A new generation of Showa Denko PMR-plates will allow to exceed the threshold capacity of hard drives of 10 TB in 2016

Welcome to our readers on the pages of the blog iCover ! The Japanese company Showa Denko KK, one of the largest independent manufacturers of hard disk plates, confirmed its intention to begin commercial production of plates with a ninth generation perpendicular magnetic recording in 2016.

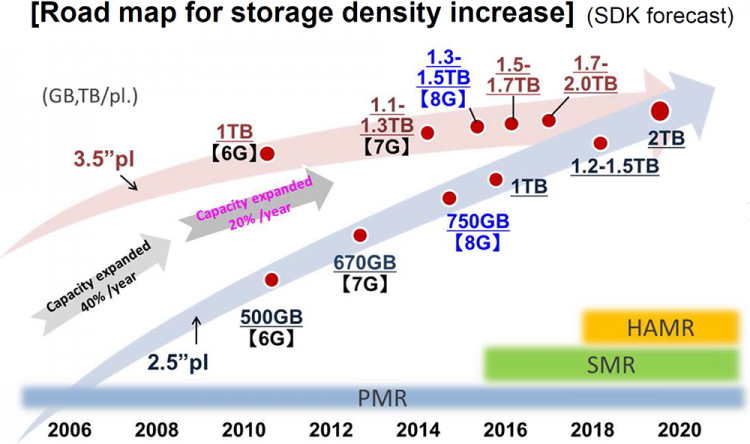

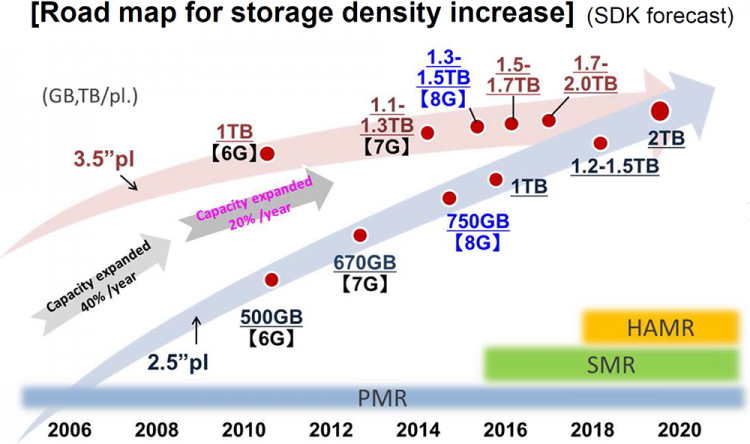

Recall that in March 2015, Showa Denko KK (SDK), with a 25% market share, launched the eighth generation perpendicular magnetic recording plates, designed for a capacity of 750 GB for 2.5-inch hard drives. Somewhat later, PMR-plates were announced for 3.5-inch discs of the eighth generation. According to the company, these plates were used in a complete set of recently presented 3.5-inch hard drives record holders HGST Ultrastar He10, filled with helium. Each of the seven plates has a capacity of 1.43 TB, and the total capacity of the hard drive, respectively, was 10 TB. In this generation, the SDK produces PMR plates with a capacity of 1.3-1.5 TB.

In the ninth generation PRM-plates SDK for 2.5-inch HDD capacity increased to 1 TB, which is 1.3 Tbit per 1 square inch and allows you to significantly increase the capacity of hard drives for mobile PCs. At the same time, due to the use of perpendicular magnetic recording technology in helium-filled HDDs, the developers promise a significant reduction in power consumption and performance gains when performing standard read and write operations.

')

Development plan directions HDD Showa Denko until 2020

According to specialists of the SDK, the ninth-generation PMR technology will allow to reach the capacity of magnetic plates for 3.5-inch HDDs up to 1.5-1.7 TB in 2016, and in 2017 to overcome the 1.7-2 TB threshold. If events evolve according to the proposed scenario, then manufacturers who have the technical ability to produce hard drives filled with helium and with an increased number of plates (HGST, Seagate) will be able to start HDD production with a capacity of more than 10 TB in 2016-2017. New opportunities for increasing HDD capacity will also be available to manufacturers who do not use helium (Toshiba) inside the drives.

