Raise3D N1 Dual 3D Printer Review

Good day. More recently, a new 3D printer maker, Raise3D, has appeared on the Russian 3D printer market.

Shanghai Fusion Tech CO., Ltd. ("Raise3D") assembled an excellent team of young graduates from leading universities and started their work 3 years ago, creating a series of Duplicator 5 printers for Wanhao, and the IdeaMaker software was also created specifically for this model. In October 2015, the company announced the creation of a line of printers under its own brand Raise3D and launched a fundraising company at the KickStarter site. The company became very successful, 445,892 USD were collected from 348 customers and in March printers were sent all over the world.

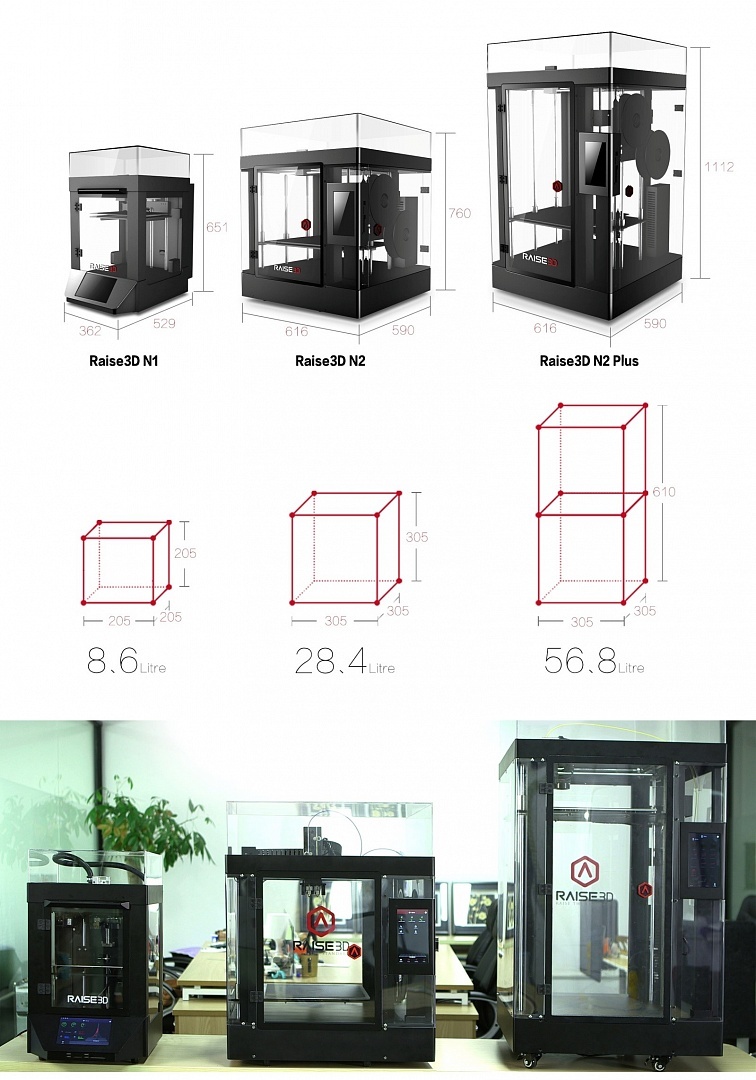

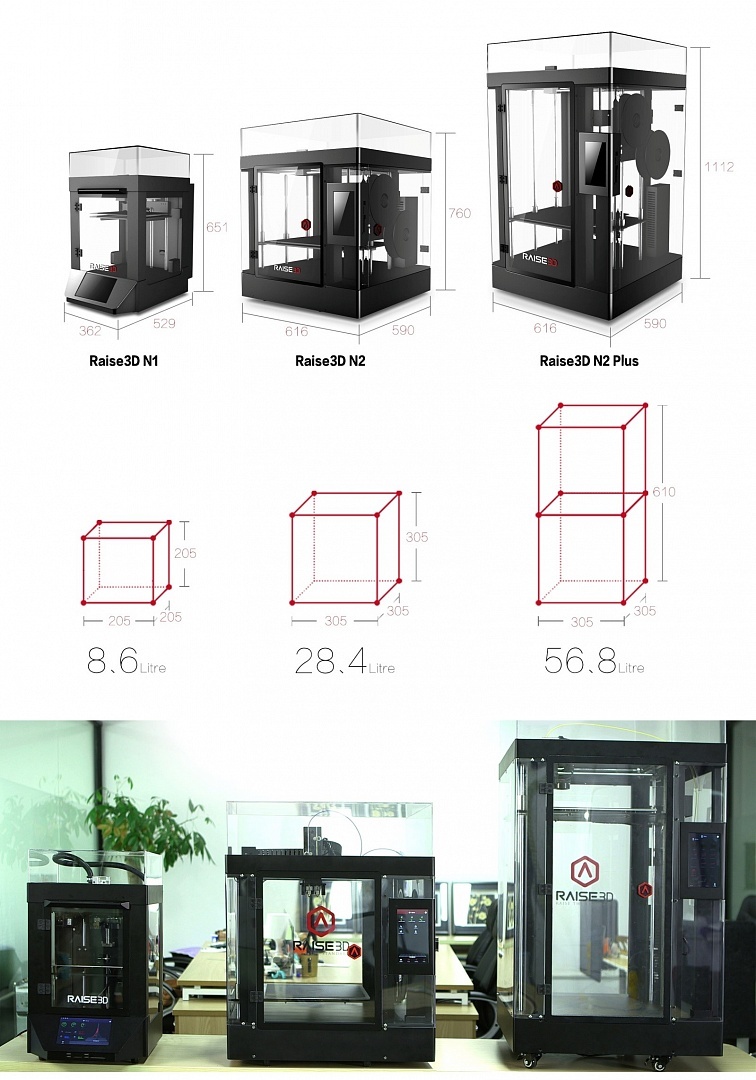

To date, Raise3D produces 3 models of 3D printers of the N. line.

')

The cost of printers: Raise3D N1 Dual 3D printer - 165,000 rubles, Raise3D N2 Dual 3D printer - 225,000 rubles, Raise3D N2 Plus Dual 3D printer - 315,000 rubles.

But we will have a review of the youngest model Raise3D N1 Dual.

