Plastic models - vacuum, water and pressure test

It is always interesting to read news about what progress Ukrainians have with 3D printer developers, but when you personally try something that was written with great fanfare in the news a year or two ago - and everything turns out to be not as optimistic as it was written .

Remember the news that Microsoft has released a 3D printing program for a mass audience ? And what, someone already uses? I've tried to use it with the Makerbot 2 3D printer: the maximum that can be achieved is that the “standard printer” icon appears in the system, which reacts to connecting or disconnecting the printer. You can also try to play around in 3D-Build'er to write three-dimensional text on the surface of some vase from the supplied set of models. This trick failed me. Well, okay, it was an addition.

All of us have read stories about the fact that 3D printers will be useful in space, that with the help of 3D printers on the Moon and Mars you can print anything you want ...

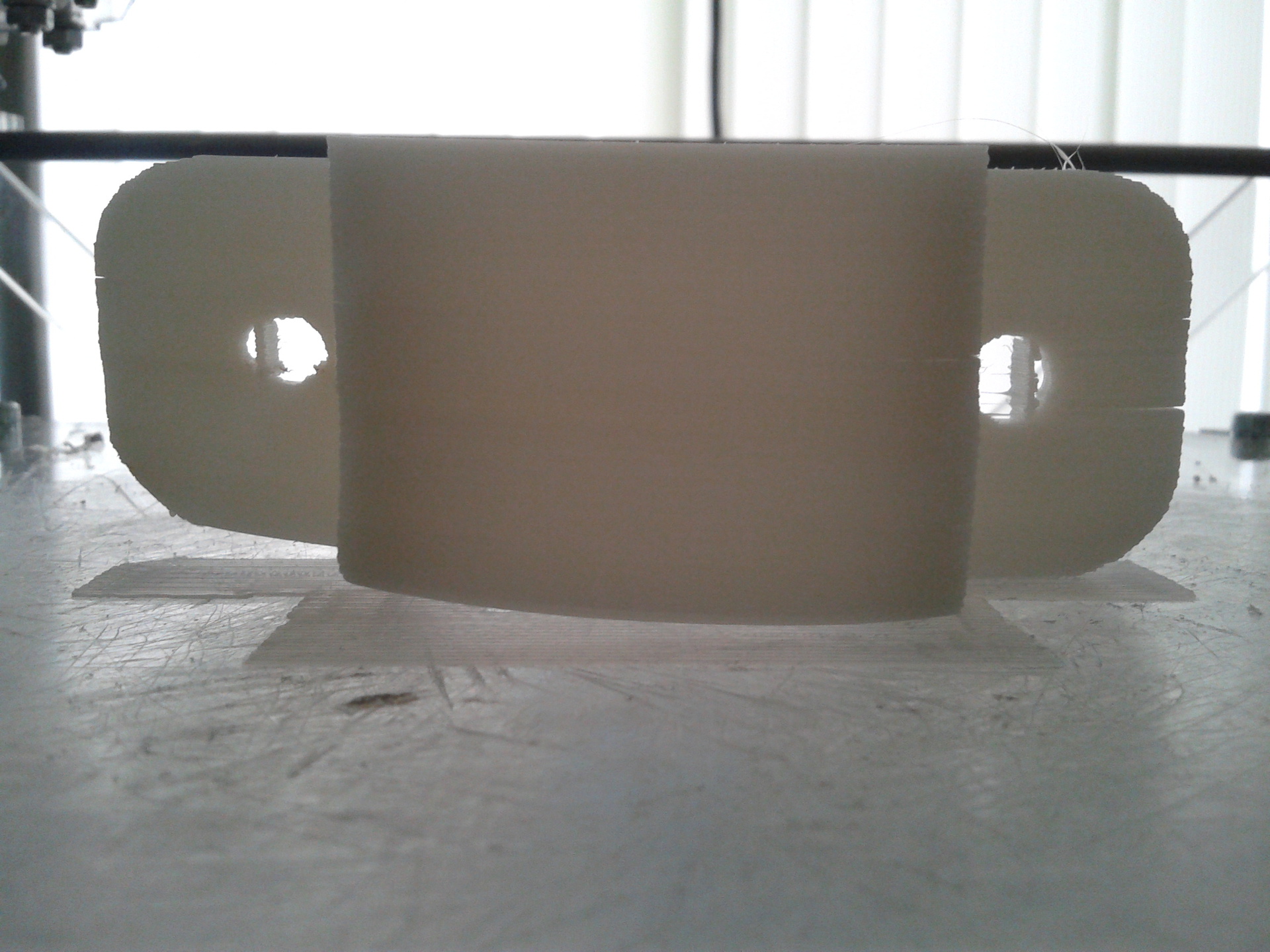

We try to print the most elementary bracket (from ABS) and ...

