3D printing on a large scale: pavilion FUSE

Different people understand the word "scale" differently. For designers and entrepreneurs, scale is the number of parts in production. For architects and designers, scale is the size of the design, and how it relates to the people who inhabit or use it.

The technology of selective laser sintering [Selective laser sintering, SLS] opens up the possibility of large-scale 3D printing in both senses. Designers can tightly pack parts to produce a lot of things at the same time, and each of these parts can be unique and respond to specific needs, since SLP eliminates the need for machining.

')

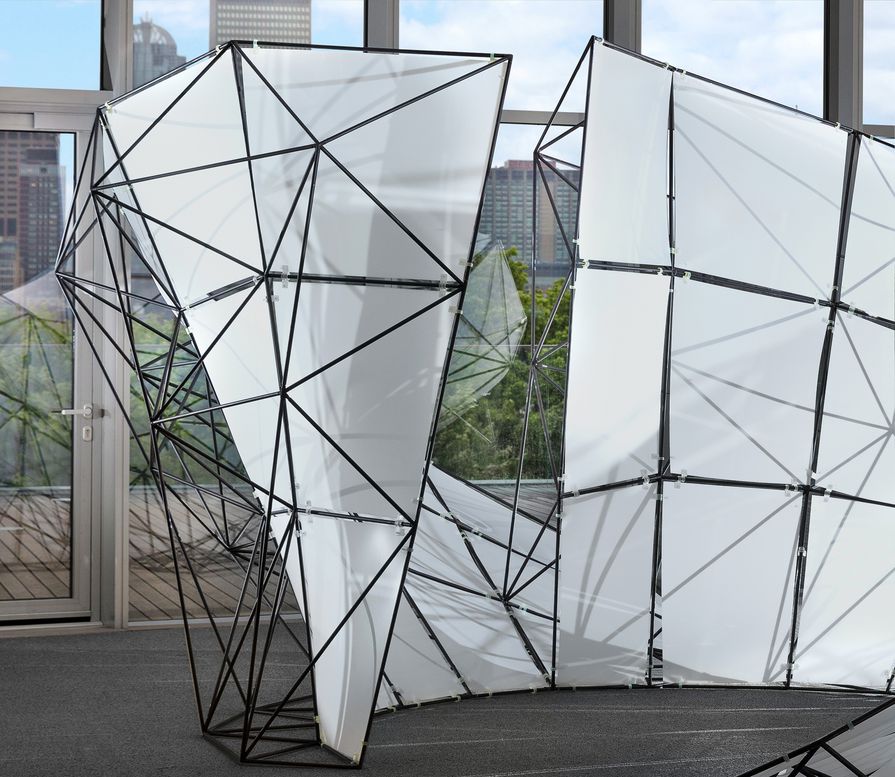

To test the possibilities of technology, we decided to print a large pavilion, which will serve as a place for meetings at the 2017 FUSE conference . We used the Fuse 1 printer to create more than a hundred construction modules, which were then assembled for four days to build a structure covering an area of 14 square meters. m

If you can create any shape, what will you do?

All three-dimensional shapes can be abstractly represented as points, edges, and faces — the printed object is represented in the STL file. Usually we make the development with a sufficiently large resolution, so that when printing the details of the desired size the grid disappears. But what if we use the cellular structure in our favor, automatically translating STL into a structured system?

Each point of intersection of the faces turns into a connecting node, each face becomes a spacer, and each face becomes a panel. This gives us the freedom to create almost any shape on a scale beyond human.

Creating large objects is interesting, and we started developing by simply enlarging popular objects. We immediately thought of increasing the Stanford rabbit and the Formlabs logo. But then we stopped at creating something more tailored for a specific purpose, so we started the development of a pavilion for FUSE 2017.

Structural design of the pavilion

We settled on a project that evolved from the equation for a Möbius strip , rotated so that it turned out to be a closed pavilion, surrounded by three broad canvases. Cloths become rigid and provide structural support when you add a space frame to the back .

