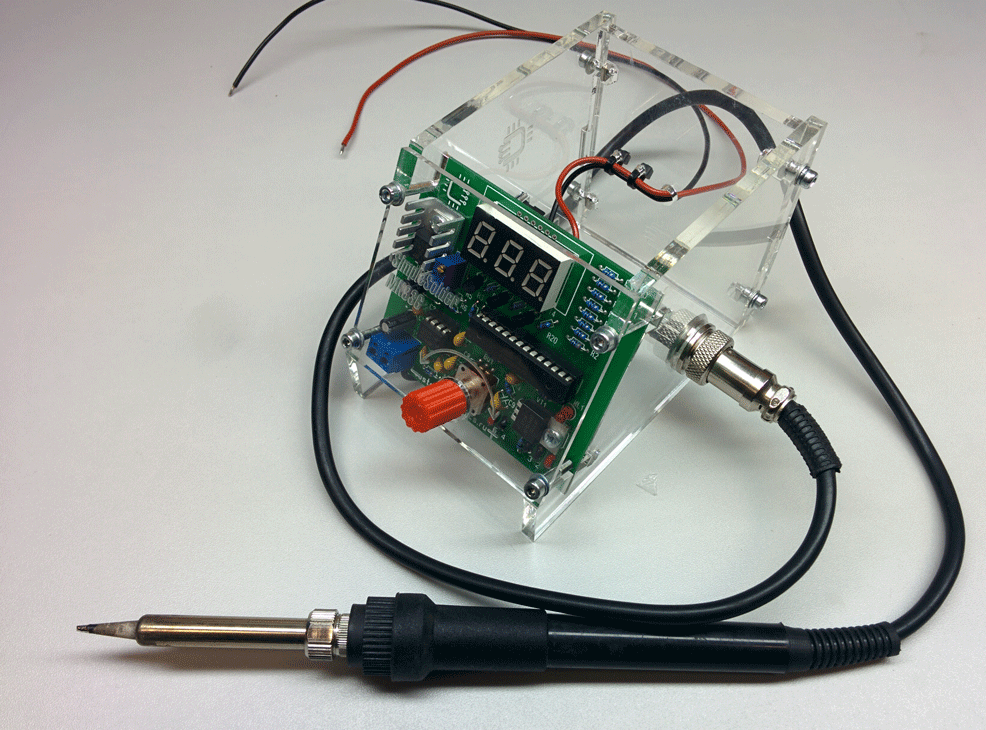

Simple Solder MK936. Soldering station for those who want it themselves

Hello!

In this article we want to share with the public a simple soldering station project with temperature stabilization that anyone can assemble with his own hands without Arduino and electrical tape!

An ordinary soldering iron, which is directly connected to the network, simply heats constantly with the same power. Because of this, it heats up for a very long time and there is no way to regulate the temperature in it. You can dim this power, but it will be very difficult to achieve a stable temperature and repeatability of soldering.

')

A soldering iron prepared for use in a composition with a soldering station has a built-in temperature sensor and this allows you to supply maximum power to it during heating and then to keep the temperature at the sensor. If you simply try to adjust the power in proportion to the temperature difference, then it will either warm up very slowly or the temperature will float cyclically. As a result, the control program must contain the PID control algorithm.

Obviously, delicate semiconductor electronics requires minimizing thermal shocks during soldering, and simply the quality of the soldering itself increases with temperature stabilization, therefore, sooner or later, many radio amateurs come to the need for soldering stations.

We tried to focus on the simplicity of repetition and cheapness. Our soldering station works with one of the cheapest soldering irons, and the rest of the elements are in the range of many radio shops.

Also note that this is a digital soldering station with a microcontroller! As a rule, the cheapest soldering stations from promoted manufacturers have an analog circuit.

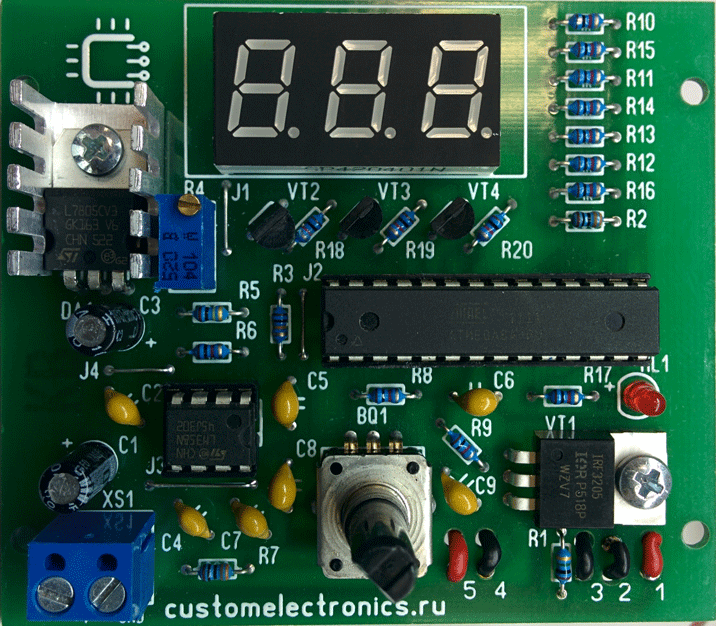

The scheme is extremely simple. At the heart of the whole microcontroller Atmega8. The signal from the thermocouple is fed to the operational amplifier with an adjustable gain (for calibration) and then to the input of the microcontroller's ADC. To display the temperature, a seven-segment indicator with a common cathode is used, the discharges of which are connected through transistors. When the knob of the BQ1 encoder is turned, the temperature is set, and the rest of the time the current temperature is displayed. When enabled, the initial value is set to 280 degrees. Determining the difference between the current and the required temperature, recalculating the coefficients of the PID components, the microcontroller warms the soldering iron with the help of PWM modulation.

