Found a way to resist an attack on 3D printers

In 2016, Geektimes published an article about hacking 3D printers in order to make changes that lead to the destruction of the object being created during its operation. In short, this is an attack on businesses that use 3D printers to create parts or parts of them in order to change the configuration of the elements produced. For example, it could be a copter screw, parts of a car body, machine parts, and more. Research scientists called "dr0wned - Cyber-Physical Attack with Additive Manufacturing" . In its course, specialists got access to the model file of the drone propeller parts, changed the model parameters, manufactured the parts and launched the drone. As a result, the screw collapsed in flight and the copter fell from a great height.

It is clear that this was only a demonstration of the possibility of an attack, which could have been much larger if it were a question of real production. Only now, after almost a year, specialists from the other team have found a way to help confront a theoretical 3D printer hacker. The results of this project were presented in Vancouver, at the USENIX Security Symposium event.

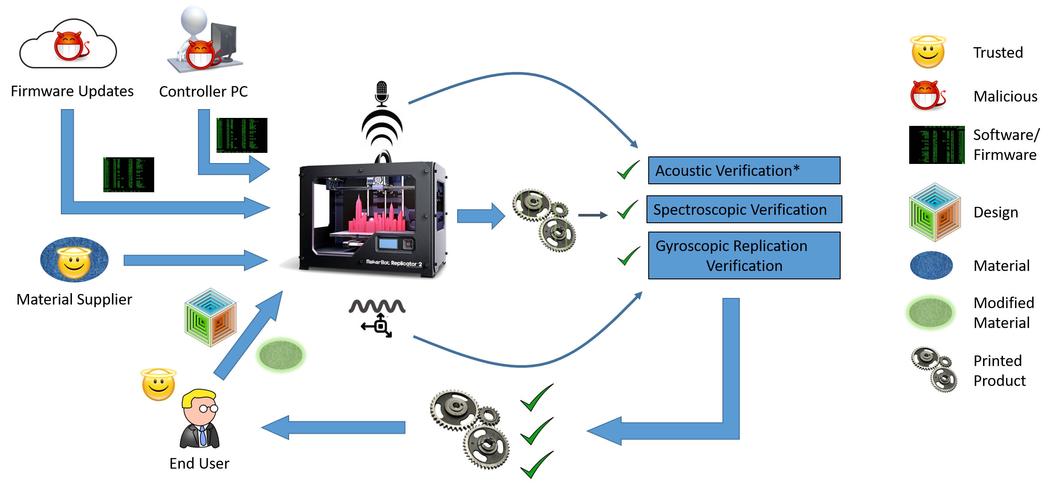

Among other methods of tracking possible damage to parts printed on a 3D printer are the analysis of device operation sounds, tracking of a manipulator, plus injection of gold microparticles into the source material in order to make sure that everything is going according to plan.

')

The document describes how researchers tested their assumptions in practice. Initially, three printers were purchased - Lulzbot Taz 6, Lulzbot Mini and Orion Delta. After that, the hackers changed the firmware of the systems, forcing the devices to print parts with defects. In some cases (yes, there in most cases) it was difficult to judge its quality and compliance with the original drawing from the detail. But all these parts were defective and would deteriorate very quickly during operation.

Scientists are thinking about the possibility of using software like firewalls and antiviruses. But it is not a panacea, since zero-day vulnerabilities and other surprises have not been canceled. Therefore, it was decided to develop a different way to protect the devices and the parts they create.

This method consists of three stages. At the first stage, the printer makes the part according to the correct drawing. The sounds of the device are recorded and saved as a reference. Subsequently, the sounds of other printers of the same model, which are working on the creation of the same part, will be recorded. If there are significant discrepancies in any case, the part and printer are carefully checked.

The second stage is similar to the first - in this case, the movements of the reference printer are tracked. If the movements of other printers of the same model differ from the standard in the manufacture of the same part, then everything is carefully checked.

Finally, during the third stage of the work described in the document, in the process of manufacturing a part, gold microparticles are introduced into the starting material. They are introduced not randomly, but at a certain time, so that the particle occupies a certain place in the part. In the future, all the details are checked for the correctness of the location of gold. If everything is within the normal range - ok, the part can be used. But for fidelity, the computer analyzes the recording of the sound of the printer and its movement. Are all three stages tested? The item is sent to the place of use.

It is clear that the danger of hacking 3D printers is most relevant in relation to industrial systems, and not home devices. Yes, if the home system is hacked, it will be unpleasant for the owner, but the problem can be solved relatively quickly. But with the hacking of industrial devices, everything is not so clear. As mentioned above, complex and expensive devices that are made using printers, not to mention people, can suffer.

“Imagine that a whole factory of 3D printers is working on manufacturing a certain kind of objects. They have no way of knowing if there are defects in the details, defects that cannot be seen with the naked eye. The result can be deplorable, and no one will understand where the problem came from, ”the authors of the project said in a statement.

The method proposed by scientists can also be used to determine a possible marriage unprovoked by man.

Source: https://habr.com/ru/post/370733/

All Articles