A simple way to get high-quality graphene: two seconds in the microwave

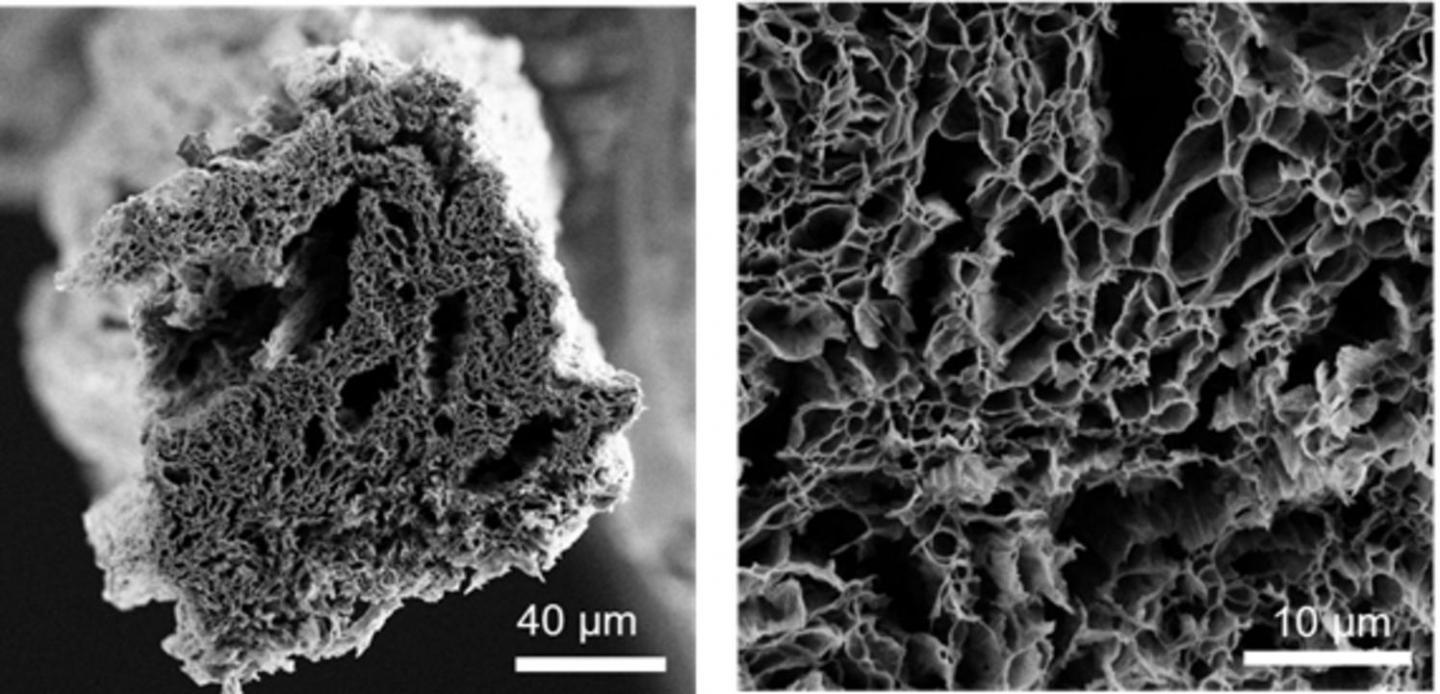

Graphene fibers under a scanning electron microscope. Pure graphene recovered from graphene oxide (GO) in a microwave. Scale 40 µm (left) and 10 µm (right). Photo: Jieun Yang, Damien Voiry, Jacob Kupferberg / Rutgers University

Graphene is a 2D carbon modification formed by a layer one carbon thick. The material has high strength, high thermal conductivity and unique physicochemical properties. It demonstrates the maximum mobility of electrons among all known materials on Earth. This makes graphene an almost perfect material in a wide variety of applications, including electronics, catalysts, batteries, composite materials, etc. Things are easy - to learn how to get high-quality layers of graphene on an industrial scale.

Chemists from Rutgers University (USA) found a simple and fast method of producing high-quality graphene by treating graphene oxide in a conventional microwave oven . The method is surprisingly primitive and efficient.

Graphite oxide is a compound of carbon, hydrogen and oxygen in various ratios, which is formed when graphite is treated with strong oxidizing agents. To get rid of the remaining oxygen in graphite oxide, and then get pure graphene in two-dimensional sheets, you need to make considerable efforts.

')

Oxide of graphite is mixed with strong alkalis and further reduce the material. The result is a monomolecular sheet with residual oxygen. These sheets are called graphene oxide (GO). Chemists have tried various ways to remove excess oxygen from GO ( 1 , 2 , 3 , 4 ), but GO (rGO) reconstituted by such methods remains a highly disordered material that is far from pure graphene prepared by chemical vapor deposition ( HOGF or CVD).

Even in an irregular form, rGO can potentially be useful for energy carriers ( 1 , 2 , 3 , 4 , 5 ) and catalysts ( 1 , 2 , 3 , 4 ), but in order to get the maximum benefit from the unique properties of graphene in electronics, you need to learn how to get pure quality graphene from GO.

