Brotherhood of Plastic

Today we will talk about weapons.

Armor T-45b power armor and MP5 Kurz

Shop additive production.

Here you can hold in your hands a classified rocket engine, or an experimental sample of silicon-germanium billet for processors, or a unique 3d printer that will rivet medical orthoses (you can look at it with one eye in the Neuron hackspace).

')

A couple of years ago, REC specialists responded to my requests and in all details told and showed how plastic production takes place from raw materials ( How PLA is manufactured for 3d printers. Report from the workshop ). Gradually, they increased the production of consumables, participated in exhibitions, introduced new materials into production, moved closer to the center of Moscow, bought their own 3d-printer fleet. Plastic REC is actively involved in the production of interesting and useful gizmos ( The benefits of 3d-printers for medicine and rocket production).

Recently, I went to visit them in the technopark on Alekseevskaya and finally, after I turned the products from “rubber” and “silicone” in my hands, we talked about the novelties of Russian 3d printers for a couple of hours, about printing clothes offered by Lem in “Return from the Stars” (in 1961), about old-school and modern Fallout, about tank polygons, rolevki and about pistols.

Under the cut: What weapons printed in the world and what can be printed in Moscow.

Following the porn industry and rocket science, 3d printers "capture" gunsmiths. (Interestingly, since all of these are innovative, will it be possible soon to buy a batch of trunks for bitcoins?)

The pioneers who printed the world's first gun on a 3d printer.

According to one of the founders of the REC company, the video with this gun was the decisive factor in doing business in the field of 3d printing.

Cody Wilson continues his activity so far and is promoting the idea that everyone can independently manufacture weapons at home.

Russian photo shoppers, too, are not made with a finger and were able to "draw" the same gun.

How does the "Liberator" (Yes, we printed a gun)

“We need more trunks,” said the Japanese.

But the craftsman was quickly arrested and only the video from the brave samurai remained in the story.

The world's first gun fully printed on a metal 3d-printer. Here it is, the inertia of thinking, many still seek to use outdated materials such as metal. But we know that the future is plastic.

Semi-automatic gun, almost entirely printed on a 3D printer

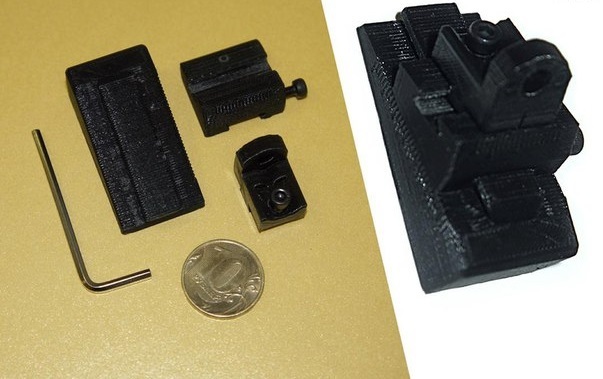

I found these samples in the Moscow office of the REC company.

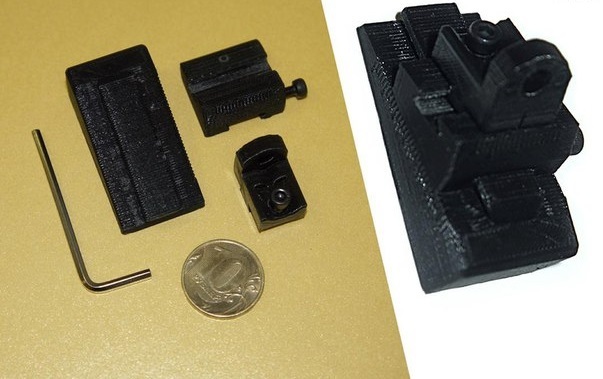

Cool aiming device. Printed from REC ABS plastic on Prism mimi from 3Dq

With this detail, the old airsoft mp5 kurz is back in business. Printed from green REC PLA to Ultimaker2

Pad on the barrel for air rifle. It has a weaver bar and bolt holes. Printed on Picaso 3d Designer in black REC ABS plastic.

Protective overlays for riflescopes. Printed on mz3d256 from black plastic REC FLEX

This bracket with straps for mounting optics, flashlights and rangefinders, is put on the airsoft gun Thompson. Printed on Picaso 3D Designer in orange REC ABS plastic, later painted with molotow paints.

