Arduino 3D printer prints functional human skin

According to WHO estimates , annually about 11 million patients in the world need skin grafts after burns, and in 265 thousand affected skin lesions are so extensive that they are fatal. Skin grafting is also required as a result of various pathologies, infections, after surgery to remove cancerous tumors, due to genetic and somatic diseases.

Usually, autogenous grafts are used to restore the skin when a skin area is taken from the recipient itself. Unfortunately, with a large area of burns it is sometimes impossible to find suitable areas in sufficient quantities.

Doctors are trying to explore different technologies to obtain a suitable substitute , but so far the results are far from ideal. The results are unreliable: the material is too fragile, it is difficult to work with it, after transplantation it is too sensitive to contact. In general, existing manufacturing methods provide an extremely unpredictable result.

')

In recent years, with the help of new technologies, scientists have been able to develop much more advanced substrates in which skin and epidermal components dynamically interact with each other, both during maturation in the laboratory and after transplantation on the human body. In particular, fibrinogen protein (and its derivative protein fibrin), a component of the blood plasma, which is synthesized in the liver, is actively used for the manufacture of such substrates. This protein turned out to be an excellent material for an artificial skin substrate - it is cheap, available in large quantities and convenient in work.

For about ten years, a group of Spanish researchers first made and tested a substrate of artificial human skin from skin plasma: see the article "Clinical Results of an Autologous Engineered Skin" , published in the Cell 2006 Tissue Bank in March 2006 (doi: 10.1007 / s10561-004- 7253-4). Clinical trials have shown encouraging results, but the transplant process itself has remained difficult. First, it required only qualified personnel: the engraftment of such a substrate is a scientific project that is being carried out by scientists in the laboratory. It was almost impossible to repeat it in an average hospital. In addition, the cultivation of the substrate took a long time: 3-4 weeks for the cultivation of one square meter.

Considering the high demand for artificial leather, scientists set a goal to optimize the technical process - to reduce the time and cost of work, as well as to maximize the automation of work. And they did it.

Print the skin on a 3D printer

As studies of recent years have shown, 3D-bioprinting perfectly manifests itself in the printing of tissues, liver and other living organs. Engineers have studied a variety of new materials suitable for human organ bioprinting on Cartesian coordinate robots (that is, on inexpensive modern 3D printers), including hydrogels, polymers, and ceramics (for bones). Significant progress has been made in the development of 3D designs for printing complex fabrics. The general approach is to print a preliminary matrix of layers based on a hydrogel in order to subsequently form cross-links between them and form a 3D framework that will support living cells and other extracellular components embedded in this framework. After a certain time of maturation in the laboratory, this printed tissue or organ can be transplanted into the human body.

According to a review of the methods of 3D printing of human skin (2016, Trends in Biotechnology ), there are two main strategies: printing at the site of damage or printing in a laboratory. In the second case, different approaches are also used.

A group of Spanish scientists from the Carlos III University of Madrid , the Center for Energy, Environmental and Technological Research, Hospital General Universitario Gregorio Marañón and the commercial company BioDan Group have developed a 3D bio printing process that seems to them the most optimal, taking into account the experience gained by predecessors. They applied the free-form fabrication (FFF) bioprinting technique to print layers in order to subsequently form cross-links between them and form a 3D framework, as described above. In separate layers are placed fibroblasts and keratinocytes , obtained as a result of a skin biopsy.

