Which 3D printer to choose? TOP-6 from 3Dtool

Good afternoon, dear readers Geektimes! 3D printers are beginning to penetrate modern life. And more and more people want to buy them. This is not a fabulous machine, and the machine that has found its application in many industries.

Manufacturers saw demand and began to produce various modifications of 3D printers. The choice of models is now very large and you can get confused in it.

We decided to help in this choice. Our blog will periodically publish a small charts, the most successful models for the acquisition. A pair of pieces for each price group. We confine ourselves to those models that are officially presented on the Russian market.

')

Conventionally, we divide them into three price categories:

- Budget segment

- Must have

- For business

Immediately we warn you that our list will not feature Chinese 3D printers purchased on Ali ... Firstly, they are not officially supplied to the Russian market, and do not have a Russian guarantee and service. And secondly, often they have a dubious quality, and require bringing them to working condition. Therefore, we will write about those 3D printers that allow, immediately after the purchase and assembly, proceed to 3D printing.

Go…

It usually presents inexpensive printers for self-assembly. Or as they call it - DIY KIT. In Russian constructors. In contrast to the already mentioned Chinese 3D printers, these designers immediately after assembly allow you to print quality. In addition to the designers in this group are assembled, ready-to-work 3D printers.

All 3D printers from the budget segment have certain limitations during operation. Usually there is one or more of these restrictions.

Here is a brief list of restrictions:

Poor print quality and low reliability are not included in this list. If there are such drawbacks, then such equipment should not be bought at all.

The first in our list, the constant hit since 2014.

This model immediately after the start of sales has gained widespread and popularity. What is the reason?

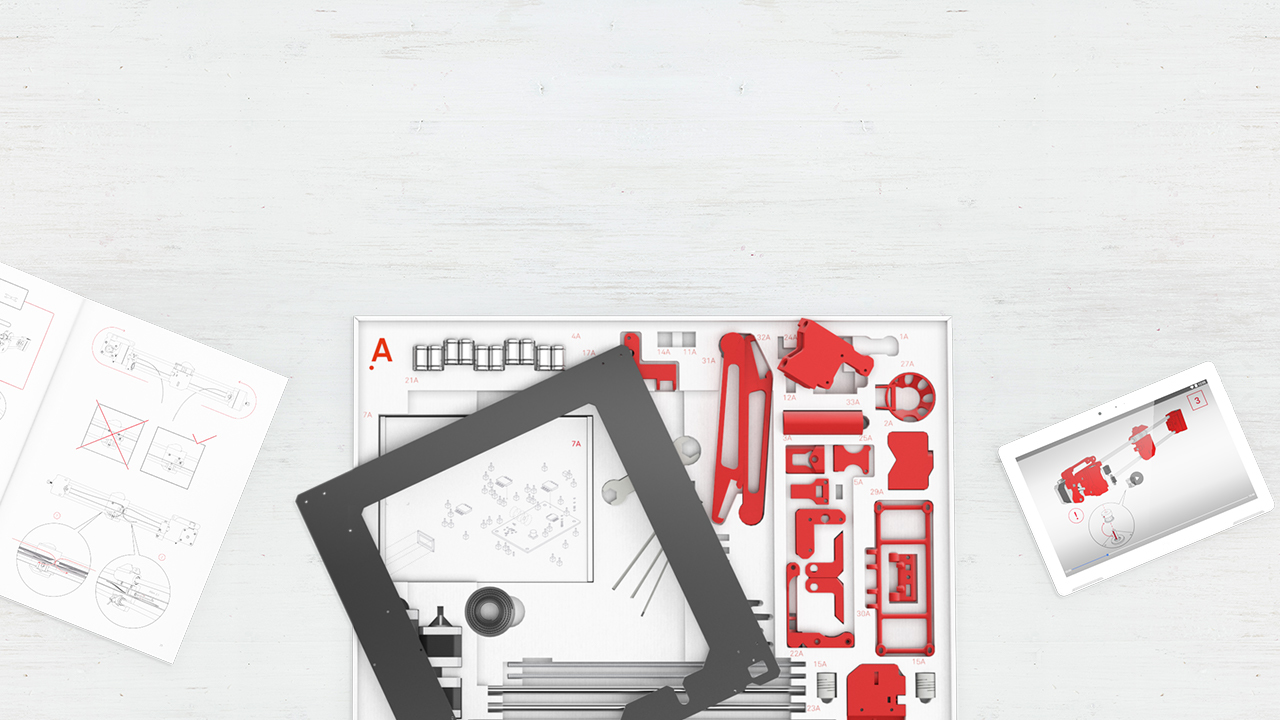

Detailed instructions, ease of assembly, decent quality 3D printing. Hephaestos has open documentation and therefore can be easily upgraded at its discretion. The printer has a large "community", in which a lot of add-ons have already been developed and made public.

At the end of 2016, the printer was updated - the design was simplified, the packaging, electronics, and extruder were updated. Build a printer has become easier and faster. The assembly process is quite simple with him even a high school student. Or a child under the supervision of an adult.

The European origin of the printer can be seen immediately - thoughtful packaging. Excellent step by step assembly instructions. High-quality components.

The printer is built on the Prusa i3 scheme, as indicated by its original name Prusa i3 Hephestos. Since the end of 2016, the 3D printer is called Hephestos 2016.

Characteristics of Hephestos 2016:

He has features. For example, there is no desktop heated. Due to the lack of a heated table, Hephaestos has a very low power consumption. It is only 60 watts. Lack of heating also simplifies the design and makes the printer safe. But imposes certain restrictions on the materials used. It is almost impossible to print with high shrinkage plastics. For example, one of the most common materials is ABS. Although now it is no longer a big problem. Many manufacturers produce materials that do not require a heated table.

PROS:

MINUSES:

Hephestos is intended primarily for exploring 3D printing. This is facilitated by ease of assembly, reliability, high potential for modernization. Despite this positioning, it is a serious machine that allows you to perform complex tasks. But we must understand that the lack of heating of the desktop and the closed case limits the choice of materials for high-quality 3D printing.

The official cost of a 3D Hephestos 2016 printer today is 39,950 rubles.

The second representative of the budget segment, a 3D printer from the Russian manufacturer.