WD Ae Hard Drives

As expected, the interest in the use of hard drives in the 3.5-inch form factor of large volumes will manifest, first of all, data processing centers (DPCs), whose requirements for the volume of stored data increase year by year. The most capacious plates will be equipped with, first of all, hard disks filled with helium, so that they can use their data storage capabilities as efficiently as possible. According to the most optimistic scenarios, if the SDK is able to establish a commercial release of 1.7-TB plates in 2016, then manufacturers, accordingly, will be able to submit hard drives with seven plates of 12 TB by the end of next year, and in the case of the announcement of 2 TB plates the opportunity to offer 14 TB drives in 2017

HGST hard disk - record holder

PMR technology is able to offer a relatively high level of performance, low cost in terms of gigabytes of stored data and stable operation, which will allow them to be used as client hard drives. At the same time, the use of thermomagnetic recording technology HAMR (heat-assisted magnetic recording), which will open up opportunities to increase the information recording density to 1.5–2 Tbit per square, looks very promising, according to SDK experts, expressed in a separate press release. inch and to the commercial release of hard drives based on this technology in 2018 or a year later. It is expected that 2.5 inch plates with a capacity of 2 TB, manufactured using HAMR technology will become a reality already in 2020. This means that mobile HDDs with a capacity of 8-10 TB can most likely be expected in less than five years.

In order to figuratively imagine what happens to the hard disk in the process of working at a rotation speed of several thousand revolutions per minute, it is enough to expose the hand from the window of a car racing at high speed. The working environment inside is quite tough, the head performs multiple write and read operations, friction and air resistance play their part.

Since helium is lighter than air, this gas is ideal for use in data storage systems. At the same time, the level of vibration (turbulence) between the disk and the head is significantly reduced. What gives such a technological solution?

Firstly, the ability to place more disks inside a standard case. So in an inch HDD case fits five, and with a decrease in resistance, you can pack the disks more tightly and place as many as seven. Moreover, since the resistance of helium is less than air, the estimated life cycle of the HDD increases.

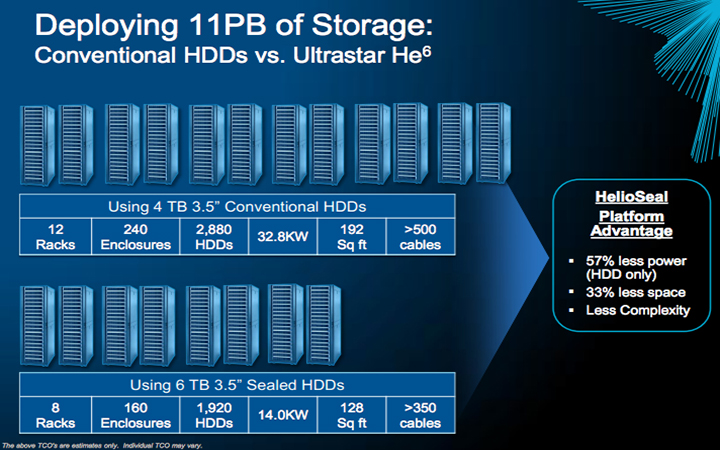

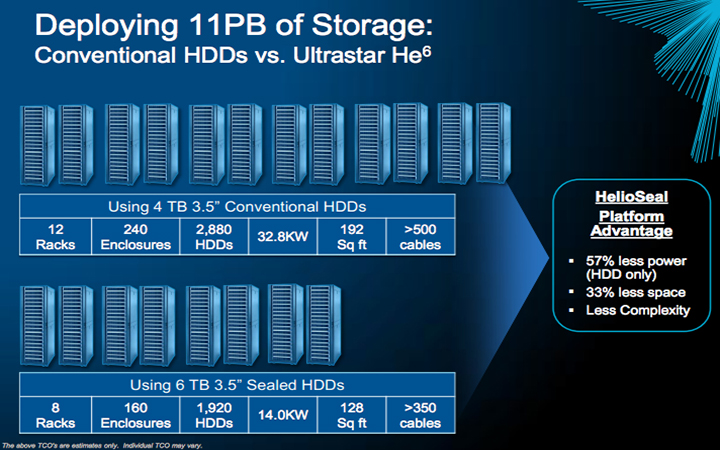

This design also significantly reduces power consumption. On small storage systems, this is traditionally unnoticeable. However, corporate customers and companies deploying commercial data centers will certainly appreciate this advantage. According to the manufacturer, the deployment of storage on 11 petabytes requires 12 racks, filled with a total of 2,880 disks. This storage requires about 33 kilowatts of electricity. At the same time, an increase in the volume of each disk by 2 TB means that only 1920 disks and 14 kW are needed to store the same amount of data in order to ensure their operation. On the other hand, fewer HDDs mean less space and fewer connecting cables.