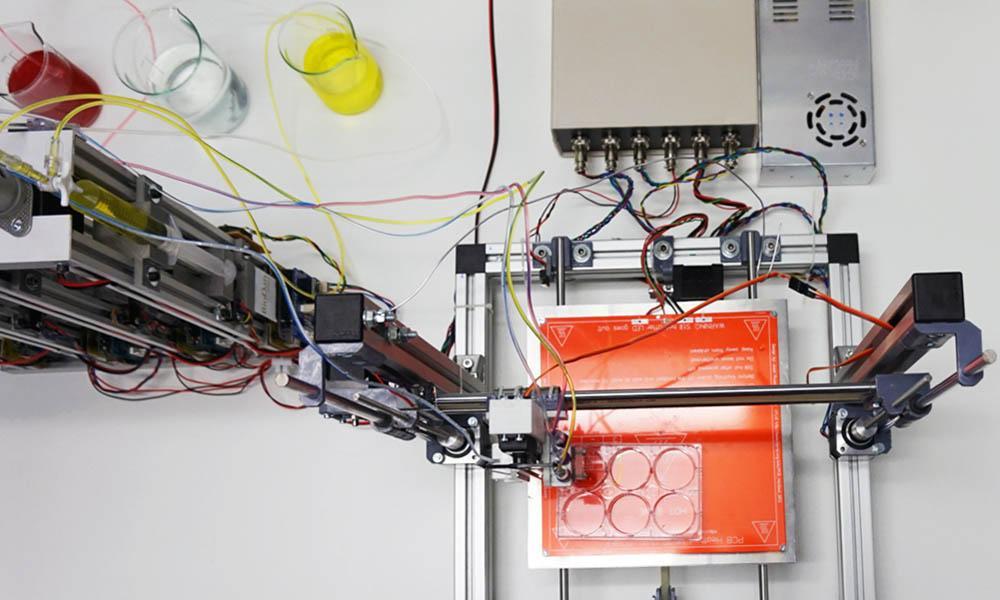

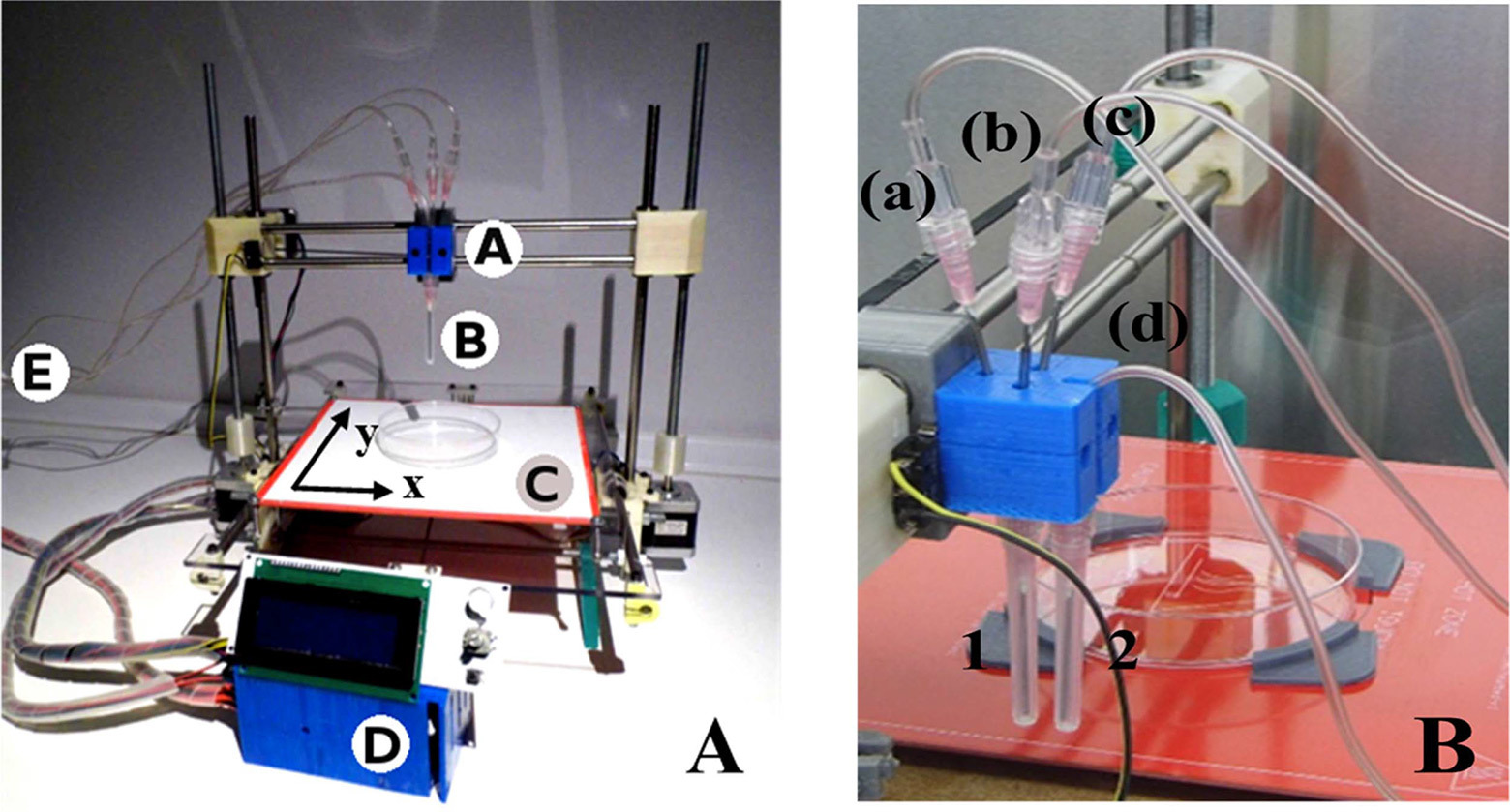

Bioprinter for printing human skin. In four cartridges - blood plasma, fibroblasts, calcium chloride and keratinocytes. The seal is controlled by an Arduino controller (ATmega2560) with RAMPS 1.4 and an LCD display. The printer with two stepper motors runs on free Marlin firmware, the calculation of the trajectories for applying layers is performed by the program Repetier 0.53. To control the volume of the applied fluid a script is written in C ++.