The printer is also built according to the Prusa i3 scheme. It is presented on the market in two versions:

The first is similar to Hephestos, a set for self-assembly for 46 900 rubles

The second option is a fully assembled 3D printer for 54,900 rubles.

Unlike the previous printer, Bizon has a heated table that has heating up to 120 ° C and it can print with a full range of materials. Including high shrinkage such as ABS.

In addition, the printer has a large print area - 300x300x350 mm.

Characteristics of BiZon Prusa i3 Steel:

Bizon 3D printer is positioned as a solution for printing large parts. It has a low cost.

PROS:

MINUSES:

If you do not want to spend a large amount on the purchase of a 3D printer, but there is a need to print with all plastics - Bizon is the best option. Add to this an impressive print area of 300x300x350 mm. The bison has more opportunities, than Hephaestos, but demands qualification at assembly. It will not be as easy for a beginner to assemble it as the Spanish Hephestos. And we must understand that the lack of a closed camera print creates problems when printing large models of ABS or Nylon.

In this group will be presented printers worth more than 100 000 rubles. They are positioned as semi-professional, universal solutions for various tasks of hobby and business. Unlike 3D printers from the first group, there is no need to collect anything. All equipment is immediately ready for operation. It has a closed case, the ability to print all kinds of consumables, high speed and print quality.

This group includes many 3D printers. But today we will focus on two of them.

Produced in Russia. It was presented in the spring of 2016 and immediately gained popularity. What was the reason? This printer can not be called outstanding. It is simple and reliable. Prints in accordance with the stated characteristics. Fantastic speed is no different. Unless, it has a print area of a little more than “classmates” - 240x215x230 mm.

But!

He always prints and stably, for many hours in a row, with all available materials. It just has nothing to break. This is such a “Kalashnikov machine gun” in the world of 3D printers.

Zenit 3D Printer Specifications

Continuous printing time of the left half of a pair of clogs

And here is the result:

Full set of all necessary characteristics, large print area, closed case. Robust metal construction ensures reliability and print quality at high speeds. Appearance leaves no questions about the purpose of the equipment - it is a machine for production.

PROS:

MINUSES:

The printer is primarily universal and can be used simultaneously to solve problems of a business or home hobby.

If you need a guaranteed result, and you are not chasing design delights, then this is one of the best options.

The price of a Zenit 3D printer in April 2017 is 119,000 rubles + 5 kg of plastic as a gift.

The name of this printer, created in Russia, speaks for itself. Hercules is big and strong. This is how this 3D printer can be described. Developers from Krasnoyarsk in the design of this 3D printer wanted to solve problems in 3D printing of large models and prototypes.

The printer has a large print chamber and a massive case, which eliminates vibrations, which has a positive effect on print quality.

Characteristics of Hercules Strong 3D Printer:

PROS:

MINUSES:

What other features does Hercules Strong have except for its size? What makes it different from other printers? First, it is the time spent on printing large objects. Hercules has the ability to print nozzles of different diameters from 0.3 mm to 1.0 mm. That is, large models can be printed with a nozzle of a larger diameter, which will significantly save time spent on 3D printing. And accordingly, if we need high quality to print a small part, then you can use a nozzle with a diameter of 0.3 mm. There are no problems with changing the nozzle, everything for this is thought out in the printer, including the plastic feed mechanism and the extruder as a whole. The second caveat - printing large models takes a lot of time and you need a printer’s reliability in the long-distance run. The manufacturer conducted a continuous printing test for more than 135 hours (this is more than 5 days!). Excellent result!

The third "trump card in the sleeve" Hercules Strong is the UniHot extruder, thanks to which the printer can quickly and accurately print rubber-like materials (Rubber, Flex).

With all these qualities, the main scope of Hercules Strong - printing large models and prototypes. But with all this, Hercules remains a versatile tool and can easily print small details with jeweler's precision.

Hercules Strong price in April 2017 - 147,000 rubles + 10 kg of plastic as a gift.

What can be attributed to this category? What requirements must these 3D printers meet?

We list these requirements:

To provide high-quality 3D printing of complex models, the printer must have at least two extruders. This is required for printing complex models with dissolvable supports. It also implies a fully enclosed case for high-quality printing materials with high shrinkage - ABS, Nylon and others.

In the professional sector, the end result is important. A designer or designer needs a layout or prototype. And the faster he gets it, the better. For this, the printer must be easy to manage and maintain. All processes should be as automated as possible, and not require human participation.

But, as everyone knows, the best cheap does not happen. Therefore, the main disadvantage of this category is quite a high price.

We have already told about this printer in the past our review . From the review it is perfectly clear why this technique got into this list.

Great solution for professional use.

Specifications:

PROS:

MINUSES:

Raise3D N2 Dual combines two rare features - a large print area and two extruders. In addition, it has interchangeable nozzles of different diameters, which makes it possible to optimize print speed depending on the size and complexity of the product. Additional features facilitate its use as a professional tool for business.

The price of a 3D printer Raise3D N2 Dual in April 2017 - 225 000 rub + 10 kg of plastic as a gift.

Probably the most sensational novelty of December 2016. The start of shipments is scheduled for May 2017. But it can already be bought on pre-order, with a significant discount. What we saw on the presentations and photos of the manufacturer is amazing.

This is really a professional-grade 3D printer for solving complex problems in many areas. Although at home to have such a handsome man, few would refuse.

Specifications:

PROS:

MINUSES:

