The defect that has been waiting for decades

On May 16, 2015, the Proton-M launch vehicle crashed with the Mexican communications satellite Mexsat-1. According to the experience of recent accidents, the most logical reason was a manufacturing defect - a poorly made or installed item with a violation of technology did not pass enough scrupulous control and broke down in flight.

However, the result of the investigation revealed an almost detective story of the defect that had been hiding in a rocket for decades.

Chronology

For those who watched the launch, the accident looked like this:

')

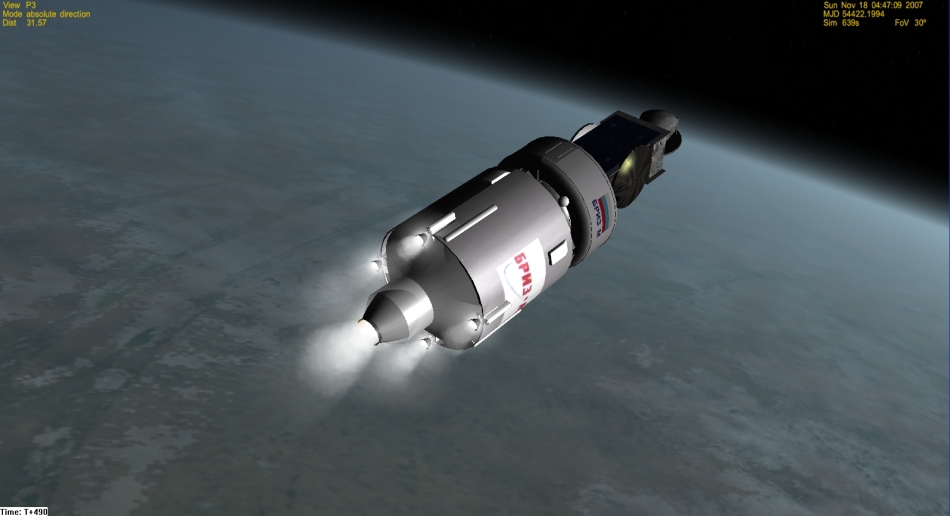

After 490 seconds, the announcer reported that an emergency situation had arisen on the rocket and had completed the report.

Four hundred and ninetieth seconds is the third stage of the work, so she immediately became the main suspect. But without access to telemetry and other data, it was impossible for a person to make any serious conclusions from outside. Finally, on May 29, a press conference was held at which the cause of the accident was named:

Commission conclusions:

- The cause of the accident is a constructive defect of the third-stage steering engine. In harsh operating conditions of the engine with a high temperature and vibration, the rotor of the turbopump assembly could lose strength. The weakened rotor vibrated even more, overheated and eventually collapsed.

- This defect, in addition to the accident in 2015, is the cause of accidents in 2014 and 1988.

- To eliminate the defect, the rotor material of the turbopump assembly will be changed. In addition, the mounting of the TNA to the frame of the main engine and the method of balancing the rotor of the TNA will be changed.

- The investigation also revealed comments on quality management at enterprises, and measures will be taken on these comments.

- The investigation was assisted by data from additional vibration sensors that were installed after the 2014 accident.

Materiel

The phrase “the rotor of the turbopump steering engine of the third stage” looks scary, so you should make an explanation.

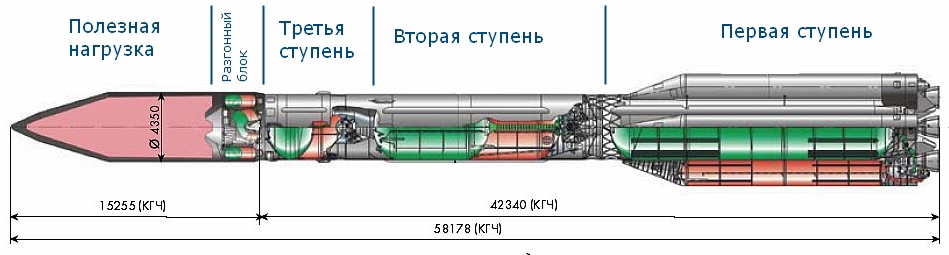

The Proton-M launch vehicle consists of three stages and a booster block:

At the stage of the third stage, it looks like this:

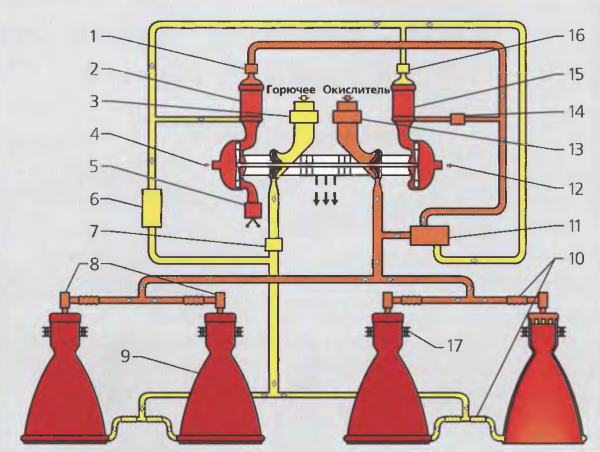

The third stage propulsion system, known as the RD-0212, consists of the RD-0213 main engine (center) and the RD-0214 engine with four combustion chambers. The steering engine is used to control the flight (combustion chambers can deviate up to 45 °), separation from the second stage and fuel deposition before launching the cruise engine.

