Opinions: Is it true that ultrasound machines are unnecessarily expensive?

The first part of the article is a post from the site Medium , where software developers and blogger Graham Jenson express their opinions about ultrasound. In the second part, the author of the blog “False lies, blatant lies and advertising of startups” [Lies, Damn Lies, and Startup PR] engineer Paul Reynolds, who has extensive experience in developing and creating these devices, argues with this opinion. He wrote a refuting post , and then in another post answered questions posed by his readers.

Why ultrasound machines are so expensive (Graham Jenson)

What technology is more useful, more knowledgeable, more interesting and more expensive than an ultrasound machine? He can look inside living beings without powerful magnets and X-rays, and he made, in fact, from the speaker and microphone, which gives the results on the screen.

Why is there no ultrasound in every biology class in every school so that you can see how muscles work and the heart beats? Why ultrasound is not at hand with the doctors, along with a stethoscope and a thermometer? Why can not I buy such a device, just to watch how my injuries heal? Probably because inexpensive devices are worth £ 20,000 ($ 30,000) .

')

After I gave $ 200 for my visit to the doctor with my injured leg, and I was examined on an ultrasound machine the size of a cabinet and looked like a TV from the 50s, I wondered how much money I could buy such a device. Having found a “cheap” device for $ 8,000, I could not link the cost with technology, simplicity and utility of such a tool.

So I did a little research.

Measuring transducer

The transducer is a ceramic with two pieces of metal on each side. If you compress the converter, it produces an electric current. If you let the current through the contacts, it moves the converter. Ultrasound requires a little more than a dozen transducers operating at a megahertz frequency. To achieve the necessary resolution of them need to build an array. For such purposes, lead zirconate titanate, or PZT , is most often used.

When the current is applied to the converter, it expands, the reverse current causes it to compress, and if you do so periodically, you will get a wave whose length will be approximately twice its thickness. Since the speed of sound in ceramics is 3200 m / s , and for a wave of 5 MHz, the length will be 0.64 mm , therefore the PZT thickness should be around 0.32 mm. This is quite a bit.

Manufacturing transducers with the required accuracy is, apparently, the reason for the high cost of ultrasound, since stringent requirements are imposed on each transducer, and many are required for ultrasonography. They are expensive, and since they require 20 pieces, they quickly increase the cost of the device.

The cheapest megahertz PZT transducers I have found cost $ 12 each . This means that an ultrasound scan with 20 transducers should cost more than $ 200, and an array of 40x40 PZT to get three-dimensional images should cost $ 19,200.

To reduce their cost, you can try to make the converter yourself. Is it possible to do it yourself? Here are some resources dedicated to this issue:

• The man himself makes converters from barium titanate .

• People try to print integrated circuits at home .

• Thesis on the creation of PZT films .

• A way to make “inexpensive high density PZT-array”.

• Description of the manufacture of flexible PZT-array .

• An array of 64 elements at 35 MHz for high resolution images .

One of the ways to produce PZT-array is using the cutting and filling method. You can make individual converters, dropping the PZT into ethanol and then spraying it onto the metal. After evaporation of ethanol on the metal will remain a thin film PZT. But this will require special equipment, and for building an array it will probably be easier to find a laboratory or a manufacturer with experience - but this is not so interesting.

Iron and software

A computer capable of working with a megahertz converter costs little today - for example, GPIO contacts on Raspberry Pi can do this. The screens are very cheap, and in general you can make a conclusion on the phone or home screen. Also, I do not think that the calculations carried out in the device, or its display can be very expensive.

Software can be expensive, but this is because each ultrasound machine uses its own, special, closed software. If there were a standard hardware platform for which software could be made, with standards and APIs, this would greatly reduce the cost of the devices. There are attempts to create an open architecture ultrasound , but I do not know how they entered the masses.

Perhaps most of the cost of the hardware and software part of the ultrasound is due to the need to obtain medical certificates. Jes user from Hacker News wrote :

Some specifications that need to be met are ISO 13485, ISO 14971, IEC 60601 3rd edition, IEC 62304, and maybe a dozen more that I forgot about, such as RoHS, WEE, radiation, and so on. If you measure the length of the embryo thigh and calculate from it the approximate fetal age of the fetus, you would not want to be mistaken in this.

