Technologies of the future: can a memory become not electric, but magnetic?

Modern memory, including Kingston products, copes well with the challenges it faces, but the world is changing and it is possible that after some time we will remember the familiar DRAM as an obsolete technology. One of the candidates for replacement is MRAM magnetoresistive memory.

Each type of memory device has its drawbacks. For example, NAND has a low write speed, SRAM memory does not allow to place cells closely (and therefore achieve high density), and is also volatile with DRAM — that is, it is reset when the supply voltage disappears. That is why scientists are constantly searching for more advanced technologies to solve various problems.

Recently, a lot of attention is paid to the three-dimensional vNAND, which allows you to radically increase the capacity of the drives, as well as to the new development of Intel and Micron, called 3D XPoint. The latter generally promises to be better than the existing memory in almost everything, but manufacturers still hide the true technology of this non-volatile memory. Intel's PR machine has created quite a bit of hype around a new technology that eclipsed no less promising developments, such as MRAM or Magnetoresistive RAM.

')

The problem of creating a fast and non-volatile memory is in front of the computer industry since the advent of the first computer, and at the moment it is not solved. Judge for yourself - we use DRAM RAM for high-speed tasks in our computers, and SSD drives (usually on NAND chips) to achieve high storage capacity. Theoretically, magnetoresistive effects can correct this injustice and create an interim solution. If the presence of a bit of information in the memory cell is recorded not by an electric, but by a magnetic field, then when the voltage is turned off, this very bit will not go anywhere and will remain on the chip for a very long time (until you get to the unit with a huge magnet). The study of this opportunity began in the first half of the twentieth century and for more than 50 years remained in the category of theoretical studies until the first MRAM prototypes were created. Work has also been carried out in our country to create a magnetoresistive memory for use in the military and aerospace fields. But only in 2006, the first commercial magnetic chip appeared on the market. It was made by Freescale Semiconductor, which separated from Motorola in 2004. And the first magnetoresistive “unicorn” was the module MR2A16A, capable of containing 4 Mbit data.

From a technical point of view, MRAM is very different from other promising types of memory - the same 3D XPoint or ferroelectric memory (FRAM), since MRAM is based on magnetic memory elements operating on the principle of magnetic tunnel junction (MTJ).

To understand the essence of this effect, we dive a little into the theory of semiconductors. Each MTJ cell consists of a control transistor, as well as two ferromagnetic layers separated by a thin dielectric layer (tunnel layer). The first layer is a permanent magnet with a defined and clearly fixed magnetic field vector. But the second ferromagnetic layer is already an alternating magnet that changes its polarization (direction of magnetization), for example, depending on the applied magnetic field.

The value of a bit in a ferromagnetic cell can be determined by checking whether the magnetization vectors of the two layers coincide or they are opposite to each other. Due to the effect of tunnel magnetoresistance, with the same polarization of the ferromagnetic layers, the electrical resistance of the cell decreases, and this state of affairs is considered a logical zero. In the opposite case, the cell resistance determines the conductive properties of the dielectric in its pure form - and the cell retains the value of the logical unit. The control transistor in this case plays the role of a "tester", which passes the current through the cell to determine which value of the bit in it is recorded.

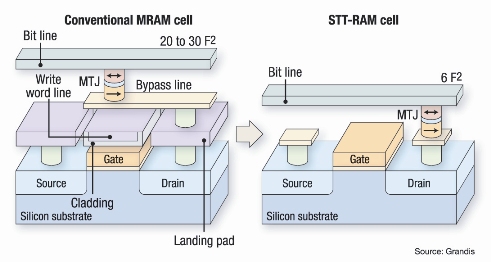

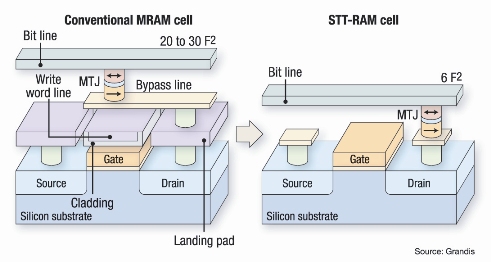

The well-known problem of MRAM memory is to write the value to a ferromagnetic cell. Initially, it was necessary to attach a forming magnetic field. However, this is very costly in terms of energy consumption (which put an end to MRAM for mobile devices), and also limits the development of technology, because when switching to a smaller process technology, it will become more difficult to create a point magnetic field that does not spoil the data in neighboring cells.

