Unpleasant news for manufacturers of diesel power plants and UPS

A year ago, information appeared: in the US state of Arizona, construction began of a generatorless data center. The project involved engineers from the local energy company Salt River Project (SRP) and specialists from BaseLayer, which develops and manufactures modular container data centers. Standard quick-assembly modules are produced using resource-saving principles that provide a high level of reliability, safety and efficiency.

')

SRP announced that it would place the data center modules outdoors near its energy infrastructure facilities, thus giving them direct access to the power grid.

And in early September of this year, the only one of its kind DC SPR Datastation was put into operation. Such a data center is able to reliably handle loads without using a diesel generator or other backup power source. It consists of BaseLayer modules and is powered by two networks, a standard transmission line and a high voltage line (230 kV). The probability of a data center leaving offline due to power outages tends to zero, since the main power channel leads to a nearby site with generating capacity, and an auxiliary power line connects the DC to another power plant.

This approach allows you to minimize the cost of building power lines, takes less time to increase the capacity of DC. Instead of starting a long-term construction work on the construction of new or expansion of old objects, organizations that need increased power will be able to get it quickly and in the required amount. Refusal of diesel power plants, UPS and placement of DCs closer to the power source will reduce the complexity of the infrastructure, and, therefore, save on capital and operating costs. The company promises reliability at the level of "seven nines" - 99.99999%.

William Slessman, BaseLayer Executive Director:

We discussed with SRP a joint agreement on the development of data centers and increasing their speed and efficiency. Knowing that the company's modular data centers are completely mobile and can be deployed literally anywhere, we decided to put them closer to the source of energy. In this project, we have implemented our ideas, trying to show that this is possible.

Another advantage of this concept is the possibility of minimizing losses in the transmission of electricity between generating capacity and the load being served.

SPR is planning an active development of this project and the deployment of modular data center class Datastation near the already existing power plants, while using power lines, leading from other generating capacity as backup power sources. The management of the company will continue to cooperate with BaseLayer, the products of this vendor, in conjunction with the advanced power supply concept, make it possible to reduce electricity consumption by 19% compared to the traditional data center with raised floor.

“When you encounter the fact that DCs are estimated to account for 2% of total energy consumption in the US, and soon, probably, the percentage will increase tenfold, then, as a generating company, you cannot ignore this fact,” notes Clint Poole, Manager SRP Telecom. “This project will help lay the foundation for the future, given the possibility of such growth, and will ensure that the computational loads are placed at the corresponding point of the power system at the level of power transmission.”

If the prototype will work without failures, then it is logical that its analogues will be built in the United States in the near future, and this is pretty unpleasant news for manufacturers of diesel generator sets and UPS.

But let's not rush time and write off the same UPS. After all, technologies for the development of uninterruptible power supplies also do not stand still. Electric car maker Tesla Motors intends to supply data center operators with its advanced Li-ion batteries.