To power the logical part of the scheme, a simple linear stabilizer DA1 to 5V was used.

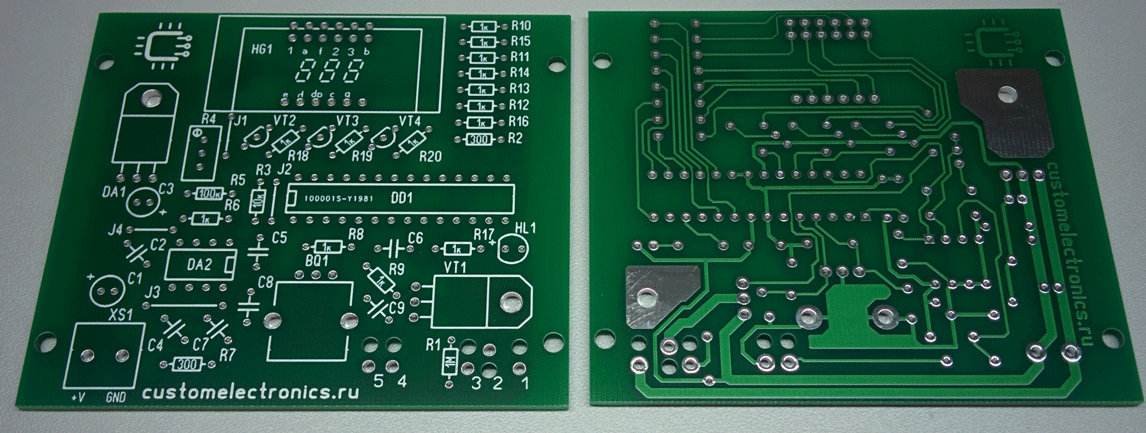

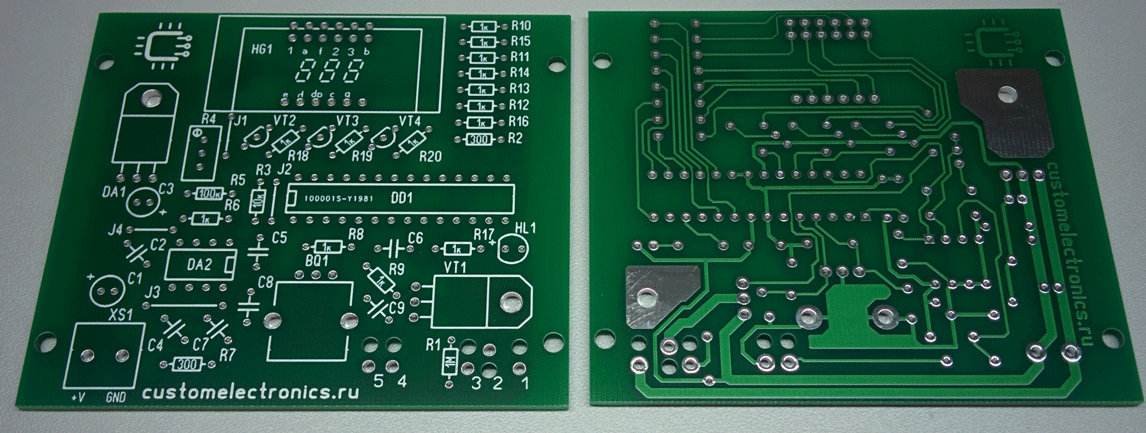

The PCB is single sided with four jumpers. The PCB file can be downloaded at the end of the article.

