Overview milling machine CNC SolidCraft CNC-6090

Hello! We conducted a testing of the milling machine Solid Craft , the results of which we offer in this review.

In this article: characteristics, equipment, review of the test work, with photos and videos, pros, cons and nuances of working with the machine.

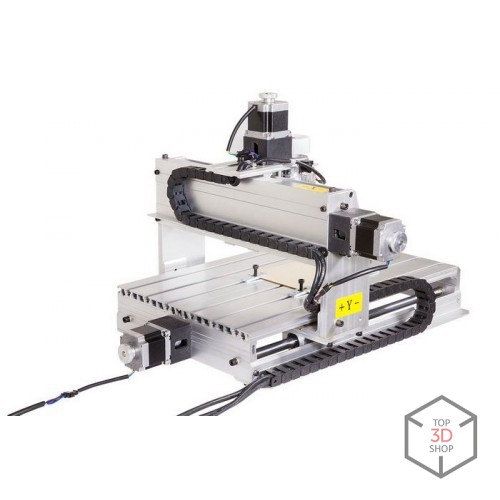

What is it

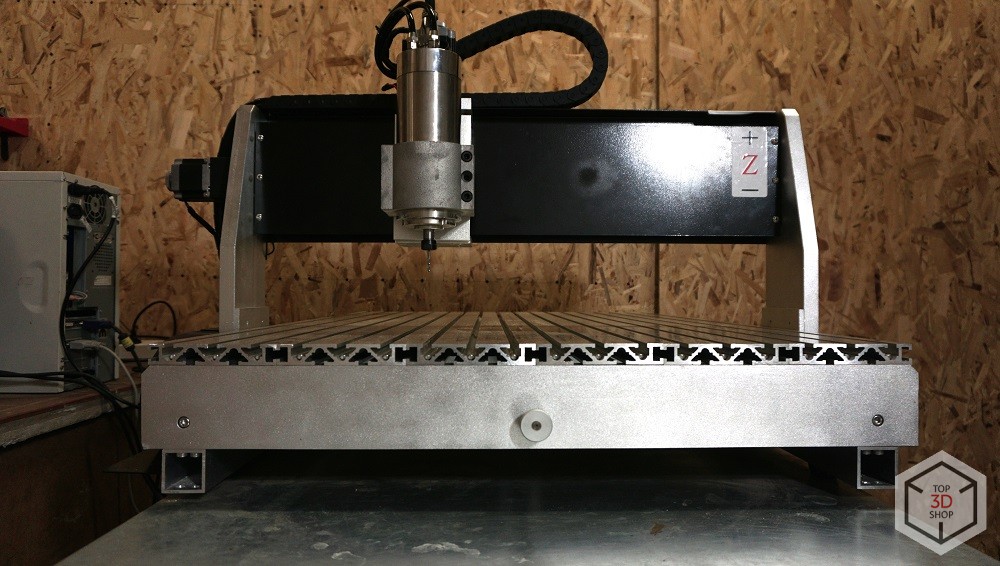

SolidCraft CNC 6090

')

Specifications

- Spindle speed: 24,000 rpm

- Size of the working field: 615x905x90 mm

- Spindle power: 800 W

- Sizes of the machine, mm: 1310980580

- Package dimensions mm: 1450x1050x780

- Machine weight with control unit, kg: 83

- Shipping weight, kg: 131

- Maximum speed: 4000 mm / min

- Spindle Cooling: Liquid

- Machine power supply: AC110V / 220V ± 10% / 50 ~ 60Hz

- Repeatability: 0.05 mm

- Software control language: HPGL, G-code

- Compatible software: NC Studio, Mach3

- Motor Type: Stepper

- Interface: LPT

- Price: 269 900 rubles

SolidCraft CNC-6090 800W is the largest desktop machine in its series, with a popular table size - 615x905x90 mm, it is large enough for most applications, but relatively compact.

It is cheaper machines with a bed. It is interesting not only in size, but also in spindle, which copes not only with wood and plastic, but also with engraving of non-ferrous metals. The 800-watt spindle is equipped with water cooling, the pump in the kit is responsible for this.

The machine can be used in furniture and advertising production, creativity, in educational institutions and laboratories. The machine has a metal case, high-quality components and assembly.

