Proteins synthesized from carbon dioxide and electricity

Translation of the news “Protein produced with electricity and carbon dioxide” , published on the NanoWerk website.

A test batch of unicellular protein was produced from carbon dioxide using electricity as part of a joint study of Lappeenranta University of Technology and VTT Research Center in Finland. The protein produced in this way can be further processed and used as food or animal feed. This method removes the environmental constraints on food production. Protein can be synthesized anywhere, where there is a renewable source of electricity, for example, solar. ( Translator's comment: for the process itself there is no difference where electricity comes from, but it’s worth considering that using fossil fuels we will produce a very large quantity of parinic gases. According to rough estimates, it will take 2 times more energy to produce food for 7.5 billion people developed all power plants in the world in 2008. )

“In practice, all the starting materials are accessible from the air. In the future, this technology may be transported, for example, to deserts or other areas threatened by hunger. One of the possible application scenarios is a home bioreactor, a household appliance that a consumer can use to produce the necessary protein. ”Explains VTT chief researcher Juha-Pekka Pitkänen.

')

Researchers are exploring the possibility of protein to act not only as food, but also as animal feed. Protein, created with the help of electricity, can serve as a substitute for fodder, freeing the land for other purposes, for example, for growing forests. Thus, food can be produced where it is needed.

“Compared to traditional agriculture, the method of production we develop does not require a place with special conditions for farming, such as temperature, humidity or a particular type of soil. This allows us to use a completely automated process to produce the necessary animal feed in a mini-factory located in a freight container on the farm. This method does not require pesticide treatment. In the closed process, only the necessary amount of substances like fertilizers is used. In this way, environmental damage such as wastewater pollution or greenhouse gas emissions can be avoided, ”says Professor Yero Ahola from Lappeenranta University of Technology.

According to researchers, the process of creating food from electricity can be almost 10 times more energy efficient than conventional photosynthesis, which is used in the cultivation of soybeans and other products. In order for the product to be competitive, the production process must be more efficient.

Currently, the production of one gram of protein takes two weeks, using a coffee cup-sized laboratory setup.

At the next stage, the researchers plan to launch a pilot project. At the pilot project stage, the material will be produced in quantities sufficient for the development and testing of feed and food products. In this way, commercialization will also be achieved.

“At the moment we are focusing on the development of technology: reactor concepts, technology, efficiency improvement and process management. Process management includes the tuning and modeling of renewable energy in order to allow germs to grow as fast as possible. The idea is to turn this concept into a mass product, reducing the price as technology becomes more and more widespread. The timing of commercialization depends on the economy, ”says Ahola.

“In the long run, protein made with electricity is planned to be used in cooking without additional processing. The mixture is very nutritious and consists of more than 50 percent of proteins and 25 percent of carbohydrates. The rest is fats and nucleic acids. The composition of the final product can be modified by changing the organisms involved in the process, ”explains Pitkianen.

This study is part of the Neo-Carbon Energy extensive research project conducted jointly by Lappeenranta University of Technology and VTT. The goal of the project is to develop a fully renewable and non-emission energy system. The study on the production of food from electricity is sponsored by the Academy of Finland and is designed for four years.

Added 07/21/17

Answers to questions from Yero Ahola:

1) Why in the process of bacteria?

