Should I put the optics in a knot?

The laying of the fiber-optic communication lines is now engaged in many companies. The main networks of the Internet are completely built on optics. In addition, there is a tendency when the optical cable is pulled straight to the apartment subscriber of a private house. How do various loads during installation affect glass fiber? Under the cut some research on this topic.

Optics to the subscriber's apartment

However, glass fiber has its significant drawbacks, namely sensitivity to mechanical loads and bends. Under load, various protective elements such as armored shells are used, but it is almost impossible to protect the cable from damage during bending. However, the main problem with bending is not even damage, but a significant increase in signal power loss at macro fiber bends resulting from the installation of subscriber cable, including in the subscriber’s apartment itself.

')

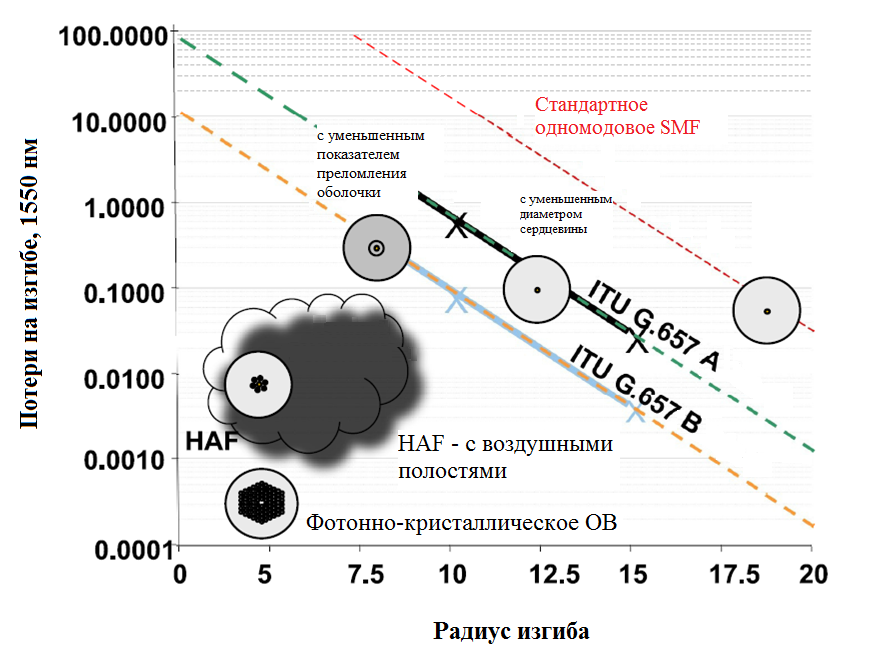

For example, in PON networks, a cable television signal that is transmitted at a wavelength of 1550 nm, on one bend of a fiber with a radius of 10 mm, can lose up to 60% (approximately 4 dB) of its power.

Losses on macrobends, in addition to access networks, also affect transport optical networks. Poor installation of couplings or the use of low-quality optical cable affects the appearance of macrobends, which cause network interruptions. That is why, especially important is the use of optical fiber class G.657A on transport networks. To solve this problem today, there are many types of bend-insensitive G.657 standard fibers. The G.657 class fibers allow you to increase the density of the components in the cross equipment. Also, if you resort to an improved fiber packing system, the weight and size of distribution cabinets can be reduced by 40% and 75%, respectively.

Below we will discuss the main features and parameters of non-critical bending fibers.

Subscriber optical cable secured with a flat bracket

Optical fiber grades specification G.657

In November of last year, a new edition of the G.657 specification, entitled “Characteristics of a bending-loss insensitive single-mode optical fiber and cable”, was published, reflecting 4 classes of optical fibers of the G.657 standard: A1, A2, B2, B3.