Since the delivery of the printer began recently, there is little information about it yet, we will try to fill this gap.

Packing / packaging

The printer is packed quite soundly. And it is completely capable of surviving Russian transport companies without loss.

Here you can see the video unpacking and a detailed analysis of the configuration.

It should be noted that the equipment is very generous. In addition to the “gentleman's” set of 2 coils of plastic and a spatula, the kit includes a scattering of spare parts and even a probe to calibrate the table.

Kinematics

With the mechanics, the Chinese decided not to reinvent the wheel and simply copied the mechanics of the famous Ultimaker, although from the point of view of various improvements they went much further, adding many unique features that you will not find in other 3D printers, even professional ones.

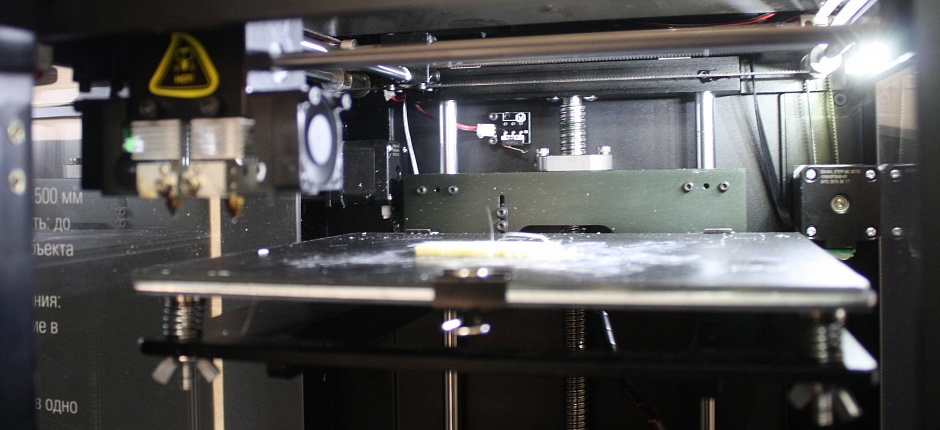

Shafts, belts, pulleys, brass bushings. No rails. Let's just say - a classic 3D printing. Reliable and efficient.