This pavilion became the largest structure known to us, created from parts of Formlabs - 4.5 m wide and 2.5 m high, it easily accommodates three people inside.

Depending on the size you need, structural issues can be quite important. Some forms have the property of self-support, being created of a certain size and from a certain material, others need additional support inside or outside to ensure rigidity and stability.

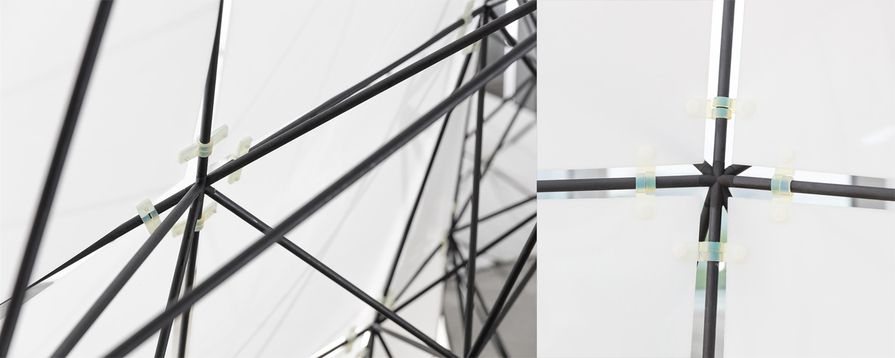

We have chosen materials that will help us create the necessary structure, which is quite strong in all directions, and does not require support by cables or columns. The connection nodes were printed on a Formlabs Fuse 1 printer from Nylon 12, a lightweight, tough and extremely durable engineering thermoplastic.

For spacers, we chose hollow fiberglass tubes. The heaviest part of the steel structure of the panel is made of dense polyethylene (HDPE), they weighed almost 45 kg. Before adding panels, the whole pavilion could easily be raised by one person.

How to turn STL into a structure?

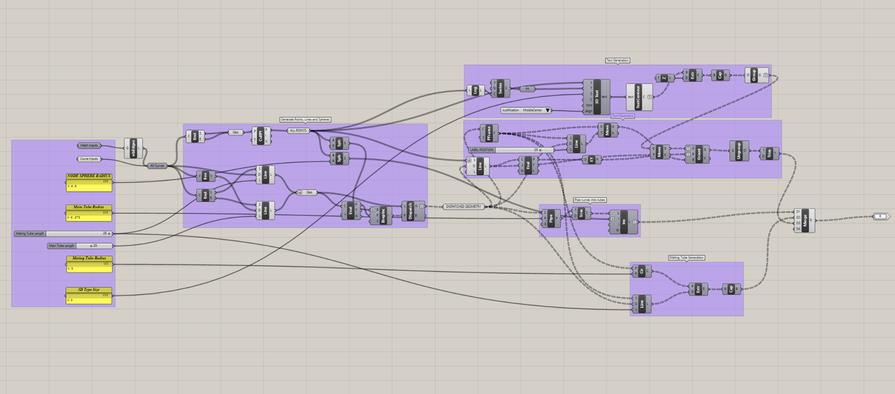

We used Rhino to transform the main surface of NURBS into a spatial framework , which gave the surface rigidity and structure. To create the form, we used a parametric design, which allowed us to choose the “resolution” of the structure (the number of edges and edges approximating it) on the fly. This is important because resolution is closely related to the cost and complexity of the assembly.

In Rhino, we used the Grasshopper scripting system to create models of connectors and edge lengths. The module generation system works with a 3D grid, which can be drawn in any CAD editor. The script takes into account the corners with adjacent edges to prevent intersections of our round edges. It also assigns a part number, which is then automatically applied to each connector.

Download the Grasshopper script for Rhino

We optimized the shape of the connecting nodes for reducing the weight and efficiency of printing. A solid outer round connector would be very durable, but at the same time it would use most of the material and would occupy the most space. The internal connector uses little material and is printed the fastest.

