Efficient quadrocopter

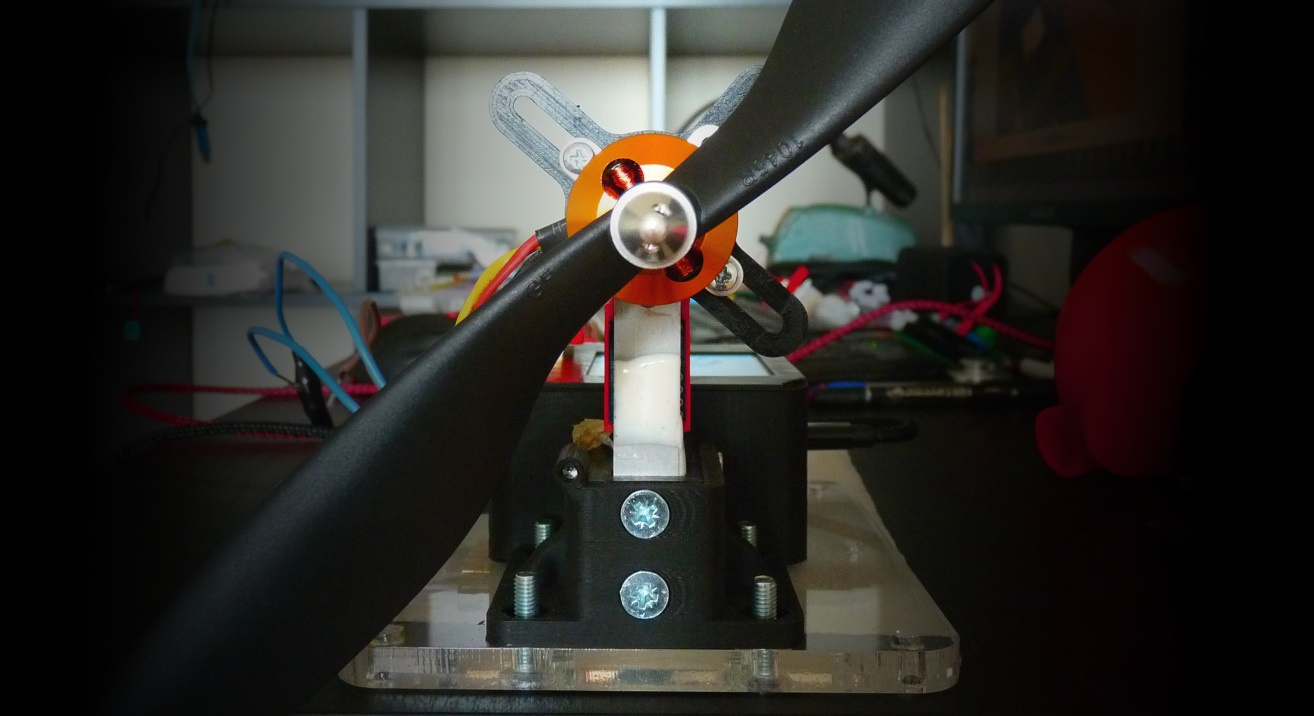

When creating a kopter, one of the most important parameters is the time of autonomous flight. If you want your copter to fly as long as possible, the motors and their rotors should work optimally with maximum efficiency. To solve this problem, we have designed a special measuring bench, which will be discussed in this article.

We are engaged in the creation of brushless motors, and recently we had an order for a quadcopter motor with at least 2 kg for each screw. Before that, we did not make motors for an air screw and we needed a measurement method and a stand for a motor with a screw.

Before you begin to choose the best motor and screw for it, you first need to figure out what losses arise in the motors.

')

The main sources of losses in brushless motors are the stator iron and its winding.

Losses on iron occur due to its magnetization reversal. These losses can be considered conditionally proportional to the engine speed and they set the minimum energy consumption of the motor. So, for example, if you take a big and powerful motor for a small copter with a small screw, then nothing good will come of it. The motor will simply idle with zero efficiency and heat the iron in the stator.

Losses in a copper wire, on the contrary, do not depend on turns, but depend on current / power consumption. These losses limit the maximum power that the motor is capable of delivering without overheating.

