History of capacitors part 2: the modern era

In the previous series:

History of capacitors part 1: the first discoveries

Condensers for dummies

At the beginning of the history of capacitors, they were used mainly to obtain the first ideas about electricity, even before the electrons were discovered. It was time for public demonstrations of the achievements of science, for example, in the form of people holding hands, through which a current of a capacitor was passed. The modern era of capacitor development begins at the end of the 18th century, when the practical use of electricity began, requiring the manufacture of capacitors with certain properties.

')

Leiden banks

Marconi with transmitter

One example of practical use was the spark transmitters that appeared before 1900 and existed in the first and second decades. Transmitters gained great voltage to discharge through the gap, and therefore for this purpose ceramic capacitors were used that could withstand such voltage. In addition, it required a high frequency. These were, in essence, Leyden banks, and they needed large sizes to obtain the necessary capacity.

Mica

In 1909, William Dubilier invented a smaller mica capacitor that was used on the receiving side in the resonant circuits of wireless equipment.

The early mica capacitors were layers of mica and copper foil, compressed together into “pack mica capacitors”. They were unreliable, and because air gaps remained between layers of mica and foil, they were subject to corrosion and oxidation, and the distance between the plates could change, which led to changes in capacity.

In the 1920s, mica capacitors were developed using silver, in which the mica was encased on both sides in metal, which eliminated air gaps. Thanks to a thin metal coating, their size could be reduced, and they were very reliable. Of course, development did not stop there. Let's look at the history of modern capacitors, marked by a series of breakthroughs that followed one after another.

Ceramics

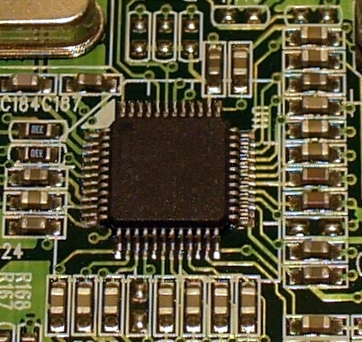

Multilayer ceramic capacitors around the microprocessor

In the 1920s, there were few mica in Germany, and there they experimented with new generations of ceramic capacitors. It was found that rutile (titanium dioxide) capacity is linearly dependent on temperature, and they can replace mica capacitors. They were first produced in small quantities, and then in larger batches in the 1940s. They consisted of discs coated on both sides with metal.

To increase the capacity, another type of ceramic was used, barium titanate, and its dielectric constant was 10 times higher than that of mica or titanium dioxide. But electrically, her parameters were less stable, and as a result, it could be used instead of mica only where reliability was not required. After World War II, this flaw was corrected.

The American company, which began work in 1961, introduced a multi-layer ceramic capacitor (MLCC), whose dimensions were smaller and the capacity larger. By 2012, the annual production of MLCC from barium titanate reached 10 12 pieces.

Aluminum Electrolytic

Electrolytic capacitor

In the 1890s, Charles Pollack discovered that the oxide layer on an aluminum anode showed stability in a neutral or alkaline environment, and in 1897 received a patent for an aluminum electrolytic capacitor with a borax. The first "wet" electrolytic capacitors appeared in radio receivers in the 1920s, but their lifespan was limited. They were called "wet" because of the water content. It was a container with a metal anode immersed in a solution of borax or other electrolyte dissolved in water. The outer part of the container served as the second plate. They were used in telephone exchanges to reduce relay noise.

A patent for the ancestor of the modern electrolytic capacitor was claimed in 1925 by Samuel Ruben. He made a sandwich of a gel-like electrolyte located between the oxide-coated anode and the second metal foil plate, eliminating the need for a container of water. The result was a "dry" electrolytic capacitor. All this seriously reduced the size and cost of capacitors.

In 1936, Cornell-Dubilier introduced its aluminum electrolytic capacitors, which included improvements such as desensitization of the anode surface, which helped to increase capacity. The company Hydra-Werke, owned by AEG, at about the same time began their mass production in Berlin.

After World War II, the rapid development of radio and television technologies led to an increase in the production of capacitors and the diversity of their styles and sizes. Improvements included a reduction in current leakage and equivalent series resistance (ESR), an increase in temperature and lifetime due to the use of new organic electrolytes. Further developments in the 1970-1990s continued this trend, reducing leakage, increasing ESR and increasing operating temperatures.

In the early 2000s, a so-called happened. " capacitor plague ", due to the fact that manufacturers used for the manufacture of capacitors stolen electrolyte recipe, which was incomplete. The absence of stabilizing components led to an early failure of capacitors.

