Repair Chinese lantern TrustFire XM-L Z5

Anecdote (instead of an epigraph). The professor gives a lecture to students: ... as you can see, this technological solution is simple, understandable, and very reliable. For these reasons, it is not used. In practice, they use another technology, which we will study over the next couple of months ...

This flashlight, which is not cheap in general, was brought in an almost perfect appearance, which speaks of its clearly untimely demise. And twice dead inside.

')

The first time he rested when the current driver's electronics burned down - quite naturally for an extreme mode at full loads. After which, apparently, the “craftsman” worked on him, by powering the crystal directly - as a result, the LED itself also burned out.

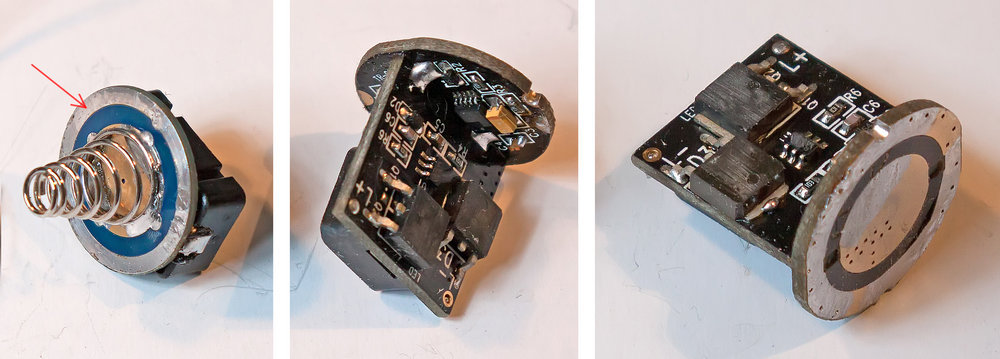

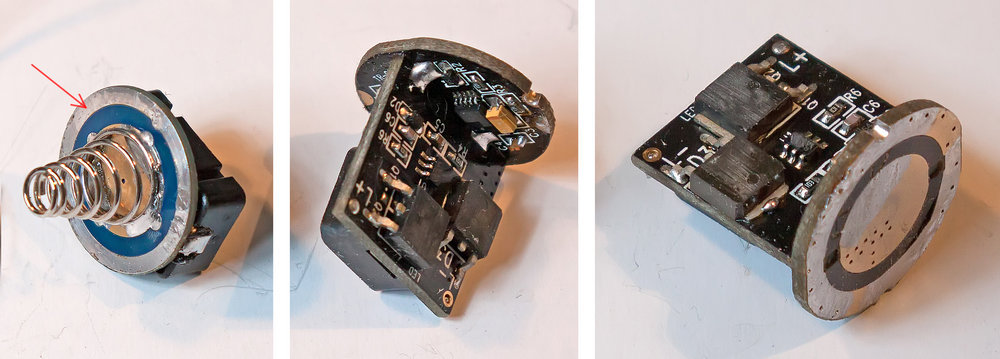

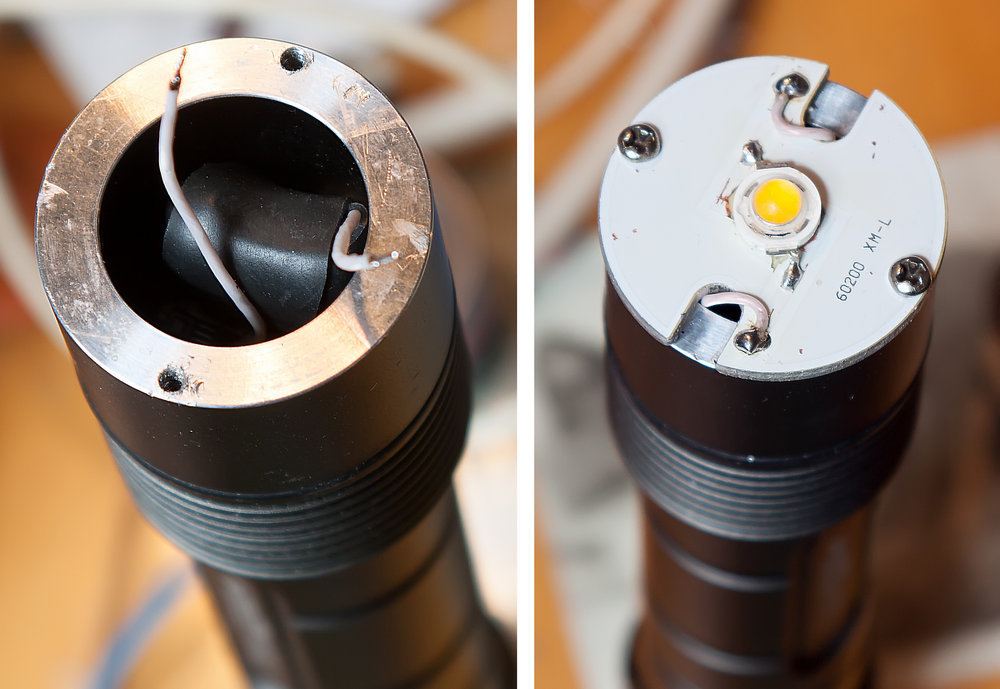

The manufacturers diligently wrote down the marking of transistors and microcircuits, probably out of a sense of shame for the non-optimal choice of components. But