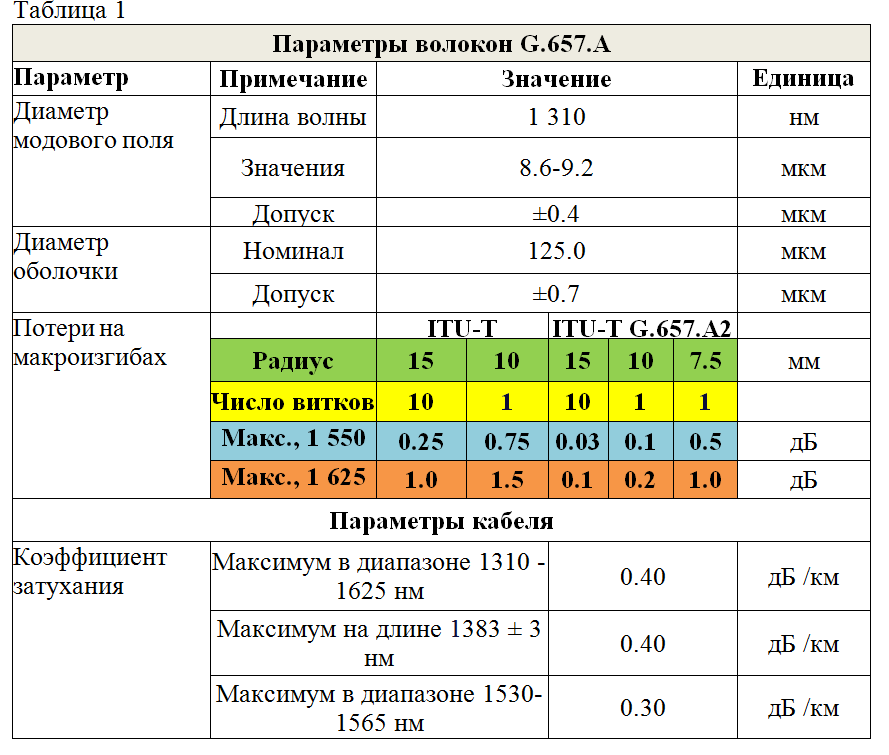

G.657.A fiber is identical in performance with G.652D fiber, with the exception of reduced macrobend losses. They are perfectly suited for operation in the O-, E-, S-, C- and L-bands (that is, in the entire operating wavelength range of standard single-mode fibers - from 1260 nm to 1625 nm). In addition, this class is also suitable for networks where ITU-T G.652.D fibers are used as standard.

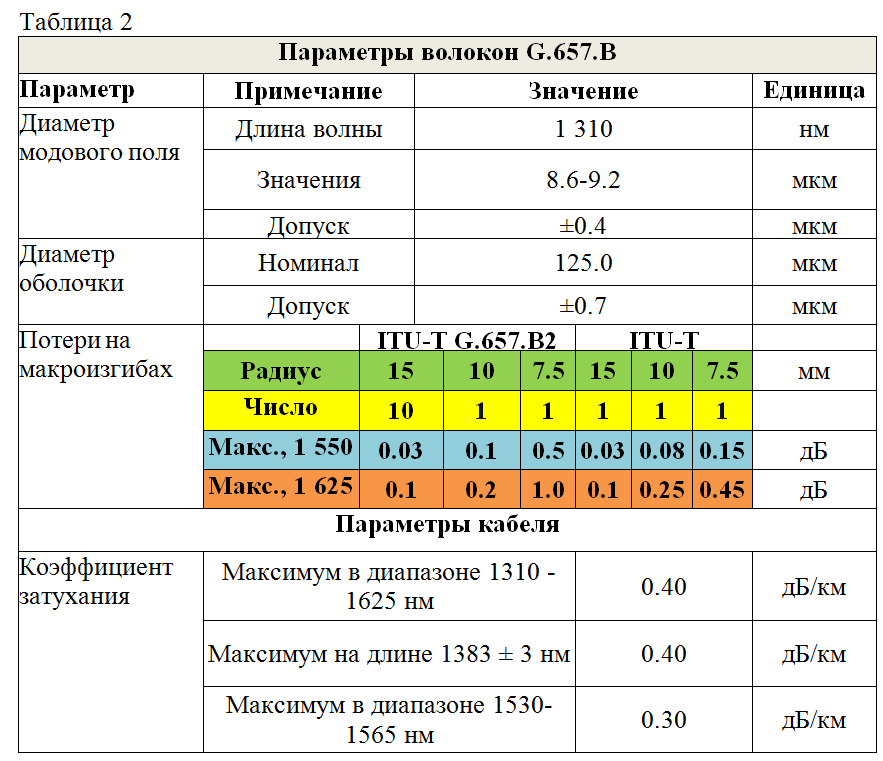

G.657.B category fibers are aimed at further reducing losses at macrobends, and therefore can be used with an even smaller bending radius. Their main purpose is networks with a length of up to 1000 meters (access networks). Suitable for use in the O-, E-, S-, C- and L- ranges (from 1260 nm to 1625 nm).