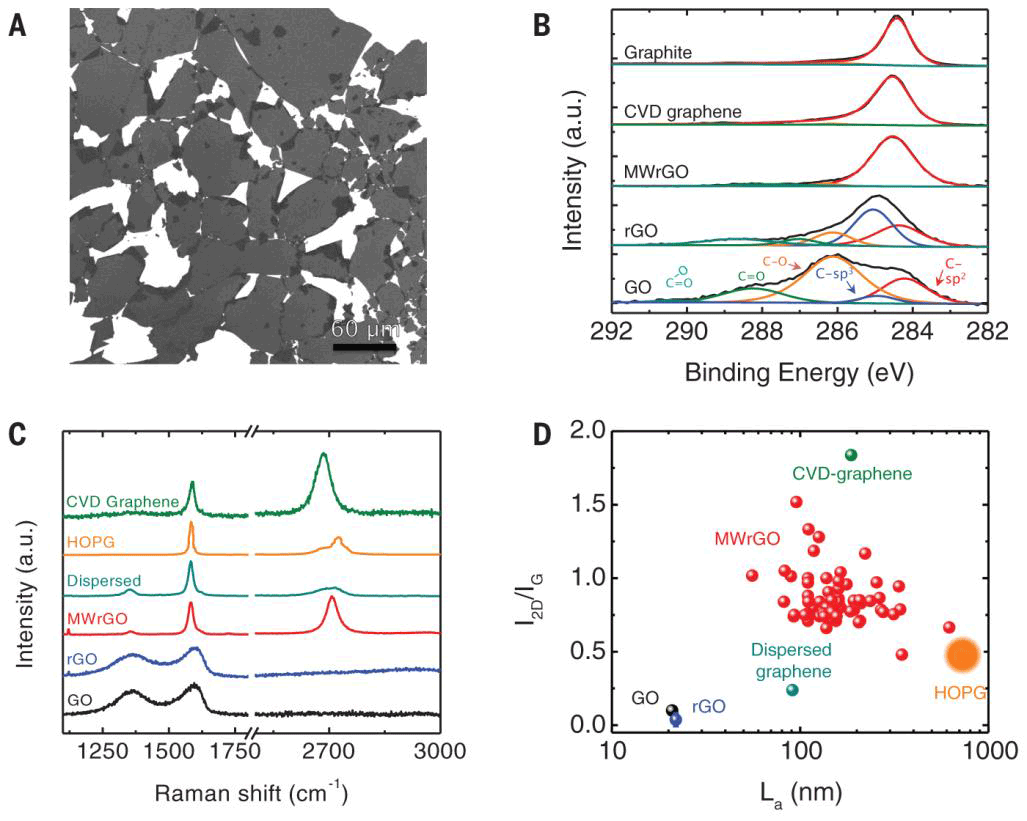

Chemists from Rutgers University offer a simple and fast way to restore GO to pure graphene using 1-2-second pulses of microwave radiation. As can be seen in the graphs, graphene obtained by “microwave reduction” (MW-rGO) is much closer in its properties to the purest graphene obtained by HOGF.

The physical characteristics of the MW-rGO, compared with intact graphene oxide GO, reduced rGO graphene oxide and graphene, obtained by chemical vapor deposition (CVD). Typical GO flakes deposited on a silicon substrate (A) are shown; X-ray photoelectron spectroscopy (B); Raman spectroscopy © and the ratio of the size of the crystals (L a ) to the ratio of the peaks l 2D / l G in the Raman spectrum for MW-rGO, GO and HFG (CVD). Illustrations: Rutgers University

Electronic and electrocatalytic properties of MW-rGO, compared with rGO. Illustrations: Rutgers University

The MW-rGO production process consists of several stages.

- Oxidation of graphite by the modified Hammers method and its dissolution to single-layer flakes of graphene oxide in water.

- Annealing GO to make the material more susceptible to microwave irradiation.

- Irradiation of flakes GO in a conventional 1000 W microwave for 1-2 seconds. During this procedure, the GO quickly heats up to a high temperature, the desorption of oxygen groups and the excellent structuring of the carbon lattice take place.

A survey with a transmission electron microscope shows that after treatment with a microwave emitter, a highly ordered structure is formed, in which the oxygen functional groups are almost completely destroyed.

The images from a transmission electron microscope show the structure of graphene sheets with a scale of 1 nm. On the left is a single-layer rGO, with many defects, including functional groups of oxygen (blue arrow) and holes in the carbon layer (red arrow). In the center and on the right - perfectly structured two-layer and three-layer MW-rGO. Photo: Rutgers University

The excellent structural properties of MW-rGO, when used in field-effect transistors, make it possible to increase the maximum mobility of electrons to about 1500 cm 2 / V · s, which is comparable to the outstanding characteristics of modern transistors with high electron mobility.

In addition to electronics, MW-rGO is useful in the production of catalysts: it showed an extremely small value of the Tafel coefficient when used as a catalyst in the oxygen evolution reaction: about 38 mV per decade. The catalyst on the MW-rGO also retained stability in the hydrogen evolution reaction, which lasted more than 100 hours.

All this suggests an excellent potential for the use of graphene restored in microwave radiation in industry.

The scientific article "High-quality graphene via microwave reduction of solution-exfoliated graphene oxide" was published on September 1, 2016 in the journal Science (doi: 10.1126 / science.aah3398).

Source: https://habr.com/ru/post/369631/

All Articles