Tantalum electrolytic

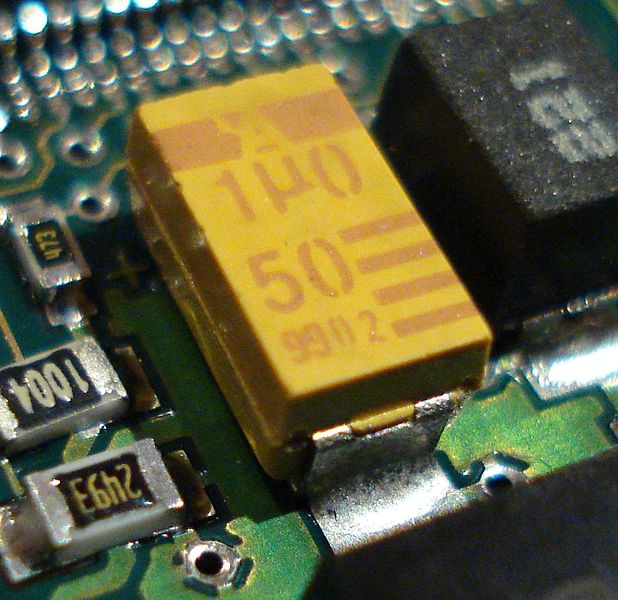

Tantalum surface placement capacitor

Tantalum electrolytic capacitors first began to be manufactured for military needs in the 1930s. They used spun tantalum foil and liquid electrolyte. In the 1950s, Bell Laboratories produced the first solid electrolyte tantalum capacitor. They ground the tantalum into powder and sintered it into a cylinder. First, liquid electrolytes were used, but then it was discovered that manganese dioxide can be used as a solid electrolyte.

And although the main inventions were made at Bell Labs, in 1954 the Sprague Electric Company improved the manufacturing process and began producing the first commercially available tantalum capacitors with solid electrolyte.

In 1975 polymeric tantalum electrolytic capacitors appeared with much higher conductivity. In them, conductive polymers replaced manganese dioxide, which led to a decrease in ESR. NEC released a polymer tantalum capacitor in 1995 for surface mounting, and in 1997 they were followed by Sanyo.

The cost of tantalum ore in the market is unstable, and jumps have already happened a couple of times - in 1980 and in 2000/2001. The last jump led to the development of niobium electrolytic capacitors with manganese dioxide electrolyte, whose properties were roughly comparable to tantalum ones.

Polymer film

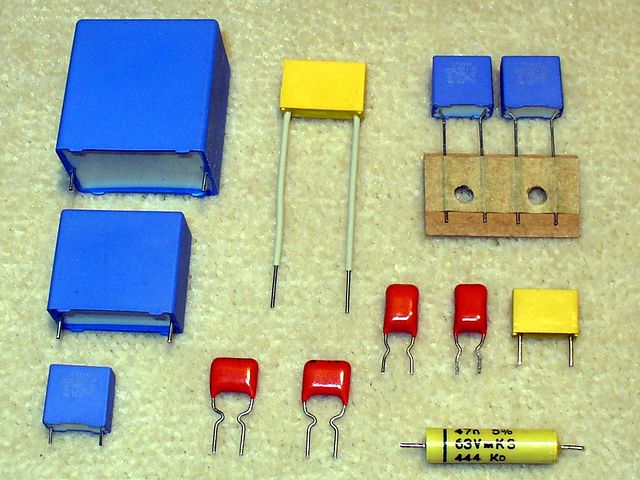

Polymer film capacitors

Capacitors on metallized paper were patented in 1900 by G.F. Mansbridge [GF Mansbridge]. Metallized paper, covering it with a binder containing metal particles. In the early 1900s, they were actively used as decoupling capacitors in telephony. During the Second World War, Bosch improved the process and produced them by coating the paper with varnish, which was then coated with metal by vacuum deposition. In 1954, Bell Labs made a metallized lacquer film 2.5 microns thick, separate from paper, which made it possible to create even smaller capacitors. This capacitor can be considered the first polymer.

Plastic studies conducted by experts in organic chemistry during World War II led to the development of this topic. One of them in 1954 was the first Mylar condenser. The Mylar brand was introduced in 1952 by the Dupont company, and it was a very durable polyethylene terephthalate (PET), a film based on synthetic polyester fiber. In 1954 a condenser was made on a mylar film 12 microns thick. By 1959, the list included capacitors made with polyethylene, polystyrene, polytetrafluoroethylene (PTFE), PET, and polycarbonate. By the 1970s, electronic devices used capacitors made of film and foil without paper.

Dual (supercapacitors)

Supercapacitors

And now the story leads us to the last type of capacitors, and very interesting, since their capacity is already measured in thousands of farads. In the early 1950s, researchers at General Electric used their groundwork in the field of fuel cells and rechargeable batteries to experiment with capacitors with porous carbon electrodes. This led to Becker's patent on "Low Voltage Electrolytic Capacitor with Porous Carbon Electrodes." GE did not engage in further development, but the principles laid down in the patent led to the creation of very high capacitors.

Ohio's Standard Oil company developed another version of them, and eventually sold the license to the NEC company in the 1970s, which brought them to the commercial version under the trademark “supercapacitor”. They worked with a voltage of 5.5 V and had capacities up to 1 F. They reached a volume of 5 cubic cm. and used as a backup power source for computer memory.

Professor Brian Evans Conway of the University of Ottawa worked on ruthenium oxide electrochemical capacitors from 1975 to 1980. In 1991, he described the difference between supercapacitors and batteries in electrochemical charge storage, and fully described the differences in 1999, reintroducing the term "supercapacitor".

Products and markets for supercapacitors gradually appeared. Well-known trademarks are Goldcaps, Dynacap and PRI Ultracapacitor, the latter of which is associated with the first supercapacitors with small internal resistance, developed in 1982 by the Pinnacle Research Institute (PRI) for the needs of the military.

Relatively recent developments in the market include lithium-ion capacitors in which activated carbon anodes are coated with lithium ions. Their capacity is thousands of farads at a voltage of 2.7V.

Source: https://habr.com/ru/post/369535/

All Articles