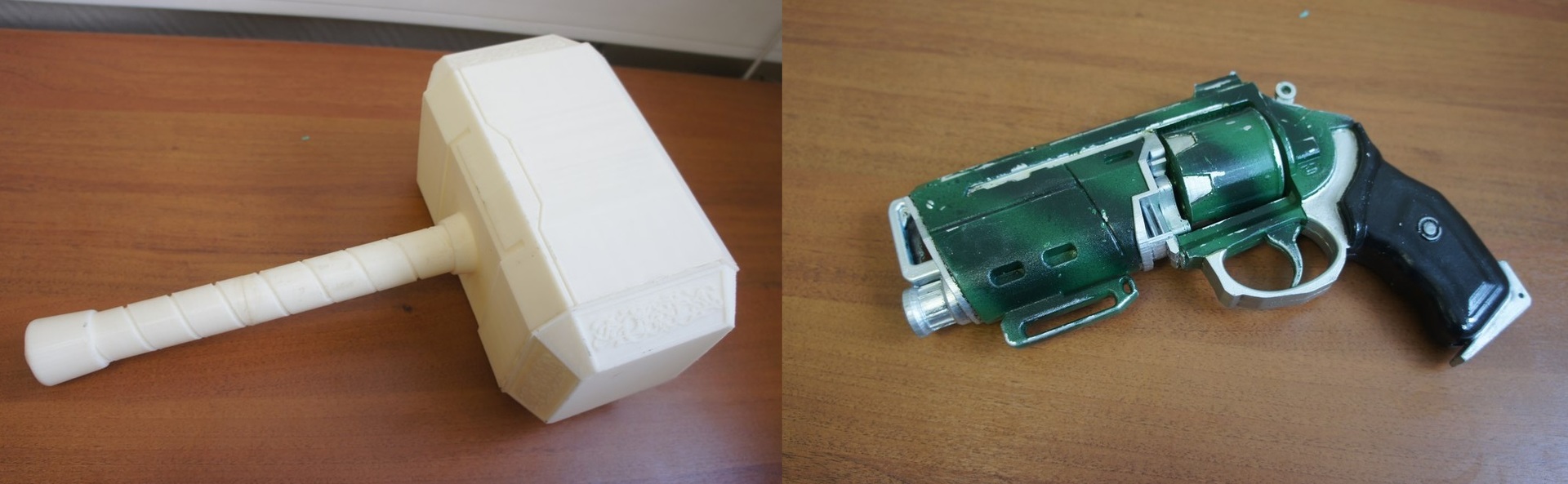

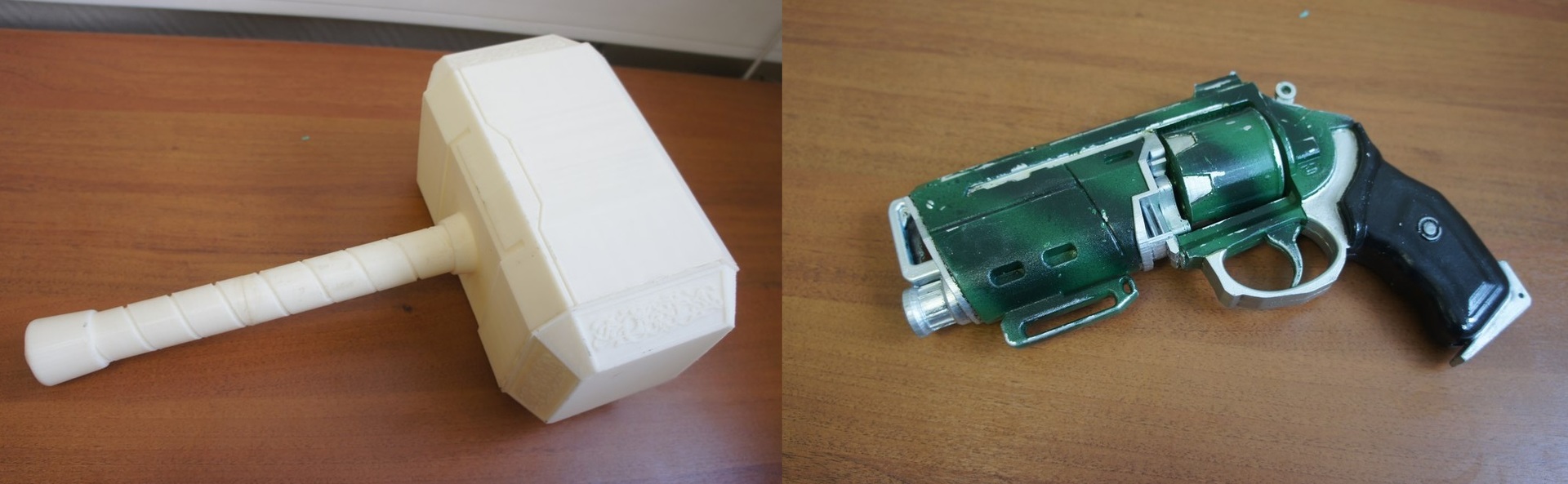

Printed on Picaso 3D Designer and MZ3D-256 3D printers in brown REC ABS plastic.