at the same time, they did not bother to conquer the copper rims on the circuit board of the switch (on the left, shown by the red arrow), and on the “nickle” of the driver board - which are wrapped with an aluminum case. I had to do it myself in order to prevent the destruction of metals in the galvanopar formed. The burnt-out crystal was dismantled with an industrial blow dryer. Instead, the newly acquired OS-Star-5W Warm White 3000K 300Lm, designed for a current of 0.7A with a voltage drop of 6v on the LED, sealed. In the flashlight it will be used at reduced power, in order to extend the life of the LED and the battery life of the flashlight from the battery.

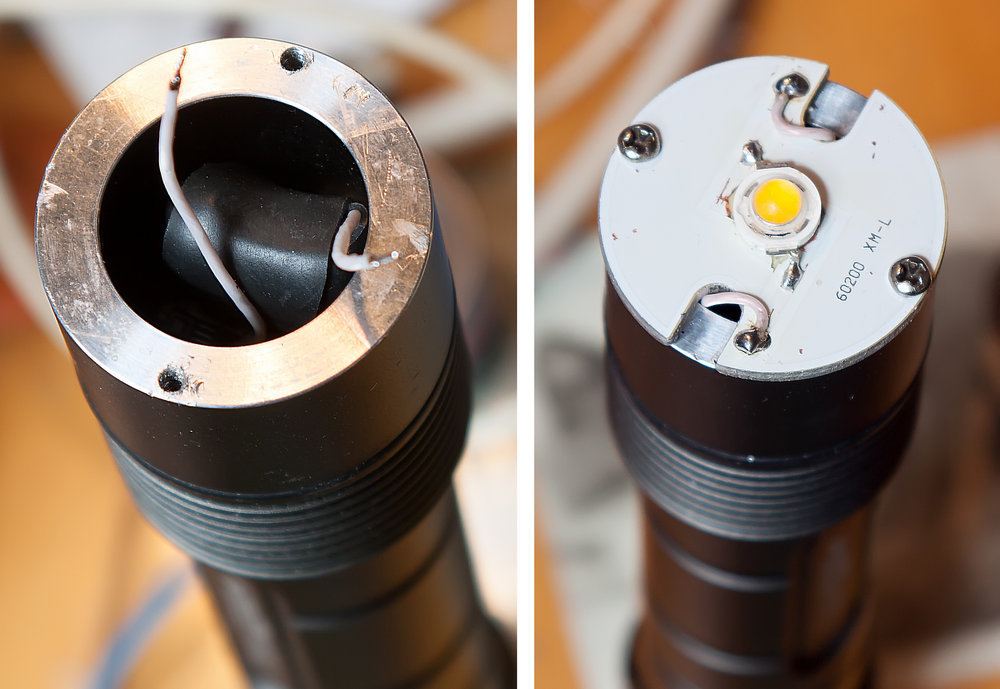

We are testing a new crystal. Its heat sink “nickle” was also soldered to the substrate to improve heat transfer, but as it turned out later, the lamp practically does not heat up on the selected working current 0.2A. A voltmeter (left) shows the voltage drop across the LED connected to the laboratory power source through a limiting resistor.

