities and talk about technology. The portal has a huge database of 3D models and application cases.

- With regards to digital production: do you see the development of the market, compared with previous years, an increase in demand? What can you say about the situation?

- The most HYIP was in 2014-15.

Since 2016, the development of the theme has begun to slow down and is now in stagnation - when many professionals have already bought equipment, and most makers simply consider good 3D printers to be too expensive. Industry growth is much slower than we would like. Companies in Russia are very reluctant to share information about how additive technologies are used - they are afraid of competition, they don’t want to reveal the secret of competitive advantage. In the coming years, we hope for a slow but sure development of additive technologies in Russia.

- What would you like to share with our readers and viewers, what useful information?

- I would like to give a couple of tips.

First of all, I want to advise our makers: Guys, do not be afraid to experiment with your 3D printers, with new types of plastic and printing modes, communicate, share cases with each other - this will benefit everyone. Producers of inexpensive printers: Do not stop, thanks to you, the industry is growing. Industries: write off your old machines and go digital. Efficiency and quality of work will grow, do not believe your eyes.

Conclusion

As we have seen in this issue, the maker in Russia is developing, which we are very pleased about. Top 3D Shop wants to help this in all available ways, so I declare a promo code for a discount: 3D VLOG .

To use the link, you must make an order through the basket on the site, enter the promotional code at the time of ordering.

There are still many enterprises in St. Petersburg that use digital production in their activities, and we will be happy to talk about them in future releases. So as not to miss - read our blog , subscribe to updates on YouTube - be aware of new products.

Source: https://habr.com/ru/post/374473/

All Articles