Electron microscope in the garage: Vacuum

For those who are not yet aware of the project - you can read here .

Thank you for the positive response to the first part , for offers of help, which were received both by personal messages and in comments. I can not exactly promise the release date of the new series, but I will try to please you at least once a week.

I also have the idea to record thematic videos about the project. Made a trial version of the internal device fore pump for this article. In this video there is something to improve: you need to replace the light in the garage, use a good microphone. I will follow the comments and views to see how much you like it.

')

Vacuum is a whole new world where familiar materials behave quite differently. Ordinary water in a vacuum instantly boils and evaporates even at its own temperature of about zero Celsius (at the same time making the vacuum not such a vacuum).

In general, in a vacuum, everything passes and evaporates: even metals, the question of vacuum depth and temperature. Just imagine that a conventional rubber seal lets through a significant amount of gas in order to prevent vacuuming. Not somewhere through the gap, but through the rubber itself. Or, for example, the flexible hose, besides passing air through itself, also evaporates slightly by itself. And the inner surface of the vacuum chamber accumulates gas in its roughness, and therefore it is usually polished. All this is very unusual to understand.

Under the vacuum, many interesting scientific instruments work: mass spectrometers, Auger spectrometers , sputtering installations, elementary particle accelerators, lasers, and, of course, various types of electron microscopes. Common household items in which there is a high vacuum are a thermos, a cathode ray tube of a TV or monitor, various types of electronic lamps.

In this article there is a visual description of everything necessary so that you understand the subject and, of course, further progress in the restoration of the microscope!

The column of this microscope is designed for high vacuum of the order of 10 ^ -5 Torr . In the environment of vacuum workers, it is customary to designate millimeters of mercury as torr, or to use units of measure for pressure — Pascal and millibars. Personally, I'm used to torr.

How to measure the vacuum is actually still a little problem! A conventional membranegauge vacuum gauge will show at best from 750 to 1 Torr, and the difference between 1 and 10 ^ -5 Torr is intangible for it (various sources indicate that it is possible to measure vacuum up to 10 ^ -3 Torr with membrane vacuum gauges, but in practice I did not come across).

Why is this difference so important? Because school physics stops working at this pressure. Let's try to visualize a vacuum of various depths:

You can visually compare the movement of molecules in a solid, liquid and gaseous substance with the help of these animations taken from here .

The free path of nitrogen molecules at atmospheric pressure is about 70 nm = 7 * 10 ^ -8 m, and the approximate size of the nitrogen molecule is 10 ^ -10 m.

Nevertheless, in spite of the fact that in the picture with the gaseous substance the molecules fly a relatively long way, Pascal's law works, and the pressure at any point in the gas will be the same.

For achieving this level of vacuum, foreline vacuum pumps are used.

Here the most interesting begins: the physical nature of the gas inside the vacuum chamber changes radically (and there will always be gas, absolute vacuum is unattainable, see above for the evaporation of everything and everyone). And the gas molecules start to hit the walls of the chamber more than they collide with each other.

High vacuum pumps are used to achieve this vacuum level.

In this case, the amount of gas passing through the rubber seals plays such a significant role that you have to switch to special flanges with copper seals .

To achieve this level of vacuum, special getter pumps are used. They do not pump the gas into the atmosphere, but absorb it (they transfer it from the gaseous phase to the solid by chemical means).

This is one of the most difficult levels, and fortunately, most old microscopes do not require such a vacuum level. In the new and most advanced devices, such a vacuum level must be maintained for the operation of field-emission cathodes.

Space vacuum depends on location. In the orbit of satellites (300km from the Earth), the pressure corresponds to ultrahigh vacuum. For comparison, in the interstellar space the vacuum is 10 ^ -17 Torr. But the fact is that even in this space there are still rare hydrogen atoms, many photons and other particles.

There is no perfect vacuum even there.

There is such an idea: you can try to heat the wire and observe its temperature. After all, the less pressure, the less gas molecules this wire can heat. This is how thermal vacuum gauges appeared (thermocouple, Pirani sensors ), which measure vacuum from ~ 0.5 to 10 ^ -4 Torr with a sufficiently high accuracy, but, obviously, by a large inertia.