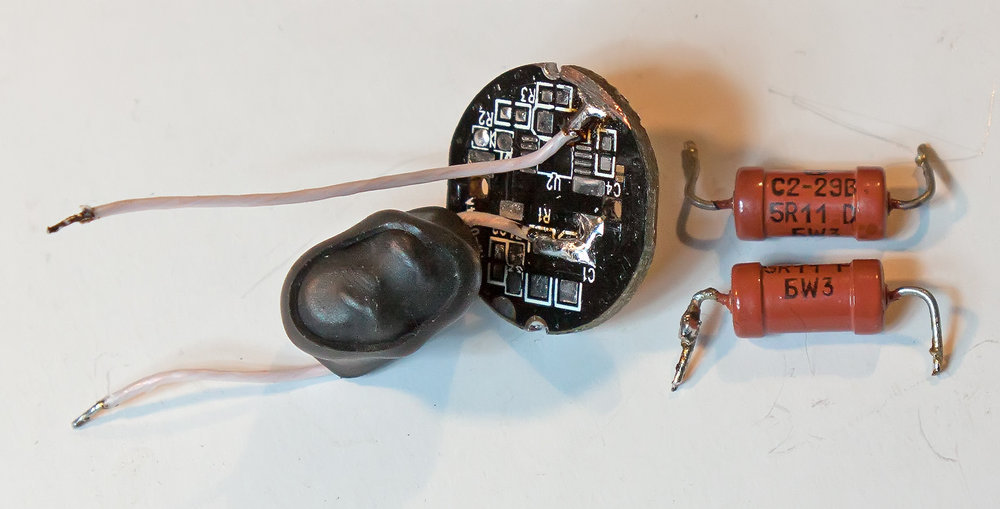

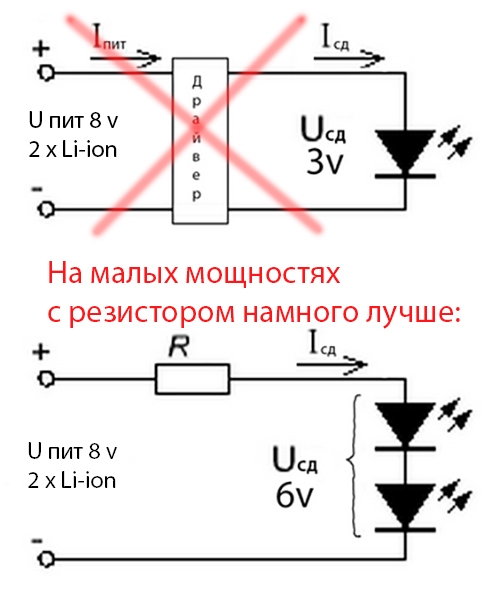

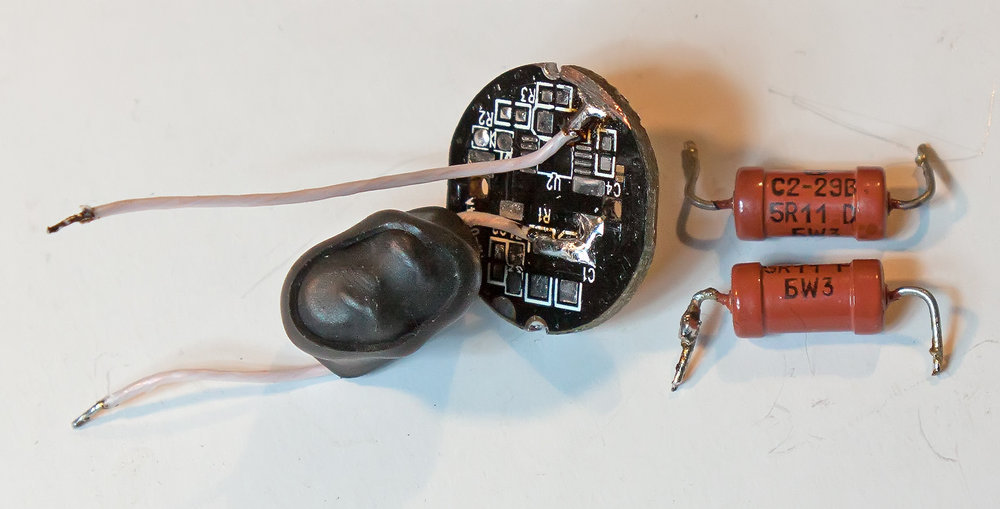

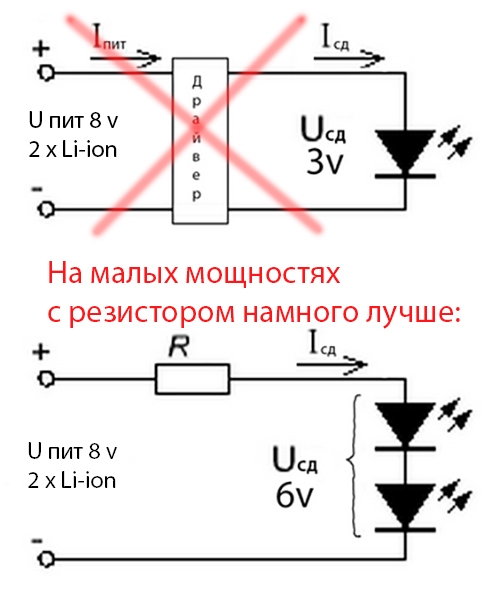

The driver can be reconstructed frozen and without a trace, and even as shown below, it is even harmful in terms of reliability and efficiency factors in the case of using a flashlight for everyday purposes. Therefore, the penny was cleared of radio components, and to limit the current of the LED in the region of 0.2A with full batteries, a resistor of 10 Ohm was used.

In the photo there are two resistors of 5.1 Ohm, similar to those packed in heat shrink. There they are connected there in series, because 10 ohm resistor was not at hand.

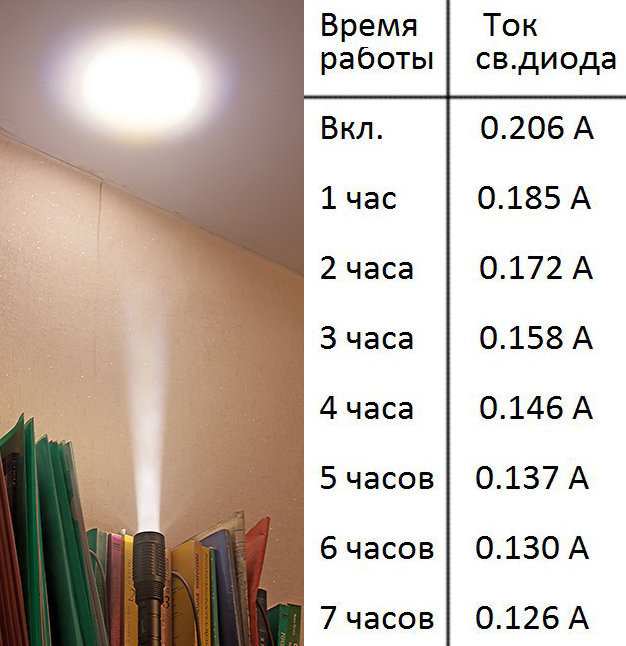