Creating any medical device can be very expensive, but it can also have other uses: education, imaging, sports training, and entertainment. The trick 22 is that in these areas ultrasound will not be used because of the high cost of the devices, and they will not become cheaper until the market for them grows beyond health care.

Who does something with the problem of expensive ultrasound

Newcastle University is working on a $ 40–50 ultrasound scan , and this work has attracted media attention . They reduced the cost of the apparatus using one movable transducer for imaging.

The company Butterfly Network Inc is trying to create a device for ultrasound on a single chip, which will cost no more than a stethoscope. They received $ 100 million in investments , and I hope they will be able to create an amazing technology, thanks to which everyone can order an ultrasound scan.

The Phillips Lumify project is a handheld device for ultrasound, connecting to a smartphone / tablet. It looks cool. But for now, not everyone can buy it .

Murchen echOpen and its offshoot are open-source projects developing a device for ultrasound and a development kit. Such projects can really help reduce the cost of ultrasound, giving access to technology to programmers and engineers.

More links for self-study:

• Basic principle of medical ultrasonic probes

• Phased Array Ultrasonics

• Pocket Ultrasound

• How does medical ultrasound imaging work?

• How to use an ultrasound machine

• Mobile Ultrasound Device with video

• Principles of Ultrasound

Reciprocal post, part 1: "Why ultrasound is so inexpensive", or "you always find it easy when someone else does the work" (Paul Reynolds)

Recently, Hackernews has a link to a post with Medium, discussing the high cost of ultrasound machines. I have been working in this industry for over 20 years, and ultrasound is my main area of expertise. Unfortunately, the mentioned post belongs to the category of those written by a specialist in another field. Such specialists often become victims of the illusion that their knowledge in their field extends to others, they do not appreciate the complexity and difficulties of others, and as a result, they miss many subtle (and not so) moments of incredibly complex technological field.

Making the article sounds like “why does a cheap ultrasound system cost $ 30,000 if I can buy inexpensive parts and assemble it very easily? It's not difficult, I figured it out in a couple of hours! ” And although premium ultrasounds may cost as much as $ 150,000 (which is a small fraction of the cost of CT and MRI systems), there is a reason why ultrasound is the most common system for imaging in the world. So let me refute the claims about its simplicity and excessive cost.

What is my knowledge to comment on articles in this area? My doctoral thesis was devoted to the modeling, development, construction and testing of ultrasound. For 13 years I led a consulting group that produced industrial software for ultrasound, as well as participated in many projects to develop and build ultrasound devices for various areas, including medicine. I am the chief editor assistant at IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, the leading journal in this field, and also served as chair of the IEEE Ultrasound Technical Program Committee for Transducers for ultrasonic sensors). I worked with the largest suppliers of ultrasound equipment in the world, as well as in small companies. I created and released commercial software and supported it for years. There are not many people who have such experience and are able to appreciate the technical details of the hardware and software.

All my thoughts relate to general things, not tied to a particular company, so I do not disclose any proprietary or proprietary information. For those interested in this issue, I highly recommend the book by Tom Zabo [Tom Szabo] " Diagnostic Ultrasound Imaging: Inside Out ", where a wide range of questions on this topic are popularly described.

First, in one paragraph, we refute the argument about the cost of ultrasound, using the basic economic principles. If you can build an effective ultrasound machine that people want to buy, less expensive than those available on the market, and you have no experience in this area - then why has someone more experienced not built such a device? Why none of the major companies collapsed prices to capture the market? If there is a cartel agreement between price-keeping companies, why the government has not condemned them (believe the person who worked in the companies - they are paranoid about compliance with the rules, do not take kickbacks and try not to do anything that looks illegal). Later I will describe the rules of the Food and Drug Administration (FDA), but for now I’ll say that although [converters] add value to the product, these are not major expenses, and, of course, you don’t need to use such devices without observing safety precautions.

I was creating hardware and software, and although software is also hard to do, equipment is harder to make. If you make a mistake while developing the equipment, you will not be able to recompile the program and in an hour get a new product, your rework and rebuilding take weeks or even months. The equipment sent to the client should work, it cannot be fixed in the field with an update, it cannot be delivered with a user agreement, which states a disclaimer of warranties or declare that it is delivered “as is”. It needs to be maintained where it works, sometimes for decades. Software can be developed on a laptop while sitting in a small room, but hardware development tools can be large and expensive, and their maintenance also costs money. When developing software, you have no problems with suppliers changing materials, formulas, prices, or even leaving the business and leaving you without spare parts. To protect yourself from these risks, you need specially trained people who are also worth the money.