To move deep into the measurements, you need to use the following idea, which sounds much more complicated than heating the wires, but is widely used. We bombard the gas with electrons, and they, colliding with gas molecules, ionize it. These positively charged ions are attracted to the collector, and thus a very small current flows in this “circuit”, the value of which is directly proportional to the pressure (the lower the pressure, the lower the current, because there are fewer ions carrying a positive charge).

This principle of measurement is called so-ionization, and allows you to measure a vacuum of 10 ^ -3 Torr (just the lower practical limit of the thermal vacuum gauge) to 10 ^ -10 Torr.

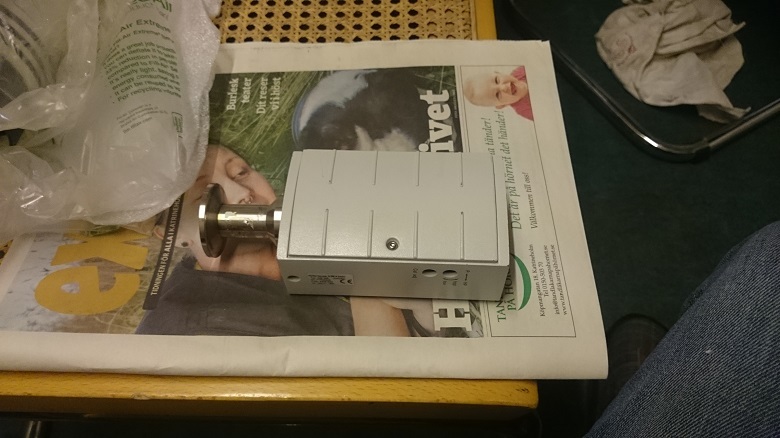

For a microscope, I managed to buy a relatively modern combined vacuum gauge (two sensors in one - Pirani and a hot cathode) at a well-known western Internet auction for not too much money ( new ones from the store can cost about 100 thousand rubles), which has an analog output and does not require additional devices except the power supply.

Probably, you already guessed that if the vacuum cleaner connected to the vacuum chamber could provide the vacuum we need, I would not write this post :)

Probably, you already guessed that if the vacuum cleaner connected to the vacuum chamber could provide the vacuum we need, I would not write this post :)

I searched for different sources, and found that a powerful household vacuum cleaner can give a vacuum of about 400-500 Torr.

If you connect the suction nozzle of a piston compressor, the result will be much better: about 100 Torr. But anyway, nothing useful will come of it. It is necessary to use special vacuum pumps.

An indispensable component of any vacuum technology is a special pump that can pump out up to 10 ^ -3 Torr in good conditions (hence the name). As a rule, it is a two-stage rotary vane pump that can provide that forevacuum pressure in the system. It is often used by installers of air conditioners to remove air from the system before freon is pumped into it.

NB! Cheaper single-stage will not work, their vacuum is much worse.

As a bonus, I made a video about how a small two-stage rotary vane forevacuum pump ITE Blue VAC works.

There are other options for fore-vacuum pumps, which are better (oil-free, for example), but are significantly more expensive (several thousand euros). While I do not have such equipment, so I can not make a full review. If I find it, I will definitely tell you in one of the articles.

If vacuum technology requires a high vacuum, then how many backing pumps do not put - the pressure does not fall below ~ 10 ^ -2 Torr (or 10 ^ -3 Torr, if you use a new pump with very good and expensive vacuum oil). To pump down below, you need to apply a high vacuum pump.

Two types of high vacuum pumps are common:

Looking at the turbomolecular pump device (TMN), you might think that this is a normal high-speed turbine, where each stage increases the pressure, and at the end everything flies into the pipe into the atmosphere. A diffusion works due to some kind of diffusion, yet they know what it is :)

No matter how wrong!

Both of these pumps are necessarily connected to the fore vacuum, and the inclusion of any of them at atmospheric pressure will lead to their failure. Oil burns in oil, and rotor discs burn in TMN.

Understanding how they work is easy if you imagine that they are not pumping a gas as a whole, but interact kinetically with individual gas molecules. The task of these pumps is to move as many gas molecules as possible from the high-vacuum chamber to the inlet of the foreline vacuum pump.

