Copter in a backpack (part 2) - Lego for drones

Hello. In this article I would like to tell you more about the design of my folding frame.

Hello. In this article I would like to tell you more about the design of my folding frame.Let me remind you that the main goal was the compactness of the drone. In my opinion, there are two of the most important design requirements:

• Frame chassis must be removable.

')

• Paws (rays) should be stacked on top of each other for maximum space saving.

In addition, I tried to further implement the following ideas:

• Modular frame design

• Vibration isolation module for electronics

Now about everything in order.

How to fold your paws as compact as possible?

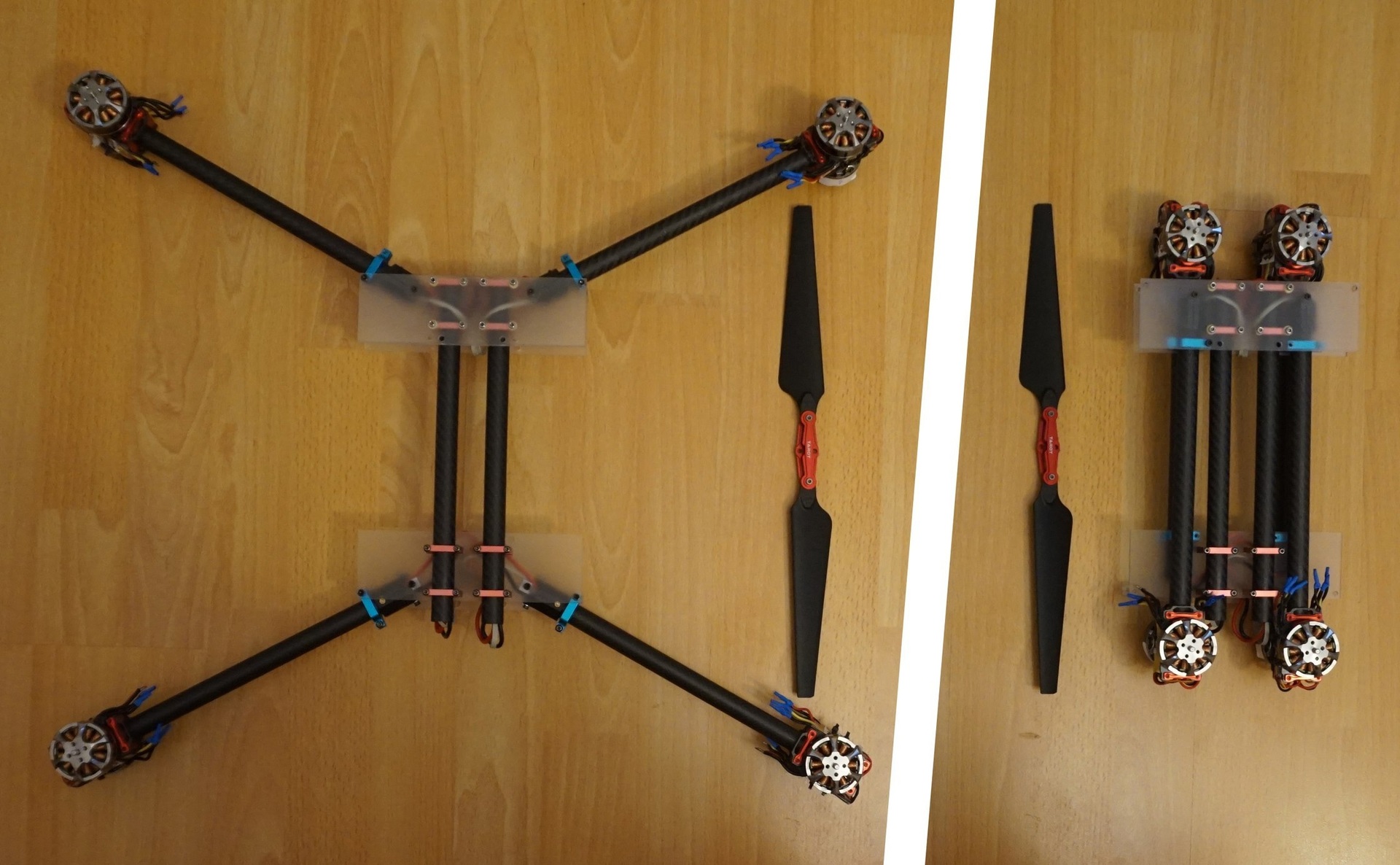

In the variant proposed by me, the rays are in pairs one above the other. Here you can already see that the design is modular: the elements of the frame can be simply moved along the carrying tubes to create drones of various sizes. The picture shows two core blocks: for the front paws and for the hind. They are attached to the unit for electronics, but more on that below.

In order for the motors to remain at the same level, a special folding mechanism is needed (see the video, I apologize for the pathos, the video was created for advertising). We also need special mounts to level the upper and lower motors (I don't have them yet).

There are alternatives, however, with their own drawbacks: you can make the paws removable, but this will not bring a noticeable gain and increase the assembly time; In addition, folding umbrella-type frames (umbrella, on the right) can theoretically be folded in the same compact way, but for this, the main plates would have to be reduced (by sacrificing space for electronics).

Why unscrew the legs?

Without a chassis, the height of the drone does not exceed 100-120 mm, which significantly simplifies transportation. Assembly time does not suffer, as the legs and paws are fixed together with one bolt (M3 is sufficient, although in the future M5).

As a result, 700mm drone easily retracts into a backpack.

Modular design and vibration insulation

It is necessary to protect the camera and control electronics from vibrations. Recently, it has become popular to place all the important elements on one isolated module, including the battery (the large mass of the module improves vibration isolation).