Then we go to the technical part. An ultrasound system consists of three main components: an acoustic transducer (transducer or simply a sensor), a system, and software. The sensor is what you hold in your hand, it contacts the patient and transmits / receives ultrasound. For each system there are several options for sensors, each has its own scope, and therefore the system must be able to support a wide range of such sensors.

The sensor is connected by cable to the system, which has all the necessary electronics, which receives signals, converts them into a picture, gives the doctor the opportunity to change the settings of work, etc. The system works under software control and displays a picture on the screen, although nowadays the boundaries between hardware and software are a bit blurred. In hospitals, such equipment is usually transported on carts, although there are more compact (and limited) systems.

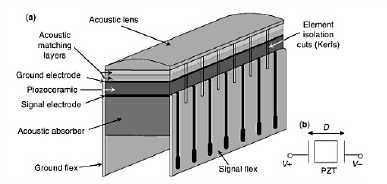

Consider a transmitter. Pictures are taken from quite good presentations ( 1 , 2 ).

The first shows the lenses (part in contact with the patient). It focuses the ultrasound and weakens it so as to avoid skin-level reverberations, which could cloud the picture - but without excessive weakening so as not to lose the signal. It must provide good contact with the patient, must be thick enough to serve as an insulator, and strong enough so that it can be cleaned, disinfected, sometimes dropped, and subjected to other influences for many years. The thickness should be the same over the entire surface, the deviation of a few percent of the wavelength will already distort the image. In this case, the wavelength of ultrasound is about 100 microns. But this is easy to do, isn't it?

Then there is a matching layer, transmitting ultrasound from piezoelectrics of high acoustic impedance to the body with low impedance. Today there are schemes with several layers, each of which must be a certain thickness, density, stiffness and the amount of signal attenuation. Sometimes they must be conductive, sometimes - insulating. They must also be machined and have a constant thickness, like lenses.

Then there is a piezoelectric active material that converts electricity into vibrations and vice versa. It must also have a certain thickness that does not vary over the surface, with an accuracy of microns. The material used is important - cheap options have different thickness and they do not work well, and those that strictly follow the specifications and work well are expensive. It must not lose its piezoelectric properties at operating temperatures and withstand strong electromagnetic fields. Piezo ceramics such as PZT have been used since time immemorial, but today, to create modern image generation modes, a piezoelectric on a single crystal can be used - it is harder to work with it, it is more expensive, but its performance indicators are better. Polyvinylidene fluoride, sprayed materials and cheap PZT, which buzzers are made of, are not applicable in this case.

Then there is a backdrop, a material that absorbs the necessary amount of acoustic energy so that the device receives a short pulse coming from the front of the sensor and used to build the picture, but at the same time absorbing it not so much to weaken the signal too much. It usually needs to be made from a dielectric, and its weight should not be a burden to the doctor.

After that, all parts need to be stapled together. The bond line should not be very thick, so as not to interfere with the passage of sound, but also not very thin, so that all layers stick together tightly. These must be micron thick bonds that do not vary throughout their area. Just right?

Let's do an acoustic stack. It can be divided into several elements involved in creating the image. Yes, they require a lot of different - in most sensors from 100 to 200 elements. The device with 20 elements, which was mentioned in the previous article, is useless for any serious applications. Moreover, all these layers and piezoelectric elements must be isolated from each other electrically and mechanically, not too thick and not too thin insulation.

Then you need a flexible circuit that transmits signals from and to each element, and it must correspond to these elements with an accuracy of 100 microns (yes, and the size of each element is no more than two human hairs), and then the circuit must be connected to cables leaving the system. All 100-200 wires go along a cable that is a couple of meters long, and it should be light and thin enough so that the doctor can use it eight hours a day without overstretching the muscles. Can you imagine how thin the individual wires are? Call the cable vendors and ask them for a small-diameter, 200-pin cable that conducts a signal without interference, and you will know its price.