... and somehow it does not work out very well. But it was a different saying.

')

And what about water gas tightness, vacuum retention or, on the contrary, excessive pressure? Surely in space these are important properties. In the laboratory or at work, they are also in demand.

Let's make a test object - a hollow sphere with a diameter of 30 mm with a wall of 5 mm and a conclusion

First, try PLA on Makerbot 2

In the mode with the highest quality and continuous filling (far right), something went wrong and the print had to be interrupted in half of the file, and when you touch the model with your hands, the bottom actually bounced (!). Two other models were grown with low quality, which is on the left - with a solid filling. They did not pass vacuum tests, and were even blown through “manually” (approximately the same way as balloons inflated) and easily, surprisingly, because the surface is solid. The most interesting thing is that the model with continuous filling was blown out better.

The test of water (by pouring water inside) models also did not pass

Water from the models seeps freely, as seen from the wet wipe, the models feel wet to the touch.

The model of the ABS with a solid filling had to be prepared using all available tools so as not to lead

However, the result was still so-so

The ABS test with water passed a little better - the water poured inside did not wet the paper napkin.

And finally, the "non-structural material" SLA-plastic, in this case IPLIT-1

Vacuum keeps - for ten minutes the hand has not moved from its place.

Water also holds, although it is known that at high humidity a model of such plastic “leads” after some time

Well, and finally, the most interesting part of the test

The model withstood at least 7 atmospheres, after which the vacuum hose not designed for high pressure burst, while the hose jerked and as a result, the model broke from hitting the concrete floor

(if someone does not know - fragility is typical for acrylic SLA - polymers).

If suddenly someone is going to repeat the test - make a conclusion a little more in the calculation of the high-pressure hose with the clamp, tie the hose and protect yourself from possible fragments - they can be as sharp as glass fragments.

PS: plans to do something like this, only with numbers

Remember the news that Microsoft has released a 3D printing program for a mass audience ? And what, someone already uses? I've tried to use it with the Makerbot 2 3D printer: the maximum that can be achieved is that the “standard printer” icon appears in the system, which reacts to connecting or disconnecting the printer. You can also try to play around in 3D-Build'er to write three-dimensional text on the surface of some vase from the supplied set of models. This trick failed me. Well, okay, it was an addition.

All of us have read stories about the fact that 3D printers will be useful in space, that with the help of 3D printers on the Moon and Mars you can print anything you want ...

We try to print the most elementary bracket (from ABS) and ...

... and somehow it does not work out very well. But it was a different saying.

')

And what about water gas tightness, vacuum retention or, on the contrary, excessive pressure? Surely in space these are important properties. In the laboratory or at work, they are also in demand.

Let's make a test object - a hollow sphere with a diameter of 30 mm with a wall of 5 mm and a conclusion

First, try PLA on Makerbot 2

In the mode with the highest quality and continuous filling (far right), something went wrong and the print had to be interrupted in half of the file, and when you touch the model with your hands, the bottom actually bounced (!). Two other models were grown with low quality, which is on the left - with a solid filling. They did not pass vacuum tests, and were even blown through “manually” (approximately the same way as balloons inflated) and easily, surprisingly, because the surface is solid. The most interesting thing is that the model with continuous filling was blown out better.

The test of water (by pouring water inside) models also did not pass

Water from the models seeps freely, as seen from the wet wipe, the models feel wet to the touch.

The model of the ABS with a solid filling had to be prepared using all available tools so as not to lead

However, the result was still so-so

The ABS test with water passed a little better - the water poured inside did not wet the paper napkin.

And finally, the "non-structural material" SLA-plastic, in this case IPLIT-1

Vacuum keeps - for ten minutes the hand has not moved from its place.

Water also holds, although it is known that at high humidity a model of such plastic “leads” after some time

Well, and finally, the most interesting part of the test

The model withstood at least 7 atmospheres, after which the vacuum hose not designed for high pressure burst, while the hose jerked and as a result, the model broke from hitting the concrete floor

(if someone does not know - fragility is typical for acrylic SLA - polymers).

If suddenly someone is going to repeat the test - make a conclusion a little more in the calculation of the high-pressure hose with the clamp, tie the hose and protect yourself from possible fragments - they can be as sharp as glass fragments.

PS: plans to do something like this, only with numbers

Source: https://habr.com/ru/post/366871/

All Articles