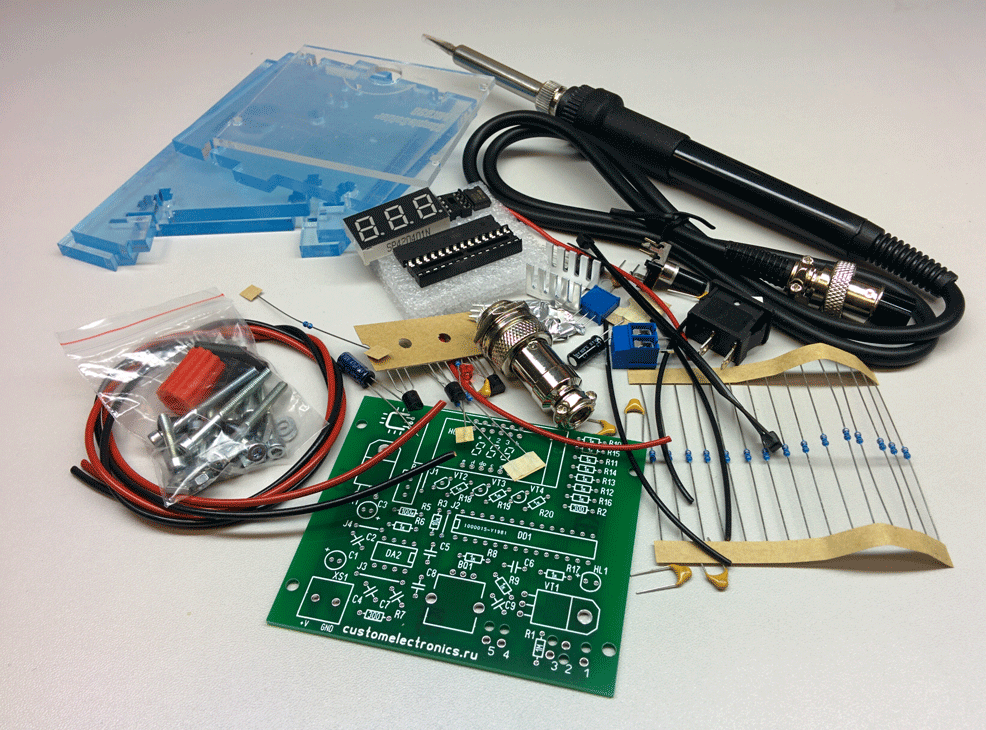

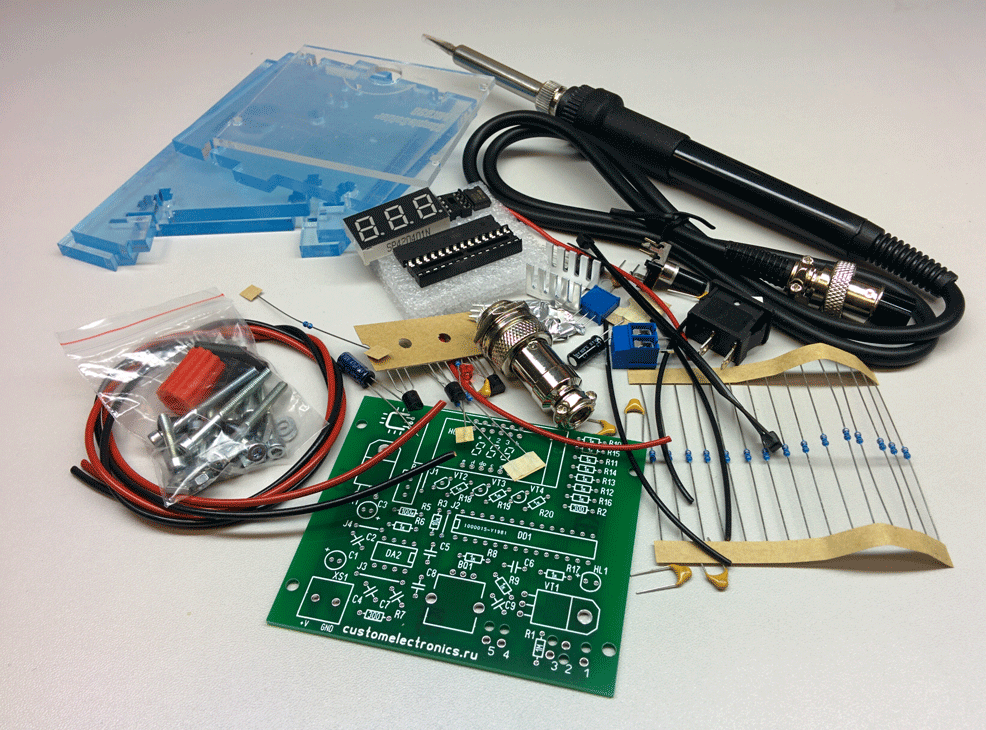

Here is a set of all the details:

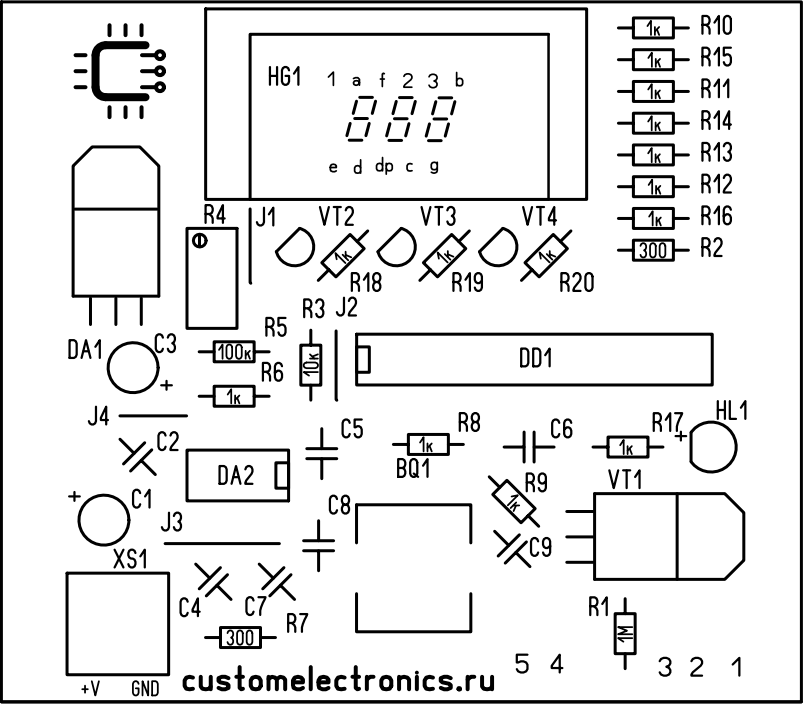

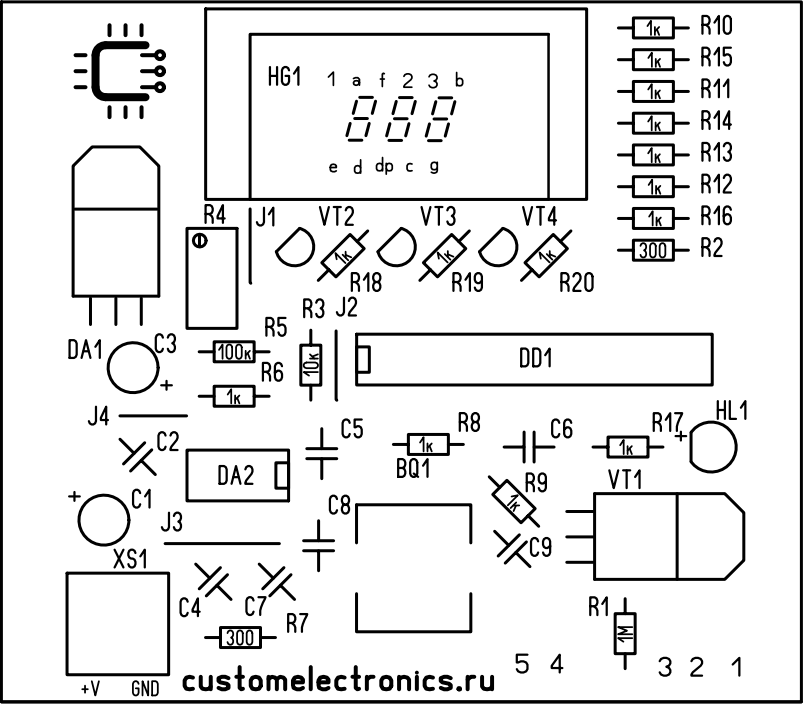

It is most convenient to assemble the board according to the assembly drawing:

Below is a detailed video of the installation process.

I want to draw attention to the important points. Observe the polarity of the electrolytic capacitors, the LED and the direction of installation of the chips. Chips should not be installed until the case is fully assembled and the supply voltage is not checked. Chips and transistors must be handled with care so as not to damage them with static electricity.