Another useful feature and advantage of hard disks filled with helium is their tightness. So, it is quite possible to use them in racks with liquid cooling. So, for example, Intel has long been experimenting with oil cooling, developing components that can be immersed in a special oil without fear of corrosion or short circuit. And the main stumbling block for Intel was just the hard drives. Oil cooling today is one of the most advanced technologies used in the design and construction of data centers. Of course, it’s still far from universal implementation, but the obvious advantages make many people think.

It is important that oil cooling will eliminate the need for all other cooling elements that lower the temperature due to the removal of hot air. Moreover, oil as a cooling element can be reused - as a source of electricity. And most importantly, it is possible to maintain a constant temperature inside the racks, which will significantly increase the efficiency of the system components, as well as their lifespan.

Today, several large companies have already announced that they intend to complete their HDD data centers filled with helium. HP plans to install such disks in its servers; on the basis of progressive HDDs, they are going to organize part of the dynamic storage system Netflix and Huawei. Of course, a special place in this cohort of CERN clients (the European Organization for Nuclear Research, which generates colossal amounts of data and uses hard disks and cassettes for recording). Already, CERN is testing in its storage system, designed for storage of 60 petabytes, disks filled with helium. So far, most of the data is stored on cassettes, but with the introduction of cost-effective "helium" disks, this trend may change.

Source 1

Source 2

Dear readers, we are always happy to meet and wait for you on the pages of our blog. We are ready to continue to share with you the latest news, review articles and other publications and will try to do everything possible so that the time spent with us will be useful for you. And, of course, do not forget to subscribe to our headings .

Our other articles and events

Recall that in March 2015, Showa Denko KK (SDK), with a 25% market share, launched the eighth generation perpendicular magnetic recording plates, designed for a capacity of 750 GB for 2.5-inch hard drives. Somewhat later, PMR-plates were announced for 3.5-inch discs of the eighth generation. According to the company, these plates were used in a complete set of recently presented 3.5-inch hard drives record holders HGST Ultrastar He10, filled with helium. Each of the seven plates has a capacity of 1.43 TB, and the total capacity of the hard drive, respectively, was 10 TB. In this generation, the SDK produces PMR plates with a capacity of 1.3-1.5 TB.

In the ninth generation PRM-plates SDK for 2.5-inch HDD capacity increased to 1 TB, which is 1.3 Tbit per 1 square inch and allows you to significantly increase the capacity of hard drives for mobile PCs. At the same time, due to the use of perpendicular magnetic recording technology in helium-filled HDDs, the developers promise a significant reduction in power consumption and performance gains when performing standard read and write operations.

')

Development plan directions HDD Showa Denko until 2020

According to specialists of the SDK, the ninth-generation PMR technology will allow to reach the capacity of magnetic plates for 3.5-inch HDDs up to 1.5-1.7 TB in 2016, and in 2017 to overcome the 1.7-2 TB threshold. If events evolve according to the proposed scenario, then manufacturers who have the technical ability to produce hard drives filled with helium and with an increased number of plates (HGST, Seagate) will be able to start HDD production with a capacity of more than 10 TB in 2016-2017. New opportunities for increasing HDD capacity will also be available to manufacturers who do not use helium (Toshiba) inside the drives.

