Metalins created by scientists from Harvard, will improve the quality of the snapshot of the camera of the smartphone to the level of DSLR-camera

Created by a group of scientists from Harvard University, miniature lenses of the size of a sandy grain may be able to compete successfully in the foreseeable future in quality of images with images taken today with the help of overall, heavy and expensive DSLR cameras, used in smartphones cameras, in the manufacture of contact lenses, in promising nanophoton communication networks, in laser microscopy, tomography, spectroscopy, etc. The prototype of the invention was presented to the interested audience last week, and ie on the work published in the pages of Science at the beginning of this month.

DSLR SLR cameras - a bottleneck in the work of modern professional photographers. They allow you to get high quality of the captured images, but at the same time remain very heavy and cumbersome. Unfortunately, high-quality and heavy optics, precise mechanics do not allow to reduce the weight and size of DSLR cameras at a pace that reduces the weight and size of other equipment. Recently, development and production of mirrorless cameras, for example, the Canon EOS M, have begun, but the characteristics obtained so far do not allow them to compete successfully with DSLR cameras.

Miniature metal images (meta-lens), developed by metamaterial scientists from Harvard University, can be used in almost all existing technologies of shooting, ranging from photography to images obtained with powerful optical microscopes and telescopes. Moreover, using metalins in cameras of mobile phones and other portable equipment will allow to get images that are not inferior in quality to pictures taken with the help of semi- and professional DSLR cameras.

')

The size of metalins is about 2 mm in diameter, and the cost of their manufacture will be 2-3 orders of magnitude cheaper than manufacturing lenses made of coated optical glass. “We would like to replace bulky optics,” explained Mohammadreza Khorasaninejad (Mohammadreza Khorasaninejad), who is the scientific director of the project in his interview with Popular Science . Using metalinzy, "... We can reduce costs by 2 or 3 orders of magnitude." In other words, the price of a $ 5,000 TOP-level lens can be reduced to potentially disappearing S5 dollars, while retaining all its capabilities. And it is very important that miniature lenses, being flat, can be manufactured in the same production facilities where standard computer chips are made.

New metalinzy will allow you to take pictures of the quality of DSLR-camera using a smartphone

The impressive size of DSLR camera lenses is explained by the use of a variety of optical elements with curved surfaces in their design. Such lenses change the shape of the light rays, refract them and focus on the surface of the photosensitive sensor. However, some of the light passing through the edges of the lenses still falls out of the focus of the image, which leads to blurring of the edges of the image. To compensate for the effect of spherical aberration is due to additional corrective lenses, which further increases the cost and increases the overall dimensions of the lens.

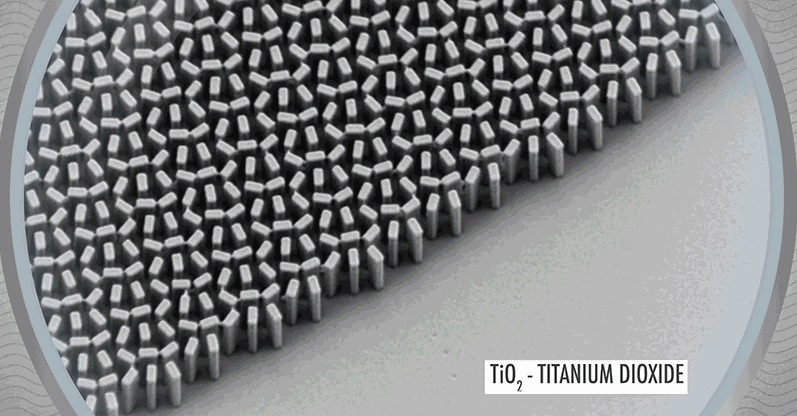

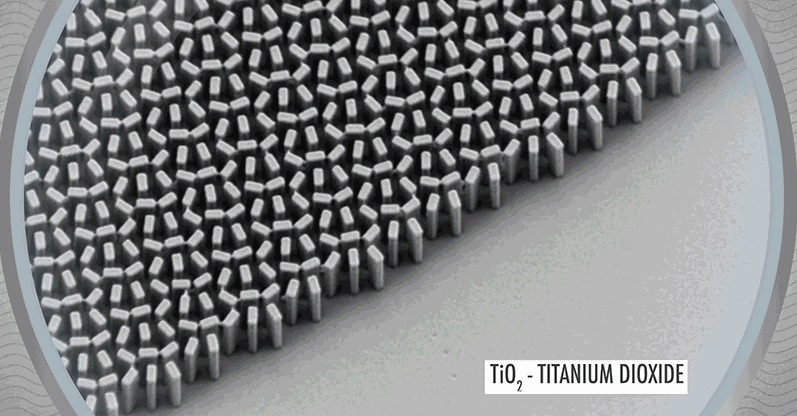

In metalins, which are flat quartz plates, on the surface of which titanium dioxide structures arranged in a special way are formed, the negative effect associated with spherical aberrations is absent by definition. Each individual element of metalins, externally similar to a miniature domino knuckle set on an edge, several dozen x several hundreds of nanometers in size, refracts incoming rays of light in its own way. At the same time, all these elements, arranged in a strictly defined order, act as one lens, focusing the rays of light at the desired point.

The prototype, created by scientists is not yet able to cover the entire range of the visible spectrum. By varying the dimensions of the elements on the surface of metalins, the height of the “knuckles”, the distance between adjacent metalins, and a number of other parameters, researchers were able to create samples of lenses that demonstrate excellent performance in the 405, 532 and 660 nanometer ranges, i.e., purple-blue, yellow-green and the red part of the visible spectrum. Already outlined ways to solve the problem of improving the quality of the image with the participation of colors and another part of the spectrum, where for now the image does not look sharp enough.

