Forgotten by time: little-known Soviet cars

It is believed that the Soviet auto industry as a whole was very poor on all fronts. Soviet motorists often got the same type, stamped cars, which could not boast of either an elegant design or a technical component. But is this really the case? Few people know that sometimes really interesting models were created at Soviet car factories, which for some reason were not put into mass production.

On the other hand, there were occasionally news that someone had collected cars in his garage that could compete or even outperform foreign concepts of that era. Like many things in the Soviet Union, these events most often remained in the shadows, and only recently photos of conceptual Soviet cars of those times began to fall into the network, which were able to reflect the true scale of this phenomenon.

Who was doing this?

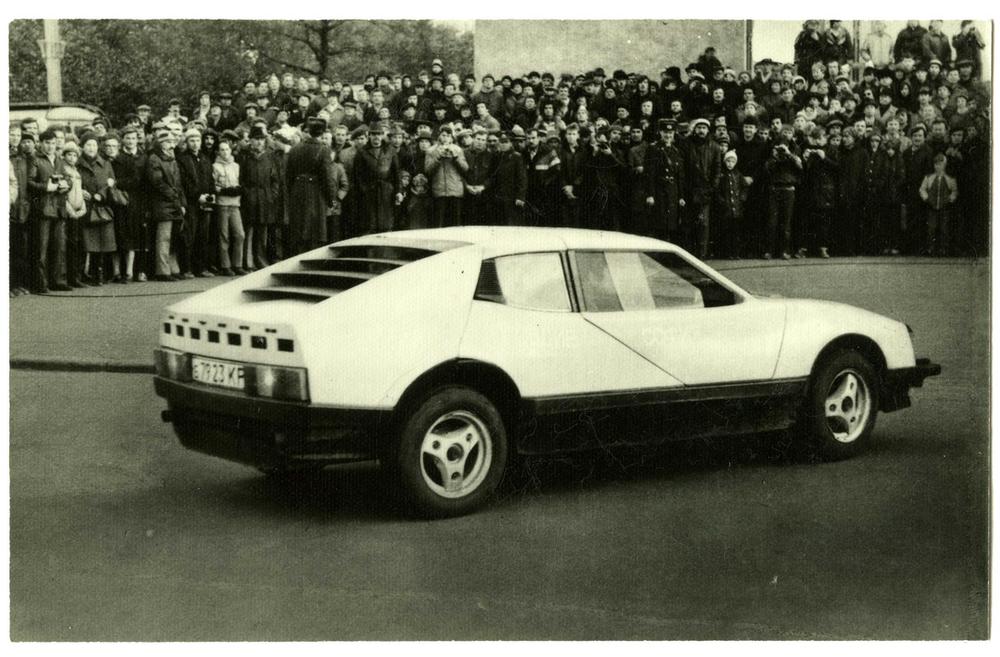

And if in the Western countries the tuning of existing cars was popular, the Soviet “homemade” preferred to create unique cars from scratch. Most often, these craftsmen created exclusive cars on their own or in a team with like-minded people for personal use. Of course, there were those who tried to promote their creations, arranging demonstration races, thereby raising the culture of the Soviet automobile industry. Such races were not ignored - in the transit cities of the following such cars collected hundreds of enthusiastic spectators. To some extent it looked like modern auto shows and exhibitions.

')

Those who did not want to attract wide public attention, and made cars exclusively for personal use, were significantly more. Practically in every more or less large Soviet city one could meet one, and even several cars, which had no analogues in the world. Such cars were created by ordinary citizens who often were not even auto mechanics. In order to make a car from scratch a person had to be at least talented and technically well-trained. But the main thing that motivated such craftsmen was the very idea to realize their creative intent. But the fee for this was very high - a few years spent in the garage and substantial costs for the component. Most often, these designers had a detailed technical design, which they tried to adhere to throughout the production. In turn, many technical units and parts were often refined “on the fly”.

In general, the authorities were quite loyal to such activities, however, there were official “Technical requirements for passenger cars made individually”, which required the use of basic technological systems, such as brakes, steering gear, lighting equipment exclusively Soviet-made.

How were they created?