The second important element when choosing a motor is a screw. Small screws have lower g / W performance (1 gram of lift / 1 watt of power consumption), but small screws are more dynamic and allow you to quickly pick up speed on racing copters. To achieve maximum flight time, the propeller must correspond to the maximum efficient mode of operation of the motor.

However, if we want to choose the best parts for our copter, then we will face a big problem when choosing them. Manufacturers give a minimum set of characteristics for their product. On the screws it is generally impossible to find any information other than their size.

Stand functionality

At the moment, several manufacturers have already presented their stands on the market. However, their capabilities do not greatly exceed the functionality of kitchen scales. And these stands are not able to give all the characteristics when the engine is running.

We also needed the following parameters from the stand: power consumption, engine speed, thrust of the screw, torque generated by the screw, efficiency of the motor, efficiency of the motor, screw.

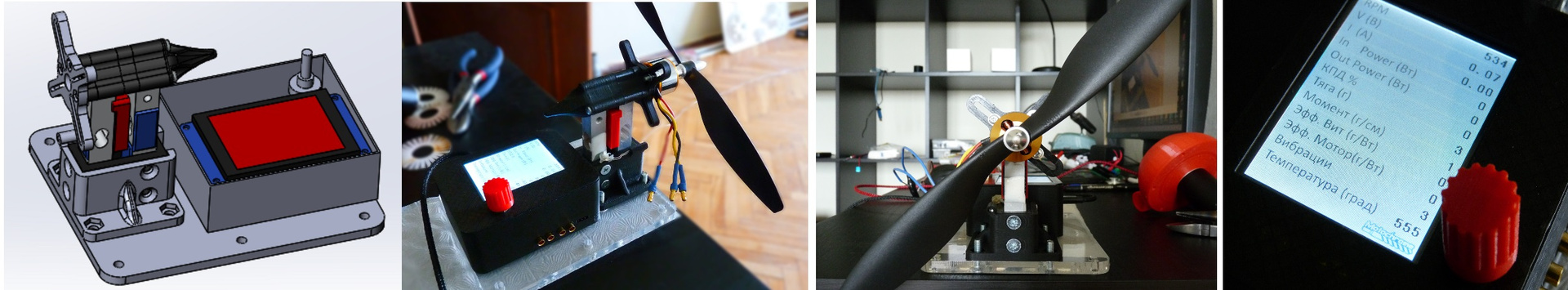

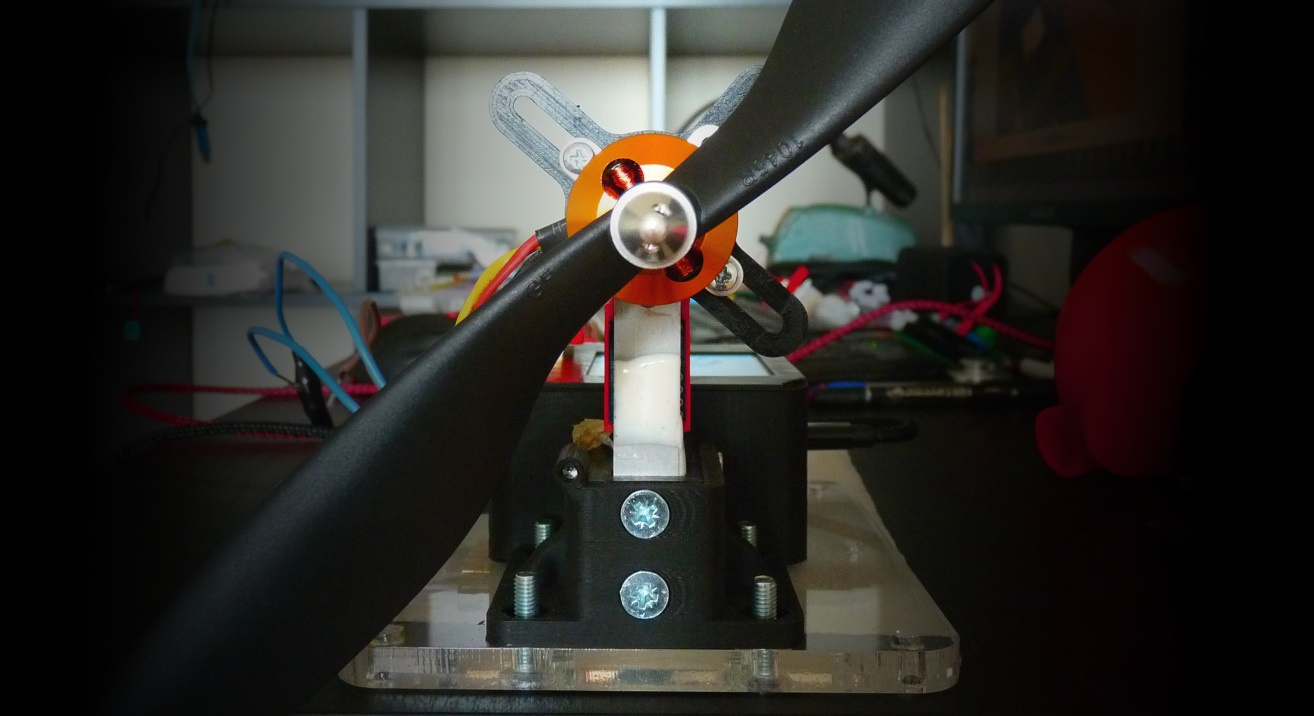

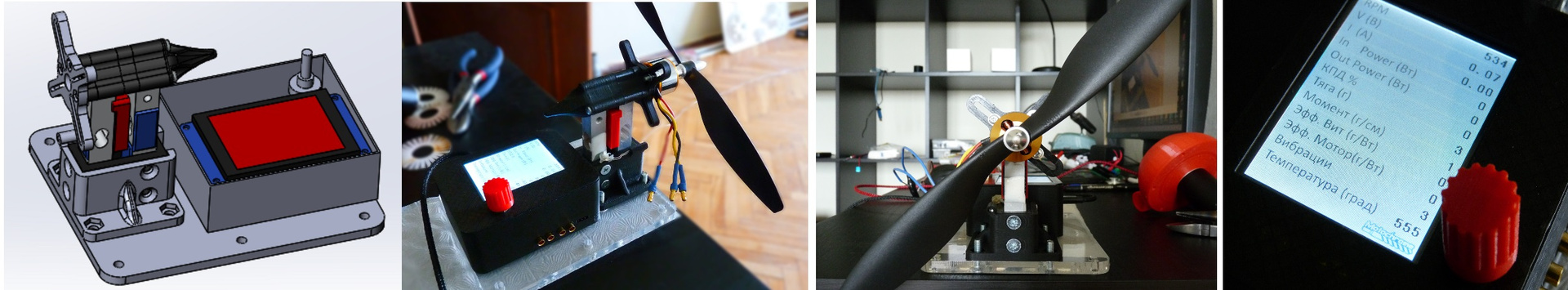

Based on these parameters, we designed the stand design and supplied it with all the necessary sensors.

To measure the force of torque and torque, now well-distributed sensors with strain resistance were selected. They have good rigidity and high measurement accuracy and are very well suited for their design.