The turbopump unit RD-0214 is interesting in that it uses two turbines on one shaft, after which the generating gas goes to charge the third stage tanks.

1 - gas generator valve; 2 - fuel gas generator; 3 - fuel starting valve; 4 — boost to fuel tank; 5 - starter; 6 - regulator; 7 - valve; 8 - valve KS; 9 - combustion chamber; 10 - bellows; 11 - stabilizer; 12 - supercharging into the oxidizer tank; 13 - oxidizer starting valve; 14 - gas generator valve; 15 - oxidizer gas generator; 16 - gas generator valve; 17 - swing assembly.

Small FAQ

Why the cause of the accident was not found in 1988?

Because rocket technology is very complicated. It is usually easy to determine “where” broke, but the question “why” is much more difficult to answer. First of all, there is almost always not enough data. A broken block flies in space, or, being burned and at least partially destroyed in the atmosphere, falls into the ocean, the taiga, or some other inaccessible place. Without access to the hardware directly, it is necessary to draw a conclusion by telemetry. And telemetry does not transmit information about the status of every part of the thousands installed.

And in the face of lack of information, it is easy to make a mistake by choosing the more likely, but incorrect version. The cause of the accident in 1988 was identified as “tube breakage”, and, perhaps, was considered to be a single defect (if the tubes of the same engine batch were normal), or strengthened the design of the broken tube, if its strength was in doubt. And the fact that this "tube breakage" was the result of damage to the TNA could not be established. In 2014, the cause of the accident was the destruction of the bearing of the turbopump shaft. Again, the place was correctly indicated, and the bearing could easily have collapsed from the shaft beat, but the true cause could not be found. Fortunately, vibration sensors were installed on a suspicious place, with the help of which, finally, they obtained the necessary information indicating the true cause of the accident.

Why did the defect manifest itself so strangely and “waited” for more than twenty years?

Because in complex technical systems, some weak points may not be obvious to designers, to pass tests well and fly well for decades, breaking only with a specific combination of factors. In real technology there is always a tolerance for the accuracy of manufacturing parts, temperature and pressure of working fluids, etc. There are many details, conditions change, the number of possible combinations, according to combinatorics, becomes enormous. And it turns out, for example, that it is slightly warmer, but within the limits of permissible, the oxidizer boils where dozens of flights flowed normally. Also, rocket technology always works at the limit of strength and other characteristics of materials - in order to remove more cargo the structure must be extremely light, the engine must produce the maximum possible traction. And a small overheating of the shaft rotating at a tremendous speed is enough for it to become a little less durable than necessary.

Our rockets often fall. Have we forgotten how to do them?

No, not forgotten. Our cosmonautics (as well as cosmonautics of any other space country) has enough problems, but it can be buried only by being deeply engaged. If you look at the accidents that have occurred, you can see that they occur for various reasons in different blocks of different devices and are not repeated. This is a good sign - after accidents, investigations are carried out and their causes are eliminated. Yes, some accidents occur for very offensive reasons, but this suggests that space is merciless towards quality.

Speaking about the state of affairs in general, we must not forget that by the number of launches we have been conducting for many years, by the number of vehicles in orbit we are among the top three, and in recent years we have been successfully testing new launch vehicles and launching unique scientific devices .

And finally, one should not forget that astronautics refers to the issues of the prestige of the state; therefore, every accident is maximally inflated by illiterate biased people with a love for global conclusions.

Have you lost confidence in Proton and there will be no more orders for commercial launches?

Of course, any accident hits the prestige of the launch vehicle, and Proton cannot boast of many years of trouble-free operation. But it is impossible to draw conclusions about the loss of trust. Here, for example, the news from January this year. The package of orders for commercial launches "Protons" is formed until 2017. And specific orders and their cost are a trade secret. It will be possible to draw conclusions about the loss of confidence in the Proton only after a noticeable drop in the number of launches (without taking into account the forced downtime to investigate accidents and refine the design after them).

On the “space accidents” tag - accidents and catastrophes, with and without people, happened and almost happened.

Source: https://habr.com/ru/post/367243/

All Articles