For elves

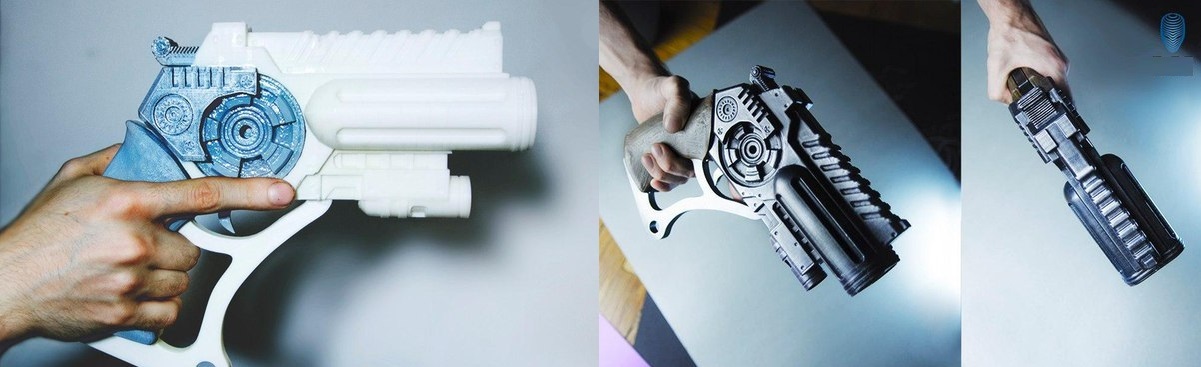

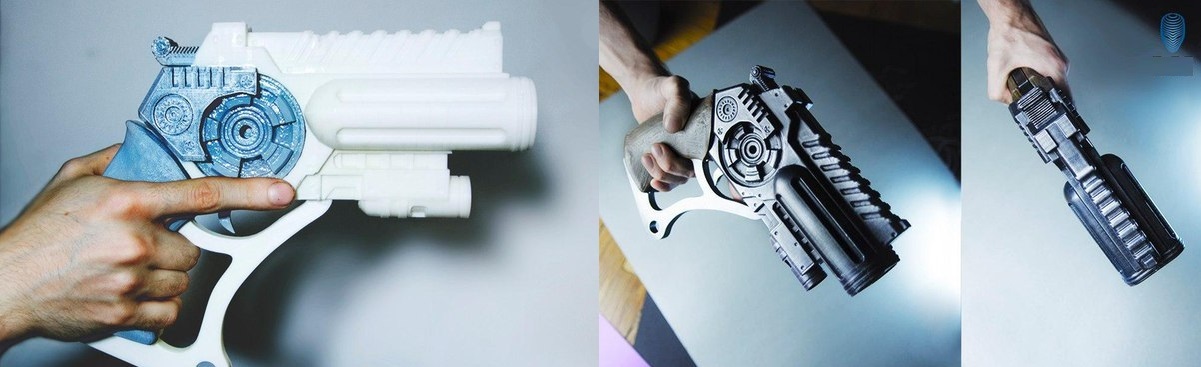

For fallout

For ironman

REC RUBBER

Rubber for 3d printing. On properties it is close to the real rubber, repeating its properties. Suitable for printing: buttons, seals, shock absorbers and even tires for radio-controlled models. Glued with synthetic rubbers or with a soldering iron

Oil / petrol resistant “rubber” material:

Flex

FLEX is a special flexible material, similar in properties to hard silicone. Resilient and pleasant to the touch. The material is resistant to oils, gasoline and various solvents. Does not give in to machining and therefore possesses high wear resistance. Glued with synthetic rubbers or with a soldering iron.