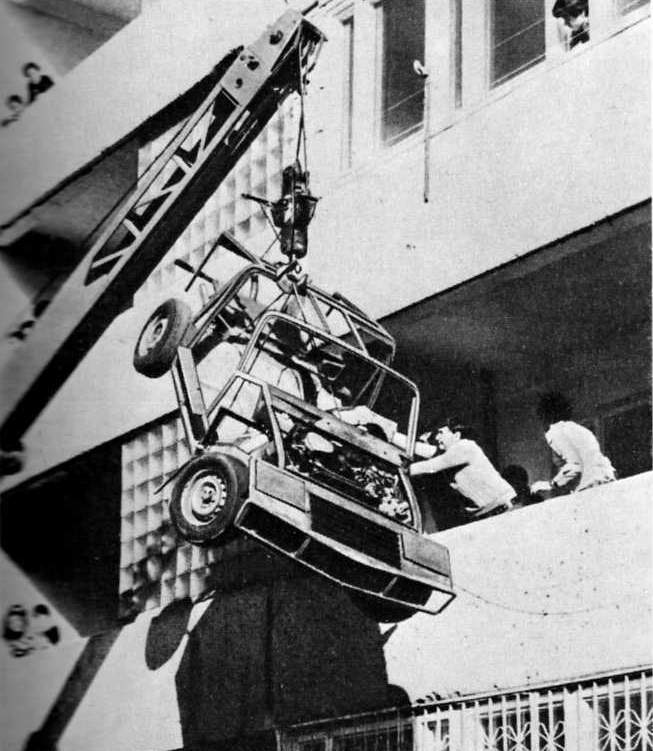

The main problem in creating self-made cars was the lack of workshops. Most of the creators of exclusive cars were the average people who lived in apartments. But even this was not an obstacle for them - one of the rooms was converted into a workshop, and in it separately created various technical units, and even whole bodies. Against this background, the descent of the finished car from the balcony of the apartment seemed a trifle. There are cases when cars were lowered to the ground with the help of ropes (a sports car of the Shcherbins brothers), sometimes a truck crane was used (concept car of Henrykh Matevosyan from Yerevan).

Whoever dealt with the technical part of self-made cars, it was also possible to turn around here. It was too boring to install an exclusive body on the Zhiguli chassis, so the designers created their own undercarriage. Sometimes it was too long and costly to order a ready engine from the store, so the masters created their own engines. Thus, in the 1980s, the spring “Spring” of designer Vladimir Mironov appeared, which had an unprecedented automatic transmission in the USSR with a V-belt variator of its own production. Of course, this technology has long been used in DAF cars, but in the Soviet Union few people knew about it, and many wanted to use the automatic transmission. The bodies of their own production are usually made of fiberglass, impregnated with epoxy resin. Body parts were glued to a blank of wood or plaster, and in rare cases in the matrix. Matrix technology was more reliable and allowed to replicate the body in small batches.

After the car was created and ready for use, it naturally needed to be registered, to get a registration certificate and numbers. To do this, it was necessary to submit to the traffic police a conclusion of a technical commission on the safety of the built vehicle. Usually such conclusions were issued by the All-Union Voluntary Society of Car Amateurs. In addition, it was necessary to attach checks of all acquired technical parts and materials confirming the legality of their purchase. However, this often turned a blind eye, and registration took place without much difficulty.

After the car received numbers, it was often further restyled. There are cases when an absolutely new one was created on the basis of one car, since a photo of a vehicle was not attached to those passports. Whatever it was, due to the fact that such cars were created with love, some of them are still on the move or are resting in museums, maintaining a decent technical and external condition.

Victory Sport, 1950

In 1948, a special decree was issued by the USSR government on the prohibition of the use of foreign cars in intra-Union auto competitions. So, in 1951, on the basis of the bodies and aggregates of the Pobeda production car produced at the Gorky Automobile Plant, a group of engineers led by A. A. Smolin invents three Pobeda Sport sport and racing cars codenamed GAZ-20- SG1 "for ring competitions. These models were the first truly successful Soviet sports cars. They were installed engines with rotary blowers with a capacity of 105 liters. with. Due to what the car could reach a speed of 190 km / h. For six years, two more copies of the sports "Victory" were created. In total, three USSR Championships (1950, 1955, and 1956) were won on the Pobeda-Sport cars.

"ZIS-112", 1951

Along with Victory-Sport, another interesting sports car was created at the Stalin plant - the ZIS-112, which was released in 1951. Due to the specific shape of the front end, it was also unofficially called “one-eyed” or “cyclop”. The car's roadster body was designed by designer Valentin Rostkov, who was inspired by the design of the Buick X90. In addition, the ZIS-112 was the first Soviet car in which the body was made of fiberglass material. The first model was not allowed to participate in races, as it had a length of six meters and a weight of almost three tons, which is why it was modified several times in the future.