Powerful 800 watt spindle.

Equipment

Complete set: machine, control board, control unit with power supply, motor drivers and frequency converter, water pump for cooling the spindle, brush, collets for 3, 4 and 6 mm, 4 clamps, two wrenches, a set of cutters and 2 adapters, a disk with software

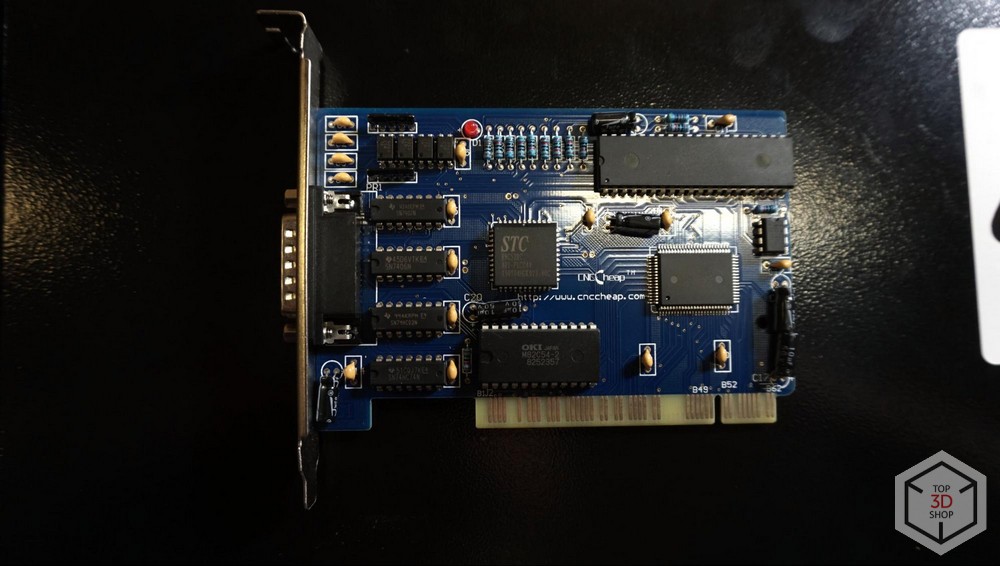

PCI card for PC with Mach3 or NC Studio included. Without it, you can not work with the machine.

A set of cables already connected.

Power supply and control.

A set of cutters and engravers, the number and type depend on the delivery.

Collet.

Assembly tools and a brush for removing sawdust.

Fasteners.

Water cooling spindle pump. The spindle is powerful, without this in any way.

