Some details of the Vulcan rocket will be printed on a 3D printer.

So it will be possible to save from 50 to 90%

ULA Photo

In its rocket, the new generation United Launch Alliance plans to use 3D printing to reduce production costs and simplify the development process with rapid prototyping. Due to the printing of plastic and metal parts, it is planned to reduce costs by a million dollars a year. In the already existing Atlas V rocket, 3D printing reduced the cost of the air conditioning system by 57%.

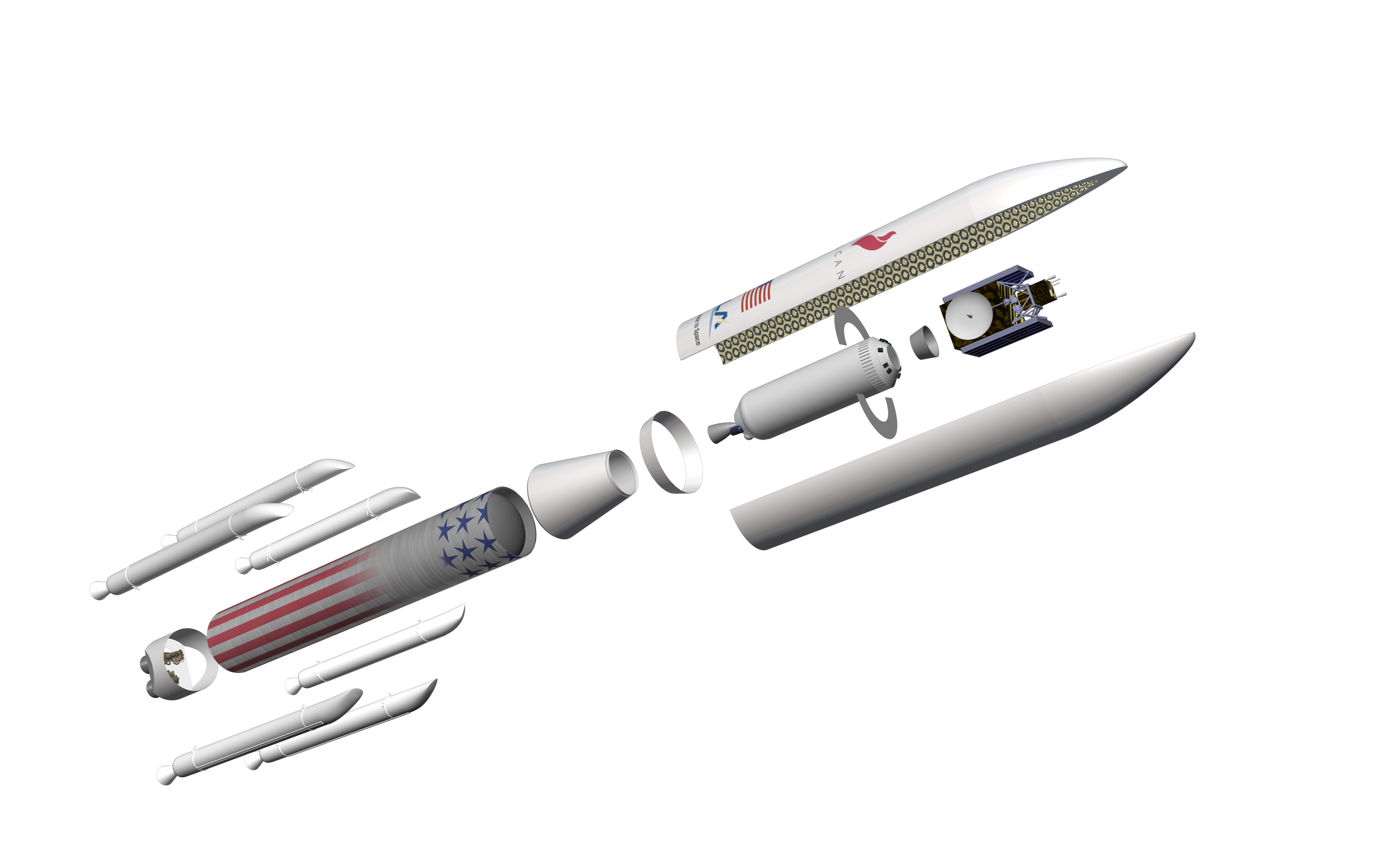

The United Launch Alliance is a joint venture of Lockheed Martin and Boeing, which makes about 12 launches per year. On April 13, at the presentation in Colorado, ULA head Tory Bruno presented a new Vulcan rocket with fully American engines. The first launch is scheduled for 2019, the cost - from $ 165 million. It is assumed that the engines of the first stage will be reused, for this they are going to shoot them, parachute and catch them with a helicopter. The new rocket, its engines and bold re-use plans are the answer to the current ULA partial dependence on Russian RD-180 supplies. It is noticeable that even the unsuccessful success of the SpaceX first-stage rocket landing program of the company SpaceX inspires concerns among the leadership of the ULA.

Parts of the Atlas and Delta missiles will also be printed, but for ULA it is important to implement 3D printing at the earliest stages of Vulcan development. Now selected parts for printing. In the lists of candidates more than 100 plastic and about 50 metal. It is planned that 3D printing will save about a million dollars a year.