Despite their completely different device, they do it in the same way: they hit these molecules in the direction of their exit (respectively, the foreline vacuum pump inlet). But you need to hit so that the molecule really flew in the direction of the exit, and not slightly changed direction (the molecules are constantly in thermal motion).

The turbomolecular pump achieves this by a multitude of very fast rotating rotor disks, the blades of which hit the molecules so that they can fly to the blade of the next disk, which will succumb even more, and thus the molecule will reach the output. It is clear that just the length of the free path of the molecule determines the gap between the rotor and the stator. For atmospheric pressure, this length is 70 nm, and therefore need a foreline pump.

For future projects, I bought such a small TM pump from Leybold.

We can not say that it is completely oil-free, because bearings there are oiled. But, of course, in comparison with the steam-oil pump, the amount of oil that penetrates into the high-vacuum part is very, very small. The small size of the pump imposes certain requirements on the speed of rotation of the disks, which for this model is 72 thousand revolutions per minute. About 10 times faster than HDD. Therefore, TMS represent a danger, since ingestion of even the slightest pollution (sand, for example, or dust) can lead to contact between the rotor and the stator, followed by their destruction and the simultaneous release of kinetic energy stored in the rotor. Therefore, they are always written on them: for safety reasons, the pump casing must be firmly fixed.

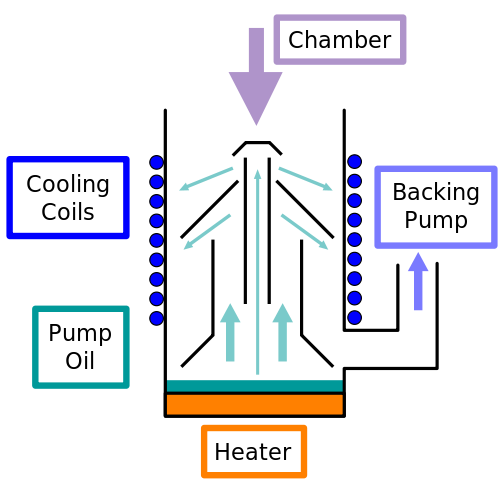

Schematically, the mechanism of work is presented as follows (from Wikipedia):

In fact, there are TMN, which contain two stages on one rotor: the molecular and a kind of pump Gede . They are structurally implemented in different ways, and allow you to make a completely oil-free system. This is very important for analytical work, but we will not go deep into the wilds.

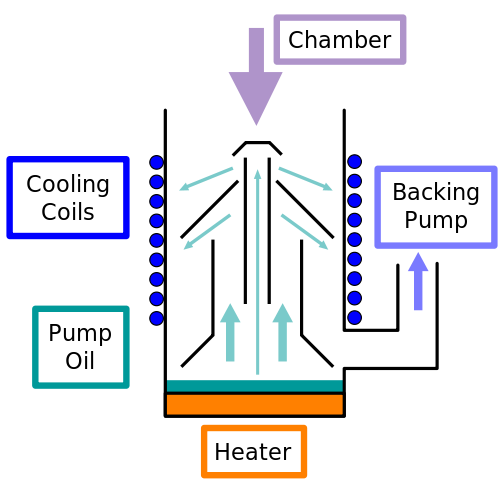

In the steam-oil pump, the molecules of the oil strike the gas molecules (hence the name KO), which fly out of the nozzle at supersonic speeds. It looks like a kettle, with a whistle that is boiling on the stove.

A picture from Wikipedia illustrates this. Oil boils at the bottom, in the center there is a cylinder with nozzles, of which the oil vapor “whistles”, outside - a radiator so that the steam condenses on the walls and flows down again in the form of oil.

In our column there is a steam oil pump, produced by the same company. When removed, it looks like this:

There was supposed to be a special heater at the bottom, for 600W and 100V, but it is not there, but there is a mounting stud. Therefore, I squeezed it into a small turning cartridge, so that the pump would sit comfortably on the table.

Then I will try to adapt something as a heater, or find among the readers who have one.

We proceed further to the restoration of the microscope.

