How I modified the 3D printer MC2 from Master Keith

I am a keen person by nature. And above all, all sorts of electronic-iron things. By this term, I mean all sorts of useful devices that are controlled by electronics — home automation, lighting, ventilation, and remote control of this economy. It is clear that against the background of the growing universal hobby of 3D printing, I could not pass by.

Why do I need a 3D printer? .. Vague thoughts wandered in my head: I would print some body, podshevochka, little pen ... I decided this way - I’ll get this thing, but we'll see!

After a brief search, the choice stopped at the most accessible option (which one I could find), but in case something happens, there would be a lot to ask for help, that is, a local Moscow one. Pal my choice on the designer MC2 production Master Kit.

')

I have known the whale for 15 years now, I occasionally use their sets for self-assembly, when it’s lazy to select parts myself. Just the same case!

The assembly process did not capture, because it did not cause any special difficulties, besides, Master Kit presented it adequately on the channel .

The process itself, of course, was not continuous, collected in the evenings in the hunt, but received pleasure from it, because as it was assembled it came to an understanding of what it was for, how it was connected, how it should function.

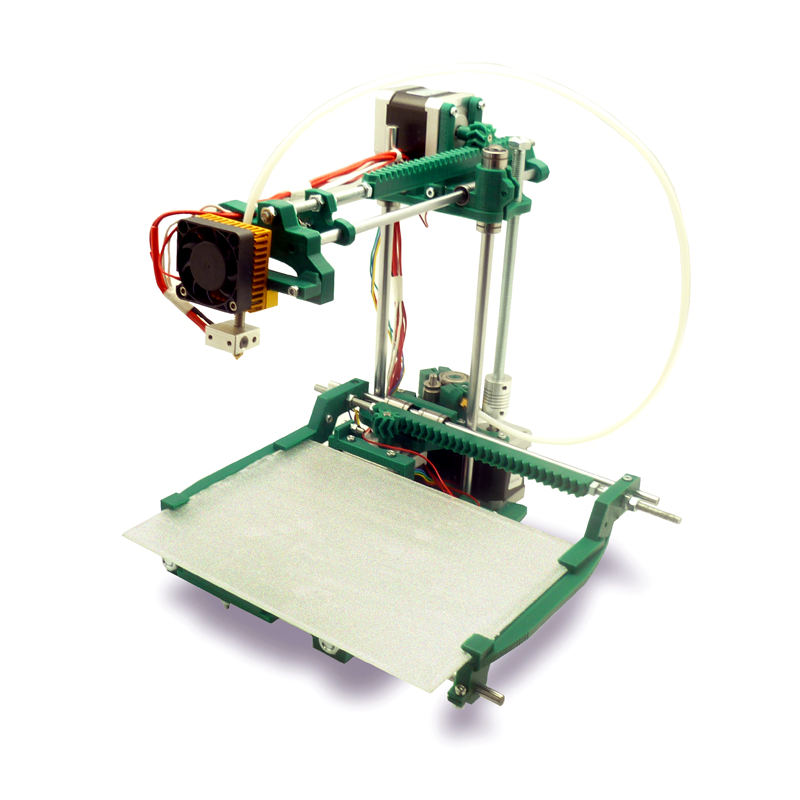

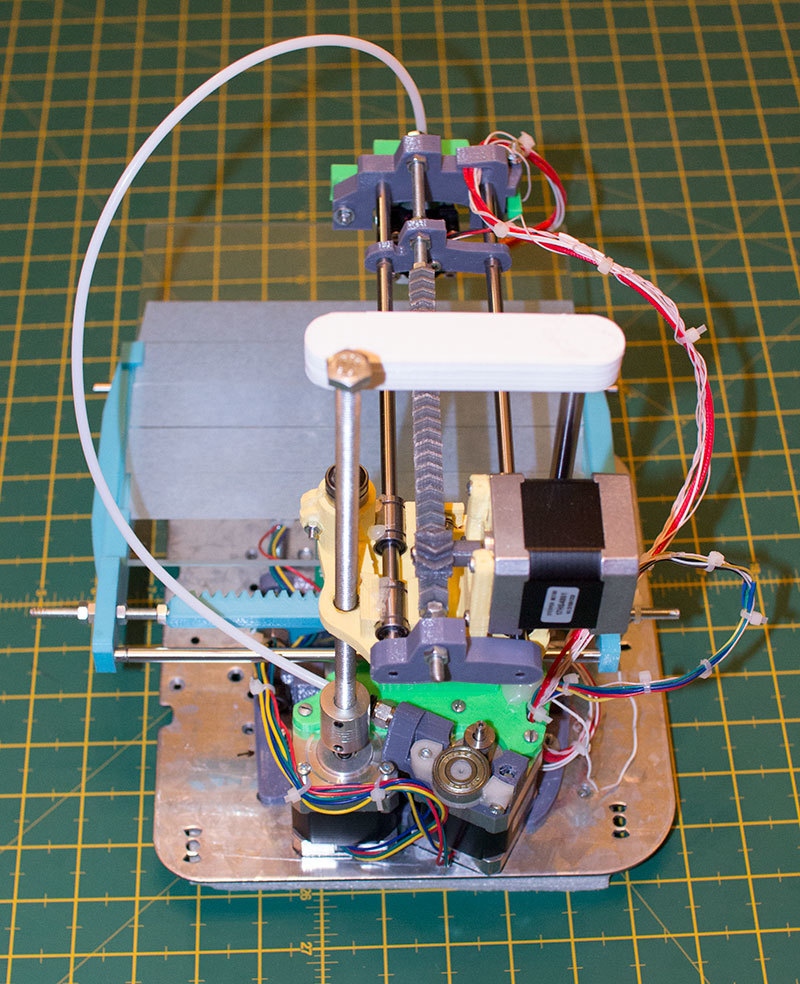

The simplicity and, at the same time, the functionality of the design simply fascinated. MC2, in comparison with frame monsters, is compact, looks openwork and pleases the eye while standing on the table. The maximum size of the print area on XYZ is 140x140x110! That's how I chose him, among other things - for the appearance, then I just realized. MS2 without power supply is on sale, but in my big economy was necessary.

I set up the electronics quickly, according to the instructions, and began to print test cubes, simultaneously mastering SketchUp and Repeater Host. I must say, the process is fascinating in itself: you draw a three-dimensional detail on the screen, and embody it in the material. I do not know how anyone, but I am delighted!