Trud 1964

The self-made car under the symbolic name "Trud" was created by the Moscow engineer O. Kucherenko in 1964. The main feature of the car was the metal body, which impresses with laborious work. The master composed all the rounded details from carefully fitted, and then welded pieces of sheet steel. The engineer did not wait for the engine from the store and installed on the "Labor" 3-cylinder engine of its own production.

Moskvich 408 "Tourist", 1964

In 1964, the “Moskvich” of the 408 series, which was very popular at that time, saw some light on the roads until now. But at the same time with the classic model, a variation of the 408th called "Tourist" was also released. The car was made in the coupe-cabriolet unusual for the Soviet man. The main disadvantage of "Tourist" was that the folding roof did not fully fit into the trunk, because of which it had to be disconnected and stored separately. The main production facilities of "Moskvich" were directed to the production of the classic 408th model, and the "Tourist" model was released in only two copies and never entered mass production in the future.

"GTSCH", 1969

Perhaps, one of the most famous Soviet "Samavto", in the title of which the surname of the brothers-creators - "Gran Turismo Shcherbininy" - is encrypted. The car was installed 2.45 liters. the engine from the GAZ-21 with a power of 75 hp, which clocked the “GTSchch” up to a speed of 150 km / h. Anatoly and Vladimir Shcherbina, the car's frame, was welded in the courtyard of a multi-storey building, after which they raised apartments to the seventh floor and gradually sheathed panels glued from fiberglass. After the body was ready, the car was lowered back into the courtyard and was fully equipped with power units, suspension, interior elements, etc. Having suffered two restyling, the car is in fairly good condition preserved to this day.

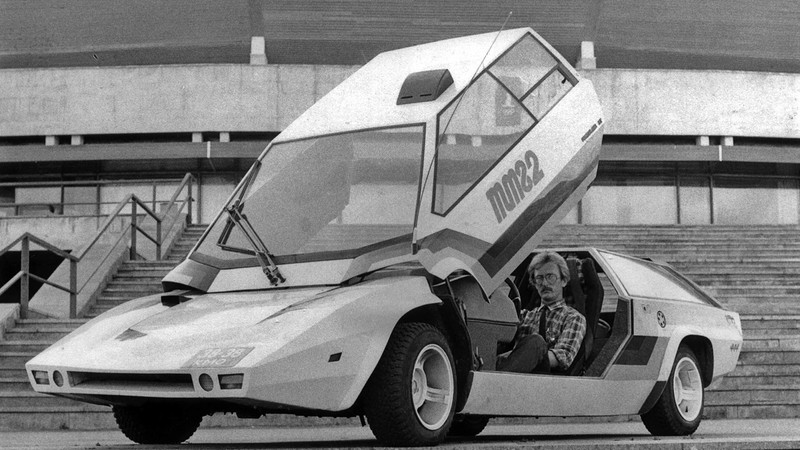

"Pangolin", 1980

Another iconic Soviet car, showing the flight of imagination of the then engineers. And built this unusual car Alexander Kulygin on the basis of the VAZ-2101. Futuristic, but at the same time relatively simple body design allowed to glue body panels on a plywood blank. They decided to call the car "Pangolin" because of the distant resemblance to the battleship. The car had a number of innovations, which at that time were unusual for the Soviet people.

Thus, the role of the doors was performed by a roof that rises with the help of a pneumatic actuator along with side and windshields, and the engine was started using a digital code. “Pangolin” Kulygin built for a year in his hometown Ukhta, along with a group of pioneer students from the circle of technical creativity. The finished car had to be transported to Moscow by rail, since the bad roads of the northern city did not allow it to do it on their own.