Fortunately, the vacuum system turned out to be “complete”, including pneumatically driven vacuum valves, a set of air solenoids for supplying compressed air to the vacuum valves, two inlet valves (you can't just take and run air into the vacuum chamber through the fore vacuum pump - this will lead to contamination of the system with oil, moreover, it is necessary to let in slowly so as not to damage the thin vacuum sensors) and the steam-oil pump.

The original installation with two forevacuum pumps was not preserved, so a friend found a rotary vane two-stage fore pump for Soviet production 2HBP-5DM for this task.

We begin to revive the system with the only remaining electrical unit - this is a vacuum control panel with solenoids.

It looks quite old-school , which only adds charm. Having examined the entire system, finding power connection points (not rocket science, with just a dozen toggle switches) with constant 24V, I tried to click the valves that no one had clicked a long time ago:

On the left - a valve for supplying compressed air to vacuum pneumatic valves, on the right - a vacuum control panel (original). All, of course, after washing and drying.

We connect the compressor with the receiver, give the pressure in the pneumatic system of 4 atm and try to connect one vacuum valve (2 minutes of sticking valves for true connoisseurs):

This is already a great source of inspiration to continue working!

The column of this microscope is regularly equipped with two fore-vacuum pumps. Why two? The instruction does not give an unequivocal answer, and after much deliberation and after I managed to fully understand the scheme and algorithm of the vacuum system, I probably found a clue (comments are welcome!).

It was in 1970 (more than 40 years ago, can you imagine?), And backing pumps then did not have great performance, and working with a microscope directly depends on how quickly the column can be pumped out, i.e. get in her high vacuum.

Therefore, as I think, Japanese engineers have designed such a system:

I do not have two fore pumps, what to do? (or rather, there is, of course, but the second is ancient and broken, and it must be repaired, and the third has too low performance). But there is one powerful 2NVR-5DM .

After some thought, I decided to make a vacuum tee myself. Plus one in the list of turning work.

All this needs to be connected with hoses. Ordinary hoses will not go (you remember that the vacuum is a thin thing), they will either shrink or evaporate. And small pieces of old came in complete disrepair.

I decided to buy new ones , since there is even an online store in Moscow that sells specialized vacuum equipment. Prices, to put it mildly, bite, but it was not enough meters, I took with a margin and at the same time scored a little more KF connections and sealing rings.

The various things mentioned in this article were found at a relatively reasonable price, or donated by kind people who share the idea of the project - to share the knowledge and experience gained.

For the sake of interest I will write you the prices and the origin of these devices and materials.

- 7 thousand rubles - hoses and vacuum fittings from the store Aktan in Moscow, Russia.

- $ 150 - combined vacuum sensor Pfeiffer from the USA.

- $ 300 - Leybold TMP50 turbomolecular pump from the USA, from the same American. But for some reason, he asked for too much money for the controller for this pump, so I decided not to rush to buy it yet.

- $ 110 - 0.25l of high-quality oil DC704 for a diffusion pump from Riga, Latvia.

- Three fore-vacuum pumps - gifts from two different people.

- Vacuum oil canister for forevacuum pumps - a gift from the same person.

In the next series - turning and milling work on the manufacture of all adapters and caps for the microscope.

As always, I welcome your suggestions and comments. See you again!

Feedback

Thank you for the positive response to the first part , for offers of help, which were received both by personal messages and in comments. I can not exactly promise the release date of the new series, but I will try to please you at least once a week.

I also have the idea to record thematic videos about the project. Made a trial version of the internal device fore pump for this article. In this video there is something to improve: you need to replace the light in the garage, use a good microphone. I will follow the comments and views to see how much you like it.

')

Vacuum

Vacuum is a whole new world where familiar materials behave quite differently. Ordinary water in a vacuum instantly boils and evaporates even at its own temperature of about zero Celsius (at the same time making the vacuum not such a vacuum).

In general, in a vacuum, everything passes and evaporates: even metals, the question of vacuum depth and temperature. Just imagine that a conventional rubber seal lets through a significant amount of gas in order to prevent vacuuming. Not somewhere through the gap, but through the rubber itself. Or, for example, the flexible hose, besides passing air through itself, also evaporates slightly by itself. And the inner surface of the vacuum chamber accumulates gas in its roughness, and therefore it is usually polished. All this is very unusual to understand.