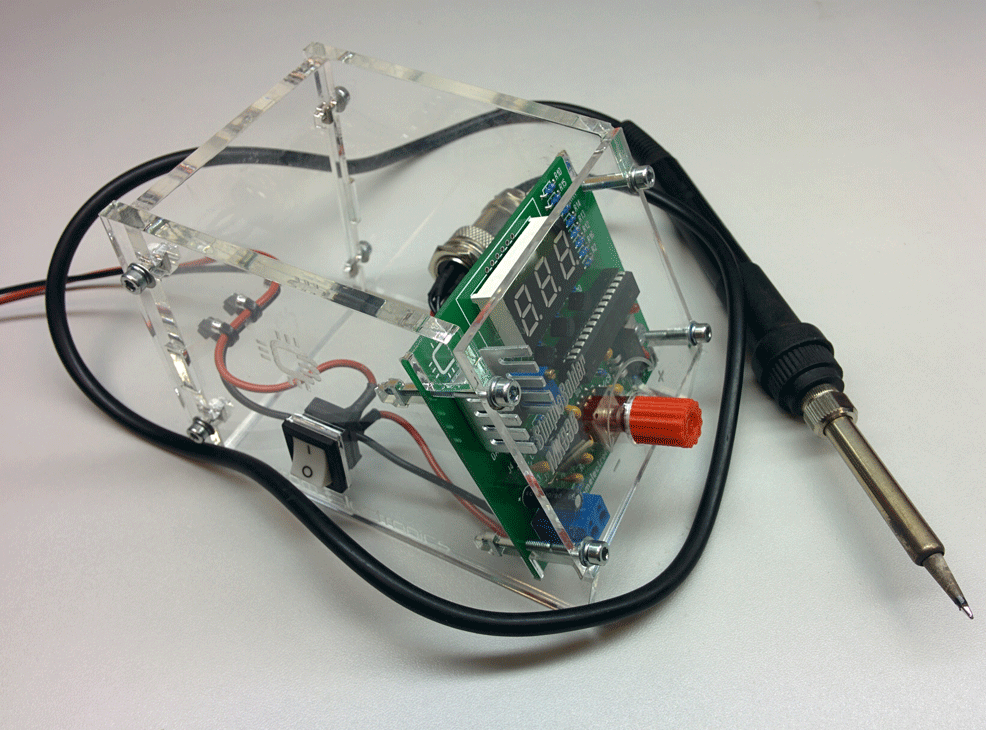

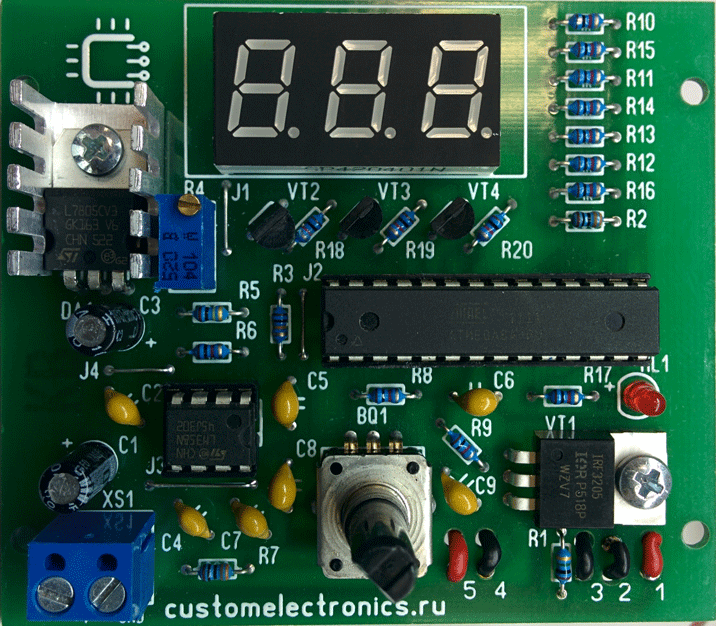

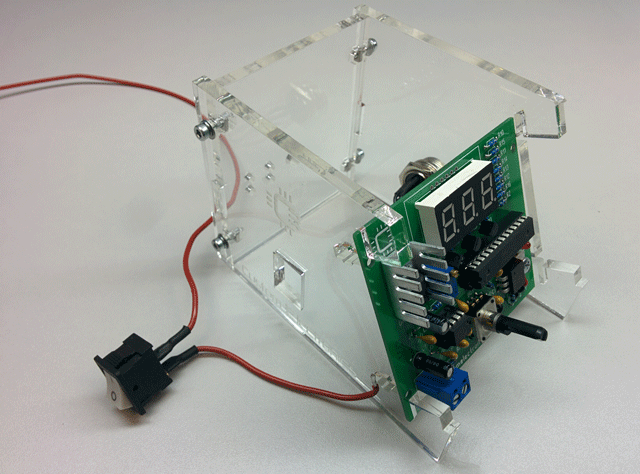

If the board is assembled correctly, it will look something like this:

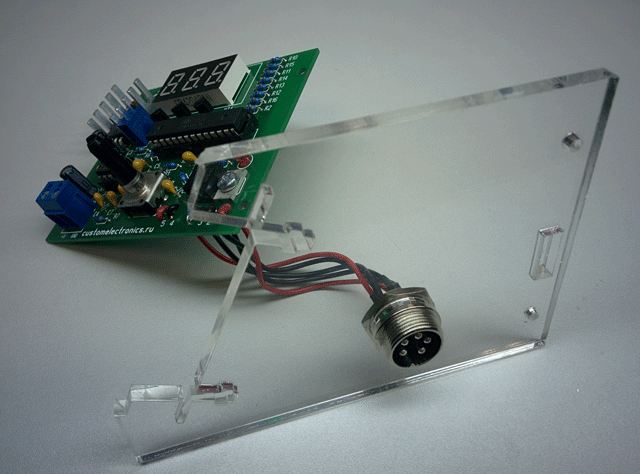

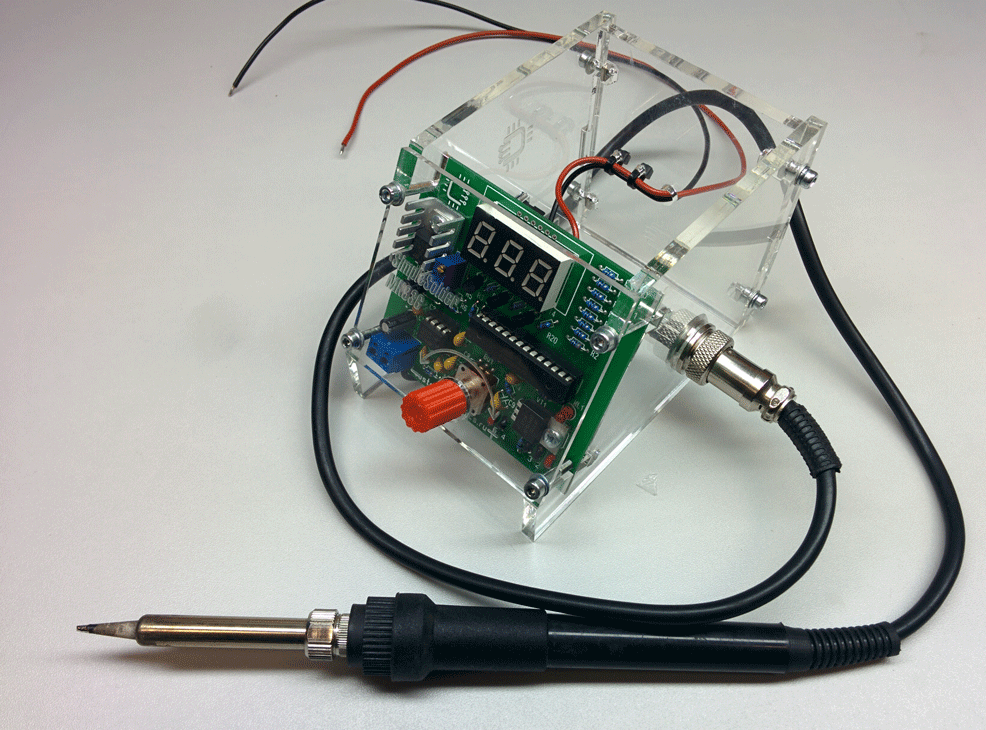

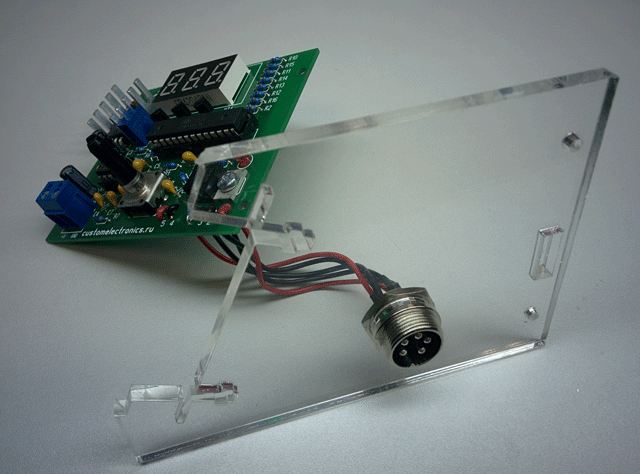

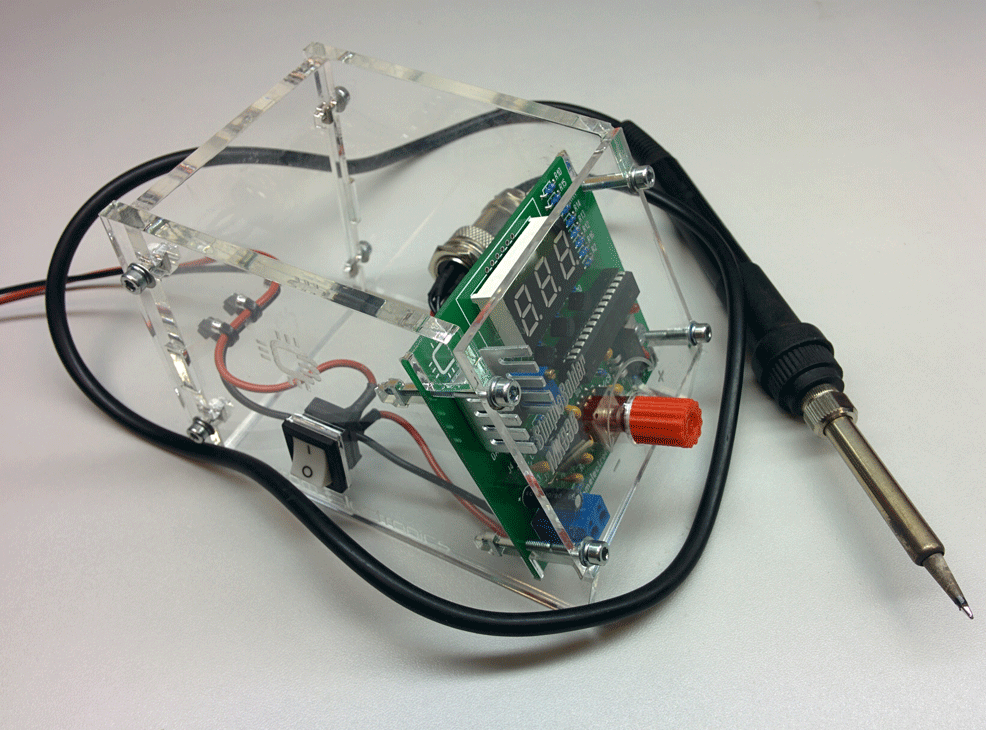

For the soldering station, we also drew a file for cutting plexiglass. It can be transferred to the company engaged in laser cutting, and they can make you the same case.

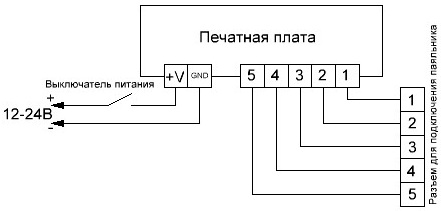

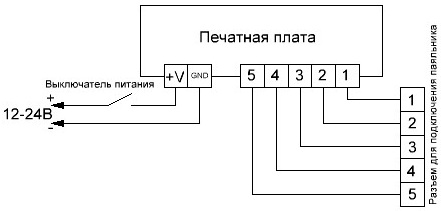

The switching circuit inside the case is not very complicated:

First you need to screw the connector to the right side of the case, and then solder the wires from the connector to the board. In this case, the contacts are soldered one to one. That is, the first to the first, the second to the second, and so on. Please note that the PCB has additional holes next to the mounting holes. Through them you can skip the wires for additional fixation.