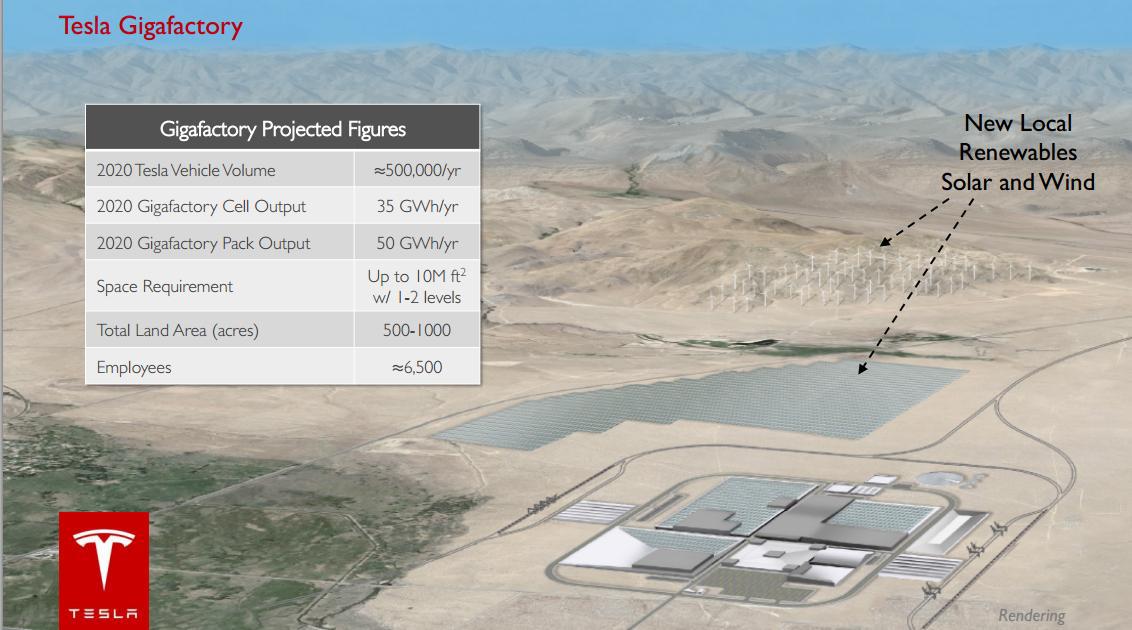

The Gigafactory battery manufacturing plant is an important part of Tesla Motors' plan, which will help increase the volume of electric cars sold and reduce their cost. The plant should be built by 2017.

Amazon’s first customer must be Amazon. The e-commerce giant is going to equip the Tesla Motors UPS-based UPS system with one of its data centers used to service the Amazon Web Services cloud platform.

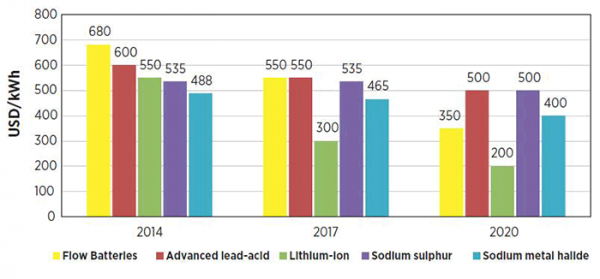

There is also good news from the Australian consulting company AECOM: by 2020, prices for Li-ion batteries will be 60% less, that is, from $ 500 per kWh to $ 200 per kWh. Such advanced UPSs to date, based on Li-ion batteries, have successfully implemented technology giants like Microsoft and Facebook in their data centers. But for owners of data centers of low and medium power such costs are now prohibitively high. If the AECOM forecast comes true, advanced UPSs that are significantly superior to traditional lead-acid analogues will find very wide application in the data center industry. Rechargeable Li-ion batteries have many advantages: high energy density with small dimensions, they are more environmentally friendly. They are also easy to maintain and have a long service life.

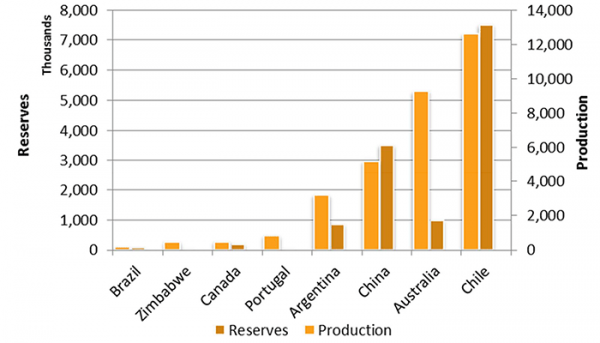

For example, Li-ion 6-kW batteries easily fit in a 2U container in the server room, and uninterruptible power supplies on Li-ion batteries work without maintenance for up to seven years. But again, it is impossible to say that everything is so smooth: the world reserves of lithium are not infinite. Explored reserves amount to 39 million tons, and only a third of them are suitable for cost-effective production. Reserves are unevenly distributed around the world. About half of all earthly reserves are located in Chile, the rest is in China and Argentina, a little in Portugal, Brazil and Zimbabwe.

Video - SRP DataStation Project Information

Source: https://habr.com/ru/post/366535/

All Articles