As a response to these challenges, improved STT-MRAM (spin-torque-transfer MRAM) technology was developed. In the very principle of information storage, nothing has changed, but the recording method has become completely different. In STT-MRAM, the spin transfer of electrons entering the free layer occurs. Under normal conditions, the electrons rotate in different directions, but if the pre-oriented charge carriers are specifically directed into the free ferromagnetic layer, the polarization will change in accordance with the direction that the angular momentum of the incoming electrons has. Simply put, information is rewritten in a cell by directing specially prepared electrons with the same spin.

Initially, the spin of electrons for recording in STT-MRAM memory was formed in the same plane as the ferromagnetic layers themselves. However, the transfer of the spin to the perpendicular plane made it possible to reduce the switching current of the cell, as well as its size, increasing the density of the cells on the crystal. And now STT-MRAM really begins to resemble the memory of the future, which can combine the best of two worlds.

Before we can talk about replacing SRAM or DRAM, STT-MRAM technology has to grow pretty well, overcome the “childhood diseases” that are sure to appear, and prove its reliability. But given that commercial samples of the new magnetic memory already exist, there may be specific niches for it.

For example, in SSD drives and RAID systems, DRAM chips are often used that store cached operations. But at power off all data with DRAM is erased. This can be a problem if important information has not yet been stored on the disk and, therefore, capacitors are installed in the SSD, and additional batteries are installed in the RAID system. They should help to record all the information before the power is completely turned off. These elements degrade over time, capacitors and batteries increase the cost of finished products and make them more complex. Meanwhile, STT-MRAM, as non-volatile memory, can solve this issue, and now the manufacturers of such chips are actively promoting a similar method of using them.

At Kingston, we are carefully monitoring the development of a whole range of new memory technologies, but for commercial products we use only mature solutions that have proven themselves and have shown high levels of reliability. Considering the current situation, it is possible that in a few years STT-MRAM or even more perfect modification of this memory will be faster and more reliable than existing solutions today, but while these technologies are in the first experiments and are not ready to work as those universal drives, choose the best of the existing solutions, which, of course, include our memory modules .

Subscribe and stay with us - it will be interesting!

For more information about Kingston and HyperX products, visit the company's official website .

Each type of memory device has its drawbacks. For example, NAND has a low write speed, SRAM memory does not allow to place cells closely (and therefore achieve high density), and is also volatile with DRAM — that is, it is reset when the supply voltage disappears. That is why scientists are constantly searching for more advanced technologies to solve various problems.

Recently, a lot of attention is paid to the three-dimensional vNAND, which allows you to radically increase the capacity of the drives, as well as to the new development of Intel and Micron, called 3D XPoint. The latter generally promises to be better than the existing memory in almost everything, but manufacturers still hide the true technology of this non-volatile memory. Intel's PR machine has created quite a bit of hype around a new technology that eclipsed no less promising developments, such as MRAM or Magnetoresistive RAM.

')

Magnetic moment or electric charge?

The problem of creating a fast and non-volatile memory is in front of the computer industry since the advent of the first computer, and at the moment it is not solved. Judge for yourself - we use DRAM RAM for high-speed tasks in our computers, and SSD drives (usually on NAND chips) to achieve high storage capacity. Theoretically, magnetoresistive effects can correct this injustice and create an interim solution. If the presence of a bit of information in the memory cell is recorded not by an electric, but by a magnetic field, then when the voltage is turned off, this very bit will not go anywhere and will remain on the chip for a very long time (until you get to the unit with a huge magnet). The study of this opportunity began in the first half of the twentieth century and for more than 50 years remained in the category of theoretical studies until the first MRAM prototypes were created. Work has also been carried out in our country to create a magnetoresistive memory for use in the military and aerospace fields. But only in 2006, the first commercial magnetic chip appeared on the market. It was made by Freescale Semiconductor, which separated from Motorola in 2004. And the first magnetoresistive “unicorn” was the module MR2A16A, capable of containing 4 Mbit data.