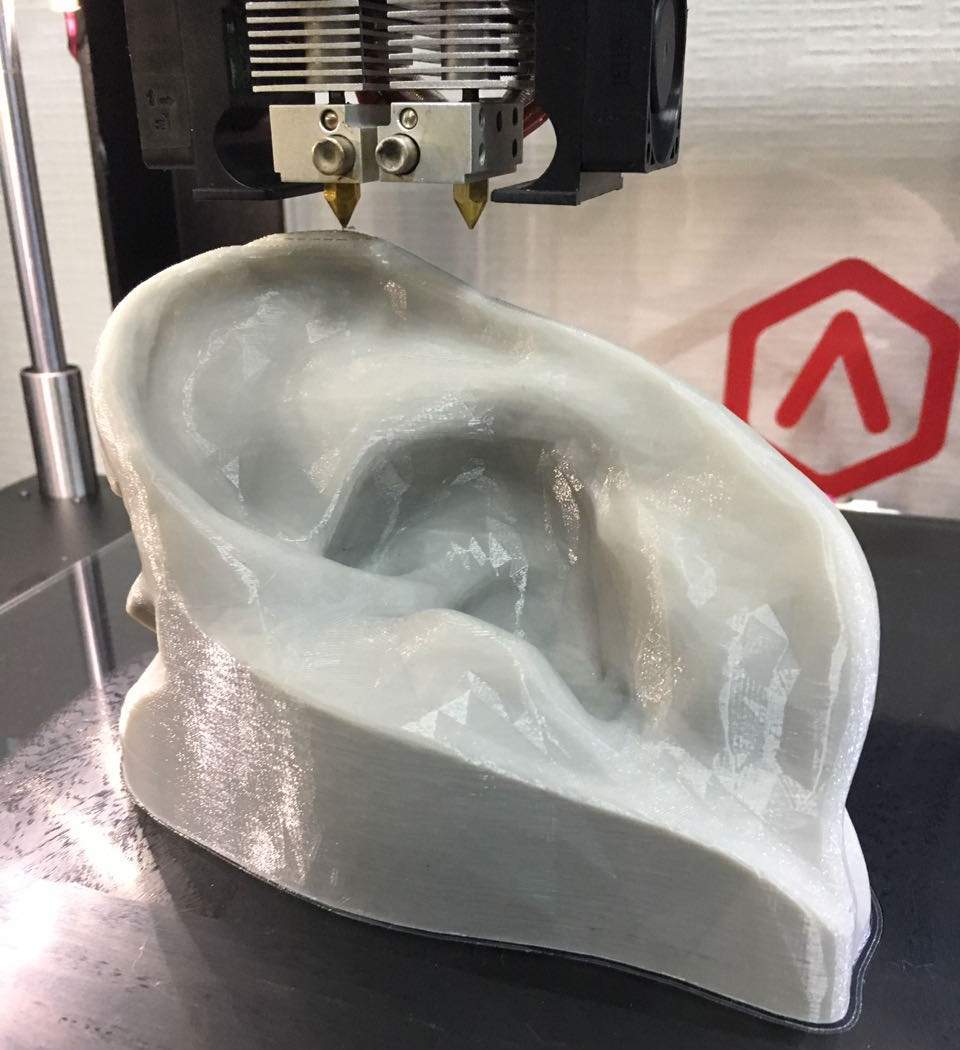

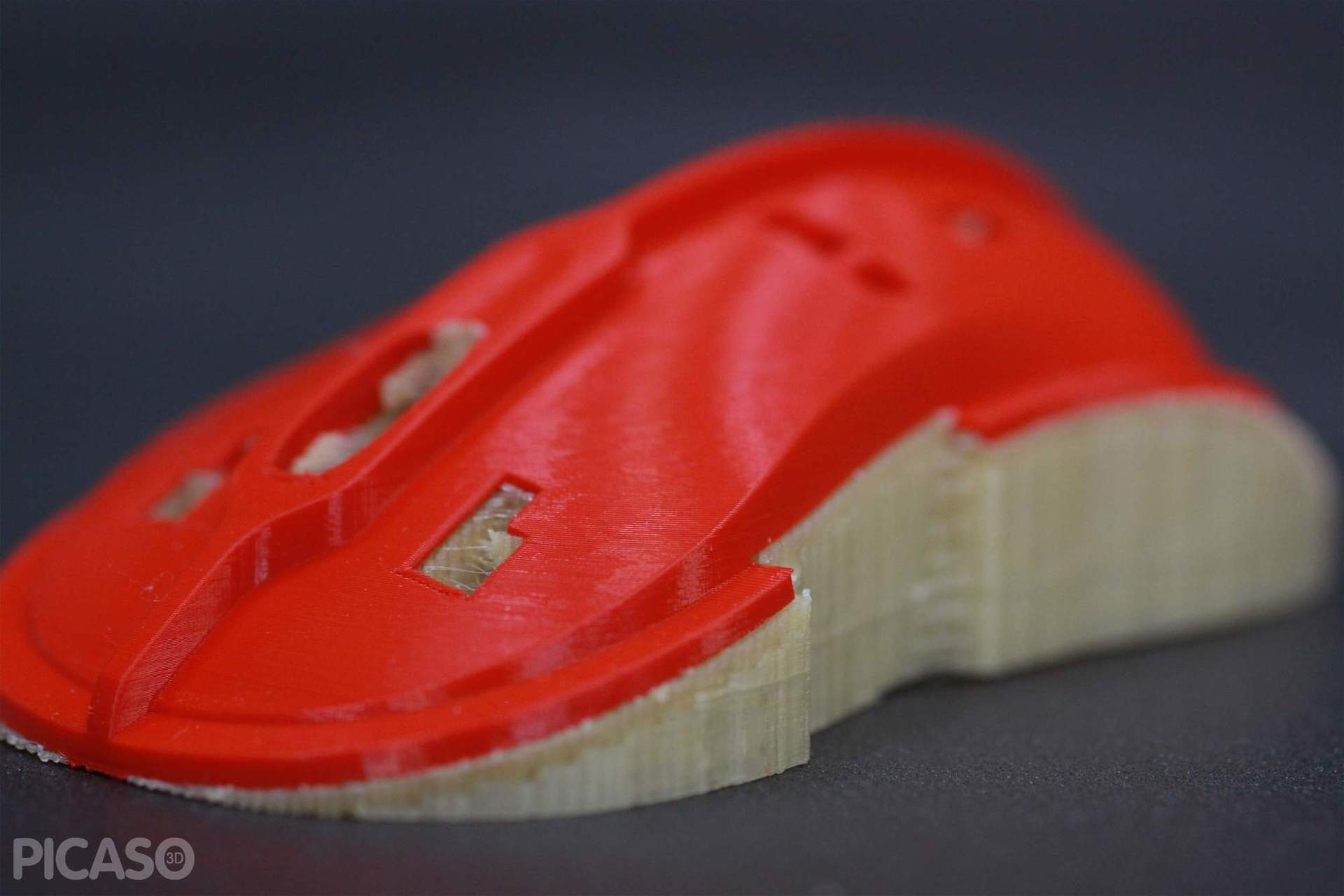

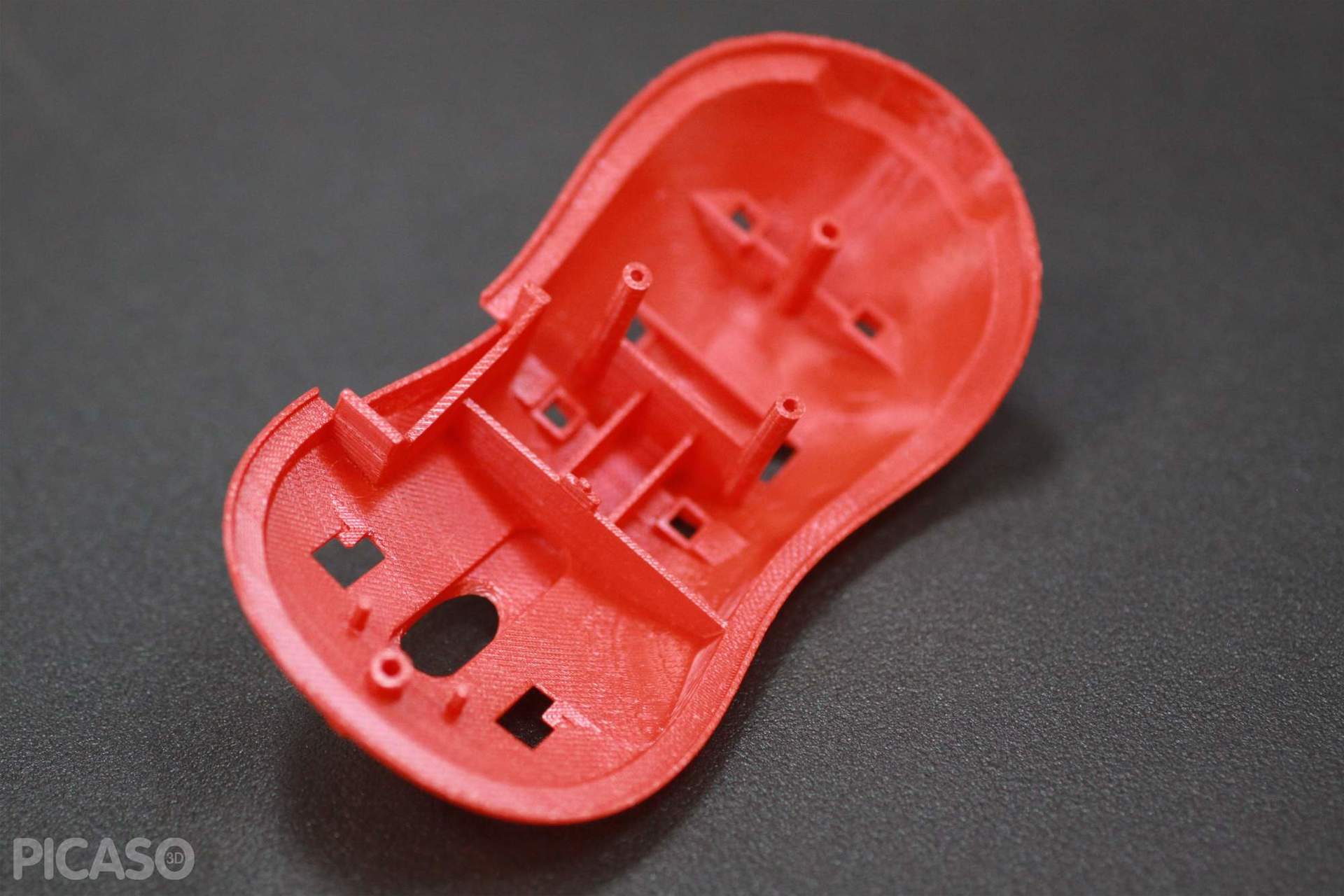

Just look at the photo below and you will understand.

We saw a lot of 3D printers. And to be honest, no one showed this quality before the announcement of PICASO 3D Designer X PRO . Indeed, it can be called the choice of professionals.

The cost of the printer on pre-order 199 000 rubles. After the start of shipments, the price will increase to 279,000 rubles.

Today it is one of the most automated 3D printers. The system of additional services facilitates the work and reduces time costs. The 3D printer itself "solves" many problems during printing.

If the solution to problems during 3D printing is beyond the capabilities of a 3D printer, then Picaso 3D Designer X PRO will alert the operator.

The software allows you to create "farm 3D printers" for large projects or small-scale production. From one computer, the operator has the ability to monitor and control multiple PICASO 3D Designer X PRO.

The main niche of this printer is the production of high-precision prototypes for business needs. If you have long wanted to use 3D printing for such tasks, but you were deterred by the price of other professional printers, then now is the time to pay attention to Picaso 3D Designer X PRO. For print quality, it can compete with many models of more expensive professional 3D printers with a price of 1 million rubles or more.

On this positive note, we complete a brief review of the most profitable purchases of 3D printers in April 2017. In more detail, about the printers presented in the article, you can find on our website www.3dtool.ru