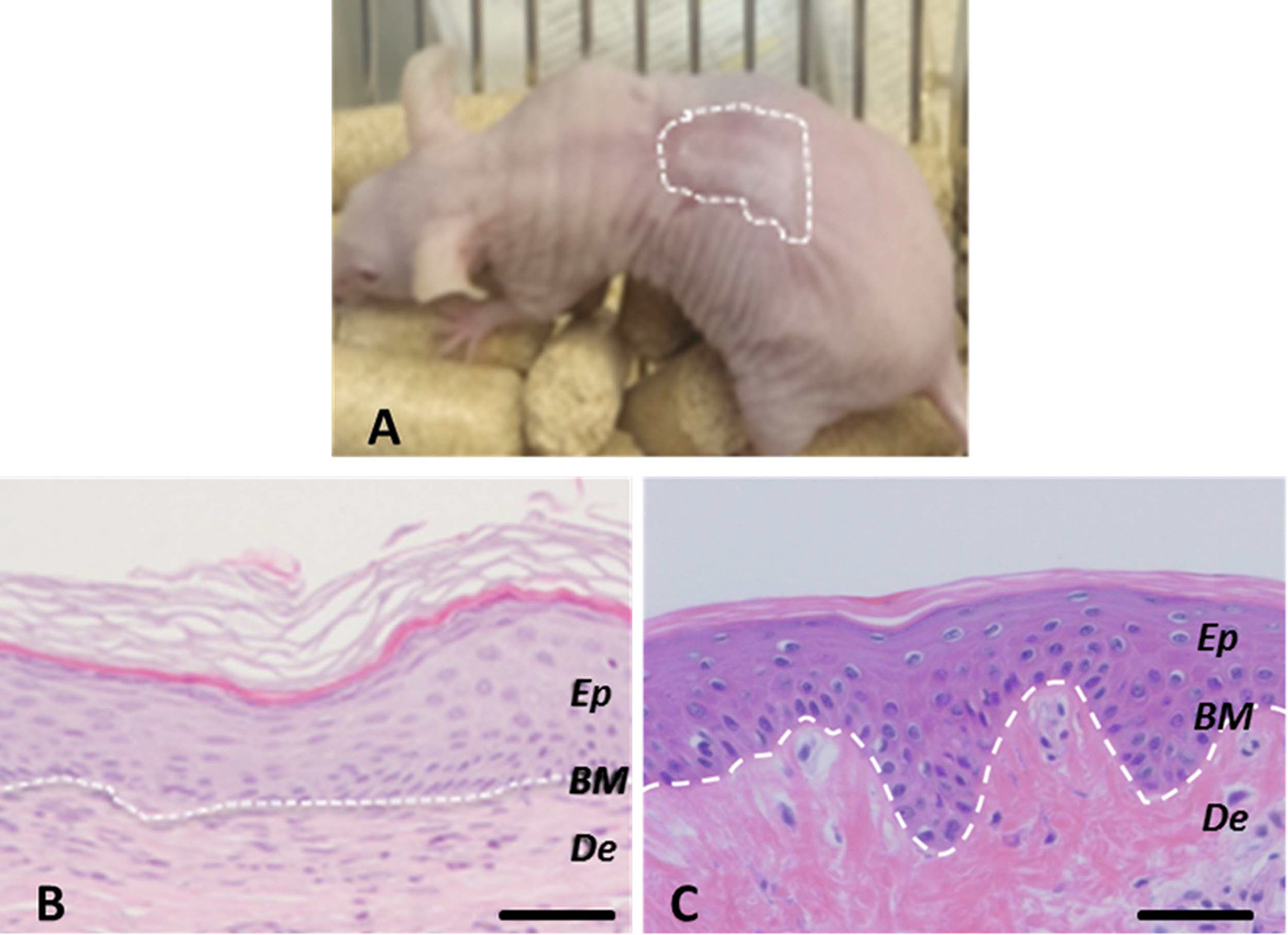

The engraftment of a sample of printed human skin in immunocompromised mice was successful. The illustrations below show the histological analysis of the sample 8 weeks after transplantation.

The developed method allows to print functional human skin using simple equipment on Arduino and cheap materials: blood plasma, fibroblasts and keratinocytes. Tests have shown that the printed leather is very similar to the real one. According to the developers, this method allows you to print the skin in the amount necessary for clinical and commercial use. So, a piece of skin 100 cm² is made in 35 minutes, including 30 minutes of fibrin hardening.

Researchers believe that due to the automation and standardization of printing, we can expect a significant reduction in the cost of skin in the future.

The scientific work was published on December 5, 2016 in the journal Biofabrication (doi: 10.1088 / 1758-5090 / 9/1/015006, pdf ).

Source: https://habr.com/ru/post/373101/

All Articles