Condensers for dummies

If you regularly create electrical circuits, you must have used capacitors. This is a standard component of the circuits, the same as the resistance that you just take from the shelf without hesitation. We use capacitors to smooth voltage / current ripples, to match loads, as an energy source for low-power devices, and other applications.

But the capacitor is not just a bubble with two wires and a pair of parameters - the operating voltage and capacitance. There is a huge array of technologies and materials with different properties used to create capacitors. And although in most cases almost any capacitor of suitable capacity will fit in any task, a good understanding of the operation of these devices can help you choose not just the right one, but the best one. If you have ever had a problem with temperature stability or the task of finding the source of additional noise, you will appreciate the information from this article.

')

Let's start with the simple

It is better to start with a simple and describe the basic principles of operation of capacitors, before moving on to real devices. The ideal capacitor consists of two conductive plates separated by a dielectric. The charge is collected on the plates, but cannot flow between them - the dielectric has insulating properties. So the capacitor accumulates charge.

Capacity is measured in farads: a capacitor in one farad produces a voltage of one volt, if there is a charge in one pendant. Like many other SI units, it has an impractical size, so if you do not take into account supercapacitors, which we will not discuss here, you will most likely encounter micro, nano and picofarades. The capacitance of any capacitor can be derived from its size and dielectric properties - if interested, the formula for this can be viewed in Wikipedia. You don't need to memorize it, unless you are preparing for an exam - but it contains one useful fact. The capacitance is proportional to the dielectric constant ε r of the used dielectric, which resulted in the sale of various capacitors that use different dielectric materials to achieve large capacitances or improve voltage characteristics.

Parasitic inductance and resistance of a real capacitor

With the use of dielectrics in capacitors, there is one problem, along with the fact that a dielectric with the necessary characteristics has unpleasant side effects. All capacitors have small parasitic resistance and inductance, which can sometimes affect its operation. Electric constants vary with temperature and voltage, piezoelectricity or noise. Some capacitors are too expensive; some have failure states. And here we come to the main part of the article, in which we will talk about the different types of capacitors, and their properties, useful and harmful. We will not cover all possible technologies, although we will describe most of the usual ones.