Few scared such a massive extruder on just 2 shafts. Although, as practice has shown, this is quite enough. Extruder unusually high. It is made for a more direct supply of capricious and soft materials.

Indeed, the printer "eats" soft flexs without interruption. Although, due to the large weight of the head, it cannot be quickly dispersed. But here you have to choose - either printing with any plastic or high printing speed.

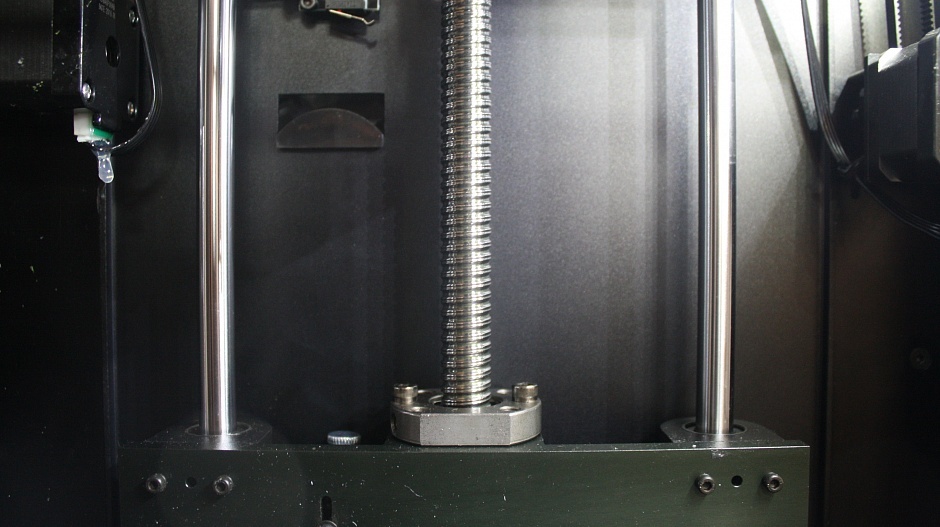

Along the Z axis there are 2 guide shafts and ball screws.

No backlash, no loose. Z-stripes - not seen when printing.

I must say that the table is aligned with the help of 4 screws. 4 points of adjustment in my opinion is not the best idea - too much time and effort is spent on leveling the table, compared to the 3-point calibration system.

Older Raise models are factory calibrated. And the height of the table relative to the nozzle is set with one screw.

Housing closed on all sides. This is a very big plus when printing with plastics that shrink. (almost all plastics with a print temperature of 240C and higher).