All this must be placed in a case that is ergonomic enough for a doctor, large enough to accommodate acoustic equipment in it, small enough to be not very heavy and smooth enough so as not to harm the patient. And among other things, he should not overheat yet, so that neither the doctor nor the patient will suffer.

Simply!

Y-yes. And I described the simplest version. I didn’t go deep into multilayered sensors, a curved substrate, exotic materials, electronics devices in a pen, dimensions of each section necessary for working with acoustics, spectral responses, temperature characteristics, appropriate electrical impedance, and all the other difficulties that we have to deal with. creating and selling such devices in reality.

And, I still forgot about universality, reliability and cost. These devices must work for years, must be compatible with each other, so that the system can generate pictures with their help, so that the user would not notice the difference, and should be cheap enough so that the user could buy them and the manufacturer would make a profit. Have you ever created a prototype? 2 prototypes? four? 100? 10,000? And so they were all the same? Yes, deciding to sell and maintain products, you fall into another world.

And, I also forgot the testing for compliance of the devices with your internal specifications, FDA rules and other regulators so that they do not hit you with current and do not burn, and give out correct medical data so that you are not diagnosed incorrectly and prescribed the correct treatment.

And I still have not got to the system and software. Only the sensor requires the work of people versed in acoustics, imaging, clinical requirements, materials, equipment design, electronics, data processing, safety, work rules, user experience, reliability, testing, business management, and much more, you can’t list . Well, and still need to support employees, office, HR-department and admin.

All this requires tremendous knowledge and effort — such as if human lives depend on them.

I have a lot of experience in the design and construction of such pieces. Could I create a company that would produce them and do it well? Yes. Could I make them much cheaper than others do? Not.

Putting it all together and get an incredibly complex electromechanical product, with micron-scale components, with requirements for long-term work for many years, reproduced without being able to take advantage of economies of scale (there are no millions of devices), based on the testimony of which decisions affecting human life. And this is only a sensor. Therefore, in fact, you need to ask, "why are ultrasound machines so inexpensive?"

Reply post, part 2: answers to questions on the first post

First, go through the technical issues. When in the text I mention the conference, I mean the symposium of the international ultrasound community IEEE UFFC .

1) But what if you put more electronics in the sensor and use the GPU to form a beam?

Sensors are really moving in this direction. After Philips introduced the first true two-dimensional array in 2003, working by means of a subarray that forms a beam of electronics in the sensor, there have been advances in this area. It is important to understand that the development of electronics (usually ASIC, a specialized integrated circuit) used in only one sensor is a huge investment of money, man-hours and time. And still it is necessary to integrate all this in the acoustic stack and make everything work smoothly. This kind of product is quite a large team developing for several years, and although the development of electronics makes this task easier for 2016 than for 2003, it is still a very big task. All large companies already have their two-dimensional arrays, but they have to offer serious advantages of using two-dimensional arrays instead of one-dimensional, since the first ones, as you might guess, cost much more.

In addition, replace the one-dimensional array with a two-dimensional one, and you will immediately get new difficulties in data processing - volumes instead of planes, thousands of individual signals instead of 200. More computing power is required, and although over the years the volumes of available power are growing, so are requests. At some point, the available computational volumes will economically overtake demand, but so far this has not happened.

What about ordinary, one-dimensional arrays? Of course, you can also push more electronics there, but remember that in one system 10-20 types of sensors are supported (cardiac, abdominal, vascular, obstetric, etc.), and that it is more logical to make a single system that has a common equipment capable of servicing many sensors, or copy the same electronics for each sensor to simplify the system? Economically, now it makes sense to collect all the common components in the system, but if the electronics become cheaper and better, then the equation changes. Now this option is being considered.

Here there are specifications of the open platform Verasonics, good equipment for those who want to learn, test and develop ultrasonic equipment, although commercial premium systems often have higher specifications. Discretization to 62.5 MHz, 14-bit, 256 channels - this is up to 224 Gb / s, or approximately one Blu-ray disc per second. Thunderbolt 3 supports up to 40 Gbps, so compare and feel the difference. No matter how good modern electronics are, the demands of top ultrasound devices are still higher. Over time, this will change.