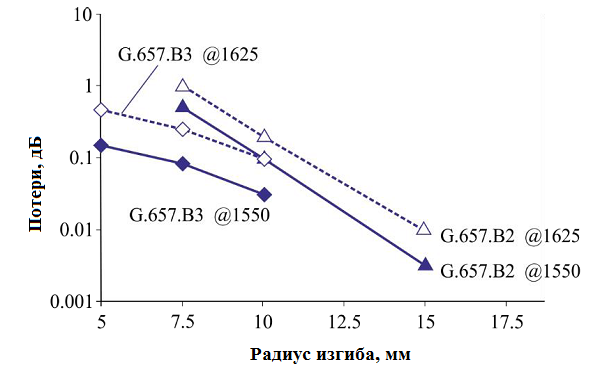

Category G.657.A1 has a minimum bending radius of 10 mm, and subcategory G.657.A2 is already 7.5 mm. In turn, the G.657.B category fibers are aimed at further reducing losses at macrobends and, therefore, can be used in cases of an even smaller bending radius. They are also intended for use in access networks, and are suitable for use in the O-, E-, S-, C- and L- ranges (from 1260 nm to 1625 nm).

Category B fibers do not have to conform to the standards of single-mode G.652.D fibers in terms of chromatic dispersion coefficient and mode polarization dispersion. These fibers are considered conditionally compatible with G.657.A and G.652.D in access networks. This means that sharing G.657.B fibers with G.657.A or G.652.D fibers in some cases may adversely affect the operation of the optical system. Compatibility is no longer fully guaranteed, and some fibers of this class may differ significantly in their parameters from G.652.D fibers.

The B2 subcategory fibers have a minimum bend radius of 7.5 mm, the B3 subcategory fibers have a radius of 5 mm.

The main parameters of G.657 fibers are given in Tables 1 and 2:

It is worth noting that with the existing criterion of the degree of fiber bending along a "bend radius", many are confused, thinking that the greater the value of the bend radius, the greater the bend. In fact, the opposite is true - the greater the bend radius, the, in fact, this bend is smaller.

As can be seen from the graphs presented, G.657.A2 and G.657.B1 fibers have the same flexural loss.

Options for the implementation of optical fibers with reduced losses on macrobending

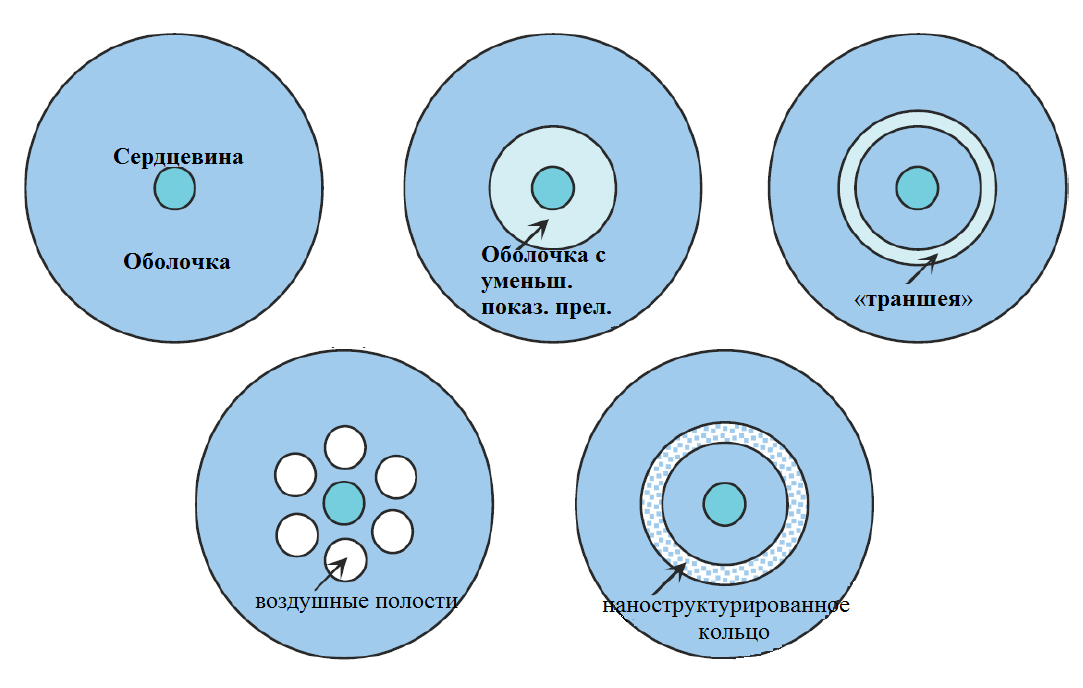

Currently, there are a number of approaches to the implementation of optical fibers with reduced losses on macrobends:

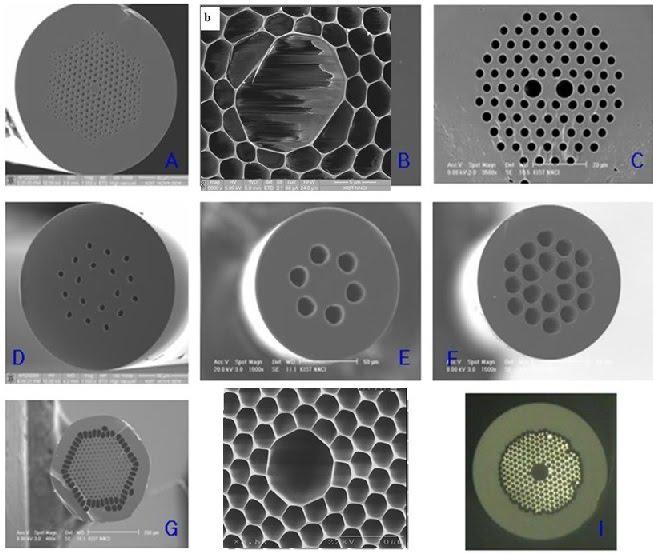

- optical fiber with a reduced core diameter;

- optical fiber with a reduced refractive index of the shell;

- optical fiber with a two-layer sheath;

- optical fiber with air cavities in the shell;

- optical fiber with a circular heterogeneity of the refractive index of the shell;

- nanostructured optical fiber;

- photonic crystal fiber;

- optical fiber with photonic bandgap.

Optical fiber with ring heterogeneity of the refractive index of the shell.

This fiber is similar to class B2 of the G.657 standard and is compatible with G.652 standard fibers. In their manufacture, the annular region of the shell is additionally alloyed with additives that lower the refractive index.

Increasing the width of the ring reduces bending loss, but this increases the critical wavelength. This fact may adversely affect fiber compatibility with standard G.652 agents.

Nanostructured fibers . They consist of a core doped with germanium and a shell that contains a nanostructured region in the form of a ring. In contrast to the fibers described above with a ring nonuniformity of the refractive index of the shell, in which the ring thickness is about 1 micron, nanostructured fibers contain air cavities with a diameter of less than 200 nm around the core. In this case, these nano-holes are arranged randomly.

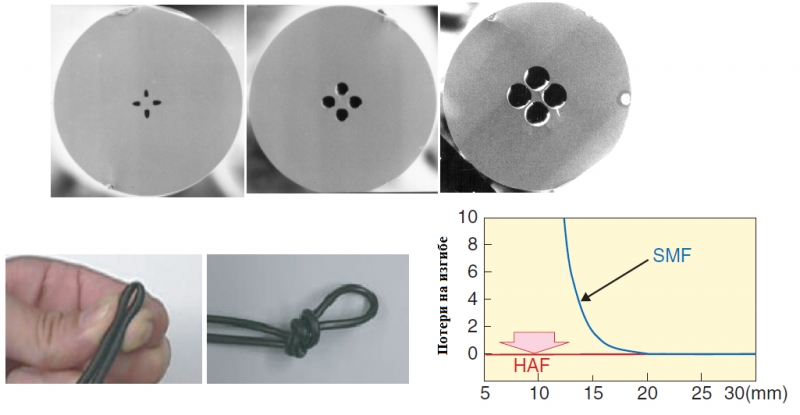

Optical fiber with coated air cavities (HAF) . In the manufacture of these fibers, around the core already have large air cavities in the form of a ring. The glass / air interface in macro-bend areas provides an excellent mode for the effect of total internal reflection, respectively, the signal energy loss becomes smaller. These fibers are fully compatible with the G.652D standard. Their main disadvantage is possible complications when mounting connectors due to air holes. The ingress of dust and dirt in the cavity will lead to the deterioration of the optical characteristics of detachable joints.

Photonic crystal fiber (PCF). There is no core in the photonic crystal fiber, and the optical guideline is formed due to the presence of dozens of holes in the fiber structure. Such a fiber is capable of transmitting optical radiation in a single-mode mode over a very wide wavelength range: from the visible part of the spectrum to infrared. By varying the size and location of the air holes, one can achieve different dispersion characteristics of the fiber. It can be formed only from quartz glass. Despite the absence of a core, the value of the attenuation coefficient of photonic crystal fibers is at the level of the values of standard single-mode SMF fibers.

The photonic crystal fiber has 500 times less loss on microbend than standard single-mode fiber, 100 times less loss than double-cladded fiber, and about 10 times less loss than air-gap optical fiber.

Today, all major fiber companies produce optical fibers with reduced macrobend losses. For example, Sumitomo, Corning, OFS corporations use various previously described approaches for the implementation of these fibers and, accordingly, produce such fibers under different brands.

Prepared by Dmitry Kusaykin

Source: https://habr.com/ru/post/373871/

All Articles