Fire hazard of Lukey soldering stations

(I apologize for the quality of the photo)

Today I was awakened by a distinct smell of smoke and the exclamations of my wife - “get up soon, you have something burning in the workshop there”. After a couple of seconds, I saw the source of a fire that had just begun - a lukey 852d + soldering station plugged into a power outlet turned off the heat to a red glow, and a plastic handle burned with a vigorous flame.

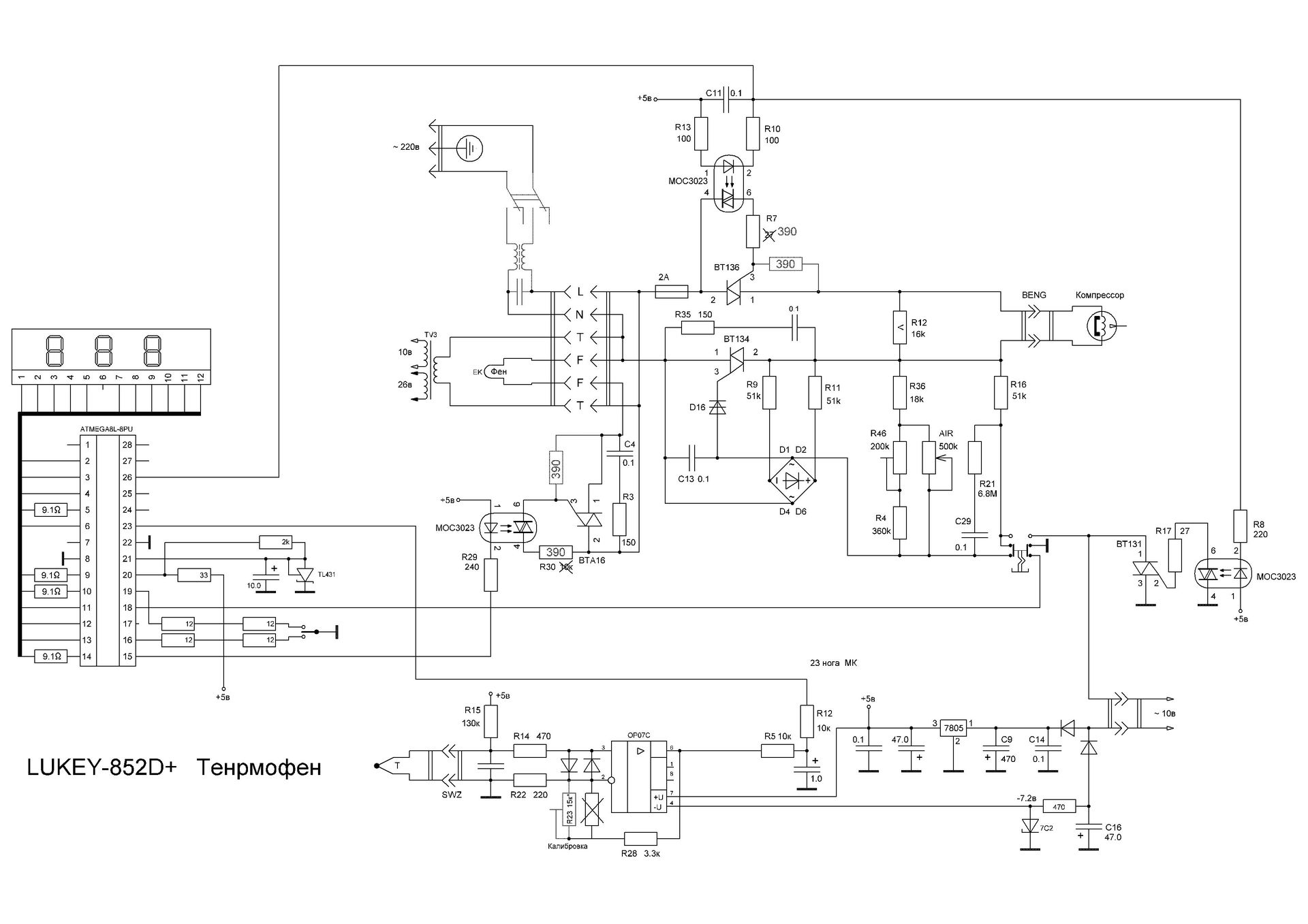

And so, what happened? When all the consequences of the fire were removed, I opened the soldering station and was unpleasantly surprised. The fact is that the heating of the hair dryer in almost all the hatches is controlled through a triac power regulator, which in this case received a PWM signal from Atmega's leg through the opto-triac pair.

')

This circuit takes power directly from the 220-volt input terminal, only the snubber RC circuit and all that is protected. When the triac BTA16 fails due to a surge in voltage, the hairdryer starts happily gambling at all its 700 kopecks of Chinese watts.

What to do?

1) Put a varistor with a cut-off of 275 volts parallel to this simistor - with short-term surges the excess will be dispersed in a spiral, and the triac will remain locked.

2) Open the circuit using a 220 volt 10 A relay by hanging the control winding through a 1500 µkf condenser, a diode and a small transformer on the pump terminals. The logic is simple - if the pump does not work, then the heating circuit of the heating coil is a priori open.

Well, do not trust the Chinese, leaving unattended the technique of Uncle Liao in standby, even if for the last 5-6 years she has been working without jambs.

Source: https://habr.com/ru/post/373321/

All Articles