Under the vacuum, many interesting scientific instruments work: mass spectrometers, Auger spectrometers , sputtering installations, elementary particle accelerators, lasers, and, of course, various types of electron microscopes. Common household items in which there is a high vacuum are a thermos, a cathode ray tube of a TV or monitor, various types of electronic lamps.

In this article there is a visual description of everything necessary so that you understand the subject and, of course, further progress in the restoration of the microscope!

Different vacuum

The column of this microscope is designed for high vacuum of the order of 10 ^ -5 Torr . In the environment of vacuum workers, it is customary to designate millimeters of mercury as torr, or to use units of measure for pressure — Pascal and millibars. Personally, I'm used to torr.

How to measure the vacuum is actually still a little problem! A conventional membrane

Why is this difference so important? Because school physics stops working at this pressure. Let's try to visualize a vacuum of various depths:

1. From atmospheric pressure to forevacuum (10 ^ -3 Torr)

for every person, even a party member, an atmospheric pillar weighing two hundred and fourteen kilos presses ... This is the law of physics.(c) I.Ilf and E.Petrov.

You can visually compare the movement of molecules in a solid, liquid and gaseous substance with the help of these animations taken from here .

|  |  |

The free path of nitrogen molecules at atmospheric pressure is about 70 nm = 7 * 10 ^ -8 m, and the approximate size of the nitrogen molecule is 10 ^ -10 m.

Nevertheless, in spite of the fact that in the picture with the gaseous substance the molecules fly a relatively long way, Pascal's law works, and the pressure at any point in the gas will be the same.

For achieving this level of vacuum, foreline vacuum pumps are used.

2. High vacuum (10 ^ -5 Torr)

Here the most interesting begins: the physical nature of the gas inside the vacuum chamber changes radically (and there will always be gas, absolute vacuum is unattainable, see above for the evaporation of everything and everyone). And the gas molecules start to hit the walls of the chamber more than they collide with each other.

High vacuum pumps are used to achieve this vacuum level.

3. Ultra-high vacuum (10 ^ -9 Torr and below)

In this case, the amount of gas passing through the rubber seals plays such a significant role that you have to switch to special flanges with copper seals .

To achieve this level of vacuum, special getter pumps are used. They do not pump the gas into the atmosphere, but absorb it (they transfer it from the gaseous phase to the solid by chemical means).

This is one of the most difficult levels, and fortunately, most old microscopes do not require such a vacuum level. In the new and most advanced devices, such a vacuum level must be maintained for the operation of field-emission cathodes.

4. Space vacuum

Space vacuum depends on location. In the orbit of satellites (300km from the Earth), the pressure corresponds to ultrahigh vacuum. For comparison, in the interstellar space the vacuum is 10 ^ -17 Torr. But the fact is that even in this space there are still rare hydrogen atoms, many photons and other particles.

There is no perfect vacuum even there.

Vacuum measurement

There is such an idea: you can try to heat the wire and observe its temperature. After all, the less pressure, the less gas molecules this wire can heat. This is how thermal vacuum gauges appeared (thermocouple, Pirani sensors ), which measure vacuum from ~ 0.5 to 10 ^ -4 Torr with a sufficiently high accuracy, but, obviously, by a large inertia.

To move deep into the measurements, you need to use the following idea, which sounds much more complicated than heating the wires, but is widely used. We bombard the gas with electrons, and they, colliding with gas molecules, ionize it. These positively charged ions are attracted to the collector, and thus a very small current flows in this “circuit”, the value of which is directly proportional to the pressure (the lower the pressure, the lower the current, because there are fewer ions carrying a positive charge).

This principle of measurement is called so-ionization, and allows you to measure a vacuum of 10 ^ -3 Torr (just the lower practical limit of the thermal vacuum gauge) to 10 ^ -10 Torr.

For a microscope, I managed to buy a relatively modern combined vacuum gauge (two sensors in one - Pirani and a hot cathode) at a well-known western Internet auction for not too much money ( new ones from the store can cost about 100 thousand rubles), which has an analog output and does not require additional devices except the power supply.