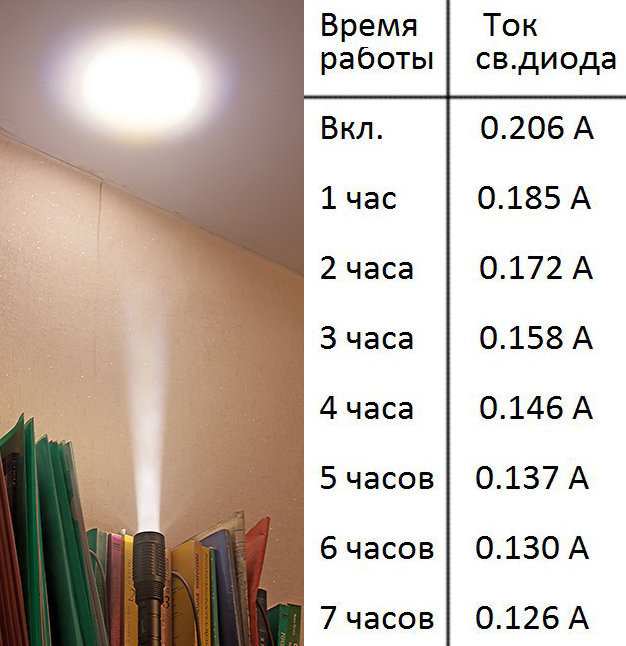

After flushing the flux and assembling the LED assembly, the flashlight was put to the test. The 18650 batteries are not “native,” torn from the batblock of an outdated notebook. Nevertheless, some reserve capacity in them still remained. Before the start of the run, they were charged up to a voltage of 4.12v each.

Current consumption was measured every hour. After 7 hours of continuous operation, the battery voltage dropped to 3.6v, which indicates that their discharge is not yet final, but is close to this. At the same time, the flashlight illuminates the room quite brightly, and on the street it shines well for more than fifty meters. Thus the product is restored, and corresponds to the wishes of the customer.