Job Overview

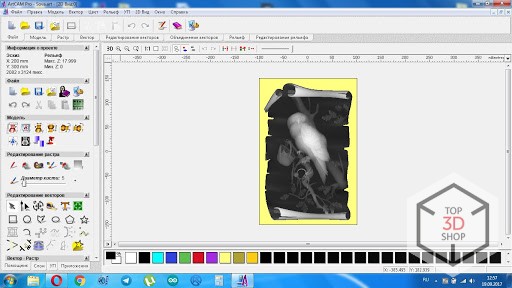

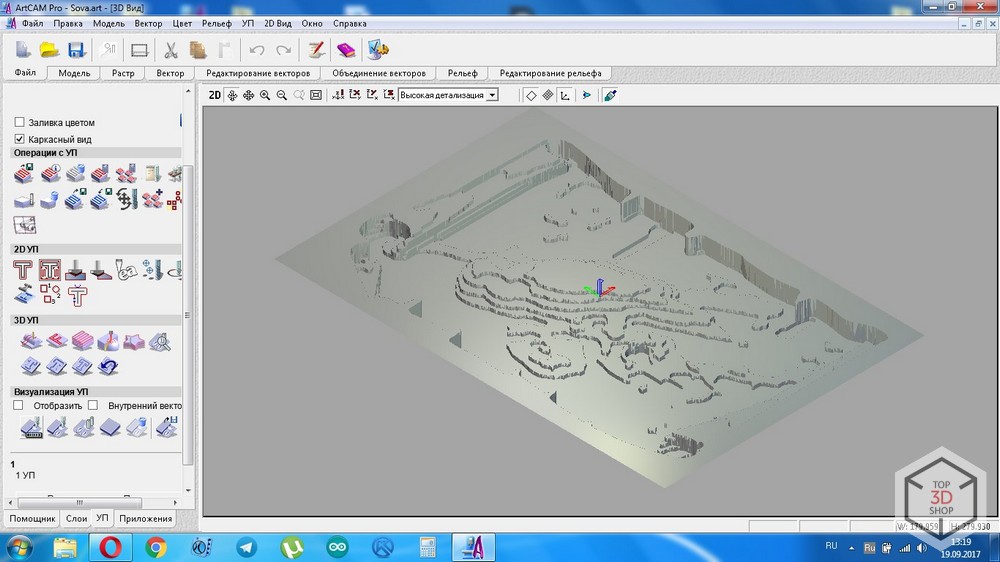

The first model for 3D milling is a bas-relief of an owl on a sheet of parchment. Worked in the program ArtCam 2008.

50 minutes of roughing, 3 hours of finishing, 15 minutes of circumcision, 15-20 minutes of finishing with Dremel. Material - furniture board made of larch.

The deer model was made of 6 mm plywood. The whole working field of the machine was 600 x 900 mm. A single-turn spiral cutter was milled at 3.175 mm, the total time was about 3 hours, it was assembled without glue.

The watch-compass was milled for about 4-5 hours, immediately clean. For this model was taken too big a mill, so it turned out not very detailed. And the material - larch furniture board - is not hard enough for more detailed products.