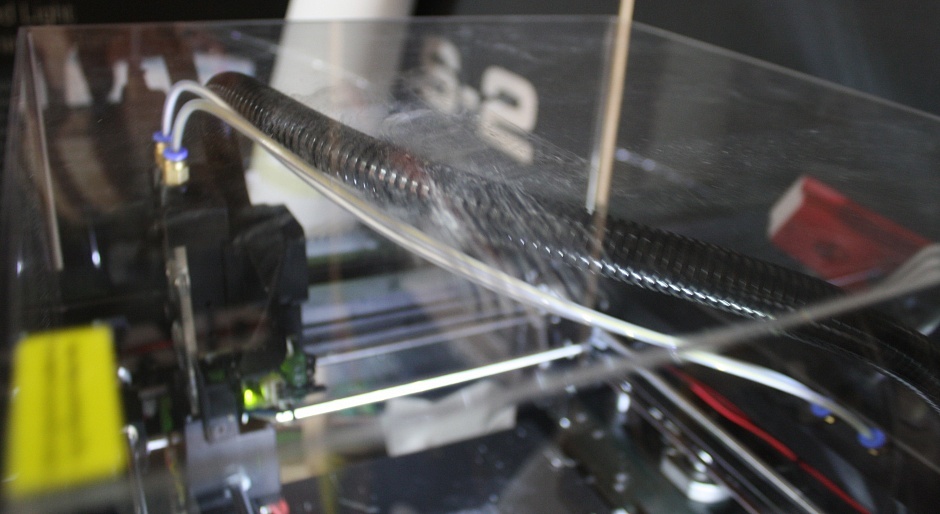

But be prepared for the fact that, over time, scuffs from the wiring harness will appear on the cap.

This has no effect on print quality, but some were very worried about this issue =)

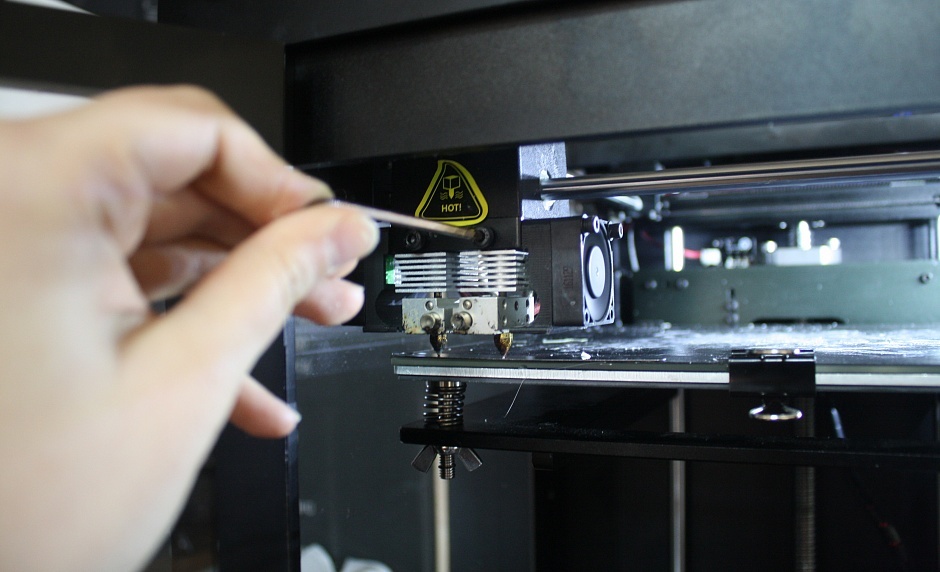

From the factory, the printer comes with a slightly raised right nozzle. Calibration of nozzles in height was quite simple. We send the table “to the house”, set up the table on the left nozzle, insert the dipstick and unscrew one screw. The nozzle itself falls into the probe).

I unscrewed both screws so that the nozzles were exactly at the same height.

Control is carried out using the touch screen tablet.