From the "silicone" you can print braid masks, soft slippers, elements of the joints, buttons and special pneumatic nozzles of complex shape

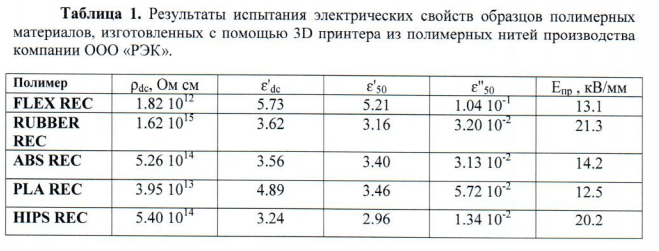

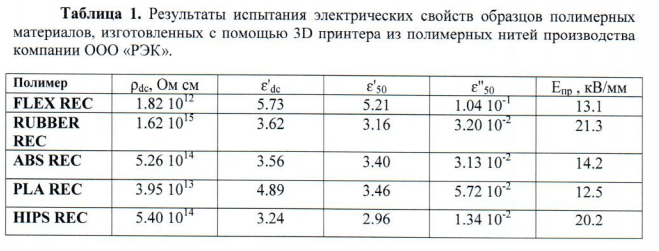

And the guys got confused and carried out tests according to GOST `on the dielectric constant of their materials:

Read more here .

Here are tests for harmful substances:

Report on how to pass the test.

REC specialists said that they “plan to start production of printing material with carbon threads in the composition. The tensile strength of the material gives indicators significantly higher than the parameters of steel. We also test samples of conductive polymers (while ABS PLA FLEX RUBBER are dielectrics). We are also going to return to the market transparent ABS plastic M-ABS. "

PS

"... but the Russian paratrooper did not say anything, but simply ... he moved the embers with a knife."

Pps

Thanks to Kirill for the detailed advice and assistance in preparing the article. (He also conducted a tour of the new REC office and showed off new items of 3d printers)

If you need to simulate power armor, buy 10 km of plastic for the IronMan suit, print a sniper rifle part or purchase a printer, you can feel free to contact:

Armor T-45b power armor and MP5 Kurz

Shop additive production.

Here you can hold in your hands a classified rocket engine, or an experimental sample of silicon-germanium billet for processors, or a unique 3d printer that will rivet medical orthoses (you can look at it with one eye in the Neuron hackspace).

')

A couple of years ago, REC specialists responded to my requests and in all details told and showed how plastic production takes place from raw materials ( How PLA is manufactured for 3d printers. Report from the workshop ). Gradually, they increased the production of consumables, participated in exhibitions, introduced new materials into production, moved closer to the center of Moscow, bought their own 3d-printer fleet. Plastic REC is actively involved in the production of interesting and useful gizmos ( The benefits of 3d-printers for medicine and rocket production).

Recently, I went to visit them in the technopark on Alekseevskaya and finally, after I turned the products from “rubber” and “silicone” in my hands, we talked about the novelties of Russian 3d printers for a couple of hours, about printing clothes offered by Lem in “Return from the Stars” (in 1961), about old-school and modern Fallout, about tank polygons, rolevki and about pistols.

Under the cut: What weapons printed in the world and what can be printed in Moscow.

Kalashnikov

“Details for the prototypes of the Russian small arms produced by the Kalashnikov concern and TsNIITOCHMASH began printing a 3D printer, reports Rambler News. We are talking about prototypes, but you can shoot from them.

Printing takes place on the equipment of the holding "Rostec" "Stankoprom", and, as specified in the press service, "from the domestic metal powder."

The concern “Kalashnikov” explained that we are talking about the details for prototypes of weapons: “These are model samples that are made in the process of designing pistols, machine guns and other products. You can shoot from them, but their main task is to try out certain design solutions. ” Weapon models, in which three-dimensional printing was used in detail, were refused to be named in Kalashnikov. ”

Following the porn industry and rocket science, 3d printers "capture" gunsmiths. (Interestingly, since all of these are innovative, will it be possible soon to buy a batch of trunks for bitcoins?)

Defense distributed

The pioneers who printed the world's first gun on a 3d printer.

According to one of the founders of the REC company, the video with this gun was the decisive factor in doing business in the field of 3d printing.

Cody Wilson continues his activity so far and is promoting the idea that everyone can independently manufacture weapons at home.

Russian photo shoppers, too, are not made with a finger and were able to "draw" the same gun.

How does the "Liberator" (Yes, we printed a gun)

Japanese

“We need more trunks,” said the Japanese.

But the craftsman was quickly arrested and only the video from the brave samurai remained in the story.

World's First 3D Printed Metal Gun

The world's first gun fully printed on a metal 3d-printer. Here it is, the inertia of thinking, many still seek to use outdated materials such as metal. But we know that the future is plastic.

Semi-automatic gun, almost entirely printed on a 3D printer

(Type) Airsoft

I found these samples in the Moscow office of the REC company.

Cool aiming device. Printed from REC ABS plastic on Prism mimi from 3Dq

With this detail, the old airsoft mp5 kurz is back in business. Printed from green REC PLA to Ultimaker2

Pad on the barrel for air rifle. It has a weaver bar and bolt holes. Printed on Picaso 3d Designer in black REC ABS plastic.