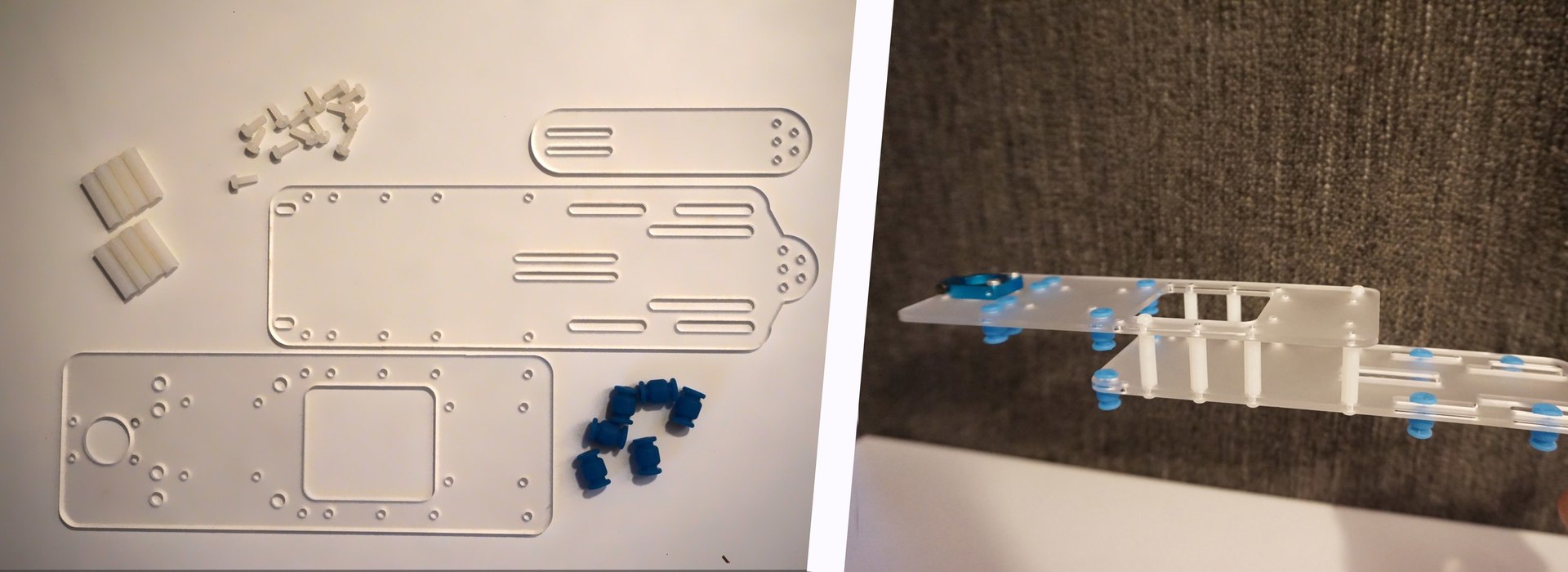

In the current design, such a unit for electronics can be placed along the carrier tubes. The first option was not tough enough, however, there is where to roam.

The module may consist of several levels, the number of vibration-proof balls may vary depending on the load.

Lego for drones

As I said, this design is suitable for drones of various sizes (from 400 to 800 mm).

As I said, this design is suitable for drones of various sizes (from 400 to 800 mm).In my experience, it is convenient to be able to rebuild the drone for propellers of a different size, without buying a frame again. Therefore, I tried to make the details of the frame as versatile as possible, by analogy with the famous designer. Some parts can be bought on the Internet, some you need to do yourself:

• Carbon fiber tubes . Indispensable for the paws, and also well suited as the basis for the frame.

• Aluminum clamps ( # 1 and # 2 ). Needed to connect the design together. Available online for M2.5 / M3 bolts (others need to be ordered in production)

• Universal plates (ideally carbon fiber). The small ones form the basis of the frame and provide a variable angle between the legs. From large assembled unit for electronics.

The result is a set of parts from which you can assemble different drones, changing:

• frame size

• foot length

• Size and rated load of the unit for electronics

Material Notice

I try to make the most of purchased parts (tubes and clips) from carbon and aluminum. Acrylic (PMMA) for plates I use temporarily to make development cheaper, and in the future I plan to switch to carbon fiber. Now the plates are cut on a laser engraver at my institute, quickly and free of charge, and for carbon fiber you need more serious equipment.

findings

• There is a compact and versatile design for the drone, which greatly simplifies transportation

• There is a flying proof of the concept

• There is a desire to bring the idea to mind (exclude plastic parts, minimize weight, etc.)

The design "without plastic" slowly matured since spring, the ideas were tested on a prototype. For the production of its parts from aluminum and carbon fiber need CNC. The arithmetic is simple (looked at the prices of production in Russia / Europe / China):

A pair of sets will cost $ 700 (at best, and without the right to make mistakes)

20 sets will cost $ 200-300 (including ordering test samples)

To fly on such a frame in the summer, you need to start collecting it now. Therefore, I decided to try to find other copterovodov, which would be interesting to join the project. Also created a campaign on Indiegogo .

I would really like to hear your opinion about this project and the very idea of Lego for drones.

Thanks for attention.

That's all, with you there was a simple service for selecting complex technology Dronk.Ru

Do not forget to subscribe to our blog , there will be many more interesting things.

Our other publications:

- NEJE engraver laser overview or promising business model

- Chuwi Ilife V5 - a $ 99 robot vacuum cleaner or how to turn daily cleaning into entertainment

- What to give boom for the New Year in the range of $ 10-20? Part 2

- Our small joys or how to please geek for the new year in the range of $ 10-20?

- The world's first pocket hexacopter for $ 18 - MJX X901

- Real discounts on gadgets or what does "vparivaet" us AliExpress?

Source: https://habr.com/ru/post/367409/

All Articles