Three pavilion connectors options: external, optimized external, internal

It was much easier to achieve the desired shape from the panels - we used the Unroll function in Rhino to get a two-dimensional diagram for laser cutting from the surface. Having filled out the folder with connector models, a list of edge lengths and panel drawings, you can start creating the structure.

How to create hundreds of unique pieces?

All 144 connectors up to 8 cm in size, made of Nylon 12, we printed out in one go, which lasted 36 hours. SLP technology does not require support for models, so the entire print volume can be used to print hundreds of unique parts at a time. We hope that the connectors of our pavilion symbolize the future possibilities of mass production to order, in which every detail can meet the unique requirements.

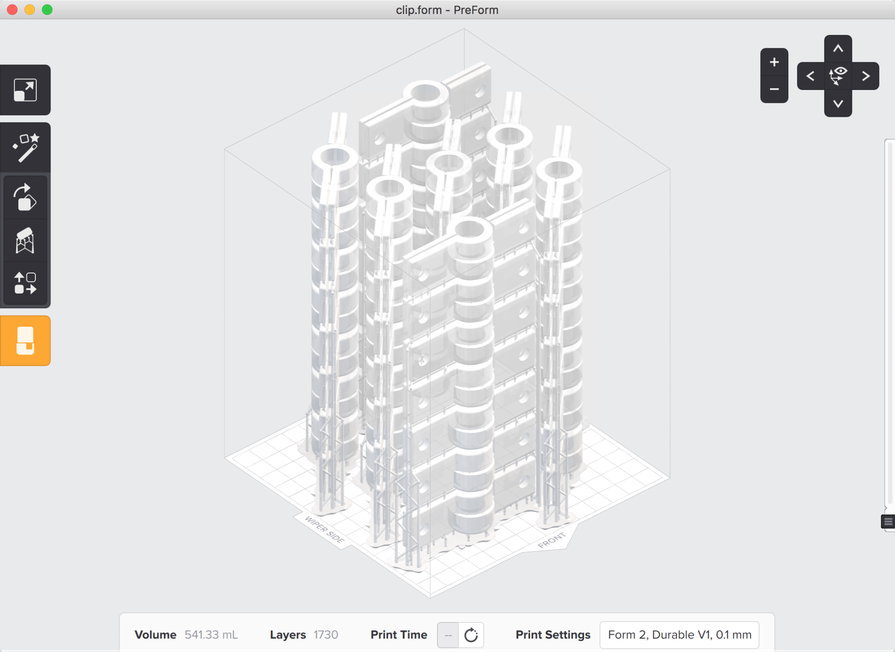

Packaging of three-dimensional parts

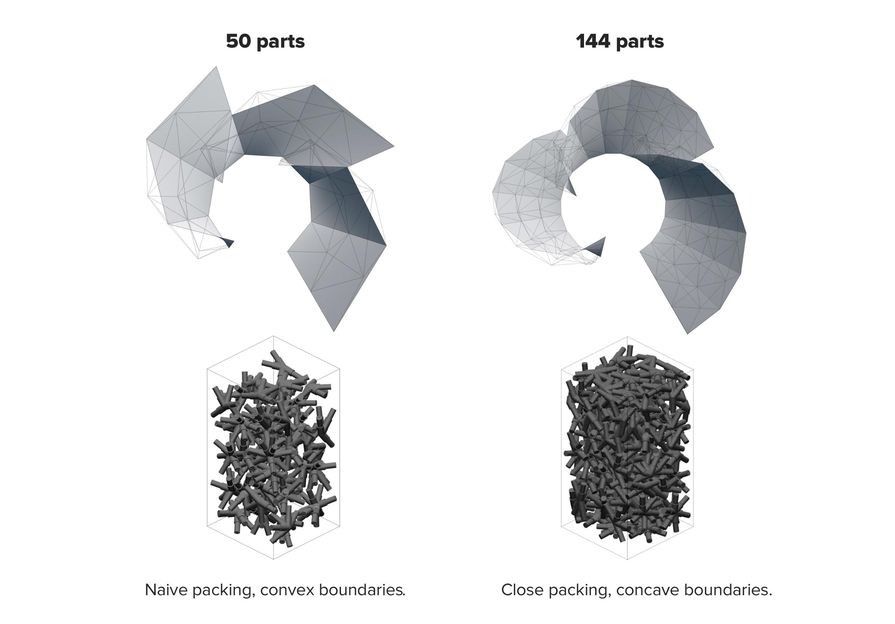

To accommodate 144 different parts in the print zone, technology is more complex than just stacking them. Fortunately, using three-dimensional packaging algorithms, we can calculate an optimized layout of parts, in which they are all close to each other. This strategy has long been used to maximize efficiency in the operation of PSU printers.

We tried several ready-made solutions, with varying success. Netfabb uses the Monte Carlo search for packaging, and yielded the best results from all commercial solutions. We were able to fit about 50 nodes in Fuse 1. However, Netfabb had difficulty working with the non-convex geometry of our nodes, and the simulation took most of the day.

Ideally, connectors should be packaged very close to each other so as to fill each other's concavities. To do this, we built a physical simulation on the Blender engine, packing the connectors into a virtual volume for printing. The nodes move and turn at the meeting, and calm down when they do not overlap.

The parts tremble chaotically until none of them overlaps each other. The whole simulation takes about a minute.

We greatly accelerated the simulation using simplified intermediate models for collision counting, rather than the final high-resolution models. This method does not guarantee a mathematically optimal solution, but works well. More importantly, we were able to fit almost three times as many nodes into the same working volume.