')

Five-meter version of the "Volcano", ULA

The detail for a rocket is expensive, and if it is ordered from a third-party company, then you need to spend time providing specifications and finding a common language. If something is wrong with the detail, then it will have to be sent back for revision. Time is spent not only on this, sometimes contractors do not have time to complete their work on time. Own 3D printing simplifies the control of the production process. Printing will be used in the traditional role - for rapid prototyping. It allows you to immediately make the necessary part so that the engineer could feel it, evaluate the functionality before placing an order for its manufacture.

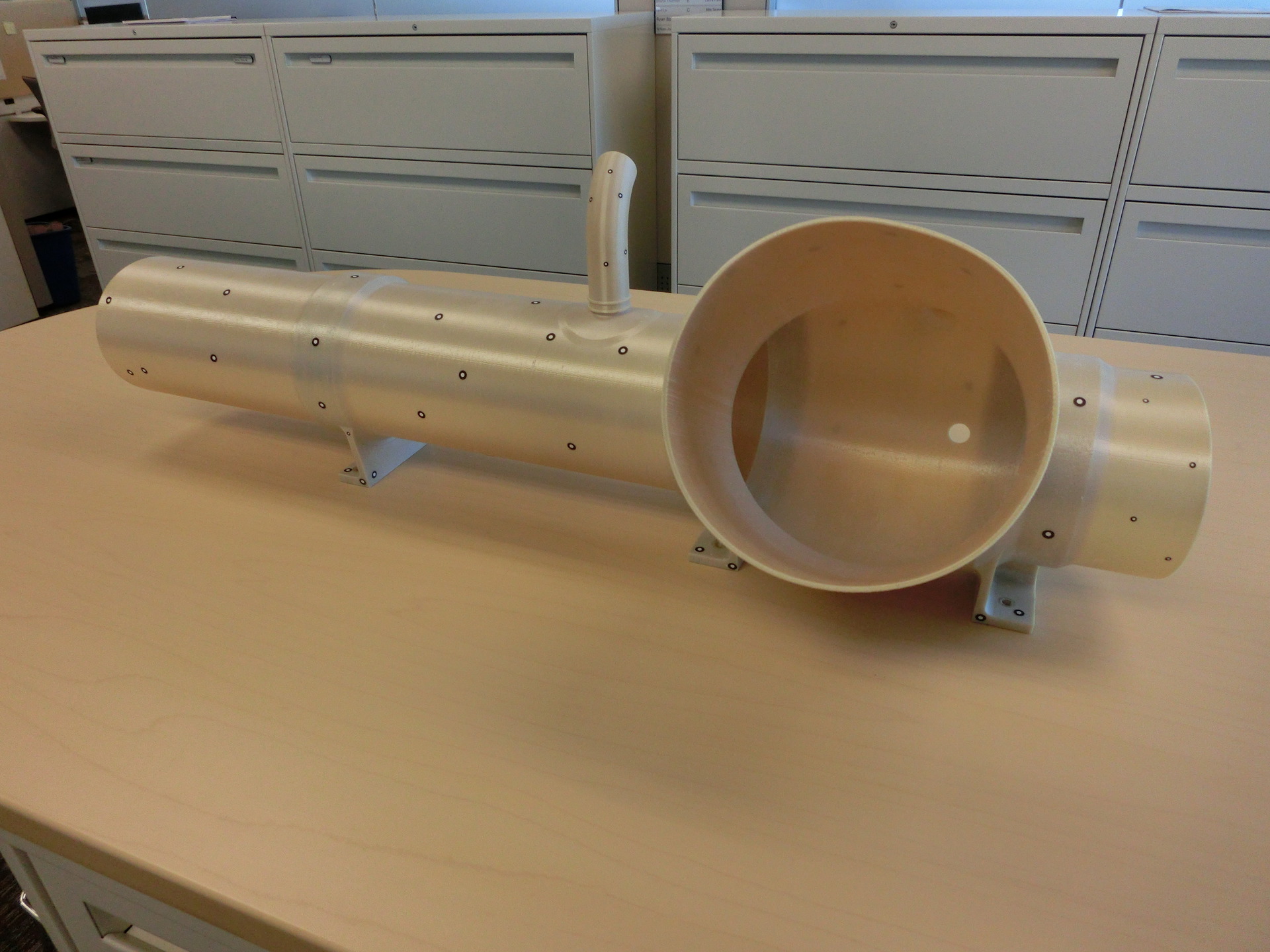

To implement these plans, two Fortus 900mc printers from Stratasys were purchased. First of all, these machines will be used to create the Atlas V rocket air conditioning system. The system is designed for the pre-flight delivery of liquid nitrogen to the electronic components of the rocket booster for their cooling. The launch with the updated hard currency is scheduled for 2016. Previously, the air conditioning system contained 140 parts, which were produced by independent suppliers. With 3D printing and layering technology, this number dropped to 16, which also reduced costs by 57%. Fell and build time of the device.

During production, Stratasys ULTEM 9085 thermoplastic is used, which has a wide range of working temperatures - from cryogenic to very hot. Two new Fortus 900mc can not print with the help of metal, 3D-printers for this purpose are only being selected.

Source: https://habr.com/ru/post/366889/

All Articles