Overview of universal robot robots

Hello! We talk about the lineup of Universal Robots collaborative robot manipulators.

The company Universal Robots, originally from Denmark, is engaged in the production of collaborative robot manipulators for automating cyclical production processes. In this article we present their main technical characteristics and consider the application.

What is it?

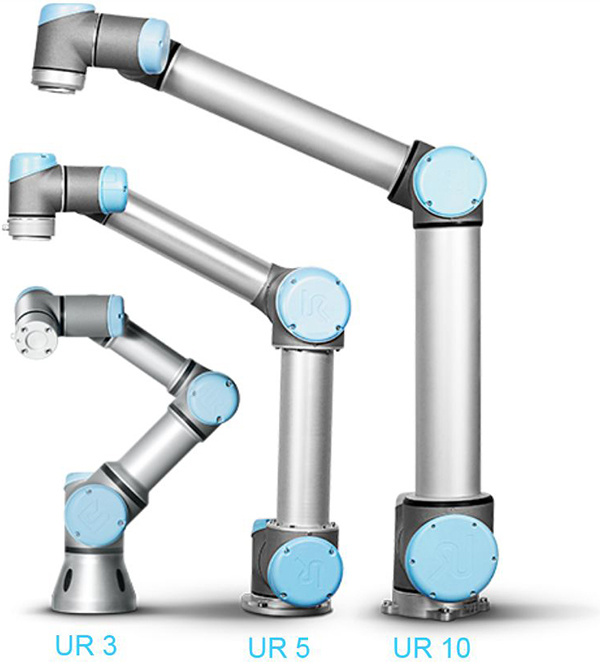

The company's products are represented by a line of three lightweight industrial handling devices with an open kinematic chain: UR3 , UR5 , UR10 .

')

All models have 6 degrees of mobility: 3 portable and 3 orienting. Devices from Universal Robots produce only angular displacement.

Robot manipulators are divided into classes, depending on the maximum permissible payload. Other differences are the radius of the working area, the weight and the diameter of the base.

All UR manipulators are equipped with high-precision absolute-position sensors that simplify integration with external devices and equipment. Due to its compact design, the UR manipulators do not take up much space and can be installed in work sections or on production lines where ordinary robots do not fit.

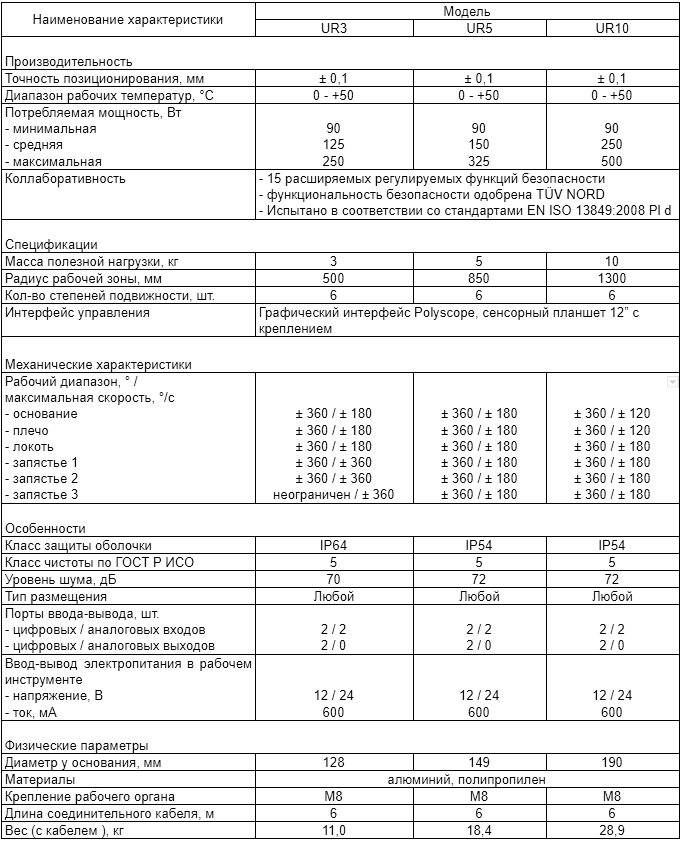

Specifications:

What is interesting

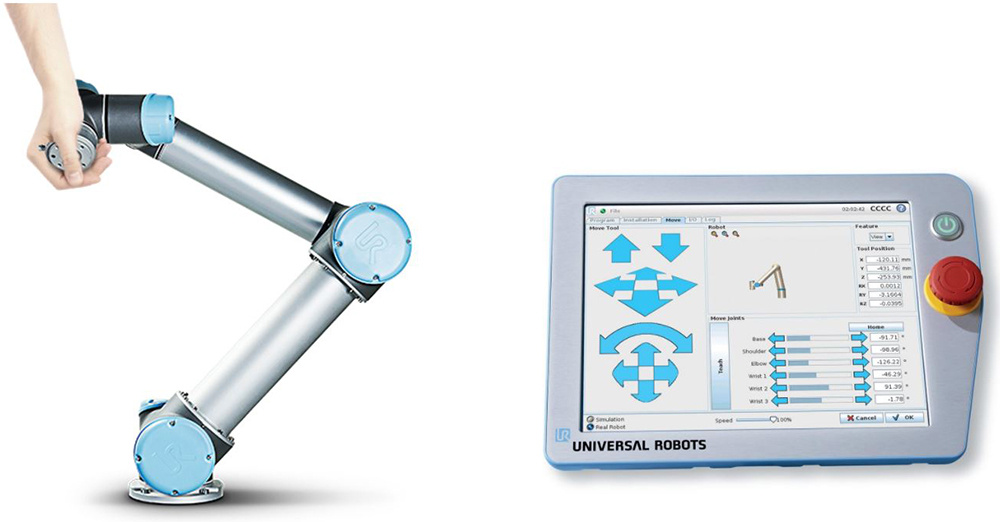

Easy programming

A specially developed and patented programming technology allows operators who do not have special skills to quickly set up UR robot manipulators and control them using the intuitive 3D visualization technology. Programming takes place by a series of simple movements of the manipulator's working body to the required positions, or by pressing the arrows in a special program on the tablet.

UR3:

UR5:

UR10:

Quick setup

The operator performing the initial launch of the equipment will need less than an hour to unpack, install and program the first simple operation.

UR3:

UR5:

UR10:

Collaboration and security

UR manipulators are able to replace operators performing routine tasks in hazardous and polluted conditions. The control system keeps records of external disturbing influences exerted on the robot arm during operation. Due to this, the UR handling systems can be operated without protective fences, close to the workplaces of personnel. Robot safety systems are approved and certified by TÜV - the German Technical Supervision Union.

UR3:

UR5:

UR10:

The variety of working bodies

At the end of the industrial manipulators UR, a standardized mounting for the installation of special working bodies is provided. Between the working body and the end link of the manipulator, you can install additional modules of power-torque sensors or cameras.

Application possibilities

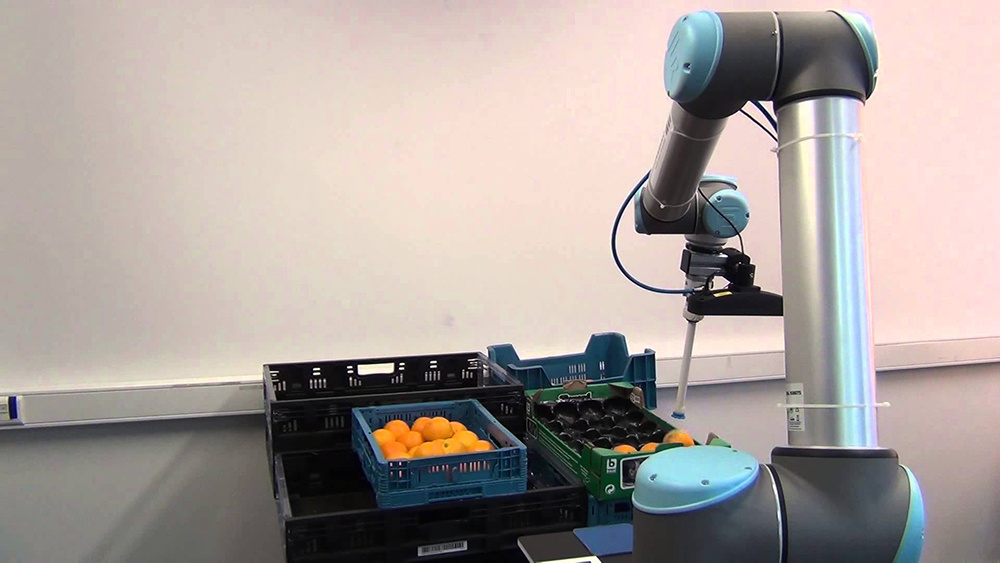

With industrial robotic manipulators, the UR opens up the possibility of automating almost all cyclic routine processes. Universal Robot devices have proven themselves in various applications.

Rerun

Installing UR manipulators in transfer and packaging areas allows for increased accuracy and reduced shrinkage. Most relocation operations can be carried out without supervision.

Polishing, buffing, grinding

The built-in sensor system allows you to control the accuracy and uniformity of the applied force on curved and uneven surfaces.