We also note that this system supports voltage with a signal sweep of up to 190 V, which means that it is impossible to use chips produced according to technical processes of minimum values. This means larger electronics and a higher cost - and this is unlikely to change in the near future; fundamental physics imposes its own limitations (perhaps, before the appearance of new materials). In recent years, improvements have been achieved with the help of piezoelectrics on a single crystal , but now nothing like this is visible on the horizon.

There is also the issue of heating. Electronics heats up. A few watts in a small handheld sensor can seriously raise the temperature and burn a patient or doctor. There are strict rules for the maximum heating of the sensors, and the quality of work is always limited by these rules - the sensor works worse than it could for safety. If on each channel the electronics gives out 50 mW, then 200 channels will give out 10 W, and this is too much. But if the electronics produces only 5 mW, then the total will be 1 W, and this will be more interesting. If it were possible to manage such a low consumption, then the argument would be transferred from the practical plane to the plane of size and economy.

Now about the formation of the beam.For a start, those interested can see a great presentation. . 2005 , , . , . ( 224 /), , , . « , – ». . GPU , , , , . , , .

From the point of view of electronics, the process is underway, but some peak ultrasound requests indicate that it has not yet reached, or is only reaching the desired condition. At the same time, there are growing requests for devices with two-dimensional arrays of converters. After 20 years, the ultrasound ecosystem will change, the cost and speed of electronics will shift the load between the system and the sensor.

2) What about micro-production or 3D printing?

Another great question, and research in this direction has been going on for the last 20 years. Research into the use of microelectromechanical systems (MEMS) in ultrasound has been funded by companies for more than 20 years. For example, in the early 1990s, cMUT (capacitive ultrasonic MEMS transducers) were declared the “next stage” of ultrasound, and today, in 2016, apart from narrow applications, such devices are only beginning to enter the market. And this is not due to lack of effort, the technology just did not work as expected. Many problems have arisen, some of which have been solved, but now they cannot yet compete with piezoelectronics and standard production in price and quality. We still need to work on them, and if they can be improved, increase reliability and reduce the cost, they will penetrate into many areas of application.

pMUT ( -) , , cMUT. , . , , , (FBAR). , , , .

3D-? , , . GE , and she, along with other companies, is already making presentations on this topic. So it's still in the bud, but new production methods are coming, and they will help improve performance, reliability and prices.

3) I can buy parts for $ x in the store, why does the system cost more than $ x?

Because building a reliable and proven platform, based on the use of which it will be possible to make medical decisions, requires a lot of effort and man-hours. This is so for any product, and even without compliance with the conditions of regulators. If you do something bad, you will sell one copy, and the business will not go, and rumors spread quickly. In an area filled with competitors like ultrasound, you will quickly lose prestige and leave the stage. Each sensor must support several image generation modes - b-mode, harmonic, Doppler, etc. - and for each of them it takes time to program and approve. Then you will need to support it, satisfy customer requests, pay your employees so that they don’t leave to develop the latest mobile application for social networks.and create a new generation of improved systems. In essence, these are standard costs and problems for any long-term enterprise. And, also profit, supporting companies afloat, ensuring the manufacture of new products and the emergence of advanced technologies.

In fact, innovations are coming, but this is not as easy as you think, this is not a microphone or a smartphone, which can be thrown out after a couple of years.

If you want to learn and participate in our industry, then welcome - there is always a place for those who help improve ultrasound technology. You can send a message to me, as I have great connections and I can connect you with the right people.

4) You did not make a price list for all components in order to prove that the price is not too high.

First, such an article would look more like a list of prices, and I tried to clearly describe what is involved in the creation of such a system, and that it is not as simple as you think. The prices from the article on Medium were based on certain statements about the simplicity of ultrasound technology, and I wanted to explain why the task of creating such devices is actually complex and multifaceted, requiring various trade-offs. For a professional, it sounds like “I can build a minicar [a children's racing car without a motor - approx. transl.] for $ 100, and if you put a motor in it, it will turn into a car! Why does automakers fight for $ 50,000 for cars ?! ”

Secondly, I have to carefully mention the prices and the possibilities of technology. I worked for different manufacturers of ultrasonic equipment, and I have to take care not to let the commercial secret out of my heart, so I act carefully and check that everything I write about is public.