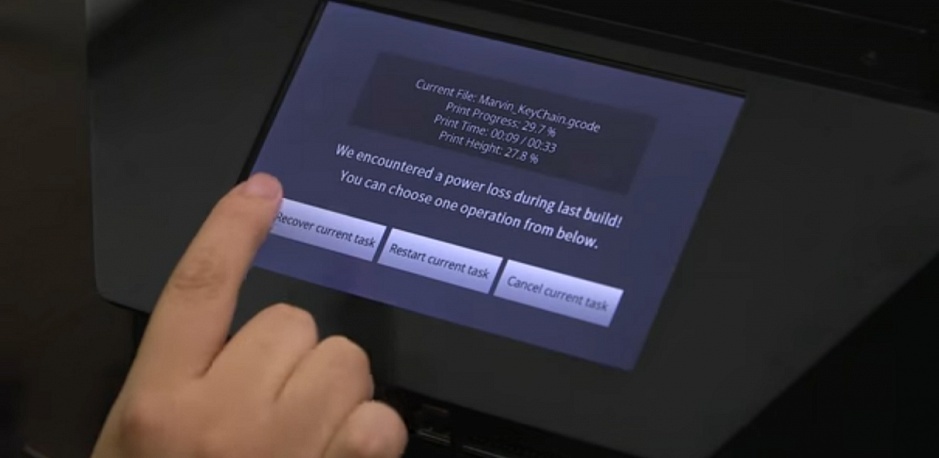

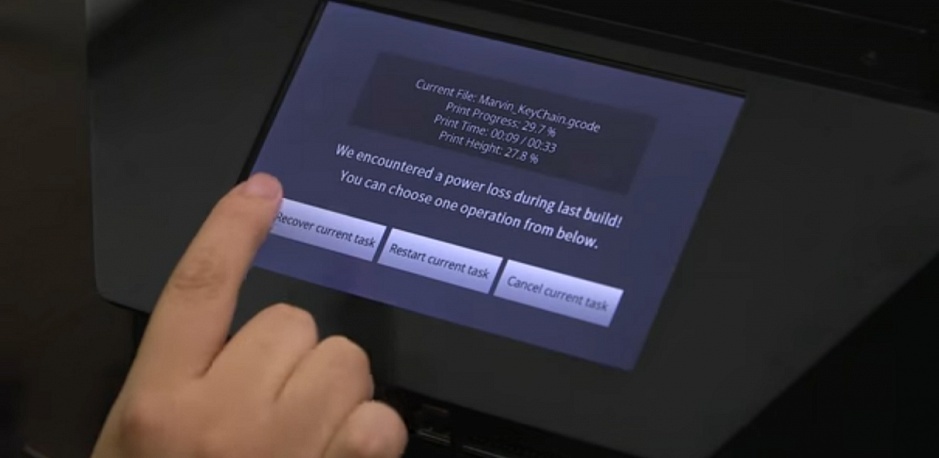

More precisely, it is a mini-computer with its own battery. During a sudden power outage, he will remember the place where the seal was broken and, when turned on, will offer to continue printing.

And of course the print results.