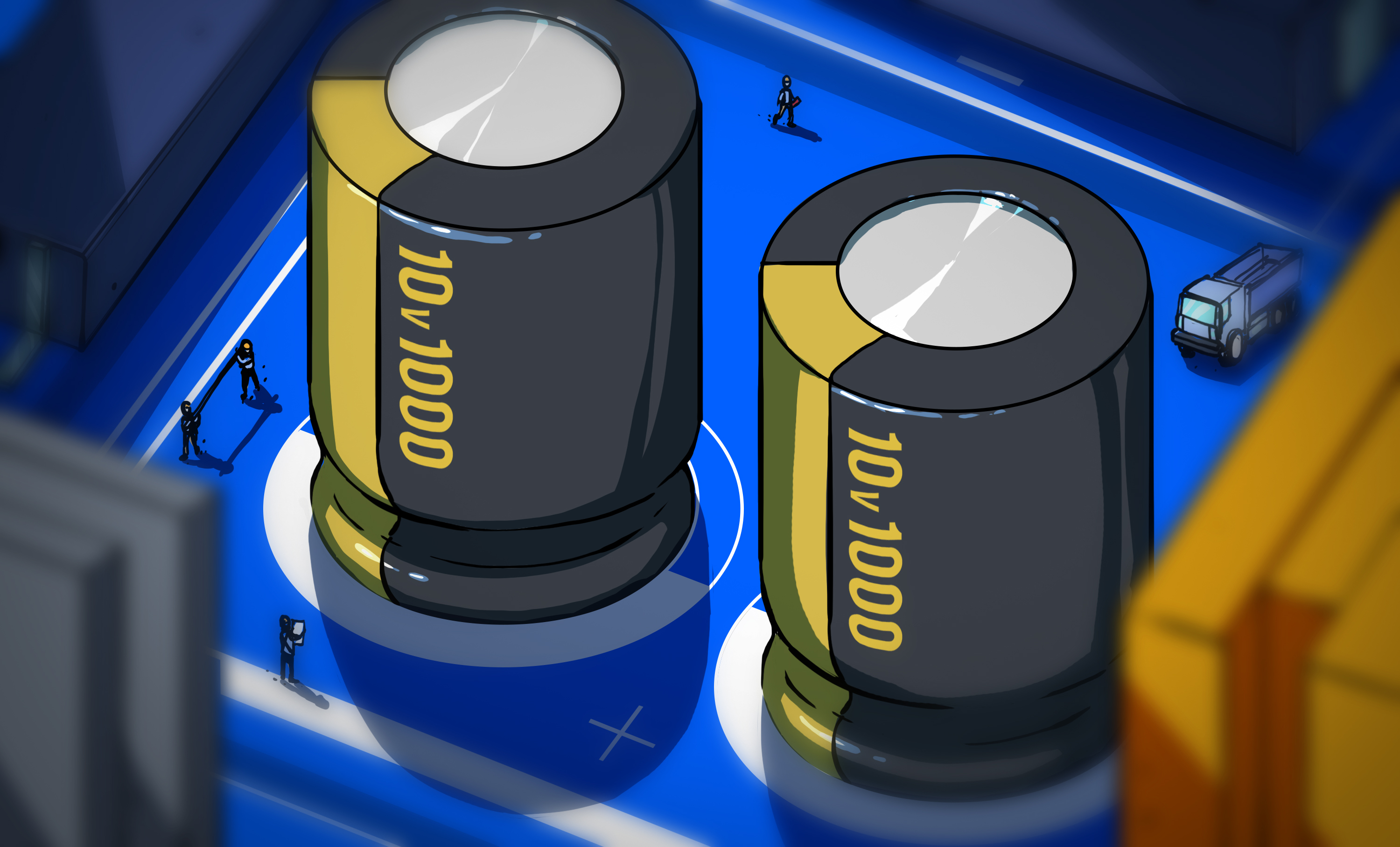

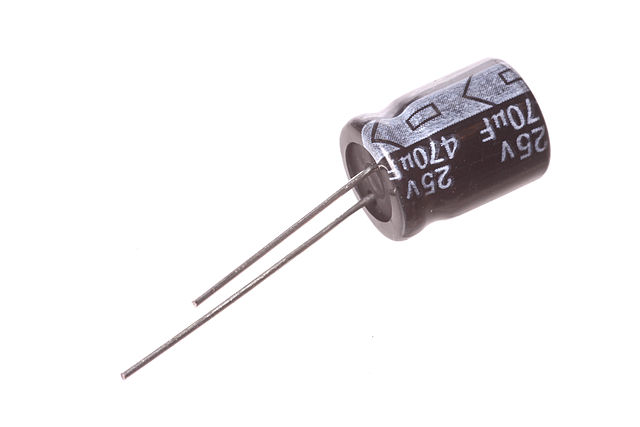

Aluminum Electrolytic

Aluminum electrolytic capacitors use an anodically oxidized layer on an aluminum sheet as one dielectric plate, and an electrolyte from an electrochemical cell as another plate. The presence of an electrochemical cell makes them polar, that is, the DC voltage must be applied in one direction, and the anodized plate must be an anode, or a plus.

In practice, their plates are made in the form of a sandwich from aluminum foil wrapped in a cylinder and located in an aluminum can. The operating voltage depends on the depth of the anodized layer.

Electrolytic capacitors have the largest capacitance among common, from 0.1 to thousands of microfarads. Due to the dense packing of the electrochemical cell, they have a large equivalent series inductance (equivalent series inductance, ESI, or effective inductance), because of which they cannot be used at high frequencies. They are usually used for power smoothing and decoupling, as well as linking at audio frequencies.

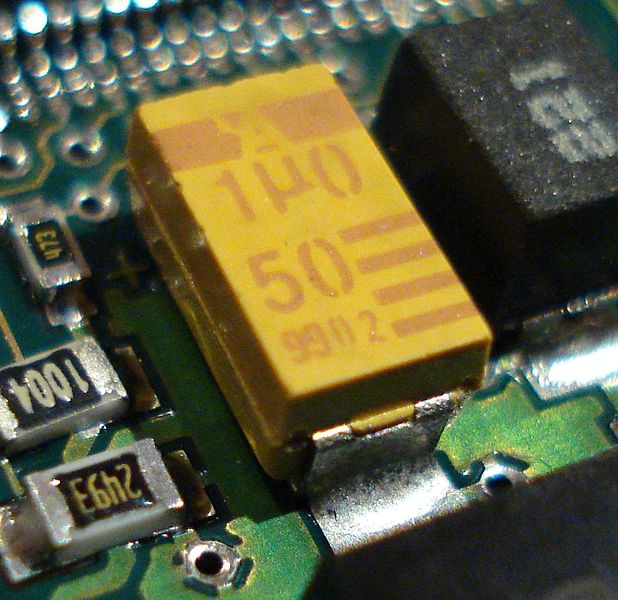

Tantalum electrolytic

Tantalum surface placement capacitor

Tantalum electrolytic capacitors are made in the form of a sintered tantalum anode with a large surface area on which a thick oxide layer is grown, and then the electrolyte from manganese dioxide is placed as the cathode. The combination of a large surface area and the dielectric properties of tantalum oxide leads to a high capacity in terms of volume. As a result, such capacitors come out much smaller than aluminum capacitors of comparable capacity. Like the latter, tantalum capacitors have polarity, so the direct current must go in exactly one direction.

Their available capacity ranges from 0.1 to several hundred microfarads. They have much less leakage resistance and equivalent series resistance (ESR), and therefore they are used in testing, measuring devices and high-quality audio devices - where these properties are useful.