And finally, the market is highly competitive, and the fact that there are no low prices for equipment says that there is something to pay for and that the prices are adequate. If you think that the market is not competitive, I do not know how I can convince you. I will try in the next paragraph.

5) Equipment manufacturers organized cartels and keep prices high

Such statements surprise me. I have been working in this field for more than 20 years and have never seen a hint that something similar is present in the field of ultrasound. Everything points to strong competition. The market has a volume of about $ 6 billion with several major players of international scale (here is a list of the largest players, here is a list of smaller players , here is a studywhere 25 companies are mentioned), and is regulated in such a way as to ensure that there are no price agreements, cartels, or other non-market manifestations. In the ratings of the company constantly change their places, each is looking for some legal advantage in technology or value. Medical use of ultrasound is also very much regulated, and many countries, especially the United States and in Europe, will be very hard hit by a company found to be in non-market behavior.

In each of the companies where I worked, I felt serious pressure to improve quality and reliability and at the same time lower prices. If you study today's systems and compare them with the old ones, you will notice both serious improvements in the top models, the price of which remained at about the same level, and the appearance of devices at relatively low prices, the capabilities of which exceed yesterday's systems.

If someone launches a company that produces high-quality ultrasound systems in large quantities at a low price, then I guarantee that this company will be bought by one of the major players who incorporates it and takes advantage of the technology. So, if you really believe in a conspiracy and that the ultrasound systems are very easy to do, then start your company and use that easy profit that everyone else misses. Even better, I will personally help you. Seriously, write to me, tell us what we are doing wrong, and I will either hire you, or find you a job in the industry, or organize a joint company to make millions. And if you are sure that there is a conspiracy, I will give you the contacts of various regulators in different countries, who will be happy to get acquainted with the evidence you have that can be used in court.

Few areas in which companies operate in a market with so much competition, unfolding among many big players. This is not an option in which " Intel owns 99% of the server market and competitors do not force it to lower prices, " it is more like the automotive industry, in which many participants compete.

6) Engineers do not understand what they are doing, and pass by the obvious things that could make the product faster, better and cheaper.

— , . , , . , , , . , , , , , . , . , - , , .

There are many professional organizations dedicated exclusively to ultrasound, mainly for medical use. One of them is the IEEE UFFC , in which I am also quite involved. IEEE is a non-profit organization dedicated exclusively to technology; it does not support any commercial companies or anyone’s interests. She publishes journals with peer-reviewed articles about the leading edge of the development of converters, materials, electronics, systems, and image creation. Every year she organizes conferences where a couple of hundred people discuss and learn best practices and technologies. This year I saw presentations3D printing converters, new materials, fast image creation via GPU, micro-production, advanced electronics for sensors. Companies spend mountains of resources on research on these topics, graduate students protect doctoral work on them, and gradually these new products are included in final products when the technology matures and becomes cost-effective and reliable.

7) The entire cost goes to compliance with the rules, without the FDA, these machines would have cost less at times!

It is difficult to refute, not citing internal figures from different companies, and I will not do that. I know that the cost of compliance with the rules, but it is not included in the list of the most costly articles. To comply with the rules and restrictions, engineering tests and documentation are required, but nothing that a good team of engineers interested in producing a safe device would have done itself. And the presence of clear rules, uniform for all, allows competitors to play in equal conditions.

, AliBaba -, . , , , , , - . , , -.

, – , - FDA .

8) !

, , – , . , , , . - , . , , , , . , , , , , . , 200 , , , .

9) , – - ?

Every year several million phones are sold, which is about 4 orders of magnitude more than ultrasound systems. On average, telephones live from 18 to 24 months, and ultrasound machines last ten or more years. The quality of the phones does not depend on people's lives. For ultrasound systems there is no economy of scale. Perhaps this is reminiscent of a dispute about what came first, the chicken or the egg, and that the “ingenious mobile application” has not yet come out, because the ultrasound system is too expensive, but if there is a demand, then the technology will come. Do you have such an application? As some have mentioned, there are rumors that Butterfly Labs is working on just this, but, despite all my connections in the industry, I have not heard anything about what they have been doing for several years now. I hope they will give out something amazing, but until then it is not necessary to apply economies of scale from the smartphone market to the market of ultrasonic devices.

Source: https://habr.com/ru/post/370021/

All Articles