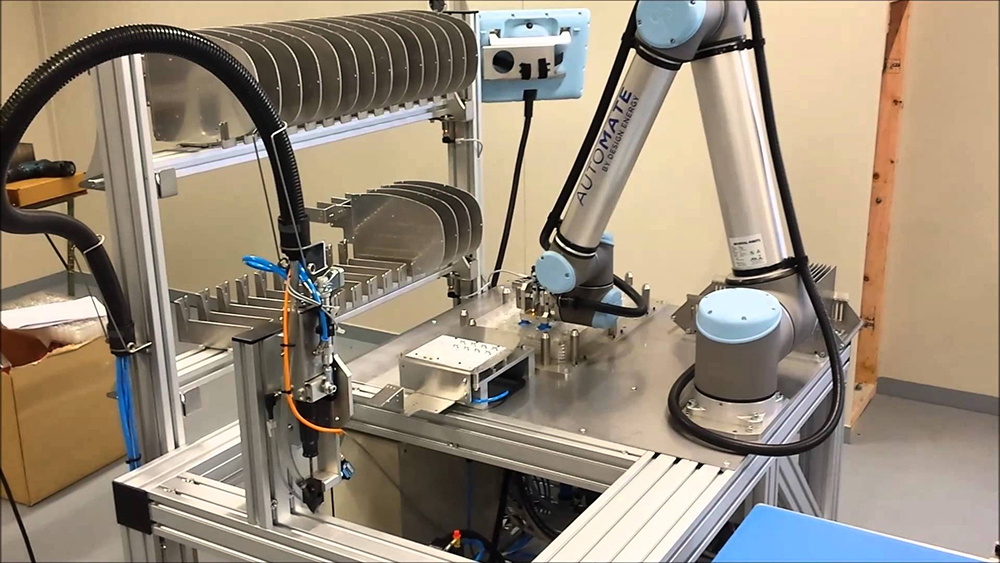

Injection molding

The high accuracy of repetitive movements allows the use of UR robots for the tasks of polymer processing and injection molding.

CNC machine maintenance

The protection class of the shell provides the ability to install manipulation systems for collaboration with CNC machines.

Packaging and Stacking

Traditional automation technologies are cumbersome and expensive. Easily customizable UR robots are able to work without protective screens next to employees or without them 24 hours a day, providing high accuracy and performance.

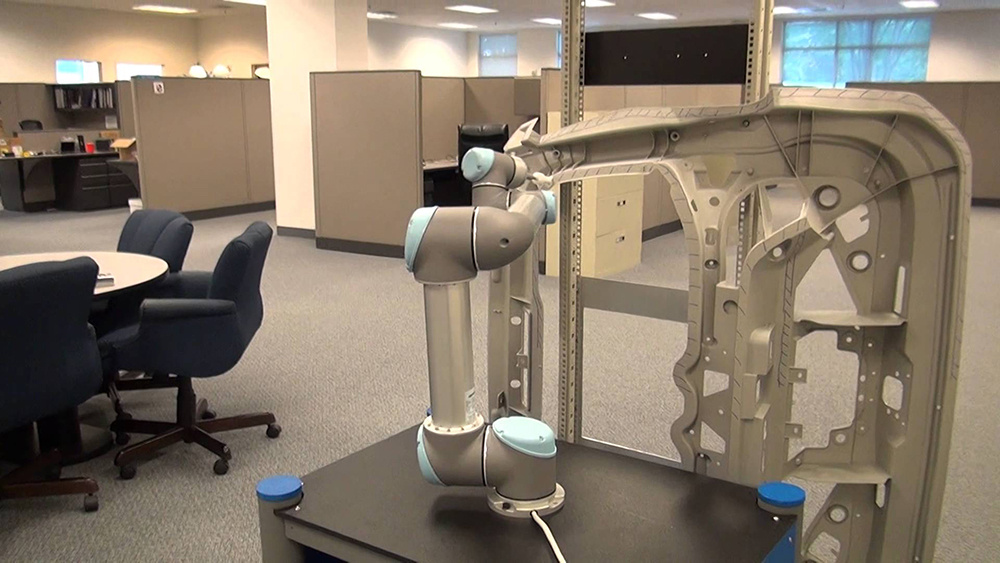

Quality control

The robotic manipulator with video cameras is suitable for carrying out three-dimensional measurements, which is an additional guarantee of the quality of products.

Assembly

A simple device for fixing the working body allows equipping UR robots with suitable auxiliary mechanisms necessary for assembling parts made of wood, plastic, metal and other materials.

Screwing

The control system allows you to control the torque developed in order to avoid excessive tightening and to ensure the required tension.

Bonding and welding

The high accuracy of the positioning of the working body allows to reduce the amount of waste during the operations of gluing or applying substances.

Industrial robot manipulators UR can perform various types of welding: arc, spot, ultrasonic and plasma.

Total:

Universal Robot Industrial Manipulators are compact, lightweight, easy to learn and handle. UR robots are a flexible solution for a wide range of tasks. Manipulators can be programmed for any actions inherent in the movements of the human hand, and the rotational movements they succeed much better. Manipulators are not characterized by fatigue and fear of injury, do not need breaks and weekends.

Solutions from Universal Robots allow you to automate any routine process, which increases the speed and quality of production.

Discuss the tasks of automating production processes using universal robots manipulators with an authorized dealer in Top 3D Shop .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/373649/

All Articles