Vacuum creation

Probably, you already guessed that if the vacuum cleaner connected to the vacuum chamber could provide the vacuum we need, I would not write this post :)

Probably, you already guessed that if the vacuum cleaner connected to the vacuum chamber could provide the vacuum we need, I would not write this post :)I searched for different sources, and found that a powerful household vacuum cleaner can give a vacuum of about 400-500 Torr.

If you connect the suction nozzle of a piston compressor, the result will be much better: about 100 Torr. But anyway, nothing useful will come of it. It is necessary to use special vacuum pumps.

Forevacuum

An indispensable component of any vacuum technology is a special pump that can pump out up to 10 ^ -3 Torr in good conditions (hence the name). As a rule, it is a two-stage rotary vane pump that can provide that forevacuum pressure in the system. It is often used by installers of air conditioners to remove air from the system before freon is pumped into it.

NB! Cheaper single-stage will not work, their vacuum is much worse.

As a bonus, I made a video about how a small two-stage rotary vane forevacuum pump ITE Blue VAC works.

There are other options for fore-vacuum pumps, which are better (oil-free, for example), but are significantly more expensive (several thousand euros). While I do not have such equipment, so I can not make a full review. If I find it, I will definitely tell you in one of the articles.

High vacuum

If vacuum technology requires a high vacuum, then how many backing pumps do not put - the pressure does not fall below ~ 10 ^ -2 Torr (or 10 ^ -3 Torr, if you use a new pump with very good and expensive vacuum oil). To pump down below, you need to apply a high vacuum pump.

Two types of high vacuum pumps are common:

Looking at the turbomolecular pump device (TMN), you might think that this is a normal high-speed turbine, where each stage increases the pressure, and at the end everything flies into the pipe into the atmosphere. A diffusion works due to some kind of diffusion, yet they know what it is :)

No matter how wrong!

Both of these pumps are necessarily connected to the fore vacuum, and the inclusion of any of them at atmospheric pressure will lead to their failure. Oil burns in oil, and rotor discs burn in TMN.

Understanding how they work is easy if you imagine that they are not pumping a gas as a whole, but interact kinetically with individual gas molecules. The task of these pumps is to move as many gas molecules as possible from the high-vacuum chamber to the inlet of the foreline vacuum pump.

Despite their completely different device, they do it in the same way: they hit these molecules in the direction of their exit (respectively, the foreline vacuum pump inlet). But you need to hit so that the molecule really flew in the direction of the exit, and not slightly changed direction (the molecules are constantly in thermal motion).

Turbomolecular pump

The turbomolecular pump achieves this by a multitude of very fast rotating rotor disks, the blades of which hit the molecules so that they can fly to the blade of the next disk, which will succumb even more, and thus the molecule will reach the output. It is clear that just the length of the free path of the molecule determines the gap between the rotor and the stator. For atmospheric pressure, this length is 70 nm, and therefore need a foreline pump.

For future projects, I bought such a small TM pump from Leybold.

We can not say that it is completely oil-free, because bearings there are oiled. But, of course, in comparison with the steam-oil pump, the amount of oil that penetrates into the high-vacuum part is very, very small. The small size of the pump imposes certain requirements on the speed of rotation of the disks, which for this model is 72 thousand revolutions per minute. About 10 times faster than HDD. Therefore, TMS represent a danger, since ingestion of even the slightest pollution (sand, for example, or dust) can lead to contact between the rotor and the stator, followed by their destruction and the simultaneous release of kinetic energy stored in the rotor. Therefore, they are always written on them: for safety reasons, the pump casing must be firmly fixed.

Schematically, the mechanism of work is presented as follows (from Wikipedia):

In fact, there are TMN, which contain two stages on one rotor: the molecular and a kind of pump Gede . They are structurally implemented in different ways, and allow you to make a completely oil-free system. This is very important for analytical work, but we will not go deep into the wilds.

Steam oil pump

In the steam-oil pump, the molecules of the oil strike the gas molecules (hence the name KO), which fly out of the nozzle at supersonic speeds. It looks like a kettle, with a whistle that is boiling on the stove.

A picture from Wikipedia illustrates this. Oil boils at the bottom, in the center there is a cylinder with nozzles, of which the oil vapor “whistles”, outside - a radiator so that the steam condenses on the walls and flows down again in the form of oil.