In the case of tantalum capacitors it is necessary to especially monitor the state of failure, it happens that they light up. Amorphous tantalum oxide is a good dielectric, and in crystalline form it becomes a good conductor. Incorrect use of a tantalum capacitor — for example, applying too much of the starting current can cause the dielectric to transition to another form, which will increase the current passing through it. True, the reputation for fire has emerged from earlier generations of tantalum capacitors, and improved production methods led to more reliable products.

Polymer films

The whole family of capacitors uses polymer films as dielectrics, and the film either lies between twisted or intermittent layers of metal foil, or has a metallized layer on the surface. Their operating voltage can reach up to 1000 V, but they do not have high capacitances - this is usually from 100 pF to units of microfarad. Each type of film has its pros and cons, but in general the whole family has a lower capacitance and inductance than that of electrolytic. Therefore, they are used in high-frequency devices and for decoupling in electrically noisy systems, as well as in general-purpose systems.

Polypropylene capacitors are used in circuits requiring good thermal and frequency stability. They are also used in power systems, for the suppression of EMF, in systems that use alternating high voltage currents.

Polyester capacitors, although they do not have such temperature and frequency characteristics, are cheap and can withstand high temperatures when soldering for surface mounting. In this regard, they are used in circuits intended for use in non-critical applications.

Polyethylene naphthalate capacitors. They do not have stable temperature and frequency characteristics, but can withstand much higher temperatures and voltages compared to polyester ones.

Polyethylene sulphide capacitors have temperature and frequency characteristics of polypropylene, and in addition can withstand high temperatures.

In the old equipment you can stumble on polycarbonate and polystyrene capacitors, but now they are no longer used.

Ceramics

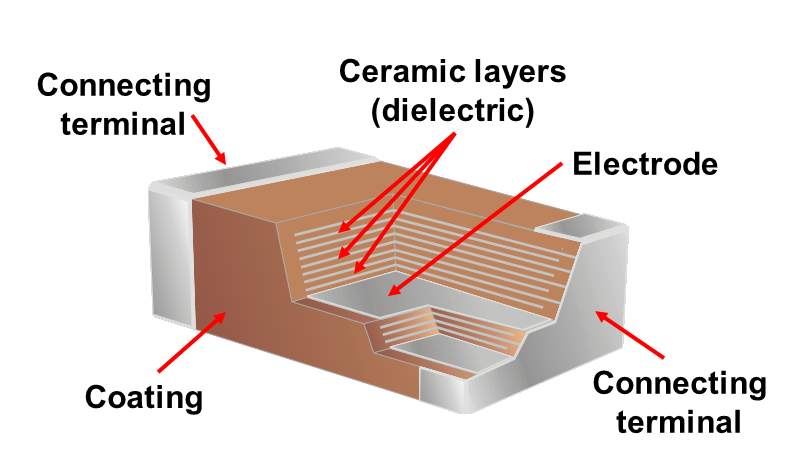

The history of ceramic capacitors is quite long - they were used from the first decades of the last century to this day. Early capacitors represented one layer of ceramics metallized on both sides. Later there are also multi-layered, where plates with metallization and ceramics are interspersed. Depending on the dielectric, their capacitances vary from 1 pF to tens of microfarads, and the voltages reach kilovolts. In all branches of electronics, where small capacity is required, one can find both single-layer ceramic disks and multi-layer packaged capacitors of surface mounting.

It is easiest to classify ceramic capacitors by dielectrics, since they give the capacitor all the properties. Dielectrics are classified by three-letter codes, where their working temperature and stability is encrypted.

C0G better stability in capacitance with respect to temperature, frequency and voltage. Used in high-frequency circuits and other high-speed circuits.

X7R does not have such good temperature and voltage characteristics, therefore they are used in less critical cases. This is usually a decoupling and various universal applications.

Y5V have much more capacity, but their temperature and voltage characteristics are even lower. Also used for decoupling and in various universal applications.

Since ceramics often has piezoelectric properties, some ceramic capacitors also exhibit a microphone effect. If you worked with high voltages and frequencies in the audio range, for example, in the case of tube amplifiers or electrostatics, you could hear the capacitors “singing”. If you used a piezoelectric capacitor to provide frequency stabilization, you might find that its sound is modulated by the vibration of its surroundings.

As we already mentioned, the article does not aim to cover all capacitor technologies. Looking at the electronics catalog you will find that some of the technologies available are not covered here. Some of the proposals from the catalogs are already outdated, or they have such a narrow niche that you will not often meet with them. We only hoped to dispel some secrets about popular capacitor models, and help you choose the right components when designing your own devices. If we have warmed up your appetite, you can study our article on inductors.

I ask you to write about the inaccuracies and errors you find through the site’s private messages . Thank.

Source: https://habr.com/ru/post/369421/

All Articles