Fisker patents solid-state lithium batteries for future electric vehicles

Fisker Automitive , created by Tesla ex-employee Henrik Fisker, announced a breakthrough in battery design. Judging by the information provided by Fisker, we are talking about a new type of solid-state batteries that will be used in the company's own electric vehicles. These batteries provide the car with a power reserve of up to 800 km, and they charge in less than a minute. Thus, the development solves two main problems of electric vehicles at once - a relatively small power reserve and charging time.

Fisker filed a patent application for its invention. Its main features are a new type of materials used to create batteries and a new technological process, which is crucial for increasing the battery capacity and charging speed.

Due to the characteristics of the electrodes of solid-state batteries, the energy density in them is 2.5 times greater than in lithium-ion batteries. It is thanks to the high density, according to scientists from Fisker, that the electric vehicle's power reserve can be increased several times, compared to its counterparts on conventional batteries. In this case, the charging time of an electric vehicle battery is less than the time that a regular car driver spends on refueling the tank.

')

Unfortunately, for the production of batteries from Fisker you need to create a completely new production. And this is possible not earlier than in a few years. According to company representatives, it will not be possible to start producing solid-state batteries no earlier than 2023.

“This breakthrough is the beginning of a new era of solid-state materials and technical processes. We are now solving all the problems that appear in the way of technology commercialization, such as low-temperature performance, cheaper manufacturing process, and the possibility of miniaturization of batteries, ” said Fabio Albano, vice president of the battery division at Fisker Inc.

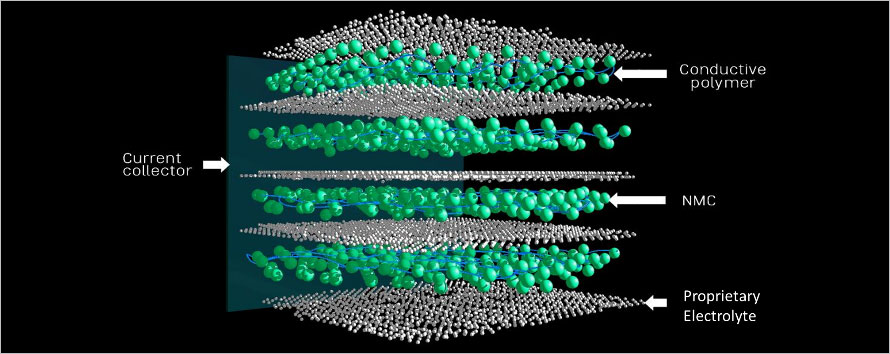

The Fisker solid-state technology provides for the use of bulk electrodes, the specific surface area of which is 25 times larger than the specific surface area of conventional film electrodes in lithium-ion batteries.

At the moment, the technology proposed by Fisker does have a number of unsolved problems. The main ones are the possibility of increasing the density of placement of electrodes, a limited temperature range of operation, a limited number of materials that can be used to create batteries, an unscalable production process. Nevertheless, Fisker promises to find solutions for each of these problems. It is for this company and it takes five years.

The design of the electrodes has already been proposed, which will allow the production of universal batteries of various sizes and voltage. But apart from purely technical problems, it is necessary to solve logistics issues as well, for now there are no ready supply chains of the necessary materials and equipment for the production of solid-state batteries. All this will have to create from scratch.

Nevertheless, the new technology offers excellent prospects. In addition to the 800 km power reserve, batteries after debugging the production process will be cheaper than current batteries. At the moment, the high cost of electric vehicles and a relatively small power reserve stop most of the potential buyers of such vehicles.

Fisker management is currently negotiating with various industry groups, trying to start production of batteries before 2023.

As already mentioned, the company will initially install its batteries in electric vehicles of its own design. But Fisker does not exclude the possibility of producing smaller batteries in order to supply them to representatives from other electronics fields.

The maximum power reserve at the moment - at Tesla electric cars. This is 540 kilometers from the Tesla model S 100D . The minimum charge time of the car battery is 30 minutes. Earlier, Tesla launched a project of stations for quick replacement of batteries, but due to technical difficulties, this system was ineffective and it was decided to abandon it.

Source: https://habr.com/ru/post/371013/

All Articles