Protective overlays for riflescopes. Printed on mz3d256 from black plastic REC FLEX

This bracket with straps for mounting optics, flashlights and rangefinders, is put on the airsoft gun Thompson. Printed on Picaso 3D Designer in orange REC ABS plastic, later painted with molotow paints.

For elves

Printed on Picaso 3D Designer and MZ3D-256 3D printers in brown REC ABS plastic.

more

Replicas of the Dagger Tauriel of the Hobbit

Model created in the free program Blender 3D

Glued with ABS plastic solution in acetone, after gluing it is smoothed with acetone pairs

Painted with mtn 94 and molotow colors

Replicas of the Dagger Tauriel of the Hobbit

Model created in the free program Blender 3D

Glued with ABS plastic solution in acetone, after gluing it is smoothed with acetone pairs

Painted with mtn 94 and molotow colors

For cinema

Armor

For elves

For fallout

For ironman

New materials

REC RUBBER

Rubber for 3d printing. On properties it is close to the real rubber, repeating its properties. Suitable for printing: buttons, seals, shock absorbers and even tires for radio-controlled models. Glued with synthetic rubbers or with a soldering iron

TTX

Nozzle temperature: 230 - 250 °

Table temperature: 100 - 120 °

Recommended print speed: 5 - 20mm / s

Thread format - 1.75mm / 2.85 mm.

Compatibility:

Ultimaker 2

Ultimaker 2 go

Ultimaker 2 Extended

Mankati Fullscale XT

Lulzbot

Velleman K8200

HICTOP

Prusa i3 / Mendel90 for 3mm bar and other 3D printers 1.75mm / 2.85 mm format

Table temperature: 100 - 120 °

Recommended print speed: 5 - 20mm / s

Thread format - 1.75mm / 2.85 mm.

Compatibility:

Ultimaker 2

Ultimaker 2 go

Ultimaker 2 Extended

Mankati Fullscale XT

Lulzbot

Velleman K8200

HICTOP

Prusa i3 / Mendel90 for 3mm bar and other 3D printers 1.75mm / 2.85 mm format

Oil / petrol resistant “rubber” material:

Flex

FLEX is a special flexible material, similar in properties to hard silicone. Resilient and pleasant to the touch. The material is resistant to oils, gasoline and various solvents. Does not give in to machining and therefore possesses high wear resistance. Glued with synthetic rubbers or with a soldering iron.

From the "silicone" you can print braid masks, soft slippers, elements of the joints, buttons and special pneumatic nozzles of complex shape

TTX

Nozzle temperature: 230 - 250 °

Table temperature: 80 - 120 °

Recommended print speed: 5 - 30mm / s

Thread format - 1.75mm / 2.85 mm.

Plastic weight: 500 g

Compatibility:

Picaso designer

Picaso Designer PRO 250

MakerBot Replictor 1, 2X

MZ3D 256

Prusa i3 hephestos

PrintBox 3D One

WanHao Duplicator i3, 4, 4X, 4S

Magnum Creative 2 UNI, PRO

Prusa i3 / Mendel90 and other printers with a thread format of 1.75mm / 2.85 mm

Table temperature: 80 - 120 °

Recommended print speed: 5 - 30mm / s

Thread format - 1.75mm / 2.85 mm.

Plastic weight: 500 g

Compatibility:

Picaso designer

Picaso Designer PRO 250

MakerBot Replictor 1, 2X

MZ3D 256

Prusa i3 hephestos

PrintBox 3D One

WanHao Duplicator i3, 4, 4X, 4S

Magnum Creative 2 UNI, PRO

Prusa i3 / Mendel90 and other printers with a thread format of 1.75mm / 2.85 mm

And the guys got confused and carried out tests according to GOST `on the dielectric constant of their materials:

Read more here .

Here are tests for harmful substances:

Report on how to pass the test.

Plans

REC specialists said that they “plan to start production of printing material with carbon threads in the composition. The tensile strength of the material gives indicators significantly higher than the parameters of steel. We also test samples of conductive polymers (while ABS PLA FLEX RUBBER are dielectrics). We are also going to return to the market transparent ABS plastic M-ABS. "

PS

"... but the Russian paratrooper did not say anything, but simply ... he moved the embers with a knife."

Pps

Thanks to Kirill for the detailed advice and assistance in preparing the article. (He also conducted a tour of the new REC office and showed off new items of 3d printers)

If you need to simulate power armor, buy 10 km of plastic for the IronMan suit, print a sniper rifle part or purchase a printer, you can feel free to contact:

Source: https://habr.com/ru/post/371757/

All Articles