The use of 3D printing in advertising

One of the applications of 3D printing is branding and advertising. Creating interior objects, elements of outdoor advertising - signs, signs, signs, souvenirs. If in the production of branded souvenirs, additive technologies no longer seem exotic, in the field of large forms, the traditional approaches are still stronger. But today, 3D printing, if not replacing milling and laser cutting, then complements these methods of manufacturing advertising structures.

How do they traditionally

In the manufacture of plates, signs, signs traditionally used laser cutting and milling. Materials - acrylic, PVC foam, monolithic and cellular polycarbonate, sheet metal.

')

The simplest example is a substrate on which elements cut from a sheet of plastic of a different color are pasted.

Sign Top 3D Shop, length - 1400 mm, made on the substrate of painted plywood. Text and logo - colored acrylic.

Made with the LaserSolid 690 CO2 cutter. Top 3D Shop makes signs, signs and similar advertising structures using classical technology. Cutting, engraving, milling .

LaserSolid 690

- laser power: 60 W;

- optional: 80-100 W laser;

- working field: 900 x 600 mm;

- price: 369 900 rub.

LaserSolid 690 is a universal machine for cutting and engraving materials from cardboard and plywood to polycarbonate, rubber and stone. Used in the manufacture of advertising structures, buildings, souvenirs, furniture items. It can be used for cutting soft materials, fabrics or fur.

A more complex example is tall letters and other elements, possibly with an integrated LED backlight. The production of such signage requires manual labor for gluing elements, trimming, machining and pasting with film or painting.

How is 3D printing applied here?

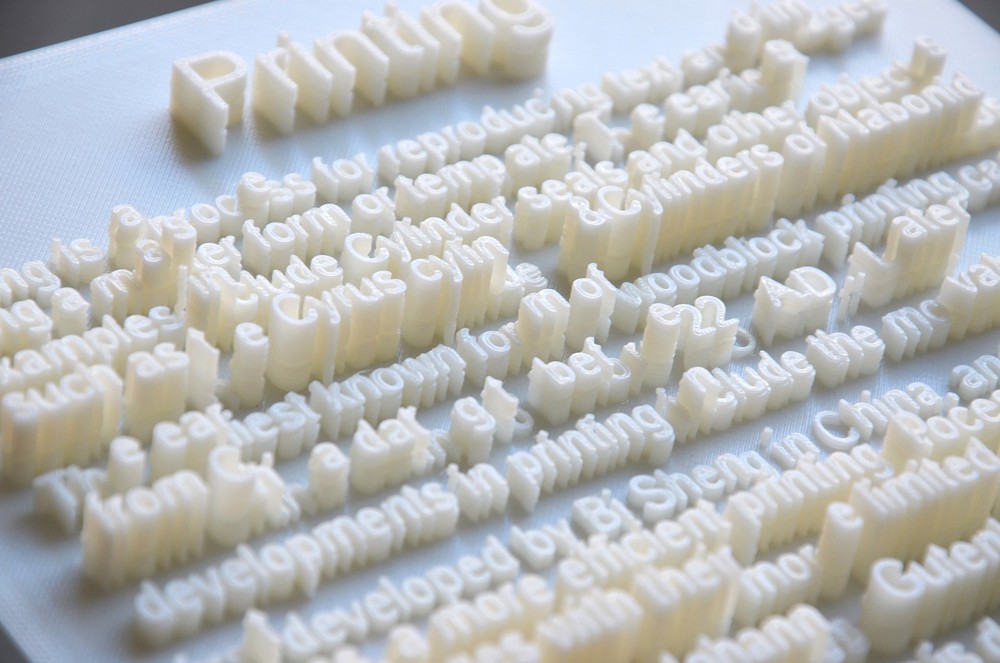

The obvious option is to create forms that are inaccessible or difficult to implement when using sheet materials. But in the manufacture of "ordinary" three-dimensional letters printing is appropriate. The fact is that the manufacture of side surfaces is a process performed either manually or with the help of expensive bending equipment. It is necessary to cut the plates of the desired size, bend, glue, process.

When using a 3D printer, the process of manufacturing the case is reduced to one stage (the cover is cut from sheet material).

The body of the letter or logo is immediately printed with the plastic of the desired color. It becomes possible to combine several materials - for example, translucent and solid, this will give an original effect when turning on the internal illumination.

The use of plastics that are resistant to UV light, eliminates the need for additional processing of structural elements. For example, SBS is a filament with minimal shrinkage and good resistance to external influences.

Limitations of 3D printing

The main problem is the small size of the printed area of most 3D printers. Large format printers are more expensive than compact desktop models, but some of them are already suitable for making street signs.