Calculations and justification

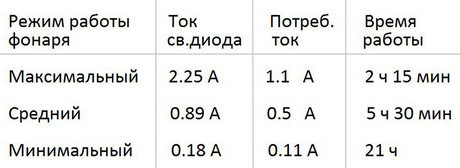

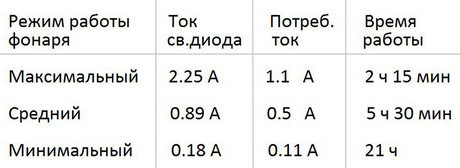

The original LED was applied with a voltage drop of 3v on it. The pivot table shows the LED current in various operating modes of the lamp, and the current consumption from the power source. The source of information from the forum , and from this review here

Based on these data, you can calculate the energy saving ratio of the batteries in the original design of the lamp:

Ke = Isd / Ipit

We get (rounded) for modes:

These figures show how many times the current consumption from the batteries is lower than the current that would be in the circuit with direct power through the limiting resistor. Those. in essence, they characterize the power savings obtained due to the pulsed LED power supply driver.

On the newly installed LED, the voltage drop is already 6v, it structurally consists of two three-volt sections connected in series. And this means that the amount of light emitted at the same flowing current is twice as large as the original three-volt one.

The current consumption of the circuit with a resistor limiter is in the range from 0.21 to 0.13 A, depending on the degree of battery discharge. But taking into account the doubling of the emitted light, the luminous flux even on discharging acb is noticeably larger than the original circuit in the minimum (economy) mode. For the resistor limiter, the current consumed from the batteries and the current of the LED are the same. But you can calculate the efficiency, as the ratio of the power supplied to the LED to the total power consumed by the entire circuit.

So the efficiency of a highly reliable flashlight with a resistor instead of a pulse driver is 74% on a fully charged battery and 81% on a discharging battery.

To calculate the efficiency in the original design with pulsed powering, we take the voltage drop across the LED 3.1v, and the LED current does not change as the battery is discharged.

It turns out that at a low power level for everyday needs, the correct selection of the LED, and the use of a simple and reliable resistor current limit, are more optimal. This approach provides greater efficiency in the use of battery energy compared to powering through a pulse driver. As well as many years of uptime, due to the reliability of the circuit, and the fact that in underloaded mode, the LED will last many times longer.

A little explanation

The driver calculates the efficiency in the circuit without taking into account the increase in current consumption as the batteries discharge. Therefore, the real efficiency with a pulse on the planted batteries will be slightly less than the values indicated in the last table.

With the driver, the LED current is kept constant, and accordingly its brightness. Therefore, as the batteries discharge, the current consumed from them begins to increase. Batteries will sit faster and faster.

With a resistor, the situation is exactly the opposite - the current consumption decreases when the batteries are discharged, and so on. allows you to stretch on a single charge and a half times ... two about longer than if it were with the driver. Of course, this is achieved at the cost of a slight decrease in brightness, but in such a situation it is better that at least a little bit of light than anything at all.

Instead of a resistor, the current regulator on an IC or a field-effect transistor was used to consider the option, but also rejected it. reduced battery life compared with a resistor circuit.

The choice of resistor was due to a reasonable compromise between the minimum required illumination when discharging batteries, and the desire to maximize extend the battery life of the lamp. This was achieved - on a lantern-powered battery, it allows you to read a book text, and gives quite acceptable illumination for orientation on the street, “punching” tens of meters.

This flashlight, which is not cheap in general, was brought in an almost perfect appearance, which speaks of its clearly untimely demise. And twice dead inside.

')

The first time he rested when the current driver's electronics burned down - quite naturally for an extreme mode at full loads. After which, apparently, the “craftsman” worked on him, by powering the crystal directly - as a result, the LED itself also burned out.

The manufacturers diligently wrote down the marking of transistors and microcircuits, probably out of a sense of shame for the non-optimal choice of components. But at the same time, they did not bother to conquer the copper rims on the circuit board of the switch (on the left, shown by the red arrow), and on the “nickle” of the driver board - which are wrapped with an aluminum case. I had to do it myself in order to prevent the destruction of metals in the galvanopar formed. The burnt-out crystal was dismantled with an industrial blow dryer. Instead, the newly acquired OS-Star-5W Warm White 3000K 300Lm, designed for a current of 0.7A with a voltage drop of 6v on the LED, sealed. In the flashlight it will be used at reduced power, in order to extend the life of the LED and the battery life of the flashlight from the battery.