Manufacturers saw demand and began to produce various modifications of 3D printers. The choice of models is now very large and you can get confused in it.

We decided to help in this choice. Our blog will periodically publish a small charts, the most successful models for the acquisition. A pair of pieces for each price group. We confine ourselves to those models that are officially presented on the Russian market.

')

Conventionally, we divide them into three price categories:

- Budget segment

- Must have

- For business

Immediately we warn you that our list will not feature Chinese 3D printers purchased on Ali ... Firstly, they are not officially supplied to the Russian market, and do not have a Russian guarantee and service. And secondly, often they have a dubious quality, and require bringing them to working condition. Therefore, we will write about those 3D printers that allow, immediately after the purchase and assembly, proceed to 3D printing.

Go…

Budget segment

It usually presents inexpensive printers for self-assembly. Or as they call it - DIY KIT. In Russian constructors. In contrast to the already mentioned Chinese 3D printers, these designers immediately after assembly allow you to print quality. In addition to the designers in this group are assembled, ready-to-work 3D printers.

All 3D printers from the budget segment have certain limitations during operation. Usually there is one or more of these restrictions.

Here is a brief list of restrictions:

- No closed camera

- Low print speed

- Small print area

- Restrictions on the types of consumables (plastics)

- The need for self-assembly

Poor print quality and low reliability are not included in this list. If there are such drawbacks, then such equipment should not be bought at all.