MRAM technology

From a technical point of view, MRAM is very different from other promising types of memory - the same 3D XPoint or ferroelectric memory (FRAM), since MRAM is based on magnetic memory elements operating on the principle of magnetic tunnel junction (MTJ).

To understand the essence of this effect, we dive a little into the theory of semiconductors. Each MTJ cell consists of a control transistor, as well as two ferromagnetic layers separated by a thin dielectric layer (tunnel layer). The first layer is a permanent magnet with a defined and clearly fixed magnetic field vector. But the second ferromagnetic layer is already an alternating magnet that changes its polarization (direction of magnetization), for example, depending on the applied magnetic field.

The value of a bit in a ferromagnetic cell can be determined by checking whether the magnetization vectors of the two layers coincide or they are opposite to each other. Due to the effect of tunnel magnetoresistance, with the same polarization of the ferromagnetic layers, the electrical resistance of the cell decreases, and this state of affairs is considered a logical zero. In the opposite case, the cell resistance determines the conductive properties of the dielectric in its pure form - and the cell retains the value of the logical unit. The control transistor in this case plays the role of a "tester", which passes the current through the cell to determine which value of the bit in it is recorded.

The evolution and appearance of STT-MRAM

The well-known problem of MRAM memory is to write the value to a ferromagnetic cell. Initially, it was necessary to attach a forming magnetic field. However, this is very costly in terms of energy consumption (which put an end to MRAM for mobile devices), and also limits the development of technology, because when switching to a smaller process technology, it will become more difficult to create a point magnetic field that does not spoil the data in neighboring cells.

As a response to these challenges, improved STT-MRAM (spin-torque-transfer MRAM) technology was developed. In the very principle of information storage, nothing has changed, but the recording method has become completely different. In STT-MRAM, the spin transfer of electrons entering the free layer occurs. Under normal conditions, the electrons rotate in different directions, but if the pre-oriented charge carriers are specifically directed into the free ferromagnetic layer, the polarization will change in accordance with the direction that the angular momentum of the incoming electrons has. Simply put, information is rewritten in a cell by directing specially prepared electrons with the same spin.

Initially, the spin of electrons for recording in STT-MRAM memory was formed in the same plane as the ferromagnetic layers themselves. However, the transfer of the spin to the perpendicular plane made it possible to reduce the switching current of the cell, as well as its size, increasing the density of the cells on the crystal. And now STT-MRAM really begins to resemble the memory of the future, which can combine the best of two worlds.

Looking for your niche

Before we can talk about replacing SRAM or DRAM, STT-MRAM technology has to grow pretty well, overcome the “childhood diseases” that are sure to appear, and prove its reliability. But given that commercial samples of the new magnetic memory already exist, there may be specific niches for it.

For example, in SSD drives and RAID systems, DRAM chips are often used that store cached operations. But at power off all data with DRAM is erased. This can be a problem if important information has not yet been stored on the disk and, therefore, capacitors are installed in the SSD, and additional batteries are installed in the RAID system. They should help to record all the information before the power is completely turned off. These elements degrade over time, capacitors and batteries increase the cost of finished products and make them more complex. Meanwhile, STT-MRAM, as non-volatile memory, can solve this issue, and now the manufacturers of such chips are actively promoting a similar method of using them.

At Kingston, we are carefully monitoring the development of a whole range of new memory technologies, but for commercial products we use only mature solutions that have proven themselves and have shown high levels of reliability. Considering the current situation, it is possible that in a few years STT-MRAM or even more perfect modification of this memory will be faster and more reliable than existing solutions today, but while these technologies are in the first experiments and are not ready to work as those universal drives, choose the best of the existing solutions, which, of course, include our memory modules .

Subscribe and stay with us - it will be interesting!

For more information about Kingston and HyperX products, visit the company's official website .

Source: https://habr.com/ru/post/374167/

All Articles