Three secrets of Ilona Mask

The next landing of the first stage of the Falcon 9 launch vehicle starts to seem familiar and routine. You might think that Mask is in the bag, and soon SpaceX with a fleet of reusable launch vehicles will become a monopolist of launch services, throwing all competitors out of the market. Actually, it is an illusion. The three first steps that have returned are only the very beginning of a long way of their exploitation. And somewhere in SpaceX's internal documents there are calculations that show the economic efficiency of a reusable launch vehicle. And in these calculations in any form, for sure, there are three parameters. These parameters, depending on their value, can make reusable Falcon 9 both effective and not. There must be some preliminary assessment of these parameters in the SpaceX documents. But the irony is that their real values do not know, not only we, but Ilon Musk himself. Because they can only be obtained by the results of many years of operation. What are these parameters?

Cost of inter-flight service

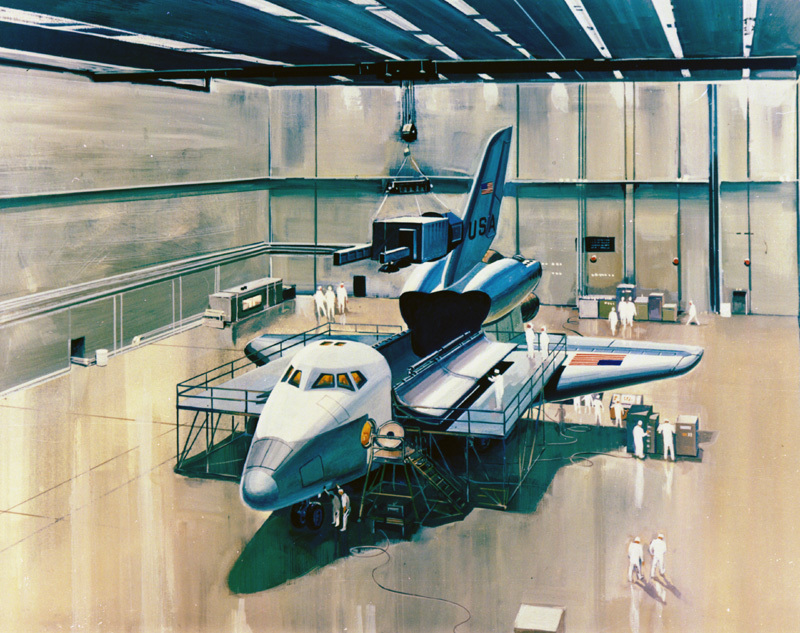

The first step successfully sat down, a wave of likes on beautiful photos and videos subsided on social networks, and the harsh engineering days began. Put the stage back to the start, fill up and run tomorrow? Nah, that doesn't happen. Even in aviation, where an airplane takes off several times a day, there is a set of checks that need to be performed at different intervals. And cosmonautics is still very far from the resource of components in thousands of hours of commercial aviation. SpaceX is not yet talking in detail about post-flight maintenance, so you will have to use a single set of available materials on reusable systems - the history of the Space Shuttle ship. So, the shuttle on the runway meets a whole caravan of special cars.

')

The convoy included not only the obvious crane, tractor, lift, generator and air conditioning. Since the shuttle used explosive hydrogen and toxic hydrazine, the list of special cars included a hefty fan and a separate car with personnel in chemical protection suits. The shuttle was hitched by a tractor, and hung with hoses, towed to the Orbiter Processing Facility - a maintenance hangar.

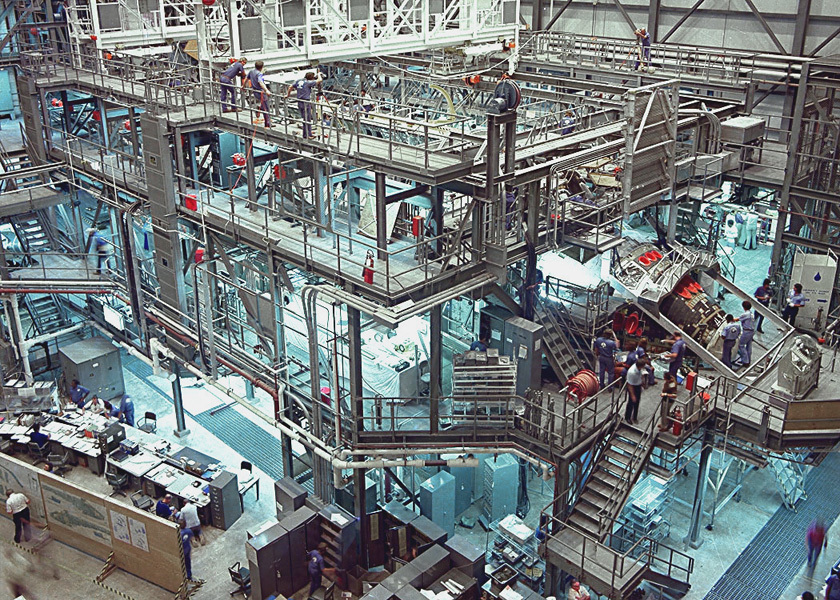

The following works were carried out in this hangar:

- Engine purge from accumulated moisture.