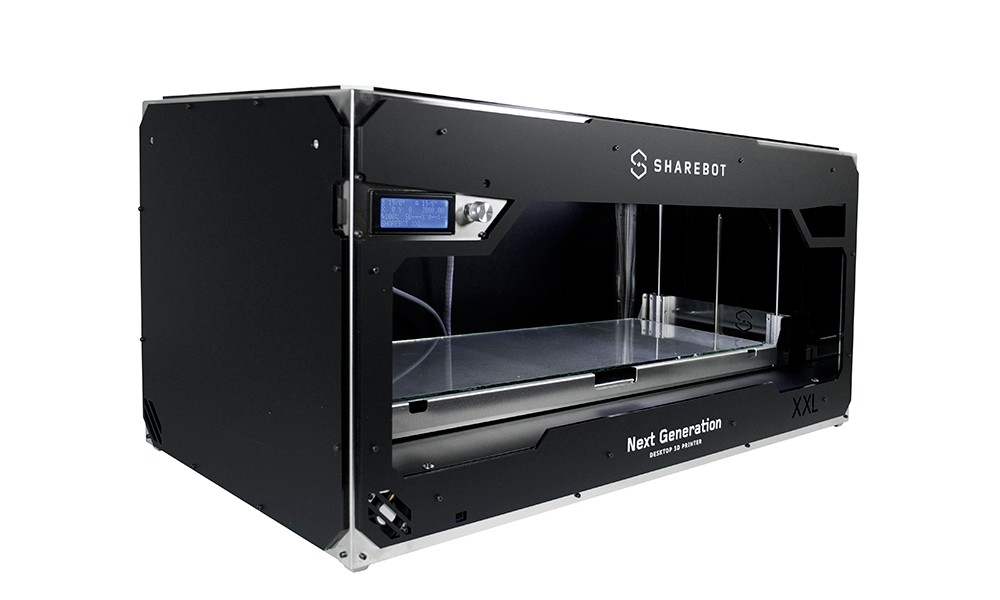

ShareBot XXL

- printing technology: FDM / FFF;

- working chamber: 705 x 250 x 200 mm;

- bar diameter: 1.75 mm;

- price: 469 940 rubles.

A wide-format device made in Italy, designed for printing large plastic parts with a slight shrinkage - there is no heating of the platform.

Hercules Strong 2017

- printing technology: FDM / FFF;

- working chamber: 300 x 300 x 400 mm;

- nozzle diameter: 0.3-1.0 mm;

- price: 170,000 rubles.

Updated version of Hercules Strong from Krasnoyarsk Imprints. Of the benefits is an enclosed printing chamber with air circulation and a heated platform, which allows working with most materials for FDM / FFF.

XYZprinting PartPro350 xBC

- printing technology: BinderJetting;

- working chamber: 350 x 222 x 200 mm;

- print speed: up to 18 mm per hour along the Z axis.

XYZprinting da Vinci Color

- printing technology: FDM / FFF;

- working chamber: 200 x 200 x 150 mm;

- bar diameter: 1.75 mm;

- price: 327 600 rub.

The key feature of the XYZprinting installation is not the dimensions of the printed area, but the possibility of full-color printing.

The combination of FDM / FFF and inkjet printing allows you to print full-color plastic objects. The dimensions of the printed area are sufficient for the manufacture of advertising objects for interior purposes.

Specavia SD-1001 Hippo

- printing technology: FDM / FFF;

- working chamber: 2000 x 1000 x 1000 mm;

- bar diameter: 1.75 or 2.85 mm;

- nozzle diameter: up to 1.0 mm;

- price: 1 460 000 rub.

Russian development, industrial printer with two printheads and a heated platform.

Implementation examples

Let's start with the Irish company GaraGeeks . Since 2015, she has been offering 3D printed signs for offices. One or two lines of text, logo, everything is pasted on the acrylic substrate. Nothing supernatural, but is made quickly and without noticeable cost of manual labor.