The first in our list, the constant hit since 2014.

Hephestos2016

This model immediately after the start of sales has gained widespread and popularity. What is the reason?

Detailed instructions, ease of assembly, decent quality 3D printing. Hephaestos has open documentation and therefore can be easily upgraded at its discretion. The printer has a large "community", in which a lot of add-ons have already been developed and made public.

At the end of 2016, the printer was updated - the design was simplified, the packaging, electronics, and extruder were updated. Build a printer has become easier and faster. The assembly process is quite simple with him even a high school student. Or a child under the supervision of an adult.

The European origin of the printer can be seen immediately - thoughtful packaging. Excellent step by step assembly instructions. High-quality components.

The printer is built on the Prusa i3 scheme, as indicated by its original name Prusa i3 Hephestos. Since the end of 2016, the 3D printer is called Hephestos 2016.

Characteristics of Hephestos 2016:

- Material used for 3D printing: PLA; FLEX; NYLON; Rubber; Laywood; Laybrick, PETG;

- Printing area: 215x210x180 mm;

- Layer height: from 60 to 300 microns;

- Thread diameter: 1.75 mm;

- Nozzle diameter: 0.4 mm;

- Print speed: 40-100 mm / s;

- Availability of heated platform: No;

- Number of print heads: 1;

- Software: Cura Software, Slic3r, Repetier, Kisslicer;

- Connecting a 3D printer to a computer: USB, SD;

- Dimensions and weight: 460x383x430 mm, Weight —9.7 kg;

- Warranty: 1 year;

He has features. For example, there is no desktop heated. Due to the lack of a heated table, Hephaestos has a very low power consumption. It is only 60 watts. Lack of heating also simplifies the design and makes the printer safe. But imposes certain restrictions on the materials used. It is almost impossible to print with high shrinkage plastics. For example, one of the most common materials is ABS. Although now it is no longer a big problem. Many manufacturers produce materials that do not require a heated table.

PROS:

- Low price

- Ease of assembly

- Reliability

- Ability to understand the design and upgrade 3D printer

- Security

MINUSES:

- Lack of heated table

- No closed enclosure

Hephestos is intended primarily for exploring 3D printing. This is facilitated by ease of assembly, reliability, high potential for modernization. Despite this positioning, it is a serious machine that allows you to perform complex tasks. But we must understand that the lack of heating of the desktop and the closed case limits the choice of materials for high-quality 3D printing.

The official cost of a 3D Hephestos 2016 printer today is 39,950 rubles.

The second representative of the budget segment, a 3D printer from the Russian manufacturer.

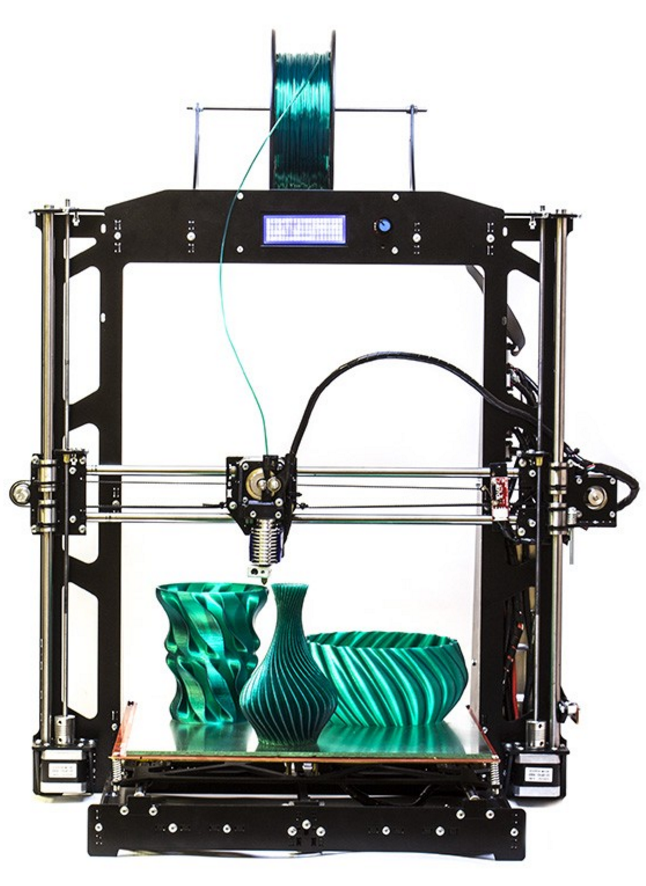

BiZon Prusa i3 Steel

The printer is also built according to the Prusa i3 scheme. It is presented on the market in two versions:

The first is similar to Hephestos, a set for self-assembly for 46 900 rubles

The second option is a fully assembled 3D printer for 54,900 rubles.

Unlike the previous printer, Bizon has a heated table that has heating up to 120 ° C and it can print with a full range of materials. Including high shrinkage such as ABS.

In addition, the printer has a large print area - 300x300x350 mm.

Characteristics of BiZon Prusa i3 Steel:

- Material used for 3D printing: ABS; PLA; HIPS; FLEX; NYLON; PVA; Rubber; T-Glass; Laywood; Laybrick;

- Printing area: 300x300x350 mm;

- Layer height: from 80 to 350 microns;

- Thread diameter: 1.75;

- The diameter of the nozzle: 0.4 mm (the ability to install a nozzle of 0.2-1.2 mm);

- Print speed: 50-100 mm / s;

- Availability of heated platform: Yes, 120;

- Number of print heads: 1;

- Software: Repetier-Host, Slic3r, Cura;

- Connecting a 3D printer to a computer: USB, SD card (offline printing);

- Dimensions and weight: 500550550 mm, Weight - 12,5 kg;

- Warranty: 6 months;

Bizon 3D printer is positioned as a solution for printing large parts. It has a low cost.

PROS:

- Low price

- There is a heated table

- All metal construction

- Large printing area

- Ability to choose a designer or assembled printer

MINUSES:

- No closed enclosure

- Building requires more time and skills (for example, compared to Hephestos)

If you do not want to spend a large amount on the purchase of a 3D printer, but there is a need to print with all plastics - Bizon is the best option. Add to this an impressive print area of 300x300x350 mm. The bison has more opportunities, than Hephaestos, but demands qualification at assembly. It will not be as easy for a beginner to assemble it as the Spanish Hephestos. And we must understand that the lack of a closed camera print creates problems when printing large models of ABS or Nylon.