- Cleaning the cargo hold.

- Drainage of hydrogen and oxygen from fuel cells and filling them with inert gases.

- Drainage of high pressure gases from the life support system.

- Cleaning the water system and toilet.

- Inspection and maintenance of thermal protection.

- Fixation of main engines and installation of protective covers.

- Installation of scaffolding for staff access.

- Removal and transportation for maintenance of main engines.

- Removal and transportation for maintenance of shunting engines (if necessary).

- Work on the upgrade and modification of the orbiter (if necessary).

I deliberately cited this long list in order to make it clear that there is much more behind the words “maintenance” than it might seem at first glance. Yes, at the first stage Falcon 9 will not have to clean the toilets, but some operations on the maintenance of engines, hydraulics, electrical systems and landing legs will have to be done. And in the history of the shuttle, as it turned out, a seemingly inconspicuous error was made. Shuttle service was seen as:

But in reality it turned out like this:

Instead of a relatively simple commercial aviation-style service, preparing the shuttle for a new flight took about 100 days. A similar mistake was made with the financial assessment of the cost of maintaining the fleet of shuttles and their maintenance. At the end of the era of shuttles on the NASA budget, they were more expensive than the ISS, the cost of shuttles was close to three billion dollars in the fiscal year with 3-5 flights, which increased the cost of one flight from the official 450 million dollars to almost a billion. The total cost of the project was reduced to three and a half times: instead of $ 54 billion, the shuttle cost 209. And the cost of one flight, calculated as the quotient of dividing the total cost by the number of flights, amounted to one and a half billion dollars in 2011 prices.

Optimists will say that the figures have already been announced - one million dollars for refueling and three million for inter-flight service, which should give a saving of 30% Maybe these figures are written in SpaceX internal documents (let's not forget that they can now be dumped so that take a larger market share). But only practice will show whether these figures will be true.

Resource

The next question is - how many starts can the first stage withstand? Modern rockets are on the verge of materials science, when there is overpressure from the pressurization system in the tanks (the fuel must be fed to the engines without interruption), the engines have enormous temperatures and pressures, and the entire rocket vibrates from the engines, turbopumps and the movement of fuel through pipelines . And it would be wrong to think that for a rocket this passes without a trace.

Metal fatigue is a process of strain accumulation under the influence of variable loads. Despite the fact that the life of the rocket stage usually ranges from 50 to 500 seconds, the engines have time to experience fatigue damage. This contributes to the high temperature in the engine and vibration.

Metal creep - slow deformation under the influence of a constant load. And here the main factors will be high temperature (reducing strength) and pressure in the engine running.

Wear Some elements of the engine, such as turbopump bearings, wear out from work under load.

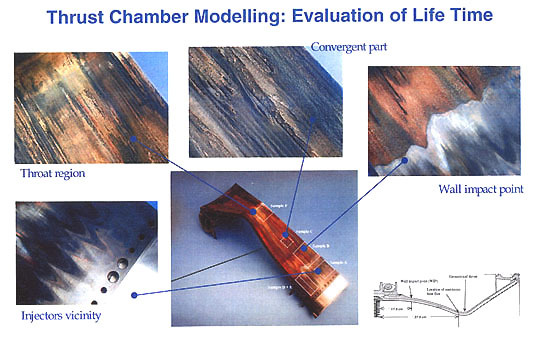

Engine damage example

And here is a diagram showing the distribution of damage to the elements of the Space Shuttle SSME engine

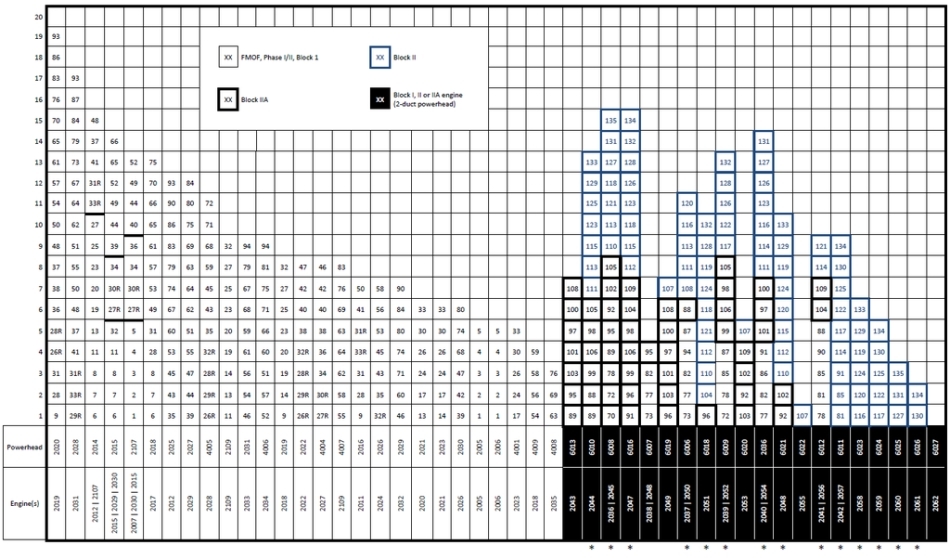

For 135 flights of shuttles, 46 engines were used (+1 non-flying). If we recount 135 missions, each of which required 3 engines, for 46 engines used in total, it turns out that, on average, one engine was used 8.8 times. Very interesting distribution of engines for missions:

Full version , larger. The numbers of missions that crashed are 33 and 107.