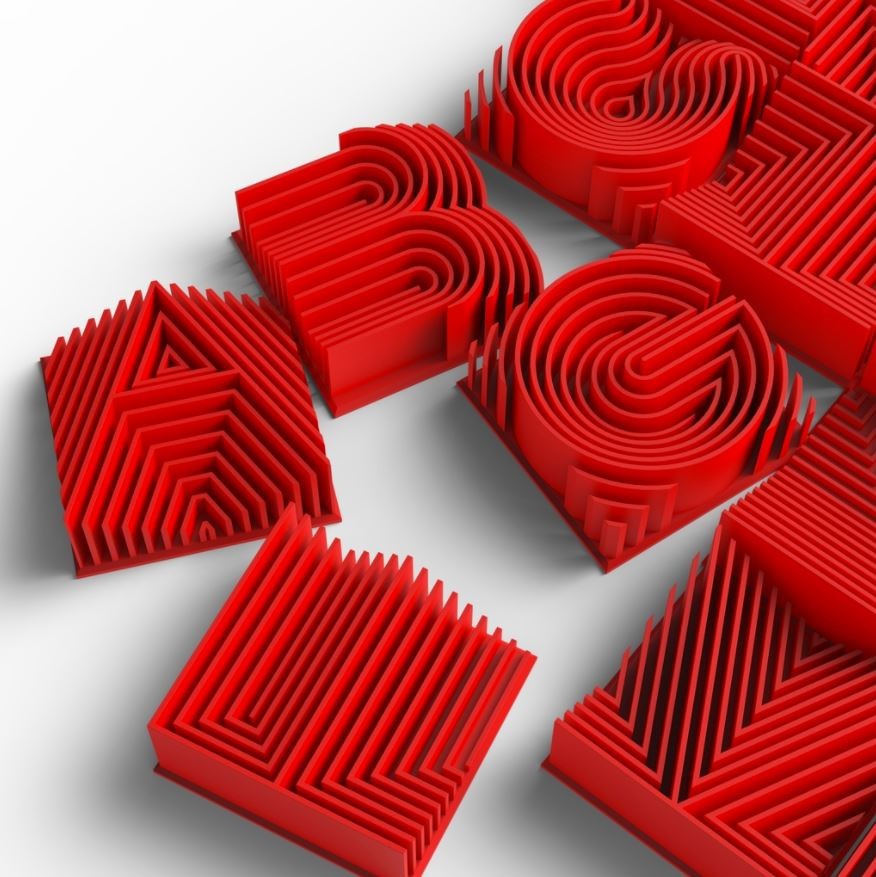

Studio My3dconcepts.com from Colorado already demonstrates more complex designs, the implementation of which without the involvement of 3D printing will be prohibitively expensive and complicated.

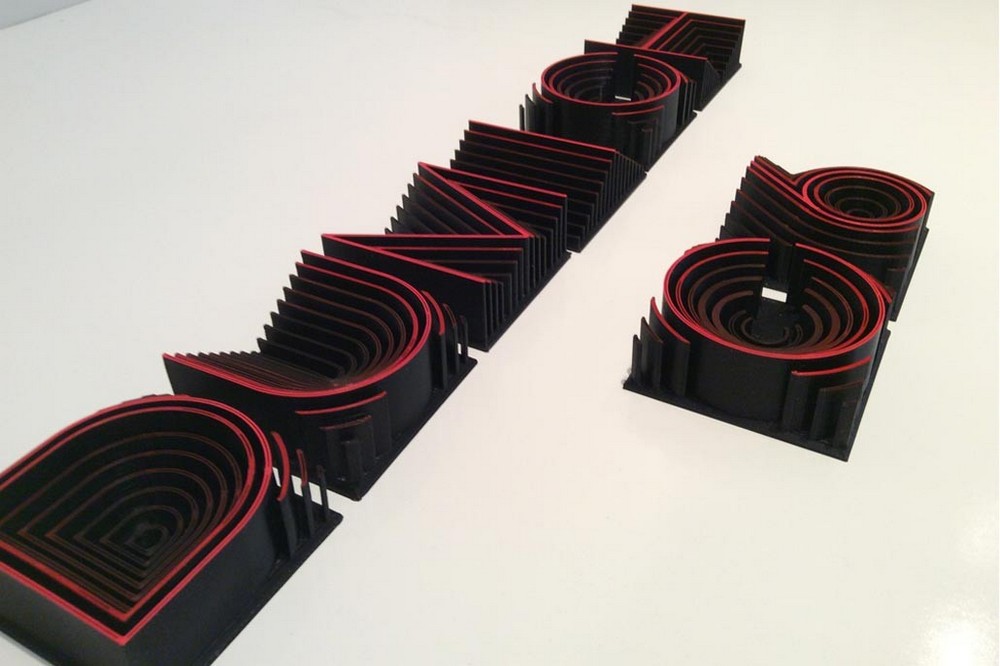

Alphabet of letters with specific relief, laid out by the user LorenIPSVM on Thingiverse.

But the letters Cloudswimmers from Belgium would hardly ever see the light without 3D printing.

Why is it worth typing letters

Because it saves time and cost of manual labor, and the end result is more dependent on the quality of printing, and not on the qualifications of the builder of the advertising structure. Printing is not only the case of volumetric letters under acrylic or metal covers - you can use elements with a pronounced complex relief, which are difficult to make from sheet materials.