Must have segment

In this group will be presented printers worth more than 100 000 rubles. They are positioned as semi-professional, universal solutions for various tasks of hobby and business. Unlike 3D printers from the first group, there is no need to collect anything. All equipment is immediately ready for operation. It has a closed case, the ability to print all kinds of consumables, high speed and print quality.

This group includes many 3D printers. But today we will focus on two of them.

Zenit 3D printer

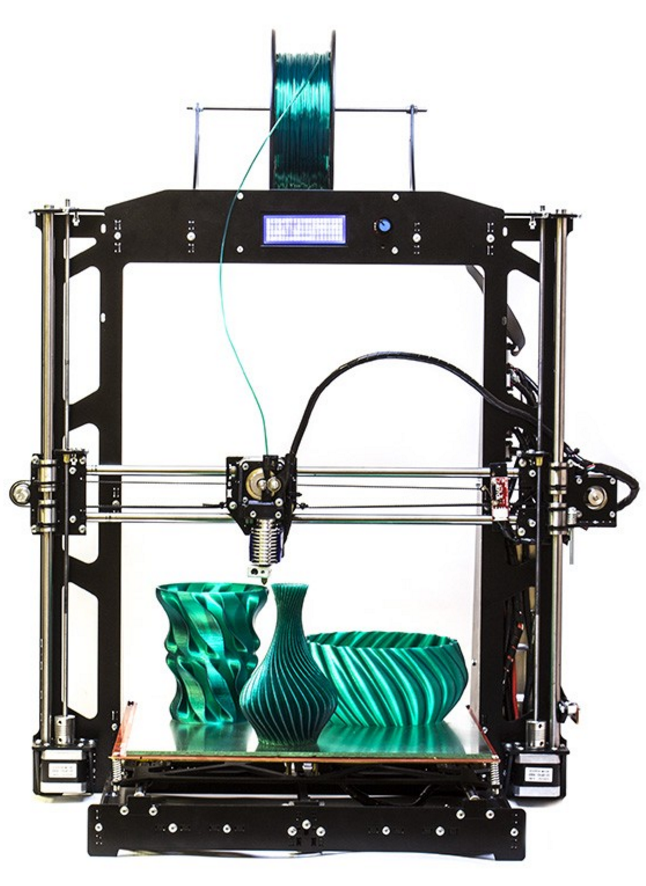

Produced in Russia. It was presented in the spring of 2016 and immediately gained popularity. What was the reason? This printer can not be called outstanding. It is simple and reliable. Prints in accordance with the stated characteristics. Fantastic speed is no different. Unless, it has a print area of a little more than “classmates” - 240x215x230 mm.

But!

He always prints and stably, for many hours in a row, with all available materials. It just has nothing to break. This is such a “Kalashnikov machine gun” in the world of 3D printers.

Zenit 3D Printer Specifications

- Material used for 3D printing: PLA, ABS, Flex, Rubber, PC, PETG, Hips, Nylon, Laywood (filament diameter 1.75mm);

- Printing area: 240x215x230 mm;

- Layer thickness: 50-300 microns;

- Availability of heated platform: Yes;

- Nozzle diameter: 0.3 mm;

- Number of print heads: 1;

- The speed of movement of the print head: up to 300 mm / s;

- Print speed: up to 35 cm3 per hour;

- Supported formats: STL;

- Connecting a 3D printer to a computer: USB (also possible to print via SD-card);

- Dimensions and weight: 460x360x370 mm, weight - 20 kg;

- Power Consumption: 220V, 50Hz, 350W;

- Warranty: 3 years;