The absolute record for the number of flights is only 19. And this engine, which was specially developed as reusable and tested for 50 missions. In this case, do not forget that the engine in any case did not fly 19 missions without a bulkhead. On the contrary, the record holder with 19 missions refers to the first version of the engine, and there it was necessary to disassemble the engine after each flight due to problems with the destruction of the turbine blades.

It is also very interesting, as the authors of the 1996 document analyzing the experience of using SSME engines and methods for increasing their service life, talk about the relationship between engine power and its service life:

One of the options for extending the life of the engine - reducing thrust. In principle, it is intuitive - less load, less wear.

Now look at the situation with the engines of Merlin. For about a year, optimists have referred to the words Mask, in which 40 or 50 engine use cycles are announced. Rocket engines are not computers, progress in them was much less, and you can absolutely say that 50 cycles without engine reassembly is simply impossible. I suspect that a bulkhead will be required after each mission, and, at least in some cases, repairs and replacement of failed nodes will be required. And this is extra time and money for each of the 9 engines on the first stage. Also, one should not forget that oxygen-kerosene engines are less physically adapted for reuse, because unlike oxygen-hydrogen engines (like the SSME shuttle engine), they have soot after the turbo pump and the combustion chamber, which will create additional problems. And finally, the cherry on the cake - the parameters of the Merlin engines increase with time, they are beginning to be exploited with more and more of a burden. And this should seriously reduce the resource of the engine. And, despite the possibility of a launch vehicle to compensate for the failure of one of the engines, I very much doubt that if frequent accidents begin with engine failure, even with the successful withdrawal of the payload, SpaceX will have customers willing to take risks.

Loss percentage

The fact that the Falcon 9 unmanned launch vehicle adds another parameter that the shuttle did not have. There must be some percentage of the loss of the first steps that cannot return, for example, due to bad weather at the landing site. The situation is complicated by the fact that SpaceX will not be able to abandon landing on the barge in the coming years. At Cape Canaveral and Vandenberg base, where SpaceX launch complexes already exist, you can launch rockets only towards the sea. A new cosmodrome in Texas is also being built on the seashore and, theoretically, landing on land is possible only if launched into a polar orbit (northward), and if there are no settlements along the way.

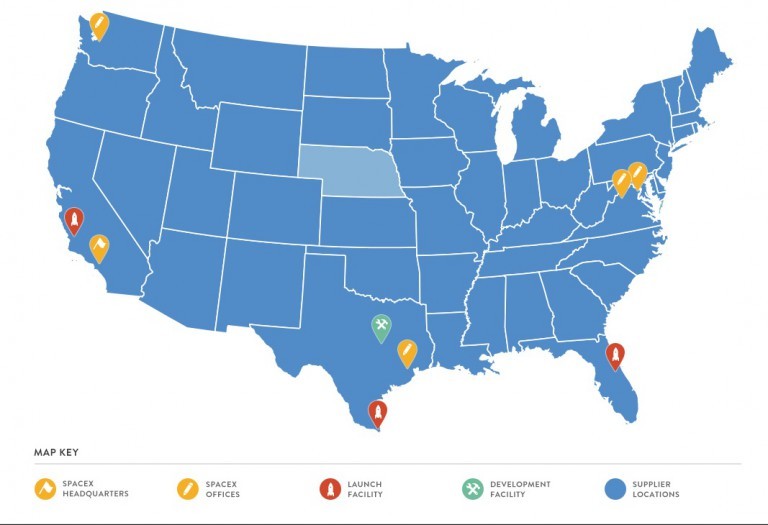

SpaceX spaceports are shown in red

I do not specifically provide statistics on the success of landings on a barge today - it is very bad simply because the technology has been worked out. But starting from this year it is worth looking at how many plantings will be successful, and what the reasons for the failures will be.

Conclusion

Once again, I emphasize that the exact value of the parameters mentioned above can only be obtained after operating experience of a reusable first stage, which has not yet been flown to SpaceX again. Also, all of the above applies to Bezos with New Shepard. Only there the easier task is solved, the engine is only one, the fuel (hydrogen) is better suited to reusable use. It is not surprising that Bezos was overtaken by Mask - he had the same rocket already flying three times.

On the tag “facilitating access to space” - reusability, air launch, “big silly carrier”, private traders and other attempts to make space closer

Source: https://habr.com/ru/post/369113/

All Articles