To measure the remaining parameters, standard sensors were selected for this: semiconductor thermal resistance for temperature, accelerometer for measuring vibrations, current sensor on the hall effect for measuring current, and divider for voltage ...

The heart of our booth is the ATMega328 microcontroller on the Arduino Nano board. It collects readings from sensors, processes them and displays on the screen. This microcontroller is optimal for this task. It has a minimum price, is not picky about power, is stable and has a sufficient number of interfaces for this task.

As a result of our work, a stand was obtained with the following parameters:

Testing

We tested our booth on the common Chinese motor 2212 and on our motor.

The Chinese motor in the whole range could not give an efficiency higher than 50%, and its efficiency was about 4-5g / Watt. Our company was able to show efficiency above 70%, while it worked at the minimum of its power (the test was at its peak to 500W, the theoretical maximum is 1500W), since the size of the screw being tested is too small for it and with a larger screw, the efficiency will only increase. Efficiency is 9g / Watt. So even taking into account the much greater weight of the motor, even a small kopter with our motor could fly longer.)

Economical option

The stand described in this article is quite complex and is designed for accurate study of the power units of the drone. For the case when I want to save money and find out just the traction of the motor, we have made a simple, cheap adapter capable of performing this function.

This adapter is attached at one end to the motor, second to a bottle of water. The bottle is set on the scales. Next, the motor starts and the thrust is measured according to the indications of the scales.