Already at the production stage, we used the advantages of parametric design in order to select the resolution for the parts suitable for our time constraints and the entire project. The ideal resolution gives a good transfer of the initial curved shape, allows you to fit all the details into the print volume, and gives you the opportunity to complete the project in a week. By speeding up the packaging of parts and increasing efficiency, we achieved improved flexibility in the selection of the shape of the final structure.

On the left - naive packing of convex parts, on the right - dense packing of convex parts.

After the conference, Michael Voglman, now working at Formlabs, released an open source solution for 3D packaging of parts. We will include automatic packaging in the PreForm program for Fuse 1.

Listing of large volumes in SLA

To fix the panels, we could use ready-made fasteners, but the schedule and geometric features of the design were pressing us. We decided to make hardware using laser stereolithography (SLA) from Durable Resin material.

More than 500 fastener parts were printed in five sets on a Form 2 printer.

We used Form 2 to quickly create 505 brackets in a few days. We designed the parts in CAD so that they were stacked, assigned the task of generating backups to PreForm, which allowed us to print out 98 brackets in one pass. Tearing off part of the backing was as easy as tearing the perforated paper.

How to assemble a large set of parts?

The most difficult part of creating a large modular structure is assembly.

Three people assembled a pavilion, working four hours a day. To facilitate the work, we sorted out all the details in advance by projecting a three-dimensional structure diagram onto the wall. Still, the assembly was a test for spatial thinking and patience. A simple search for a part and finding its correct orientation took a lot of time.

Working with a small budget and a rather modest structure, we decided to assemble the structure manually. But what if someone wants to build a larger structure, or increase its resolution? They can be helped by robots - machines are much better able to cope with moving parts into an exact position, and architects are already starting to create structures suitable for robotic assembly.

The future of digital manufacturing and architecture

We, designers, imagine the future in which the transformation of a digital spatial concept into a real design will be as easy and automatic as 3D printing. The system used to build the pavilion for FUSE can be applied to the design of rooms, furniture, the creation of sculptures, etc. By combining advanced design techniques with digital manufacturing devices such as Fuse 1, the architects will not encounter any obstacles to the realization of any form they can imagine.

Source: https://habr.com/ru/post/373857/

All Articles