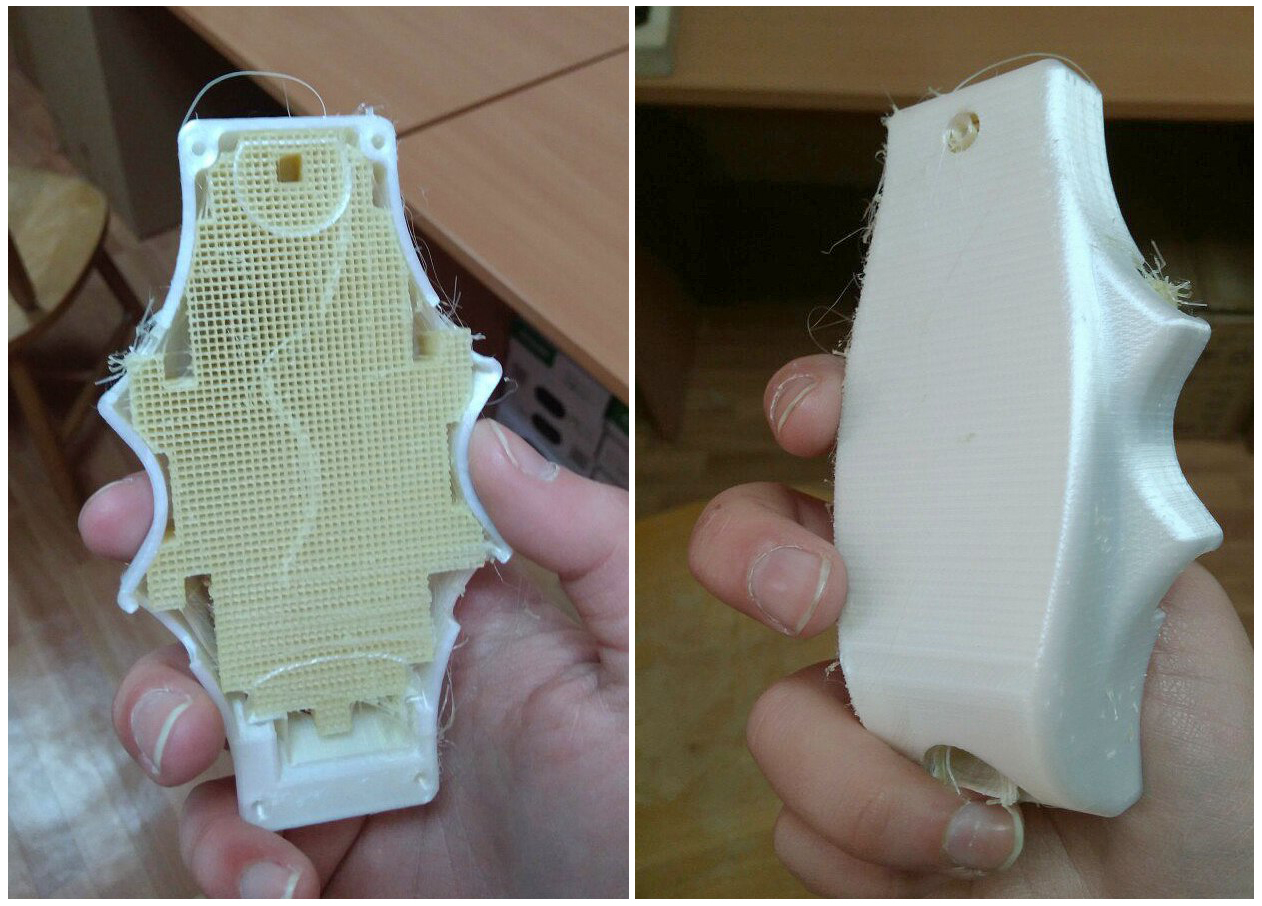

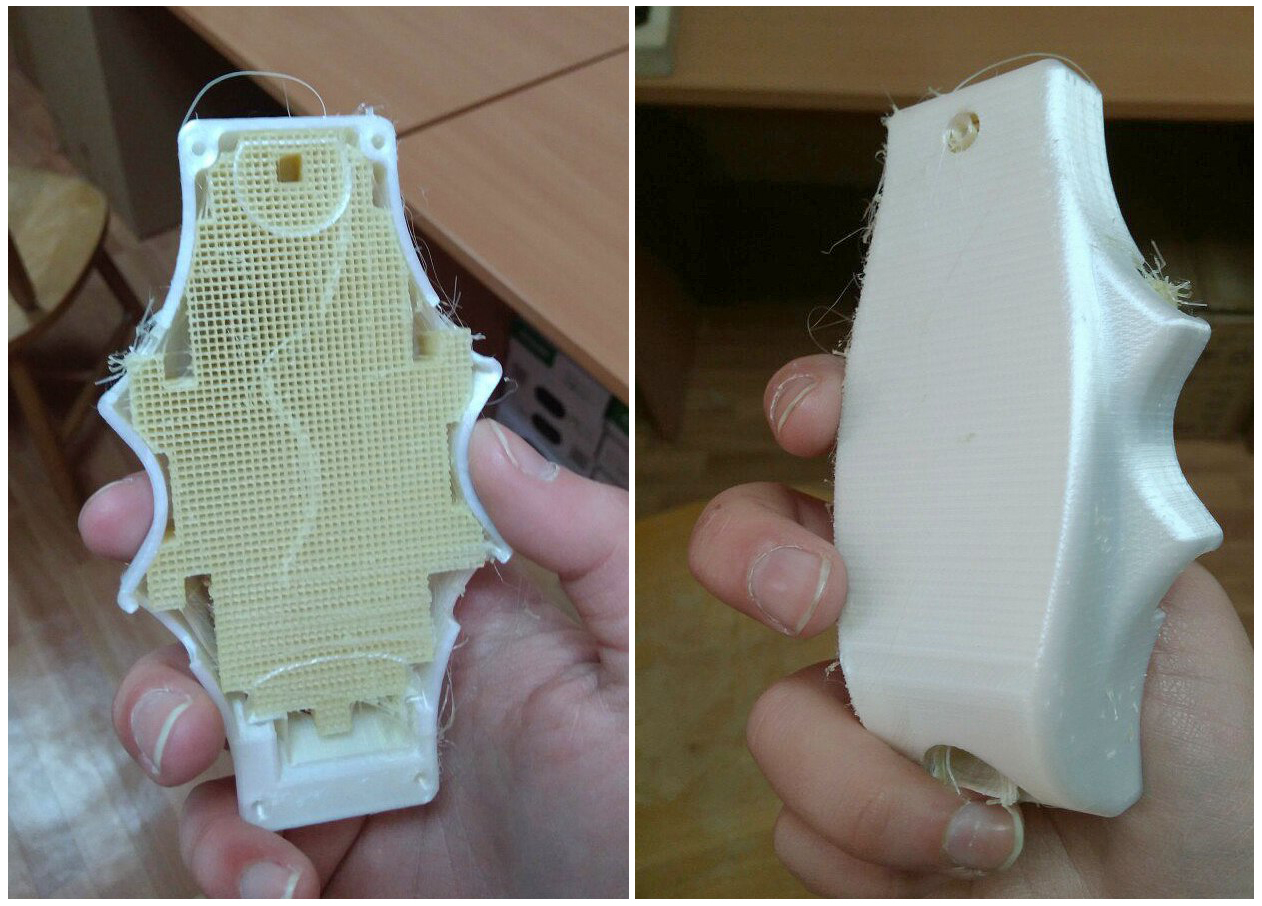

Layer 0.2, Makerbot ABS plastic, printing time almost 15 hours. Details for a small vice.

Themselves vice. Esun Green ABS, Fiber Force Carbon Black and soft NinjaFlex red =)

Layer 0.15, PLA plastic, Esun PVA support.

Soft Flex from ESUN. Layer 0.15

Mask of the Joker. 5 pieces. PLA, layer 0.15, printing time of one piece from 9 to 12 hours.

In the future, the mask will look something like this.

Results

Working with a printer was nice.

The printer is very quiet! This is the quietest printer that we came across. This will be a very big plus if you are going to buy a printer home.

In the printer slicer - ideaMaker the Russian language has now appeared. For beginners, this will be a huge plus, and will help not to get confused in a huge number of settings.

By tradition, a minute of advertising)

Buying equipment in our company, you get 10 advantages:

1. Ability to use the program Trade In.

2. Warranty - 12 months

3. Instructions in Russian

4. Technical support during the whole period of operation.

5. You buy a 3D printer from an official distributor in Russia.

6. Free shipping.

7. Free training in our office.

8. The ability to buy a printer on credit through banks TKS, OTP, Renaissance.

9. 10% discount on plastic forever.

10. The opportunity to see the printer in our demo room.

The review was prepared by the specialist in 3D printing of Color World company, Anna Panfilova.

Subscribe to our groups on Facebook, VK and YouTube to keep up with the latest events.

Shanghai Fusion Tech CO., Ltd. ("Raise3D") assembled an excellent team of young graduates from leading universities and started their work 3 years ago, creating a series of Duplicator 5 printers for Wanhao, and the IdeaMaker software was also created specifically for this model. In October 2015, the company announced the creation of a line of printers under its own brand Raise3D and launched a fundraising company at the KickStarter site. The company became very successful, 445,892 USD were collected from 348 customers and in March printers were sent all over the world.

To date, Raise3D produces 3 models of 3D printers of the N. line.

')

The cost of printers: Raise3D N1 Dual 3D printer - 165,000 rubles, Raise3D N2 Dual 3D printer - 225,000 rubles, Raise3D N2 Plus Dual 3D printer - 315,000 rubles.