In our column there is a steam oil pump, produced by the same company. When removed, it looks like this:

There was supposed to be a special heater at the bottom, for 600W and 100V, but it is not there, but there is a mounting stud. Therefore, I squeezed it into a small turning cartridge, so that the pump would sit comfortably on the table.

Then I will try to adapt something as a heater, or find among the readers who have one.

We proceed further to the restoration of the microscope.

Ii. Connecting the vacuum system

Fortunately, the vacuum system turned out to be “complete”, including pneumatically driven vacuum valves, a set of air solenoids for supplying compressed air to the vacuum valves, two inlet valves (you can't just take and run air into the vacuum chamber through the fore vacuum pump - this will lead to contamination of the system with oil, moreover, it is necessary to let in slowly so as not to damage the thin vacuum sensors) and the steam-oil pump.

The original installation with two forevacuum pumps was not preserved, so a friend found a rotary vane two-stage fore pump for Soviet production 2HBP-5DM for this task.

We begin to revive the system with the only remaining electrical unit - this is a vacuum control panel with solenoids.

Vacuum control panel

It looks quite old-school , which only adds charm. Having examined the entire system, finding power connection points (not rocket science, with just a dozen toggle switches) with constant 24V, I tried to click the valves that no one had clicked a long time ago:

On the left - a valve for supplying compressed air to vacuum pneumatic valves, on the right - a vacuum control panel (original). All, of course, after washing and drying.

We connect the compressor with the receiver, give the pressure in the pneumatic system of 4 atm and try to connect one vacuum valve (2 minutes of sticking valves for true connoisseurs):

This is already a great source of inspiration to continue working!

Connection foreline pump

The column of this microscope is regularly equipped with two fore-vacuum pumps. Why two? The instruction does not give an unequivocal answer, and after much deliberation and after I managed to fully understand the scheme and algorithm of the vacuum system, I probably found a clue (comments are welcome!).

It was in 1970 (more than 40 years ago, can you imagine?), And backing pumps then did not have great performance, and working with a microscope directly depends on how quickly the column can be pumped out, i.e. get in her high vacuum.

Therefore, as I think, Japanese engineers have designed such a system:

- The first pump pumps out (forvacuum) the entire column with the exception of a high-vacuum steam-oil pump;

- The second pump in parallel, without having direct communication with the first (everything is blocked by valves), pumps out the steam-oil pump, allowing it to warm up and start.

I do not have two fore pumps, what to do? (or rather, there is, of course, but the second is ancient and broken, and it must be repaired, and the third has too low performance). But there is one powerful 2NVR-5DM .

After some thought, I decided to make a vacuum tee myself. Plus one in the list of turning work.

All this needs to be connected with hoses. Ordinary hoses will not go (you remember that the vacuum is a thin thing), they will either shrink or evaporate. And small pieces of old came in complete disrepair.

I decided to buy new ones , since there is even an online store in Moscow that sells specialized vacuum equipment. Prices, to put it mildly, bite, but it was not enough meters, I took with a margin and at the same time scored a little more KF connections and sealing rings.

Project's budget

The various things mentioned in this article were found at a relatively reasonable price, or donated by kind people who share the idea of the project - to share the knowledge and experience gained.

For the sake of interest I will write you the prices and the origin of these devices and materials.

- 7 thousand rubles - hoses and vacuum fittings from the store Aktan in Moscow, Russia.

- $ 150 - combined vacuum sensor Pfeiffer from the USA.

- $ 300 - Leybold TMP50 turbomolecular pump from the USA, from the same American. But for some reason, he asked for too much money for the controller for this pump, so I decided not to rush to buy it yet.

- $ 110 - 0.25l of high-quality oil DC704 for a diffusion pump from Riga, Latvia.

- Three fore-vacuum pumps - gifts from two different people.

- Vacuum oil canister for forevacuum pumps - a gift from the same person.

In the next series - turning and milling work on the manufacture of all adapters and caps for the microscope.

As always, I welcome your suggestions and comments. See you again!

Source: https://habr.com/ru/post/369939/

All Articles