WD Ae Hard Drives

As expected, the interest in the use of hard drives in the 3.5-inch form factor of large volumes will manifest, first of all, data processing centers (DPCs), whose requirements for the volume of stored data increase year by year. The most capacious plates will be equipped with, first of all, hard disks filled with helium, so that they can use their data storage capabilities as efficiently as possible. According to the most optimistic scenarios, if the SDK is able to establish a commercial release of 1.7-TB plates in 2016, then manufacturers, accordingly, will be able to submit hard drives with seven plates of 12 TB by the end of next year, and in the case of the announcement of 2 TB plates the opportunity to offer 14 TB drives in 2017

HGST hard disk - record holder

PMR technology is able to offer a relatively high level of performance, low cost in terms of gigabytes of stored data and stable operation, which will allow them to be used as client hard drives. At the same time, the use of thermomagnetic recording technology HAMR (heat-assisted magnetic recording), which will open up opportunities to increase the information recording density to 1.5–2 Tbit per square, looks very promising, according to SDK experts, expressed in a separate press release. inch and to the commercial release of hard drives based on this technology in 2018 or a year later. It is expected that 2.5 inch plates with a capacity of 2 TB, manufactured using HAMR technology will become a reality already in 2020. This means that mobile HDDs with a capacity of 8-10 TB can most likely be expected in less than five years.

Why fill the hard drives with helium?

In order to figuratively imagine what happens to the hard disk in the process of working at a rotation speed of several thousand revolutions per minute, it is enough to expose the hand from the window of a car racing at high speed. The working environment inside is quite tough, the head performs multiple write and read operations, friction and air resistance play their part.

Since helium is lighter than air, this gas is ideal for use in data storage systems. At the same time, the level of vibration (turbulence) between the disk and the head is significantly reduced. What gives such a technological solution?

Firstly, the ability to place more disks inside a standard case. So in an inch HDD case fits five, and with a decrease in resistance, you can pack the disks more tightly and place as many as seven. Moreover, since the resistance of helium is less than air, the estimated life cycle of the HDD increases.

This design also significantly reduces power consumption. On small storage systems, this is traditionally unnoticeable. However, corporate customers and companies deploying commercial data centers will certainly appreciate this advantage. According to the manufacturer, the deployment of storage on 11 petabytes requires 12 racks, filled with a total of 2,880 disks. This storage requires about 33 kilowatts of electricity. At the same time, an increase in the volume of each disk by 2 TB means that only 1920 disks and 14 kW are needed to store the same amount of data in order to ensure their operation. On the other hand, fewer HDDs mean less space and fewer connecting cables.

Another useful feature and advantage of hard disks filled with helium is their tightness. So, it is quite possible to use them in racks with liquid cooling. So, for example, Intel has long been experimenting with oil cooling, developing components that can be immersed in a special oil without fear of corrosion or short circuit. And the main stumbling block for Intel was just the hard drives. Oil cooling today is one of the most advanced technologies used in the design and construction of data centers. Of course, it’s still far from universal implementation, but the obvious advantages make many people think.

It is important that oil cooling will eliminate the need for all other cooling elements that lower the temperature due to the removal of hot air. Moreover, oil as a cooling element can be reused - as a source of electricity. And most importantly, it is possible to maintain a constant temperature inside the racks, which will significantly increase the efficiency of the system components, as well as their lifespan.

Today, several large companies have already announced that they intend to complete their HDD data centers filled with helium. HP plans to install such disks in its servers; on the basis of progressive HDDs, they are going to organize part of the dynamic storage system Netflix and Huawei. Of course, a special place in this cohort of CERN clients (the European Organization for Nuclear Research, which generates colossal amounts of data and uses hard disks and cassettes for recording). Already, CERN is testing in its storage system, designed for storage of 60 petabytes, disks filled with helium. So far, most of the data is stored on cassettes, but with the introduction of cost-effective "helium" disks, this trend may change.

Source 1

Source 2

Dear readers, we are always happy to meet and wait for you on the pages of our blog. We are ready to continue to share with you the latest news, review articles and other publications and will try to do everything possible so that the time spent with us will be useful for you. And, of course, do not forget to subscribe to our headings .

Our other articles and events

- A selection of Christmas gifts to 2016 rubles from iCover

- Buy iMac or Macbook win headset

- Review of the portable audio player Cowon Plenue M: The thing is in the sound

- One manufacturer - different destinies: external HDD LaCie P'9220 1 TB and Rugged Triple 2 TB

- Smart cleaning with iRobot + gifts

- Exclusive records from iCover and Warner Music

- 20% discount on futurism and classics

Source: https://habr.com/ru/post/367439/

All Articles