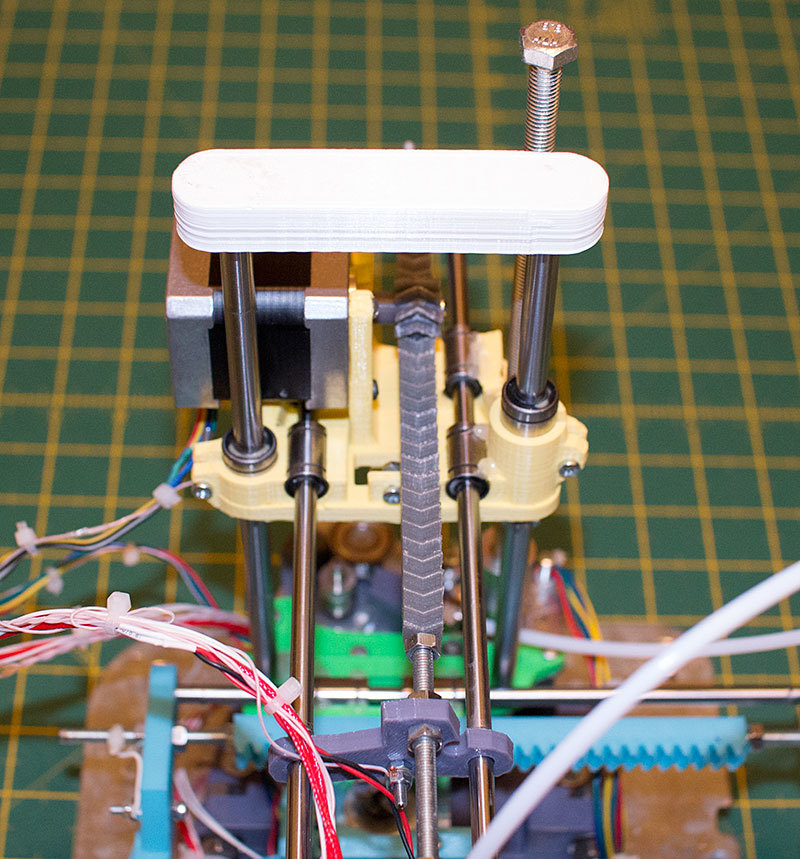

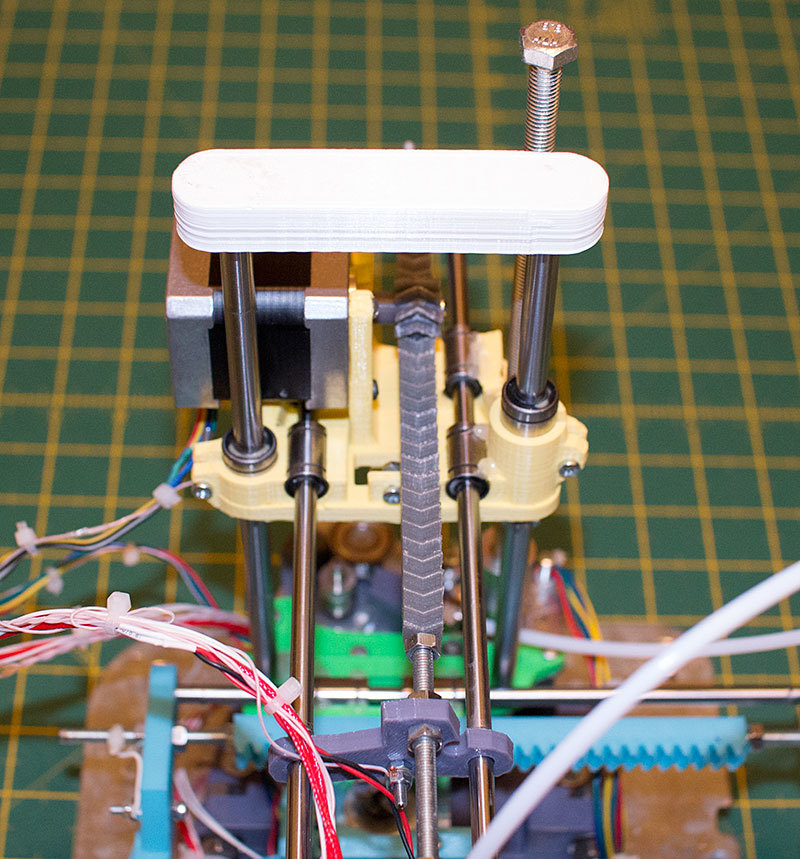

The first part I drew and printed after the test cubes was the attachment on the shafts of the printer's Z-axis. First, I wanted to practice on a real subject, and secondly, it seemed to me that it would be harder on all axes. That turned out this nozzle with the third time.

Then they offered me to try an E3D extruder . And what not to try? Printed holder suitable, set, tried - a good extruder. While I tried, I scored it with plastic, of course, but I learned how to clean it with a gas stove and wires of different diameters.

But it was mostly clogged by the fact that the controller turned off the extruder cooling fan before printing. When I turned off this action, the adventures of cleaning the extruder stopped immediately.

In terms of software, I tried two slicers built into Repeater Host: Slic3r and Cura. For now, the Cura observations are more like short: the interface is simpler, and most importantly, printing is smoother due to, I think, more correct generation of G feed codes and retraction. Slic is then poured, it is not pouring. Maybe, of course, I do not set it up well ...

