Engineers accidentally increased battery life by several hundred times.

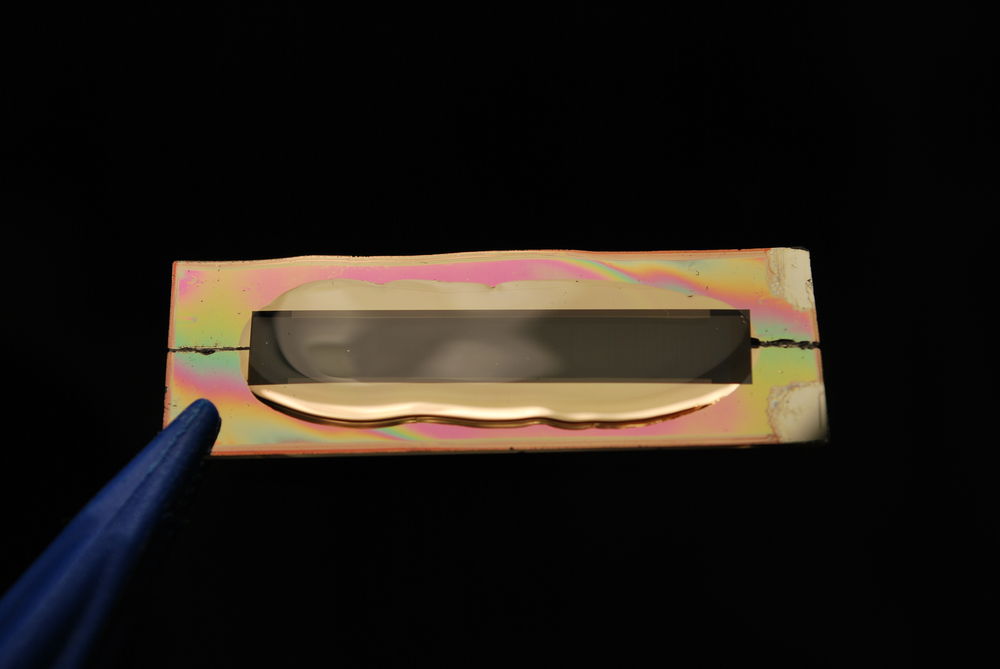

Engineers from the University of California at Irvine, trying to create a solid-state battery, suddenly got cathodes that withstand a couple of orders of magnitude more recharge cycles than conventional ones. The cathodes consisted of gold nanowires coated with gel.

The cathodes obtained by scientists survived 200,000 recharge cycles without significant corrosion. The loss of capacity compared with the first cycles amounted to no more than 5%. Conventional lithium-ion batteries last several thousand cycles. Scientists do not yet know how their design can withstand such loads: they simply tried to create a battery where gel would be used instead of liquid electrolyte.

Because traditional batteries are temperature sensitive and may explode, engineers are looking for a replacement. But until much success has been achieved in this matter, the liquid has a high conductivity and allows partial charging and discharging.

')

The cathode consists of a gold nanowire, coated with manganese oxide and protected by a layer of gel, used as an electrolyte. The gel protects the wire from corrosion. Battery capacity is proportional to the length of the wire. This is not a unique design, with the exception of the gel, which gives it unusual properties.

“We began to experience recharge cycles, and at some point we discovered that the battery was not going to die,” says Reginald Penner, lead author of the work, revealing. - The gel does not just prevent the wire from falling apart - it seems that it gives the metal oxide additional softness and protects it from microdamages. It increases the strength of metal oxide. ”

So far, scientists have not created a full-fledged battery, and tested only the material for the anode. In addition, technology separates the cost of production from a quick industrial application - the microscopic amount of gold used to create the nanowire still raises the cost of construction. Penner thinks that another metal, such as nickel, may be suitable. So far, scientists are planning to create full-fledged batteries to assess the performance of their new design in conditions close to real ones.

Source: https://habr.com/ru/post/372143/

All Articles