The structure of the metalins surface

One of the “firm” merits of metalins is incomparably higher efficiencies. The researchers arrived at this conclusion back in 2011, when, through experimentation, they obtained an efficiency of 99%. This means that when passing through the metalins, only 1% of the light flux is lost. And such a result today can not be repeated even using the best lenses made of glass.

It’s still difficult to name the month and the year when metalins announced by a group of researchers from Harvard can reach the camera lenses of smartphones. It is clear that the first step towards this goal will be to overcome the problems of picture quality in the entire visible spectral range. At the same time, the application of the advantages of development in its current form can be found now: for example, it is the possibility of using them in scientific and technological equipment, which uses the technology of processing the laser beam and other light sources with a specific wavelength in the process.

Science

Bbc

That's all with you was Dronk.Ru. Do not forget to return money for purchases in China and subscribe to our blog , there will be many more interesting things.

We recommend:

- Save up to 8% on every purchase on AliExpress and other online stores in China

- Why do online stores give money for purchases?

- Return your money - Choose a cashback service for Aliexpress

- The history of the development of Dronk.ru - from choosing quadcopters to returning money for purchases on AliExpress and not only

- The best cashback service or 5 main criteria for evaluating cashback service

DSLR SLR cameras - a bottleneck in the work of modern professional photographers. They allow you to get high quality of the captured images, but at the same time remain very heavy and cumbersome. Unfortunately, high-quality and heavy optics, precise mechanics do not allow to reduce the weight and size of DSLR cameras at a pace that reduces the weight and size of other equipment. Recently, development and production of mirrorless cameras, for example, the Canon EOS M, have begun, but the characteristics obtained so far do not allow them to compete successfully with DSLR cameras.

Miniature metal images (meta-lens), developed by metamaterial scientists from Harvard University, can be used in almost all existing technologies of shooting, ranging from photography to images obtained with powerful optical microscopes and telescopes. Moreover, using metalins in cameras of mobile phones and other portable equipment will allow to get images that are not inferior in quality to pictures taken with the help of semi- and professional DSLR cameras.

')

The size of metalins is about 2 mm in diameter, and the cost of their manufacture will be 2-3 orders of magnitude cheaper than manufacturing lenses made of coated optical glass. “We would like to replace bulky optics,” explained Mohammadreza Khorasaninejad (Mohammadreza Khorasaninejad), who is the scientific director of the project in his interview with Popular Science . Using metalinzy, "... We can reduce costs by 2 or 3 orders of magnitude." In other words, the price of a $ 5,000 TOP-level lens can be reduced to potentially disappearing S5 dollars, while retaining all its capabilities. And it is very important that miniature lenses, being flat, can be manufactured in the same production facilities where standard computer chips are made.

New metalinzy will allow you to take pictures of the quality of DSLR-camera using a smartphone

The impressive size of DSLR camera lenses is explained by the use of a variety of optical elements with curved surfaces in their design. Such lenses change the shape of the light rays, refract them and focus on the surface of the photosensitive sensor. However, some of the light passing through the edges of the lenses still falls out of the focus of the image, which leads to blurring of the edges of the image. To compensate for the effect of spherical aberration is due to additional corrective lenses, which further increases the cost and increases the overall dimensions of the lens.

In metalins, which are flat quartz plates, on the surface of which titanium dioxide structures arranged in a special way are formed, the negative effect associated with spherical aberrations is absent by definition. Each individual element of metalins, externally similar to a miniature domino knuckle set on an edge, several dozen x several hundreds of nanometers in size, refracts incoming rays of light in its own way. At the same time, all these elements, arranged in a strictly defined order, act as one lens, focusing the rays of light at the desired point.

The prototype, created by scientists is not yet able to cover the entire range of the visible spectrum. By varying the dimensions of the elements on the surface of metalins, the height of the “knuckles”, the distance between adjacent metalins, and a number of other parameters, researchers were able to create samples of lenses that demonstrate excellent performance in the 405, 532 and 660 nanometer ranges, i.e., purple-blue, yellow-green and the red part of the visible spectrum. Already outlined ways to solve the problem of improving the quality of the image with the participation of colors and another part of the spectrum, where for now the image does not look sharp enough.

The structure of the metalins surface

One of the “firm” merits of metalins is incomparably higher efficiencies. The researchers arrived at this conclusion back in 2011, when, through experimentation, they obtained an efficiency of 99%. This means that when passing through the metalins, only 1% of the light flux is lost. And such a result today can not be repeated even using the best lenses made of glass.

It’s still difficult to name the month and the year when metalins announced by a group of researchers from Harvard can reach the camera lenses of smartphones. It is clear that the first step towards this goal will be to overcome the problems of picture quality in the entire visible spectral range. At the same time, the application of the advantages of development in its current form can be found now: for example, it is the possibility of using them in scientific and technological equipment, which uses the technology of processing the laser beam and other light sources with a specific wavelength in the process.

Science

Bbc

That's all with you was Dronk.Ru. Do not forget to return money for purchases in China and subscribe to our blog , there will be many more interesting things.

We recommend:

- Save up to 8% on every purchase on AliExpress and other online stores in China

- Why do online stores give money for purchases?

- Return your money - Choose a cashback service for Aliexpress

- The history of the development of Dronk.ru - from choosing quadcopters to returning money for purchases on AliExpress and not only

- The best cashback service or 5 main criteria for evaluating cashback service

Source: https://habr.com/ru/post/369419/

All Articles