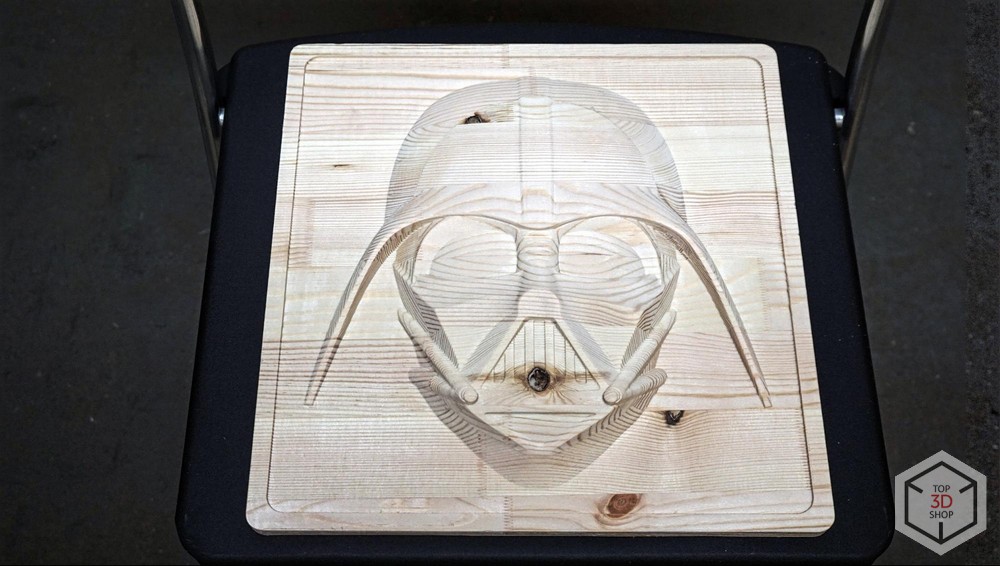

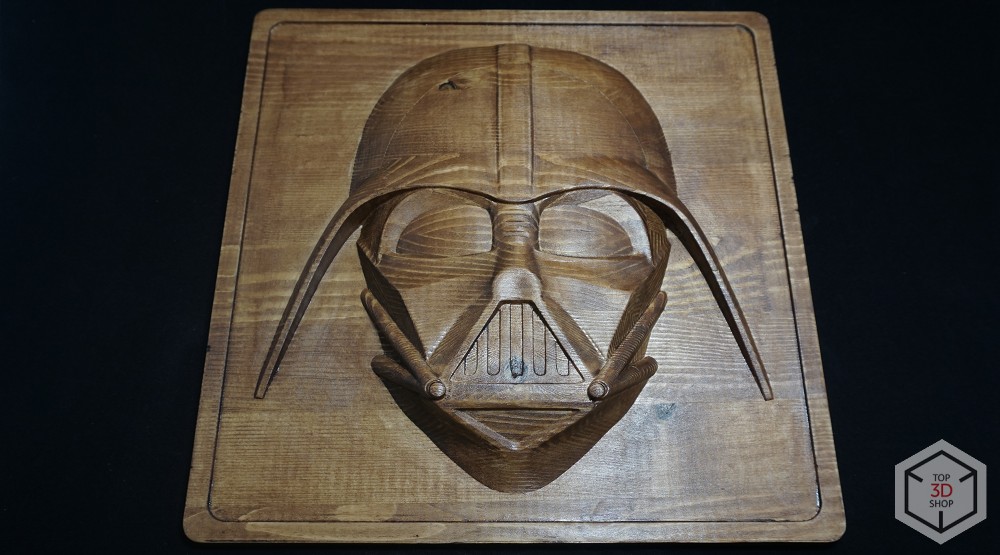

Darth Vader's mask was made in two passes - 3 hours of roughing, 8 hours of finishing, 20-30 minutes of trimming, subsequent removal of the pile and grinding. Furniture shield larch.

The product is varnished, sanded and varnished again.

Pros and cons of the machine

Pros:

- Relatively small size that allows you to place it on the workbench

- Water cooling spindle

- The ability to manually bring the mill, thanks to the handles on the engines

- Easy to connect and run

- Reliable metal construction

Minuses:

- With intensive removal of a large amount of material at high speeds, there is insufficient rigidity along the X axis. Solution: do not overload the mill, give less intensive modes of operation.

- Small working area along the Z axis, 90 mm in height. For most decorative and furniture tasks, however, this is enough with a margin.

- ArtCam with the machine is in English, without Russification. Solution: use other software with support for the Russian language.

- You have to be prepared for noise and a lot of waste. Solution: a closed case is sold to the machine separately, which will not allow sawdust to scatter around the room.

Nuances of work

- The NC Studio driver is not installed with a single click. Nothing complicated, you just need to know this: you need to go to the device manager, find an undefined device in it, update its driver and set the driver path to the NC Studio program file - where you installed it.

- The program, respectively, and the machine, work with XP and Windows 7, with a bit of 32 bits. On the one hand, this is good - the machine is undemanding and will work with the old computer, on the other - you will not connect it to the new one. In addition, without installing the complete board into the system unit, it also will not start, that is - work with any laptops is ordered. We need a cheap old sistemnik.

- All screw fasteners of the machine, after unpacking, it is desirable to tighten, especially the coupling on the shafts of the engines. Machine rides from afar, transportation makes itself felt.

- You can train on a cheap softwood furniture panel, but because of the softness and resinousness, you should not expect a good result from such blanks.

- Cutters are expensive and brittle, however, as for all similar machines - this is not a minus of the machine, it is a given. It is necessary to take this into account when forming the program and setting the speed.

Available modifications

SolidCraft CNC-3040 Light

- Spindle speed: 24,000 rpm

- Size of the working field: 300x400x55 mm

- Spindle power: 400 W

- Price: from 99 900 rubles

Interesting compact size and a spindle of 400 watts, sharpened by working with wood and plastic. Due to its low price, it is available for home use in creative work and for educational institutions. It differs from the competitors by a metal case, high-quality components and assembly.

It is also available with a 800 W spindle, in this modification it copes not only with wood and plastic, but also with non-ferrous metal engraving.

SolidCraft CNC-4060

- Spindle speed: 24,000 rpm

- Size of the working field: 385x580x55 mm

- Spindle power: 800 W

- Price: 199 900 rub.

Total

The machine is interesting and, as we believe, very good. Suitable for the manufacture of outdoor advertising, interior decoration, furniture panels, bas-reliefs and carved images, including - for branded souvenirs and promotional products from wood, plywood, plastics, composites and non-ferrous metals.

Relatively low price allows you to use the machine and for home or cottage production, as well as for the offices of labor in schools. He has his own shortcomings and subtleties, we have listed above, but there are more positive properties.

We can recommend it for purchase to anyone who is satisfied with the dimensions of the working field of the machine and the list of processed materials.

To choose a machine with the help of a qualified specialist, taking into account your goals and needs, contact sales@top3dshop.ru

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/370849/

All Articles