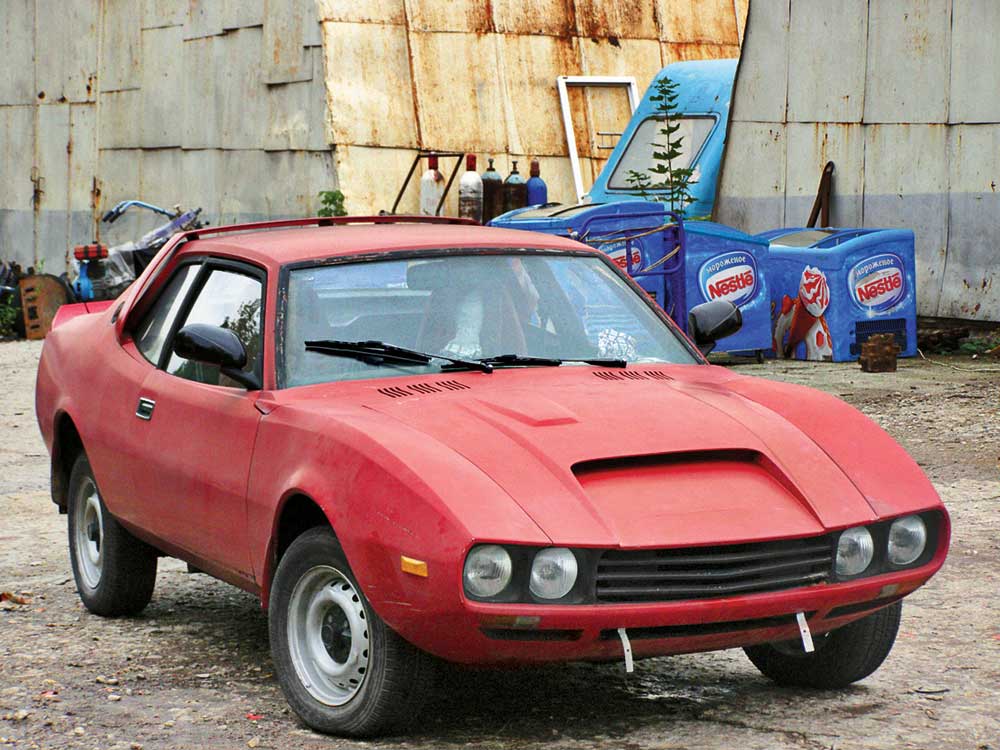

"Mercury", 1982

In the early 1980s. A group of three enthusiasts: a painter, a sculptor and a locksmith decided to create an exclusive car based on a VAZ-2106. The mechanic, Vladimir Ivanovich Mishchenko, who led the project, already had experience in building self-made cars. In 1982, the light came homemade passenger car "Mercury". In total, five copies of the car were built: three in Moscow and two in Tbilisi. The first experimental model was built in one of the Moscow basements, and one of the best-preserved copies of the “Mercury” was recently converted into an electric vehicle.

"Laura", 1985

In 1981, in Leningrad, there was a regular run of home-made cars, organized by the magazine "Technology-Youth". Two comrades, Gennady Khainov and Dmitry Parfenov, impressed by this spectacle, decide to create their own cars. The next three years, the friends spent at work in a barn on the outskirts of the city, and now - in 1985 two practically identical cars were created, which received the common name "Laura".

The highlight of the car was a homemade McPherson-type suspension and a futuristic body, with a supporting frame made of water pipes, pasted over with sandwich panels made of fiberglass and foam plastic. The engine for the “Laura” was taken from the VAZ-2105, the CV joints were used from the Niva, and the gearbox from the Zaporozhets was turned over backwards. The companions' strength calculations were performed using a computer from one of the universities under the guise of laboratory work.

Triton, 1985

The Triton is a unique amphibian of its kind created by Moscow engineer D. Kudryachkov. The car was simultaneously registered in the traffic police and in the State Inspectorate of small vessels. On the "Triton" was installed engine from the Volga GAZ-21, and the transmission from Zaporozhets ZAZ-968. The car felt great both on land and on water. On the highway, it was distinguished by its stability and smoothness. A water cannon was taken by the constructor for movement on water, allowing it to move through shallow water at a speed of 50 km / h. While driving in the water, the wheels went up along the sides with a cable winch.

Okhta 1987

In 1986, the Leningrad Laboratory of Perspective Vehicle Design was launched under US, where Soviet prototypes of future automobiles were to be created. Dmitry Parfenov became head of the laboratory, and Gennady Khainov, the founder of Laura, became his deputy. The launch project of the laboratory was the creation of a promising minivan called "Ohta".

A year later, the first prototype was completed. The seven-seater interior of the car could be transformed - the front seats could turn around 180ᵒ, and the middle row could be upgraded to a table. From under the front bumper at high speeds, a spoiler was advanced to increase downforce. Unfortunately, the mass construction of the car was not destined to happen due to the imminent collapse of the USSR.

Source: https://habr.com/ru/post/373931/

All Articles