A cheap replacement for Dongle Gear (patent protection for laser cartridges for HP and Canon)

Due to high speed, reliability and low cost of printing, laser printers are in the greatest demand all over the world. Especially this superiority is noticeable in the extremely profitable corporate segment, where companies of the secondary print market also strive to: manufacturers of alternative consumables (cartridges, toner, paper) and smaller ones tied up for service, first of all refills of original and compatible cartridges. Large vendors, predictably, do not want to share profits, so that with the third-party offices who want to pinch a piece of the cake, there has been a technological and legal war for a long time.

On the technical side, the most popular means of protecting laser original cartridges are chips with a digital toner consumption meter (the situation is similar with inkjet cartridges). After the cartridge has fulfilled a strictly specified amount of it - the printer can block printing, even if the powder is still there. However, such severe restrictions do not always work and often the user simply receives a warning about the end of the toner without stopping the work.

From the legal side, everything is more complicated - cartridge designs and toner chemical composition are often protected by patents, so copying them “head-on” is often impossible (or rather, of course, only key sales markets will be closed for them), which is why manufacturers of alternative consumption you have to go for various tricks to maintain compatibility with the device and at the same time not get a lawsuit for pirated copying of the patented technology.

However, the above protection measures did not prevent third-party manufacturers from doing their work, followed by even more sophisticated responses: in 2008, Canon released the first laser cartridges with special mechanics, called Dongle Gear, which seriously complicated the lives of "pirates." It should be noted, by the way, that historically Canon is working with Hewlett-Packard in the direction of laser printers, so the changes have affected the design of the cartridges of both companies.

To explain the essence of innovation, we briefly clarify the principle of laser printing. In the printer itself is only mechanics and laser, and the main printing filling falls on the cartridge. Inside is a PCR roller, which evenly transfers charge to the photodrum. With a narrow-beam laser, the printer “flashes” the charge from the drum, forming an electrostatic image to which negatively charged toner particles stick. In this form, the adhered toner reaches the paper, onto which it is transferred under the action of an additional transfer roller. Well, and a little later the paper is held together with toner under the action of high temperature in the so-called “stove” (two more rollers). In the old models of printers, instead of rollers, charged thread-short wires were used, but their operating principle was identical.

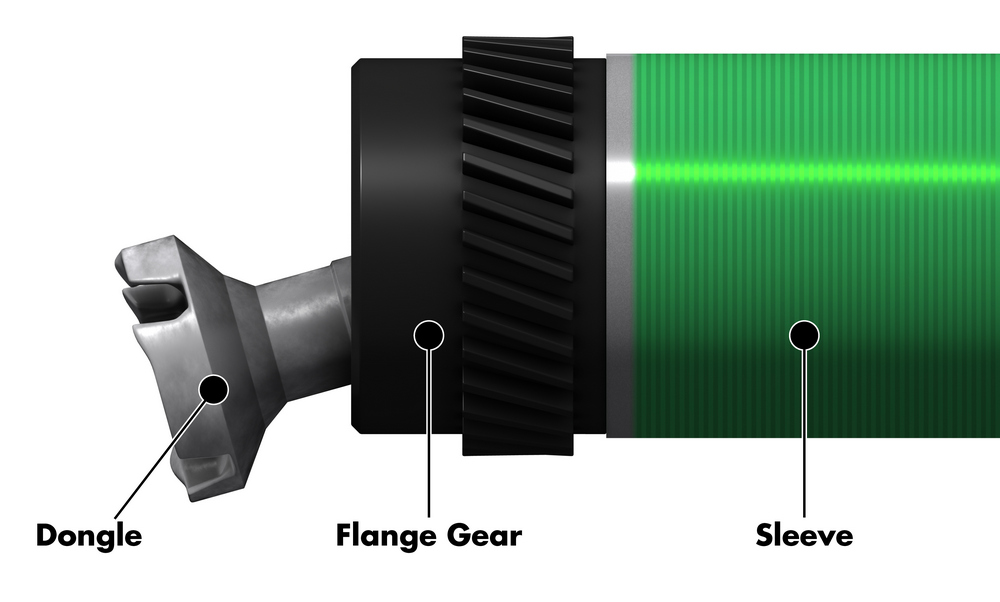

Simply put, the work of the laser cartridge is to constantly rotate several rollers. In the most common case, the printer rotates the core axis of the photodrum, and the rotation of the remaining elements is transmitted through the gears. But in the cartridges Dongle Gear instead of a solid axis uses something like a circular hinge with a latching mechanism. That is, while the cartridge is not in the printer, the transfer is loosely dangling in all directions and rigidly sits in the groove only inside the device.

A simple and elegant solution seriously hit third-party manufacturers. The trick is that they are faced with a choice: to make cartridges with a similar circular gear, or to come up with an alternative with the standard axis. Those who went the first way ended up falling victim to a spontaneous squall of lawsuits against them (in May 16, Canon filed a lawsuit against 33 companies at once and secured from the American ITC a ban on the importation of products in the US violating their exclusive rights), and the rest were forced to produce cartridges with simplified axial mechanics, much less convenient to use on printers with a hinge (the cartridge was inserted, but then it was extremely difficult to remove).

As always, ordinary buyers had to pay for the fight against piracy - the cost price of cartridges with complicated mechanics turned out to be higher than that of ordinary ones. What influenced the price of both the originals themselves and their “restored” (refilled) versions.

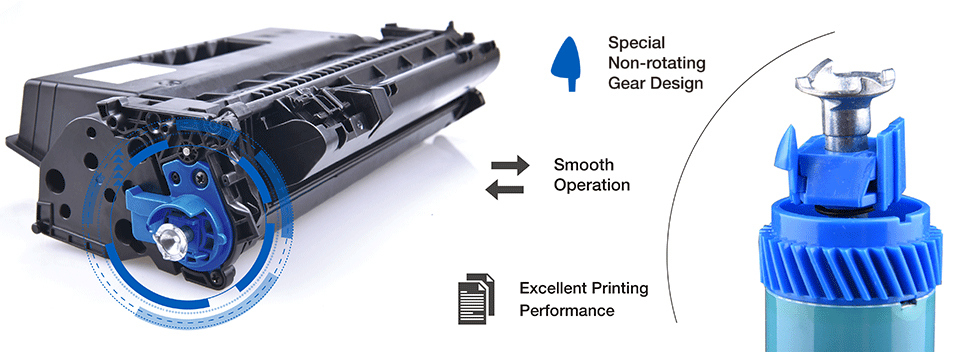

The time will appear in the history of the prince in shining armor. From the very moment the new mechanism was introduced, G & G, a subsidiary of Ninestar, began developing an adequate alternative. And in 2014, the first prototype of the BlueDrive mechanism appeared, which serves as a full replacement for the original Dongle Gear. It took another two years to litigate with the US commission on international trade, but in the summer of 2016, companies gave the green light ( official document confirming the uniqueness of the device ). BlueDrive technology was recognized as an original development that does not violate Canon's patent rights.

From that moment on, Ninestar had the opportunity to create cheap and user-friendly alternative cartridges compatible with Dongle Gear for Canon and HP printers, which they proudly share with their customers in a recent brochure .

')

Source: https://habr.com/ru/post/373751/

All Articles