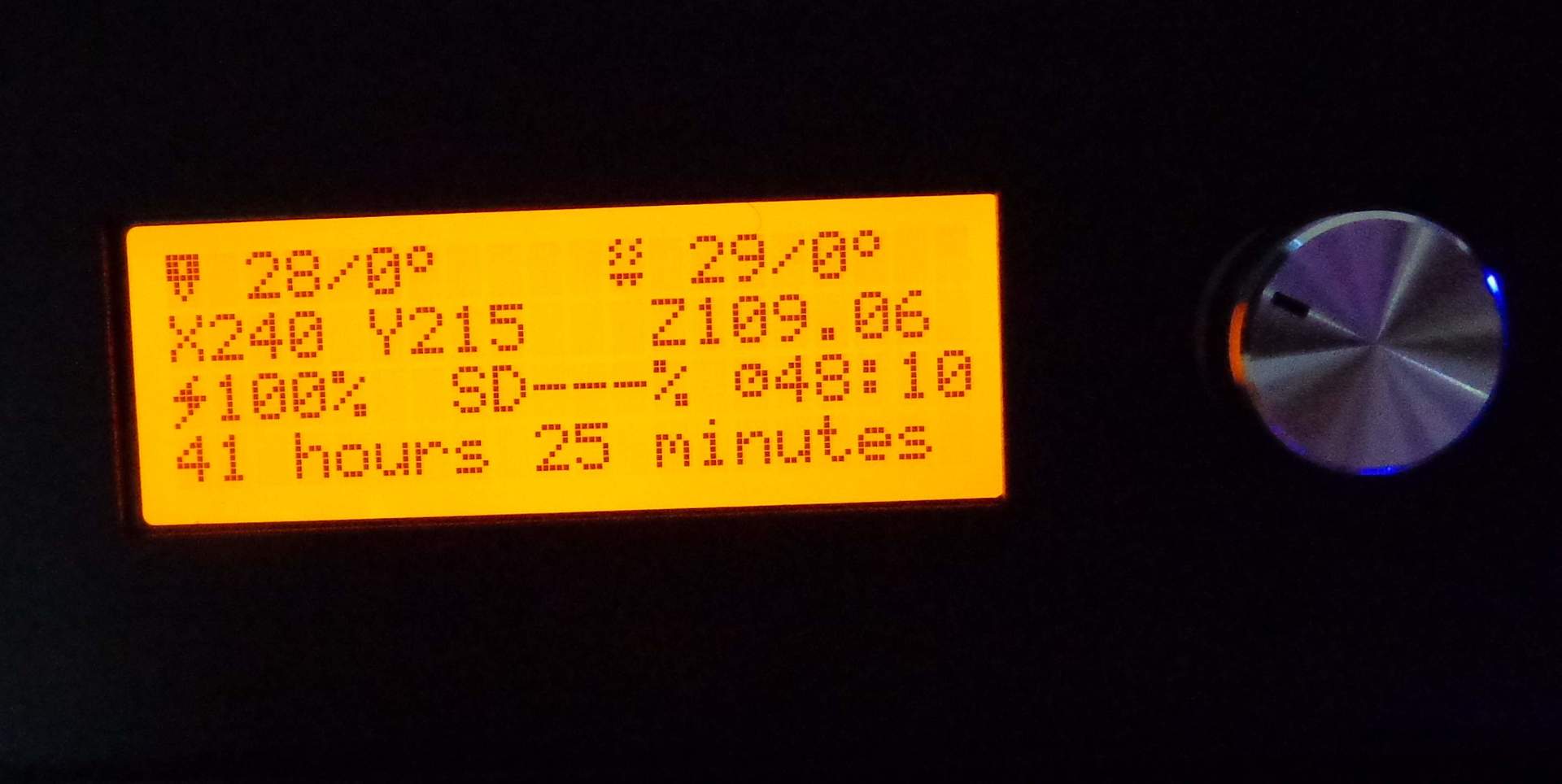

Continuous printing time of the left half of a pair of clogs

And here is the result:

Full set of all necessary characteristics, large print area, closed case. Robust metal construction ensures reliability and print quality at high speeds. Appearance leaves no questions about the purpose of the equipment - it is a machine for production.

PROS:

- Hard metal enclosed housing

- Large printing area 240x215x230 mm

- Heated table

- Low noise during operation

- The ability to print all available materials

- High reliability.

- 3 year warranty

MINUSES:

- Not the most modern look. Although it is not important for the machine

The printer is primarily universal and can be used simultaneously to solve problems of a business or home hobby.

If you need a guaranteed result, and you are not chasing design delights, then this is one of the best options.

The price of a Zenit 3D printer in April 2017 is 119,000 rubles + 5 kg of plastic as a gift.

3D printer Hercules Strong

The name of this printer, created in Russia, speaks for itself. Hercules is big and strong. This is how this 3D printer can be described. Developers from Krasnoyarsk in the design of this 3D printer wanted to solve problems in 3D printing of large models and prototypes.

The printer has a large print chamber and a massive case, which eliminates vibrations, which has a positive effect on print quality.

Characteristics of Hercules Strong 3D Printer:

- Material used for 3D printing: ABS, PLA, HIPS, Flexible Materials (Watson, Rubber, FLEX), Bronze;

- Printing area: 300x290x370 mm;

- Layer thickness: from 20 to 800 microns;

- The presence of a heated platform: Yes (glass ceramics);

- Number of printheads: 1 (nozzle diameter 0.4 mm), Additional nozzles (as an option) 0.3mm, 0.5mm, 0.8mm, 1mm;

- Print speed: up to 80 mm / s;

- Supported formats: STL, OBJ;

- Software: Repetier-Host, Simplify3D, Cura .;

- Connecting a 3D printer to a computer: USB (also possible to print via SD-card);

- Dimensions and weight: 573520670 mm, weight - 22 kg;

- Power Consumption: 550W.

- Warranty: 1 year;

PROS:

- Hard metal enclosed housing

- Large printing area 300x290x370 mm

- High print quality

- Possibility of fast quality printing with flexible materials

- The possibility of high-quality printing nozzles of different diameters

MINUSES:

- Dimensions

What other features does Hercules Strong have except for its size? What makes it different from other printers? First, it is the time spent on printing large objects. Hercules has the ability to print nozzles of different diameters from 0.3 mm to 1.0 mm. That is, large models can be printed with a nozzle of a larger diameter, which will significantly save time spent on 3D printing. And accordingly, if we need high quality to print a small part, then you can use a nozzle with a diameter of 0.3 mm. There are no problems with changing the nozzle, everything for this is thought out in the printer, including the plastic feed mechanism and the extruder as a whole. The second caveat - printing large models takes a lot of time and you need a printer’s reliability in the long-distance run. The manufacturer conducted a continuous printing test for more than 135 hours (this is more than 5 days!). Excellent result!

The third "trump card in the sleeve" Hercules Strong is the UniHot extruder, thanks to which the printer can quickly and accurately print rubber-like materials (Rubber, Flex).

With all these qualities, the main scope of Hercules Strong - printing large models and prototypes. But with all this, Hercules remains a versatile tool and can easily print small details with jeweler's precision.

Hercules Strong price in April 2017 - 147,000 rubles + 10 kg of plastic as a gift.

Segment "For Business"

What can be attributed to this category? What requirements must these 3D printers meet?

We list these requirements:

- Print any complexity of prototypes or details.

- Increased resource and reliability

- Additional functions for work in the "printing farms"

- The simplest printing process

- Maximum automation

- Printing with any available consumables

- Easy maintenance

To provide high-quality 3D printing of complex models, the printer must have at least two extruders. This is required for printing complex models with dissolvable supports. It also implies a fully enclosed case for high-quality printing materials with high shrinkage - ABS, Nylon and others.

In the professional sector, the end result is important. A designer or designer needs a layout or prototype. And the faster he gets it, the better. For this, the printer must be easy to manage and maintain. All processes should be as automated as possible, and not require human participation.

But, as everyone knows, the best cheap does not happen. Therefore, the main disadvantage of this category is quite a high price.

3D printer Raise3D N2 Dual

We have already told about this printer in the past our review . From the review it is perfectly clear why this technique got into this list.

Great solution for professional use.

Specifications:

- Material used for 3D printing: PLA, ABS, Filaflex, PVA, PC, Hips, Nylon, Laywood;

- Printing area: 305x305x305 mm;

- Layer thickness: from 10 to 200 microns;

- Nozzle diameter: 0.4 mm;

- The presence of a closed camera 3D printing: Yes;

- Heated table: Yes, up to 110 ° C;

- Extruder temperature: up to 300 ° C;

- Number of print heads: 2;

- Software: IdeaMaker proprietary software;

- Connecting a 3D printer to a computer: USB, SD;

- Touch screen: 7 ″;

- Warranty: 1 year;

PROS:

- Closed body on a rigid frame

- Large print area 305x305x305mm

- Heated table

- Low noise during operation

- The ability to print all available materials

- Two extruders allow you to print complex models using water-soluble supports

- A large number of management interfaces

- Remote control capability

- Autonomous power supply of the central control unit.