But we will have a review of the youngest model Raise3D N1 Dual.

Since the delivery of the printer began recently, there is little information about it yet, we will try to fill this gap.

Packing / packaging

The printer is packed quite soundly. And it is completely capable of surviving Russian transport companies without loss.

Here you can see the video unpacking and a detailed analysis of the configuration.

It should be noted that the equipment is very generous. In addition to the “gentleman's” set of 2 coils of plastic and a spatula, the kit includes a scattering of spare parts and even a probe to calibrate the table.

Kinematics

With the mechanics, the Chinese decided not to reinvent the wheel and simply copied the mechanics of the famous Ultimaker, although from the point of view of various improvements they went much further, adding many unique features that you will not find in other 3D printers, even professional ones.

Shafts, belts, pulleys, brass bushings. No rails. Let's just say - a classic 3D printing. Reliable and efficient.

Few scared such a massive extruder on just 2 shafts. Although, as practice has shown, this is quite enough. Extruder unusually high. It is made for a more direct supply of capricious and soft materials.

Indeed, the printer "eats" soft flexs without interruption. Although, due to the large weight of the head, it cannot be quickly dispersed. But here you have to choose - either printing with any plastic or high printing speed.

Along the Z axis there are 2 guide shafts and ball screws.

No backlash, no loose. Z-stripes - not seen when printing.

I must say that the table is aligned with the help of 4 screws. 4 points of adjustment in my opinion is not the best idea - too much time and effort is spent on leveling the table, compared to the 3-point calibration system.

Older Raise models are factory calibrated. And the height of the table relative to the nozzle is set with one screw.

Housing closed on all sides. This is a very big plus when printing with plastics that shrink. (almost all plastics with a print temperature of 240C and higher).

But be prepared for the fact that, over time, scuffs from the wiring harness will appear on the cap.

This has no effect on print quality, but some were very worried about this issue =)

From the factory, the printer comes with a slightly raised right nozzle. Calibration of nozzles in height was quite simple. We send the table “to the house”, set up the table on the left nozzle, insert the dipstick and unscrew one screw. The nozzle itself falls into the probe).

I unscrewed both screws so that the nozzles were exactly at the same height.

Control is carried out using the touch screen tablet.

More precisely, it is a mini-computer with its own battery. During a sudden power outage, he will remember the place where the seal was broken and, when turned on, will offer to continue printing.

And of course the print results.

Layer 0.2, Makerbot ABS plastic, printing time almost 15 hours. Details for a small vice.

Themselves vice. Esun Green ABS, Fiber Force Carbon Black and soft NinjaFlex red =)

Layer 0.15, PLA plastic, Esun PVA support.

Soft Flex from ESUN. Layer 0.15

Mask of the Joker. 5 pieces. PLA, layer 0.15, printing time of one piece from 9 to 12 hours.

In the future, the mask will look something like this.

Results

Working with a printer was nice.

The printer is very quiet! This is the quietest printer that we came across. This will be a very big plus if you are going to buy a printer home.

In the printer slicer - ideaMaker the Russian language has now appeared. For beginners, this will be a huge plus, and will help not to get confused in a huge number of settings.

By tradition, a minute of advertising)

Buying equipment in our company, you get 10 advantages:

1. Ability to use the program Trade In.

2. Warranty - 12 months

3. Instructions in Russian

4. Technical support during the whole period of operation.

5. You buy a 3D printer from an official distributor in Russia.

6. Free shipping.

7. Free training in our office.

8. The ability to buy a printer on credit through banks TKS, OTP, Renaissance.

9. 10% discount on plastic forever.

10. The opportunity to see the printer in our demo room.

The review was prepared by the specialist in 3D printing of Color World company, Anna Panfilova.

Subscribe to our groups on Facebook, VK and YouTube to keep up with the latest events.

Source: https://habr.com/ru/post/370307/

All Articles