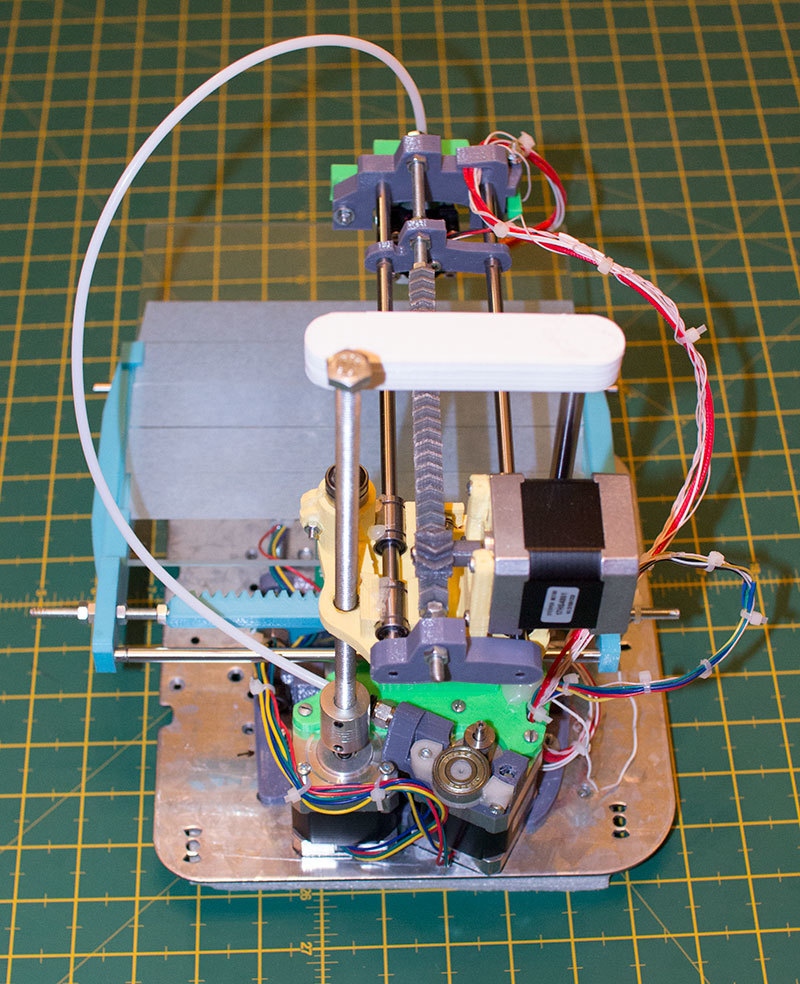

My last opus in the finalization of this happened. I dragged the MC2 from the table to the window sill and back countless times and gored a few — there’s really nothing to grab onto (the top of the shafts on top is just worn, not secured). Rummaging in stocks of iron found once prikopanny metal back of the monitor. It turned out to be the ideal size for a platform for a printer — only holes had to be drilled. Stepper motors screwed right through to the platform, two screws in each remained native, and the other two were replaced with M3x45. The village, as it was.

From the bottom, I glued two pieces of foamed polyethylene to the platform, the vibrations, noise and ideas like “I shook your table” immediately stopped. Now you can leave to print at night, from the next room (bedroom) can not hear how the device prints.

Well, in short, I serviced the printer, now I would need something useful for the home, for the family to make. Muse visited in the morning in the bathroom. There is such a stand for toothbrushes:

With ordinary brushes, everything is fine, but with electric nozzles, this is not a problem. While you are putting one, the other falls out. Having suffered from drawing (I still know SketchUp badly) I depicted inserts, typed ... and experienced unearthly pleasure when these things, like a glove, got into their proper places along with the nozzles. The sharp edges of the parts scratched a little with a scalpel, and then anointed with dichloroethane. In my opinion, it turned out very decently. I give to the court of honest people.

I am planning to try to replace the tabletop with textolite and build a heated table and try to print it with ABS. I found a bunch of places in the house where you can use printed parts: fallen off and lost plugs from furniture and equipment, brackets, stands and the like. I don’t look at art yet, but what the hell is not joking.

Summary. Satisfied with the purchase; the process is fun; use on the face; there is where to go next. People who are interested, actively engage in new interesting business!