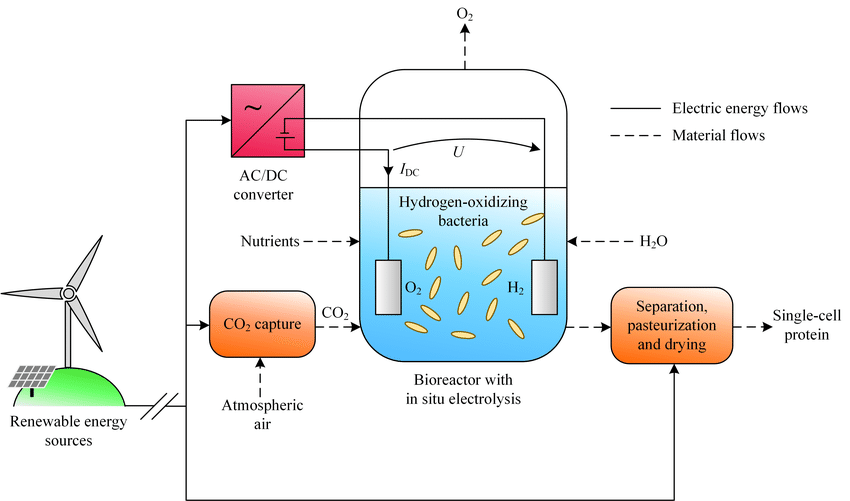

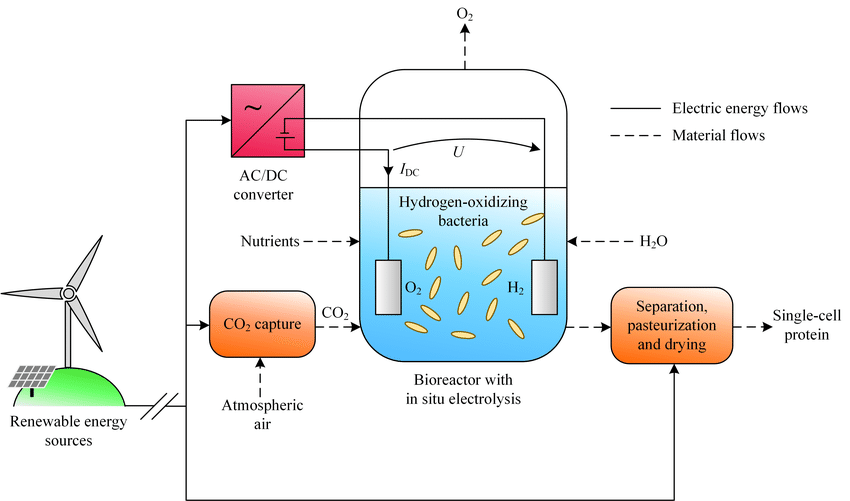

Bacteria consume hydrogen and oxygen from electrolysis, oxidizing hydrogen to water. The resulting energy is used by bacteria for life. In particular, bacteria consume water and carbon dioxide from the atmosphere, synthesizing complex organic compounds. The illustration below shows the process of movement of substances and energy in this process.

Installation scheme Source: https://www.researchgate.net/project/MOPED-Microbial-Oil-and-Proteins-from-Air-by-Electricity-Driven-Microbes Special thanks to Konstantin Malyutin for his work on finding this illustration.

2) What bacteria were used in the prototype setup?

Several types of bacteria have been tested. One of them was Rhodococcus opacus . These bacteria are chemolithotrophic, capable of extracting energy for life from chemical reactions of the oxidation of metals or hydrogen. Such bacteria are often found, for example, under the ground, where they live due to the oxidation of the decay products of organic compounds.

3) What is the planned size of the pilot plant?

At the second stage, it is planned to assemble a reactor with a capacity of about 5 kW, capable of producing up to 5 kg of product per day. It is expected that the installation will take up to 10 cubic meters. The main volume is occupied by the electrolysis reactor.

4) How profitable is it?

If you count on the mass production of reactors, then the main expense will be electricity. According to preliminary estimates of productivity and based on the price of 10 cents per kWh of electricity, 1 kg of the mixture will cost 2.4 euros. Of course, to this price you should add the cost of installing and processing the mixture itself before making the finished product. But overall, it looks cost-effective.

5) Is it necessary to use GMOs?

No, all bacteria used in the process are obtained from natural habitats.

A test batch of unicellular protein was produced from carbon dioxide using electricity as part of a joint study of Lappeenranta University of Technology and VTT Research Center in Finland. The protein produced in this way can be further processed and used as food or animal feed. This method removes the environmental constraints on food production. Protein can be synthesized anywhere, where there is a renewable source of electricity, for example, solar. ( Translator's comment: for the process itself there is no difference where electricity comes from, but it’s worth considering that using fossil fuels we will produce a very large quantity of parinic gases. According to rough estimates, it will take 2 times more energy to produce food for 7.5 billion people developed all power plants in the world in 2008. )

“In practice, all the starting materials are accessible from the air. In the future, this technology may be transported, for example, to deserts or other areas threatened by hunger. One of the possible application scenarios is a home bioreactor, a household appliance that a consumer can use to produce the necessary protein. ”Explains VTT chief researcher Juha-Pekka Pitkänen.

