Siemens has replaced managers with a computer program.

The AI at the Siemens factory will distribute tasks to robots and humans, programming their joint work.

If you once had the idea that the project manager is a practically useless position and can be automated, then you were right. Siemens has done this.

Many modern factories use industrial robots. Often there are more robots on the assembly line than humans. The main problem with this automation is that robots need to be reprogrammed for each job. It is necessary to repair faulty mechanisms, and only a person can do it, even at the risk of their lives . In any case, humans and robots are destined to work together. So, Siemens is testing a new configuration of such cooperation: at its “factory of the future” people and robots work together under the control of a computer program (you can call it a weak form of Artificial Intelligence).

Siemens AG - German concern, which is engaged in including mechanical engineering and electrical engineering. The company has 366,000 employees, dozens of factories in different countries, an annual turnover of € 80 billion. The concern spends almost € 4 billion a year on R & D, which is comparable to the Russian federal budget spending on science (336 billion rubles in 2017). Considering the scale of Siemens activities and the number of factories, the industrial giant is extremely interested in maximum automation of production.

')

So, industrial robots work. The time has come for Automation 2.0, where Artificial Intelligence effectively manages robots and humans, writes Fast Company . AI programs robots and distributes tasks to people.

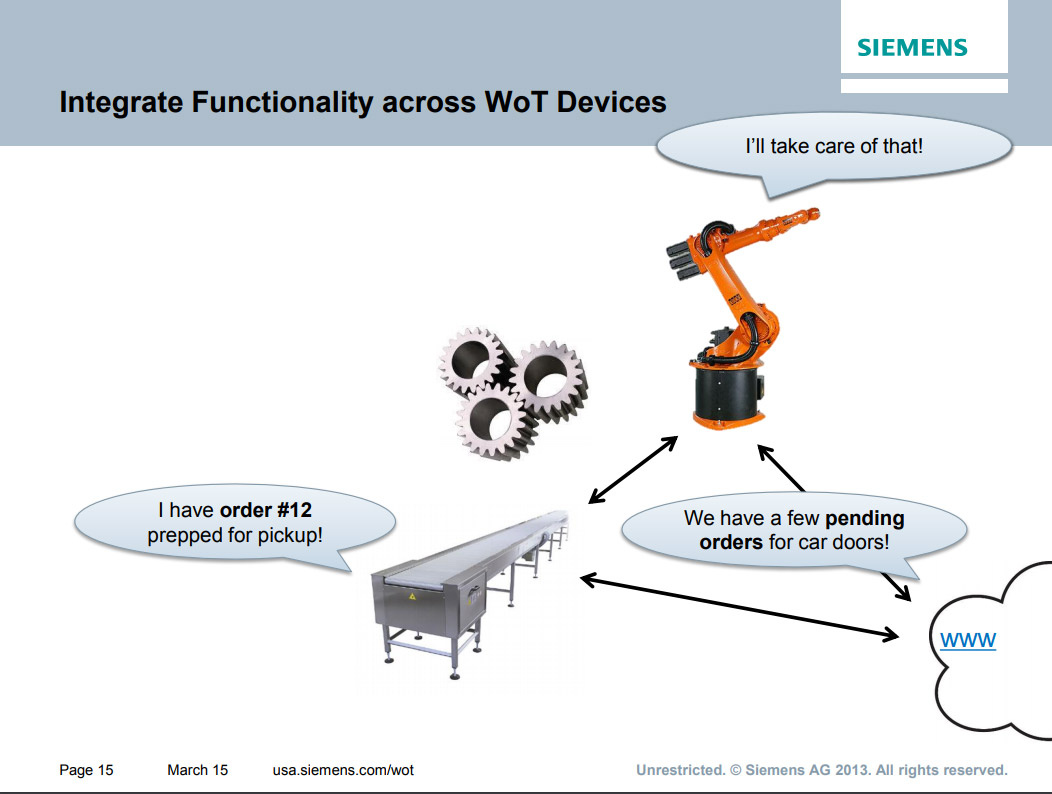

“Instead of programming each robot, we say that this machine can do this task, but this machine has the following features,” explains Florian Michahelles, who heads the Siemens Web of Things research team in Berkeley (USA). His group has developed a program called the “reasoner”. This is a kind of expert system. It independently determines what steps need to be taken to produce a specific product, then distributes tasks among the robots in accordance with the capabilities of each of them.

According to the calculations of researchers, the automated factory UberManufacturing will work "under the order", as a taxi service Uber. Unlike modern factories of mass production, this factory can accept small piece orders - and reconfigure robots on the fly.

Slides from the presentation by Florian Michaelus, where the topic of an automated factory with a “reasoner” is touched upon

Siemens is one of the first companies that integrates modern robots and artificial intelligence programs. Some researchers believe that the future is such an integration of robotics, AI, and machine learning. Analysts at McKinsey Global Institute believe that the increase in productivity from automation in the coming decades will significantly exceed the average annual increase in productivity from the steam engine in 1850-1910 (0.3%), from early robotics in 1993-2007 (0.4%) and information technology in the years 1995-2005 (0.6%). In 2015-2065, automation will increase productivity by 0.8-1.4% annually. For a developed western economy this is a very big growth.

A preliminary analysis shows that only 5% of the staff will lose their jobs due to the full automation of their activities (probably, project managers may be among them). But automation will partially affect virtually every profession: from miners and landscape designers to bankers, welders and executive directors.

The professions most likely to be automated are those associated with physical labor, which is performed in a well-structured and predictable environment. The potential of automation by profession is well depicted in the McKinsey interactive tool for 750 professions. It shows the professions with an automation potential ranging from 1% (financial advisors) to 100% (loading machine operators).

The Siemens research group has already conducted an experiment and proved that an automated AI-controlled factory can operate on a small scale: the test system used several types of robots and assembled five types of furniture with four leg configurations, six colors and three types of floor protectors (total 360 possible product combinations). Thus, the automated factory will be able to fulfill personalized orders in small batches.

Although the system provides for the integration of human labor and robots, but experts are well aware that the proportion of people in factories will gradually decrease. In the future, robots will be able to cope perfectly with all the tasks and without us, including the repair of damage and the reproduction of their own kind. So under the control of AI, such a factory can operate continuously.

Source: https://habr.com/ru/post/370713/

All Articles