Production of any volume objects

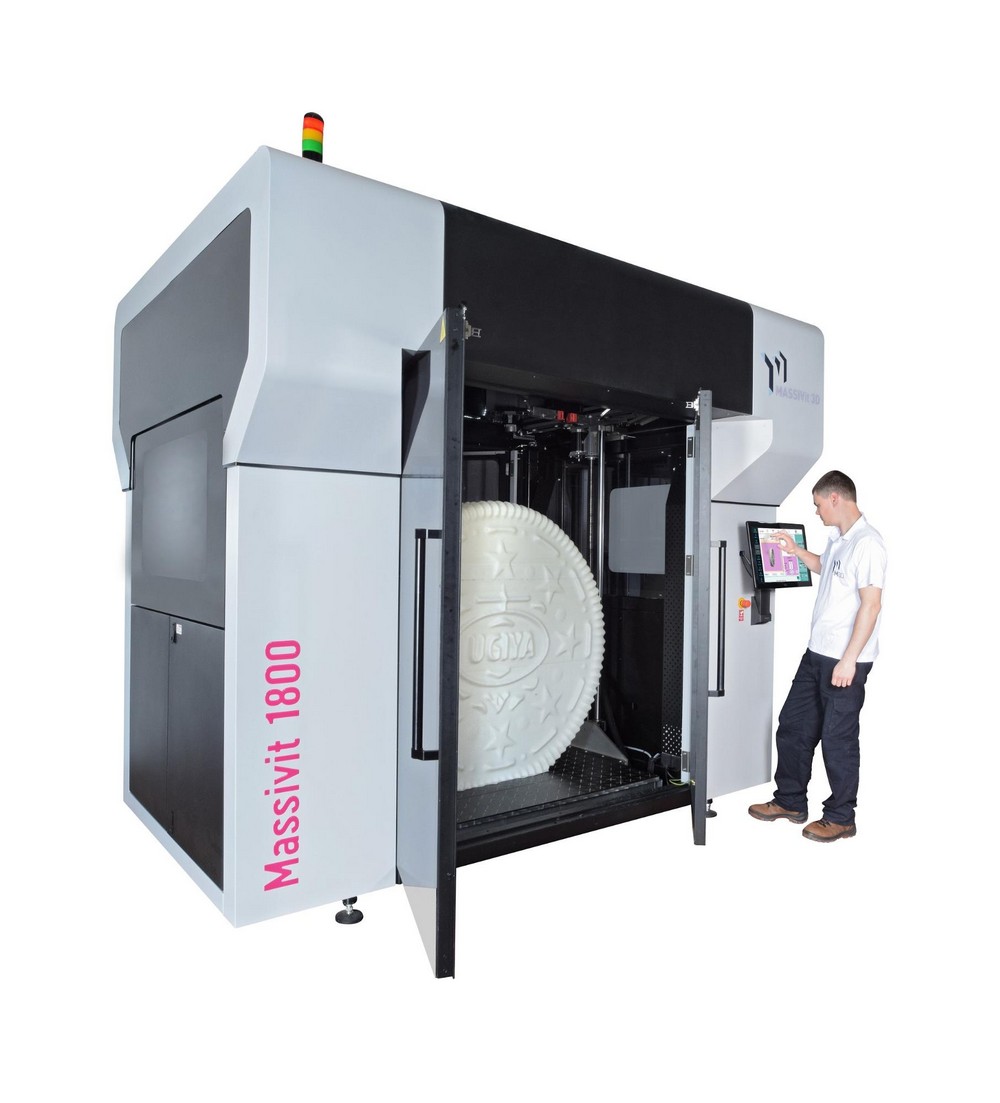

3D printing in the design of shop windows, interiors, exhibition stands is used not only in combination with the usual advertising production technologies. With the help of large-format 3D-printers materialize objects of complex shape. So, the Israeli company Massivit offers Massivit 1800 for quick printing of objects from a photopolymer gel.

An example of the use of large-format 3D printing in an advertising campaign is the design of a tour bus.

Massivit 1800

- technology: printing by photopolymer gel;

- construction area: 1500 x 1200 x 1800 mm;

- print speed: up to 35 cm per hour on the Z axis.

Massivit 1800 quickly forms large objects from a UV-curable photopolymer gel. The finished product is subjected to grinding, painting, varnishing.

Combination of technology

3D printing cannot completely replace traditional production technologies of advertising constructions. But it simplifies a number of operations, reduces the dependence of the quality of the result on the qualifications of the staff. For example, the body of volume letters are printed entirely, it remains to mount the backlight if necessary and close the letter with a lid. Printing capabilities unleash the hands of designers, allowing you to create complex volumetric shapes. Cyclopean advertising facilities have not yet been printed, but it is a matter of time, because building 3D printers can be involved in the process.

Top 3D Shop will offer you all the necessary equipment for the manufacture of advertising structures - laser cutters , milling machines , large-format 3D-printers . In addition, you can order the production of signs, sign boards and similar products. We will advise on the issues of choice, we will repair and adjust the equipment, we will train the staff.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/371081/

All Articles