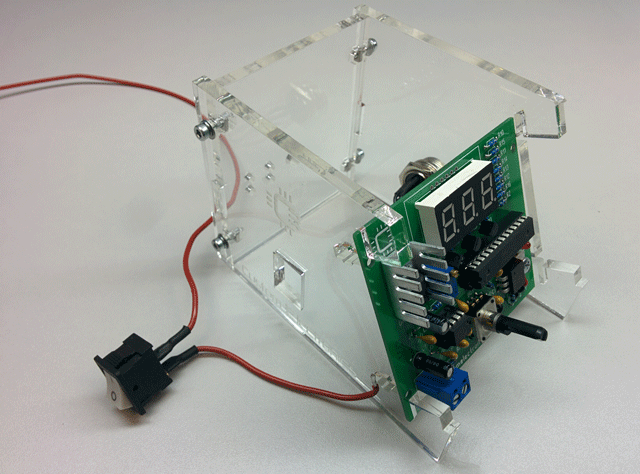

Next, you need to twist the screws on the left and rear walls of the housing. Remember that plexiglass is a fragile material and do not overtighten the screw connections!

In the next step, these two parts come together. Then you need to connect the power wires. Plus power connects through the power switch. Please note that you do not need to install the front panel yet.

The HEX file for the controller firmware will also be at the end of the article. The fusion bits should remain factory-set, that is, the controller will operate at 1 MHz from the internal generator.

The first switch is made before installing the microcontroller and the operational amplifier on the board. First you need to check the power scheme. To do this, the board must be supplied with a constant supply voltage from 12 to 24V and check that the output of the stabilizer DA1 contains a supply voltage of 5V. After that, when the power is disconnected in compliance with the key position, the DA1 and DD1 microcircuits are installed into the panels.

Now when you turn it on again, the following functions should work: the temperature will be displayed on the indicator, the encoder will change it, the soldering iron will start to heat up, and the LED will indicate the operating mode.

Next, you need to calibrate the soldering station.

The best option for calibration is the use of an additional thermocouple. It is necessary to set the required temperature and check it on the sting by the reference device. If the readings differ, then twist the gain of the opamp with a multi-turn trimmer resistor R4.

If you don’t have a test meter at hand, you can set a resistor of about 90kΩ and then select the temperature by experiment.

After the soldering station is checked and calibrated, you can carefully install the front panel so that the parts do not crack.

For those who like to watch others work:

This simple soldering station, made with the support of the Goods from China Radio Amateur group, will greatly change your impression of soldering, if you soldered to this only with a regular soldering iron!

A few words should be said about the soldering iron. This is the easiest soldering iron with a temperature sensor. He has the usual nichrome heater and the cheapest sting. It is better to replace the sting, for example, with such . Any one with an external diameter of 6.5 mm, internal 4 mm, and a shank length of 25 mm is suitable.

All project files can be downloaded from our website . We will be very happy if they are helpful to you.

Now we are working on the development of a soldering dryer and we are very interested in your vision of the main characteristics of such a device, so that you want to assemble it. We will be very grateful if you answer several questions of our questionnaire (at the end you can see the answers of other users).

Thank you for your attention!

In this article we want to share with the public a simple soldering station project with temperature stabilization that anyone can assemble with his own hands without Arduino and electrical tape!

What is a soldering station

An ordinary soldering iron, which is directly connected to the network, simply heats constantly with the same power. Because of this, it heats up for a very long time and there is no way to regulate the temperature in it. You can dim this power, but it will be very difficult to achieve a stable temperature and repeatability of soldering.

')

A soldering iron prepared for use in a composition with a soldering station has a built-in temperature sensor and this allows you to supply maximum power to it during heating and then to keep the temperature at the sensor. If you simply try to adjust the power in proportion to the temperature difference, then it will either warm up very slowly or the temperature will float cyclically. As a result, the control program must contain the PID control algorithm.

Obviously, delicate semiconductor electronics requires minimizing thermal shocks during soldering, and simply the quality of the soldering itself increases with temperature stabilization, therefore, sooner or later, many radio amateurs come to the need for soldering stations.

Features of our development

We tried to focus on the simplicity of repetition and cheapness. Our soldering station works with one of the cheapest soldering irons, and the rest of the elements are in the range of many radio shops.

Also note that this is a digital soldering station with a microcontroller! As a rule, the cheapest soldering stations from promoted manufacturers have an analog circuit.

Specifications

- Powered by a DC voltage source of 12-24V

- Power consumption, with 24V power: 50W

- Soldering iron resistance: 12Ω

- Time of an exit to an operating mode: 1-2 minutes depending on the feeding tension

- Maximum deviation of temperature in the stabilization mode, not more than 5 degrees

- Regulation algorithm: PID

- Temperature display on a seven-segment display

- Heater type: nichrome

- Type of temperature sensor: thermocouple

- Temperature calibration capability

- Setting the temperature with the help of an ecoder

- LED to display the status of the soldering iron (heating / work)

Schematic diagram

The scheme is extremely simple. At the heart of the whole microcontroller Atmega8. The signal from the thermocouple is fed to the operational amplifier with an adjustable gain (for calibration) and then to the input of the microcontroller's ADC. To display the temperature, a seven-segment indicator with a common cathode is used, the discharges of which are connected through transistors. When the knob of the BQ1 encoder is turned, the temperature is set, and the rest of the time the current temperature is displayed. When enabled, the initial value is set to 280 degrees. Determining the difference between the current and the required temperature, recalculating the coefficients of the PID components, the microcontroller warms the soldering iron with the help of PWM modulation.

To power the logical part of the scheme, a simple linear stabilizer DA1 to 5V was used.