Why do I need a 3D printer? .. Vague thoughts wandered in my head: I would print some body, podshevochka, little pen ... I decided this way - I’ll get this thing, but we'll see!

After a brief search, the choice stopped at the most accessible option (which one I could find), but in case something happens, there would be a lot to ask for help, that is, a local Moscow one. Pal my choice on the designer MC2 production Master Kit.

')

I have known the whale for 15 years now, I occasionally use their sets for self-assembly, when it’s lazy to select parts myself. Just the same case!

The assembly process did not capture, because it did not cause any special difficulties, besides, Master Kit presented it adequately on the channel .

The process itself, of course, was not continuous, collected in the evenings in the hunt, but received pleasure from it, because as it was assembled it came to an understanding of what it was for, how it was connected, how it should function.

The simplicity and, at the same time, the functionality of the design simply fascinated. MC2, in comparison with frame monsters, is compact, looks openwork and pleases the eye while standing on the table. The maximum size of the print area on XYZ is 140x140x110! That's how I chose him, among other things - for the appearance, then I just realized. MS2 without power supply is on sale, but in my big economy was necessary.

I set up the electronics quickly, according to the instructions, and began to print test cubes, simultaneously mastering SketchUp and Repeater Host. I must say, the process is fascinating in itself: you draw a three-dimensional detail on the screen, and embody it in the material. I do not know how anyone, but I am delighted!

The first part I drew and printed after the test cubes was the attachment on the shafts of the printer's Z-axis. First, I wanted to practice on a real subject, and secondly, it seemed to me that it would be harder on all axes. That turned out this nozzle with the third time.

Then they offered me to try an E3D extruder . And what not to try? Printed holder suitable, set, tried - a good extruder. While I tried, I scored it with plastic, of course, but I learned how to clean it with a gas stove and wires of different diameters.

But it was mostly clogged by the fact that the controller turned off the extruder cooling fan before printing. When I turned off this action, the adventures of cleaning the extruder stopped immediately.

In terms of software, I tried two slicers built into Repeater Host: Slic3r and Cura. For now, the Cura observations are more like short: the interface is simpler, and most importantly, printing is smoother due to, I think, more correct generation of G feed codes and retraction. Slic is then poured, it is not pouring. Maybe, of course, I do not set it up well ...

My last opus in the finalization of this happened. I dragged the MC2 from the table to the window sill and back countless times and gored a few — there’s really nothing to grab onto (the top of the shafts on top is just worn, not secured). Rummaging in stocks of iron found once prikopanny metal back of the monitor. It turned out to be the ideal size for a platform for a printer — only holes had to be drilled. Stepper motors screwed right through to the platform, two screws in each remained native, and the other two were replaced with M3x45. The village, as it was.

From the bottom, I glued two pieces of foamed polyethylene to the platform, the vibrations, noise and ideas like “I shook your table” immediately stopped. Now you can leave to print at night, from the next room (bedroom) can not hear how the device prints.

Well, in short, I serviced the printer, now I would need something useful for the home, for the family to make. Muse visited in the morning in the bathroom. There is such a stand for toothbrushes:

With ordinary brushes, everything is fine, but with electric nozzles, this is not a problem. While you are putting one, the other falls out. Having suffered from drawing (I still know SketchUp badly) I depicted inserts, typed ... and experienced unearthly pleasure when these things, like a glove, got into their proper places along with the nozzles. The sharp edges of the parts scratched a little with a scalpel, and then anointed with dichloroethane. In my opinion, it turned out very decently. I give to the court of honest people.

I am planning to try to replace the tabletop with textolite and build a heated table and try to print it with ABS. I found a bunch of places in the house where you can use printed parts: fallen off and lost plugs from furniture and equipment, brackets, stands and the like. I don’t look at art yet, but what the hell is not joking.

Summary. Satisfied with the purchase; the process is fun; use on the face; there is where to go next. People who are interested, actively engage in new interesting business!

Source: https://habr.com/ru/post/369235/

All Articles