We are testing a new crystal. Its heat sink “nickle” was also soldered to the substrate to improve heat transfer, but as it turned out later, the lamp practically does not heat up on the selected working current 0.2A. A voltmeter (left) shows the voltage drop across the LED connected to the laboratory power source through a limiting resistor.

The driver can be reconstructed frozen and without a trace, and even as shown below, it is even harmful in terms of reliability and efficiency factors in the case of using a flashlight for everyday purposes. Therefore, the penny was cleared of radio components, and to limit the current of the LED in the region of 0.2A with full batteries, a resistor of 10 Ohm was used.

In the photo there are two resistors of 5.1 Ohm, similar to those packed in heat shrink. There they are connected there in series, because 10 ohm resistor was not at hand.

After flushing the flux and assembling the LED assembly, the flashlight was put to the test. The 18650 batteries are not “native,” torn from the batblock of an outdated notebook. Nevertheless, some reserve capacity in them still remained. Before the start of the run, they were charged up to a voltage of 4.12v each.

Current consumption was measured every hour. After 7 hours of continuous operation, the battery voltage dropped to 3.6v, which indicates that their discharge is not yet final, but is close to this. At the same time, the flashlight illuminates the room quite brightly, and on the street it shines well for more than fifty meters. Thus the product is restored, and corresponds to the wishes of the customer.

Calculations and justification

The original LED was applied with a voltage drop of 3v on it. The pivot table shows the LED current in various operating modes of the lamp, and the current consumption from the power source. The source of information from the forum , and from this review here

Based on these data, you can calculate the energy saving ratio of the batteries in the original design of the lamp:

Ke = Isd / Ipit

We get (rounded) for modes:

- maximum - 2.05

- medium - 1.78

- minimum - 1.63

These figures show how many times the current consumption from the batteries is lower than the current that would be in the circuit with direct power through the limiting resistor. Those. in essence, they characterize the power savings obtained due to the pulsed LED power supply driver.

On the newly installed LED, the voltage drop is already 6v, it structurally consists of two three-volt sections connected in series. And this means that the amount of light emitted at the same flowing current is twice as large as the original three-volt one.

The current consumption of the circuit with a resistor limiter is in the range from 0.21 to 0.13 A, depending on the degree of battery discharge. But taking into account the doubling of the emitted light, the luminous flux even on discharging acb is noticeably larger than the original circuit in the minimum (economy) mode. For the resistor limiter, the current consumed from the batteries and the current of the LED are the same. But you can calculate the efficiency, as the ratio of the power supplied to the LED to the total power consumed by the entire circuit.

So the efficiency of a highly reliable flashlight with a resistor instead of a pulse driver is 74% on a fully charged battery and 81% on a discharging battery.

To calculate the efficiency in the original design with pulsed powering, we take the voltage drop across the LED 3.1v, and the LED current does not change as the battery is discharged.

It turns out that at a low power level for everyday needs, the correct selection of the LED, and the use of a simple and reliable resistor current limit, are more optimal. This approach provides greater efficiency in the use of battery energy compared to powering through a pulse driver. As well as many years of uptime, due to the reliability of the circuit, and the fact that in underloaded mode, the LED will last many times longer.

A little explanation

The driver calculates the efficiency in the circuit without taking into account the increase in current consumption as the batteries discharge. Therefore, the real efficiency with a pulse on the planted batteries will be slightly less than the values indicated in the last table.

With the driver, the LED current is kept constant, and accordingly its brightness. Therefore, as the batteries discharge, the current consumed from them begins to increase. Batteries will sit faster and faster.

With a resistor, the situation is exactly the opposite - the current consumption decreases when the batteries are discharged, and so on. allows you to stretch on a single charge and a half times ... two about longer than if it were with the driver. Of course, this is achieved at the cost of a slight decrease in brightness, but in such a situation it is better that at least a little bit of light than anything at all.

Instead of a resistor, the current regulator on an IC or a field-effect transistor was used to consider the option, but also rejected it. reduced battery life compared with a resistor circuit.

The choice of resistor was due to a reasonable compromise between the minimum required illumination when discharging batteries, and the desire to maximize extend the battery life of the lamp. This was achieved - on a lantern-powered battery, it allows you to read a book text, and gives quite acceptable illumination for orientation on the street, “punching” tens of meters.

Source: https://habr.com/ru/post/368007/

All Articles