MINUSES:

- Price

Raise3D N2 Dual combines two rare features - a large print area and two extruders. In addition, it has interchangeable nozzles of different diameters, which makes it possible to optimize print speed depending on the size and complexity of the product. Additional features facilitate its use as a professional tool for business.

The price of a 3D printer Raise3D N2 Dual in April 2017 - 225 000 rub + 10 kg of plastic as a gift.

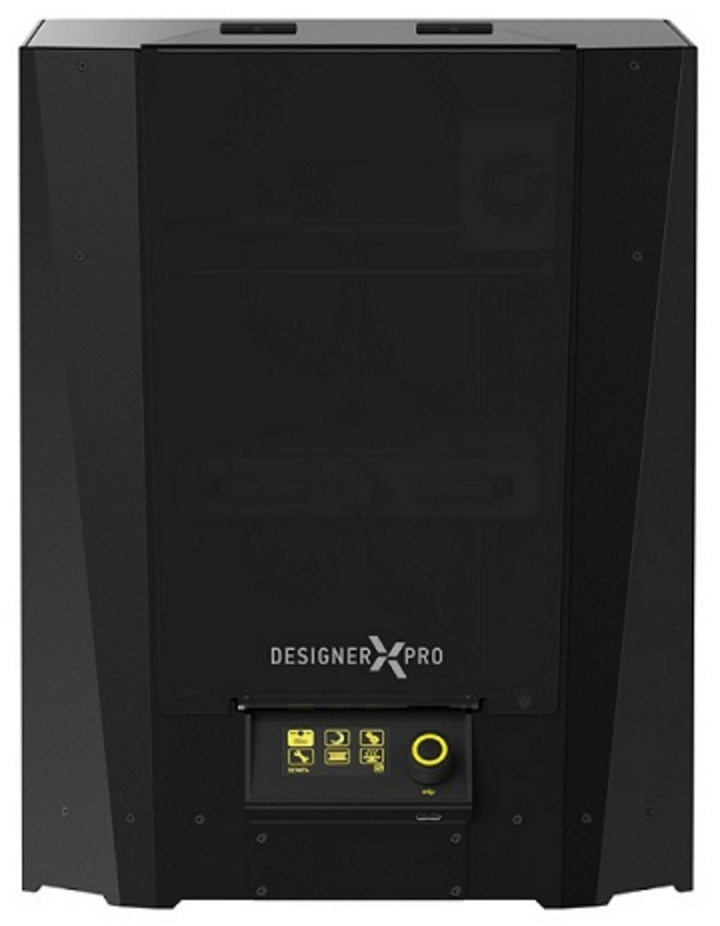

3D printer PICASO 3D Designer X PRO

Probably the most sensational novelty of December 2016. The start of shipments is scheduled for May 2017. But it can already be bought on pre-order, with a significant discount. What we saw on the presentations and photos of the manufacturer is amazing.

This is really a professional-grade 3D printer for solving complex problems in many areas. Although at home to have such a handsome man, few would refuse.

Specifications:

- Material used for 3D printing: PLA, ABS, PLA Flexible, PVA, PC, Hips, Nylon, Laywood, FilaFlex, Filamentarno;

- Printing area: 200x200x210 mm;

- Body Material: Aluminum (composite);

- Guides: XY: rail (steel), Z: cylindrical (steel);

- Layer thickness: from 5 to 20 microns;

- Positioning accuracy: XY: 11 microns; Z: 1.25 microns;

- Availability of heated platform: Yes;

- Printing platform: Aluminum - glass;

- Number of print heads: 2;

- Automatic table calibration: Yes;

- Nozzle diameter: 0.3 mm;

- Maximum extruder operating temperature: 380C;

- Maximum working temperature of the working platform: 140C;

- Noise level: 55 dBA;

- Management board: based on the ARM CORTEX M4 core 32-bit STM processor;

- Interfaces: USB, Ethernet, USB Flash [included];

- Print speed: up to 30 cm 3 / hour;

- Supported formats: STL, PLG;

- Software: Picaso 3D Polygon X Software

- Dimensions and weight: 492390430; Weight - 16 kg;

- Dimensions and weight in packing: 690x500x470; Weight - 22 kg;

- Power Consumption: 220V, 50Hz (110V 60Hz option available) 400W;

- Warranty: 2 years;

PROS:

- Closed body on a rigid frame

- Heated table

- The ability to print all available materials

- JetSwitch Extruder allows you to print complex models using water-soluble support c high speed.

- Remote control

- Automate the printing process

- Ability to create a whole "farm" of 3D printers X PRO

MINUSES:

- Price (pre-order is not so scary)

Just look at the photo below and you will understand.

We saw a lot of 3D printers. And to be honest, no one showed this quality before the announcement of PICASO 3D Designer X PRO . Indeed, it can be called the choice of professionals.

The cost of the printer on pre-order 199 000 rubles. After the start of shipments, the price will increase to 279,000 rubles.

Today it is one of the most automated 3D printers. The system of additional services facilitates the work and reduces time costs. The 3D printer itself "solves" many problems during printing.

If the solution to problems during 3D printing is beyond the capabilities of a 3D printer, then Picaso 3D Designer X PRO will alert the operator.

The software allows you to create "farm 3D printers" for large projects or small-scale production. From one computer, the operator has the ability to monitor and control multiple PICASO 3D Designer X PRO.

The main niche of this printer is the production of high-precision prototypes for business needs. If you have long wanted to use 3D printing for such tasks, but you were deterred by the price of other professional printers, then now is the time to pay attention to Picaso 3D Designer X PRO. For print quality, it can compete with many models of more expensive professional 3D printers with a price of 1 million rubles or more.

On this positive note, we complete a brief review of the most profitable purchases of 3D printers in April 2017. In more detail, about the printers presented in the article, you can find on our website www.3dtool.ru

Source: https://habr.com/ru/post/373379/

All Articles