Mount on the adapter is made universal and fits almost all common motors. At the second end of the adapter there is a thread for winding onto a 5 liter bottle.

We are engaged in the creation of brushless motors, and recently we had an order for a quadcopter motor with at least 2 kg for each screw. Before that, we did not make motors for an air screw and we needed a measurement method and a stand for a motor with a screw.

Before you begin to choose the best motor and screw for it, you first need to figure out what losses arise in the motors.

')

The main sources of losses in brushless motors are the stator iron and its winding.

Losses on iron occur due to its magnetization reversal. These losses can be considered conditionally proportional to the engine speed and they set the minimum energy consumption of the motor. So, for example, if you take a big and powerful motor for a small copter with a small screw, then nothing good will come of it. The motor will simply idle with zero efficiency and heat the iron in the stator.

Losses in a copper wire, on the contrary, do not depend on turns, but depend on current / power consumption. These losses limit the maximum power that the motor is capable of delivering without overheating.

The second important element when choosing a motor is a screw. Small screws have lower g / W performance (1 gram of lift / 1 watt of power consumption), but small screws are more dynamic and allow you to quickly pick up speed on racing copters. To achieve maximum flight time, the propeller must correspond to the maximum efficient mode of operation of the motor.

However, if we want to choose the best parts for our copter, then we will face a big problem when choosing them. Manufacturers give a minimum set of characteristics for their product. On the screws it is generally impossible to find any information other than their size.

Stand functionality

At the moment, several manufacturers have already presented their stands on the market. However, their capabilities do not greatly exceed the functionality of kitchen scales. And these stands are not able to give all the characteristics when the engine is running.

We also needed the following parameters from the stand: power consumption, engine speed, thrust of the screw, torque generated by the screw, efficiency of the motor, efficiency of the motor, screw.

Based on these parameters, we designed the stand design and supplied it with all the necessary sensors.

To measure the force of torque and torque, now well-distributed sensors with strain resistance were selected. They have good rigidity and high measurement accuracy and are very well suited for their design.

To measure the remaining parameters, standard sensors were selected for this: semiconductor thermal resistance for temperature, accelerometer for measuring vibrations, current sensor on the hall effect for measuring current, and divider for voltage ...

The heart of our booth is the ATMega328 microcontroller on the Arduino Nano board. It collects readings from sensors, processes them and displays on the screen. This microcontroller is optimal for this task. It has a minimum price, is not picky about power, is stable and has a sufficient number of interfaces for this task.

As a result of our work, a stand was obtained with the following parameters:

- Power supply via BEC module controller 5-9V, or via micro USB

- Thrust measurement up to 5 kg with an accuracy of + -5g

- Measurement of the moment up to 3 kg / cm with an accuracy of + -5g / cm

- Voltage measurement up to 30V with accuracy + -0.2V

- Current measurement up to 30A with an accuracy of + -0.1A

- Efficiency measurement with an accuracy of + -2.5%

- The ability to measure screw speed in the range of 1000-15000RPM

- The ability to measure relative vibrations. (You can use this parameter to balance a motor with a screw by reducing the vibration parameter)

- Measuring the temperature of the motor (* currently not fully implemented in the stand, we used a separately connected sensor)

- The ability to control the gas pedal directly from the remote

Testing

We tested our booth on the common Chinese motor 2212 and on our motor.

Video Test Example

The Chinese motor in the whole range could not give an efficiency higher than 50%, and its efficiency was about 4-5g / Watt. Our company was able to show efficiency above 70%, while it worked at the minimum of its power (the test was at its peak to 500W, the theoretical maximum is 1500W), since the size of the screw being tested is too small for it and with a larger screw, the efficiency will only increase. Efficiency is 9g / Watt. So even taking into account the much greater weight of the motor, even a small kopter with our motor could fly longer.)

Economical option

The stand described in this article is quite complex and is designed for accurate study of the power units of the drone. For the case when I want to save money and find out just the traction of the motor, we have made a simple, cheap adapter capable of performing this function.

This adapter is attached at one end to the motor, second to a bottle of water. The bottle is set on the scales. Next, the motor starts and the thrust is measured according to the indications of the scales.

Mount on the adapter is made universal and fits almost all common motors. At the second end of the adapter there is a thread for winding onto a 5 liter bottle.

Source: https://habr.com/ru/post/373515/

All Articles