Printed circuit board

The PCB is single sided with four jumpers. The PCB file can be downloaded at the end of the article.

Component List

- BQ1. Encoder EC12E24204A8

- C1. Electrolytic capacitor 35V, 10µF

- C2, C4-C9. Ceramic capacitors X7R, 0.1µF, 10%, 50V

- C3. Electrolytic capacitor 10V, 47µF

- DD1. ATmega8A-PU microcontroller in DIP-28 package

- DA1. C Stabilizer L7805CV to 5V in TO-220 package

- DA2. Operational amplifier LM358DT in DIP-8 package

- HG1. Seven-segment three-digit indicator with a common cathode BC56-12GWA. Also, the board provides a seat for a cheap analogue .

- HL1. Any indicator LED for a current of 20mA with a pitch of 2.54 mm

- R2, R7. Resistors 300 Ohm, 0.125W - 2pcs

- R6, R8-R20. Resistors 1KΩ, 0.125W - 13pcs

- R3. 10kΩ resistor, 0.125W

- R5. 100kΩ resistor, 0.125W

- R1. Resistor 1Ω, 0.125W

- R4. Trimmer 3296W 100kΩ

- VT1. Field-effect transistor IRF3205PBF in the case TO-220

- VT2-VT4. BC547BTA Transistors in TO-92 package - 3pcs

- Xs1. Two-prong terminal with lead pitch 5.08 mm

- Radiator for the FK301 stabilizer

- DIP-28 body block

- DIP-8 body block

- Connector for soldering iron

- Power Switch SWR-45 BW (13-KN1-1)

- Soldering iron . We will write about it later

- Details from plexiglas for the body (files for cutting at the end of the article)

- Encoder knob. You can buy it, or you can print it on a 3D printer. File for downloading the model at the end of the article

- Screw M3x10 - 2pcs

- Screw M3x14 - 4pcs

- Screw M3x30 - 4pcs

- M3 nut - 2pcs

- Square M3 Nut - 8pcs

- M3 washer - 8pcs

- M3 horizontal washer - 8pcs

- Also required for the assembly of assembly wires, ties and shrink tube

Here is a set of all the details:

PCB Mounting

It is most convenient to assemble the board according to the assembly drawing:

Below is a detailed video of the installation process.

I want to draw attention to the important points. Observe the polarity of the electrolytic capacitors, the LED and the direction of installation of the chips. Chips should not be installed until the case is fully assembled and the supply voltage is not checked. Chips and transistors must be handled with care so as not to damage them with static electricity.

If the board is assembled correctly, it will look something like this:

Assembly of the case and mounted installation

For the soldering station, we also drew a file for cutting plexiglass. It can be transferred to the company engaged in laser cutting, and they can make you the same case.

The switching circuit inside the case is not very complicated:

First you need to screw the connector to the right side of the case, and then solder the wires from the connector to the board. In this case, the contacts are soldered one to one. That is, the first to the first, the second to the second, and so on. Please note that the PCB has additional holes next to the mounting holes. Through them you can skip the wires for additional fixation.

Next, you need to twist the screws on the left and rear walls of the housing. Remember that plexiglass is a fragile material and do not overtighten the screw connections!

In the next step, these two parts come together. Then you need to connect the power wires. Plus power connects through the power switch. Please note that you do not need to install the front panel yet.

Controller firmware and setup

The HEX file for the controller firmware will also be at the end of the article. The fusion bits should remain factory-set, that is, the controller will operate at 1 MHz from the internal generator.

The first switch is made before installing the microcontroller and the operational amplifier on the board. First you need to check the power scheme. To do this, the board must be supplied with a constant supply voltage from 12 to 24V and check that the output of the stabilizer DA1 contains a supply voltage of 5V. After that, when the power is disconnected in compliance with the key position, the DA1 and DD1 microcircuits are installed into the panels.

Now when you turn it on again, the following functions should work: the temperature will be displayed on the indicator, the encoder will change it, the soldering iron will start to heat up, and the LED will indicate the operating mode.

Next, you need to calibrate the soldering station.

The best option for calibration is the use of an additional thermocouple. It is necessary to set the required temperature and check it on the sting by the reference device. If the readings differ, then twist the gain of the opamp with a multi-turn trimmer resistor R4.

If you don’t have a test meter at hand, you can set a resistor of about 90kΩ and then select the temperature by experiment.

After the soldering station is checked and calibrated, you can carefully install the front panel so that the parts do not crack.

Video build

For those who like to watch others work:

Conclusion

This simple soldering station, made with the support of the Goods from China Radio Amateur group, will greatly change your impression of soldering, if you soldered to this only with a regular soldering iron!

A few words should be said about the soldering iron. This is the easiest soldering iron with a temperature sensor. He has the usual nichrome heater and the cheapest sting. It is better to replace the sting, for example, with such . Any one with an external diameter of 6.5 mm, internal 4 mm, and a shank length of 25 mm is suitable.

Project files

All project files can be downloaded from our website . We will be very happy if they are helpful to you.

Announcement

Now we are working on the development of a soldering dryer and we are very interested in your vision of the main characteristics of such a device, so that you want to assemble it. We will be very grateful if you answer several questions of our questionnaire (at the end you can see the answers of other users).

Thank you for your attention!

Source: https://habr.com/ru/post/373095/

All Articles