')

Produced protein

Researchers are exploring the possibility of protein to act not only as food, but also as animal feed. Protein, created with the help of electricity, can serve as a substitute for fodder, freeing the land for other purposes, for example, for growing forests. Thus, food can be produced where it is needed.

“Compared to traditional agriculture, the method of production we develop does not require a place with special conditions for farming, such as temperature, humidity or a particular type of soil. This allows us to use a completely automated process to produce the necessary animal feed in a mini-factory located in a freight container on the farm. This method does not require pesticide treatment. In the closed process, only the necessary amount of substances like fertilizers is used. In this way, environmental damage such as wastewater pollution or greenhouse gas emissions can be avoided, ”says Professor Yero Ahola from Lappeenranta University of Technology.

Tenfold energy efficiency

According to researchers, the process of creating food from electricity can be almost 10 times more energy efficient than conventional photosynthesis, which is used in the cultivation of soybeans and other products. In order for the product to be competitive, the production process must be more efficient.

Currently, the production of one gram of protein takes two weeks, using a coffee cup-sized laboratory setup.

At the next stage, the researchers plan to launch a pilot project. At the pilot project stage, the material will be produced in quantities sufficient for the development and testing of feed and food products. In this way, commercialization will also be achieved.

“At the moment we are focusing on the development of technology: reactor concepts, technology, efficiency improvement and process management. Process management includes the tuning and modeling of renewable energy in order to allow germs to grow as fast as possible. The idea is to turn this concept into a mass product, reducing the price as technology becomes more and more widespread. The timing of commercialization depends on the economy, ”says Ahola.

50 percent protein

“In the long run, protein made with electricity is planned to be used in cooking without additional processing. The mixture is very nutritious and consists of more than 50 percent of proteins and 25 percent of carbohydrates. The rest is fats and nucleic acids. The composition of the final product can be modified by changing the organisms involved in the process, ”explains Pitkianen.

This study is part of the Neo-Carbon Energy extensive research project conducted jointly by Lappeenranta University of Technology and VTT. The goal of the project is to develop a fully renewable and non-emission energy system. The study on the production of food from electricity is sponsored by the Academy of Finland and is designed for four years.

Added 07/21/17

Answers to questions from Yero Ahola:

1) Why in the process of bacteria?

Bacteria consume hydrogen and oxygen from electrolysis, oxidizing hydrogen to water. The resulting energy is used by bacteria for life. In particular, bacteria consume water and carbon dioxide from the atmosphere, synthesizing complex organic compounds. The illustration below shows the process of movement of substances and energy in this process.

Installation scheme Source: https://www.researchgate.net/project/MOPED-Microbial-Oil-and-Proteins-from-Air-by-Electricity-Driven-Microbes Special thanks to Konstantin Malyutin for his work on finding this illustration.

2) What bacteria were used in the prototype setup?

Several types of bacteria have been tested. One of them was Rhodococcus opacus . These bacteria are chemolithotrophic, capable of extracting energy for life from chemical reactions of the oxidation of metals or hydrogen. Such bacteria are often found, for example, under the ground, where they live due to the oxidation of the decay products of organic compounds.

3) What is the planned size of the pilot plant?

At the second stage, it is planned to assemble a reactor with a capacity of about 5 kW, capable of producing up to 5 kg of product per day. It is expected that the installation will take up to 10 cubic meters. The main volume is occupied by the electrolysis reactor.

4) How profitable is it?

If you count on the mass production of reactors, then the main expense will be electricity. According to preliminary estimates of productivity and based on the price of 10 cents per kWh of electricity, 1 kg of the mixture will cost 2.4 euros. Of course, to this price you should add the cost of installing and processing the mixture itself before making the finished product. But overall, it looks cost-effective.

5) Is it necessary to use GMOs?

No, all bacteria used in the process are obtained from natural habitats.

Source: https://habr.com/ru/post/373653/

All Articles