Dc motor from kinder surprise

Introduction

My name is Konstantin, and I am a student of the Novosibirsk State Technical University. It so happened that I was studying physics, but the theorist didn’t come out of me so much, so there will be very few theories in my publications or even be completely absent.

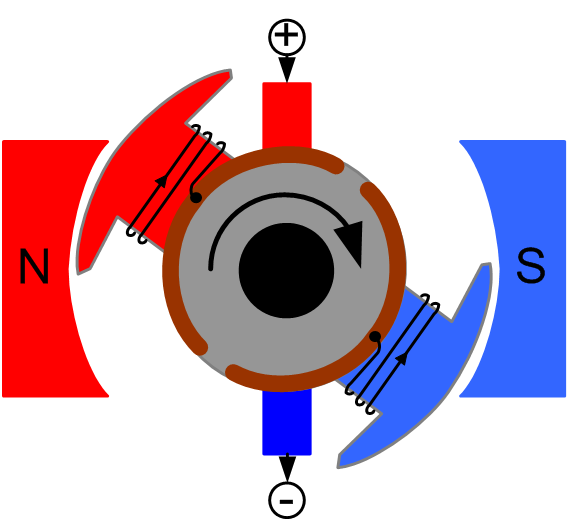

As the name implies, we will collect with you a DC motor.

I had a book in my childhood where there was an instruction on how to make it from a box of matches, straws and 2x magnets, but we will not do this, as well as we will not do something like this:

Motors in 10 minutes

I think that what I’m showing will not turn out to be new, but a quick search in Google gave only results that are higher, so let's start, but for those who don’t know what they mean: DC motor

I got this thing:

Cooking

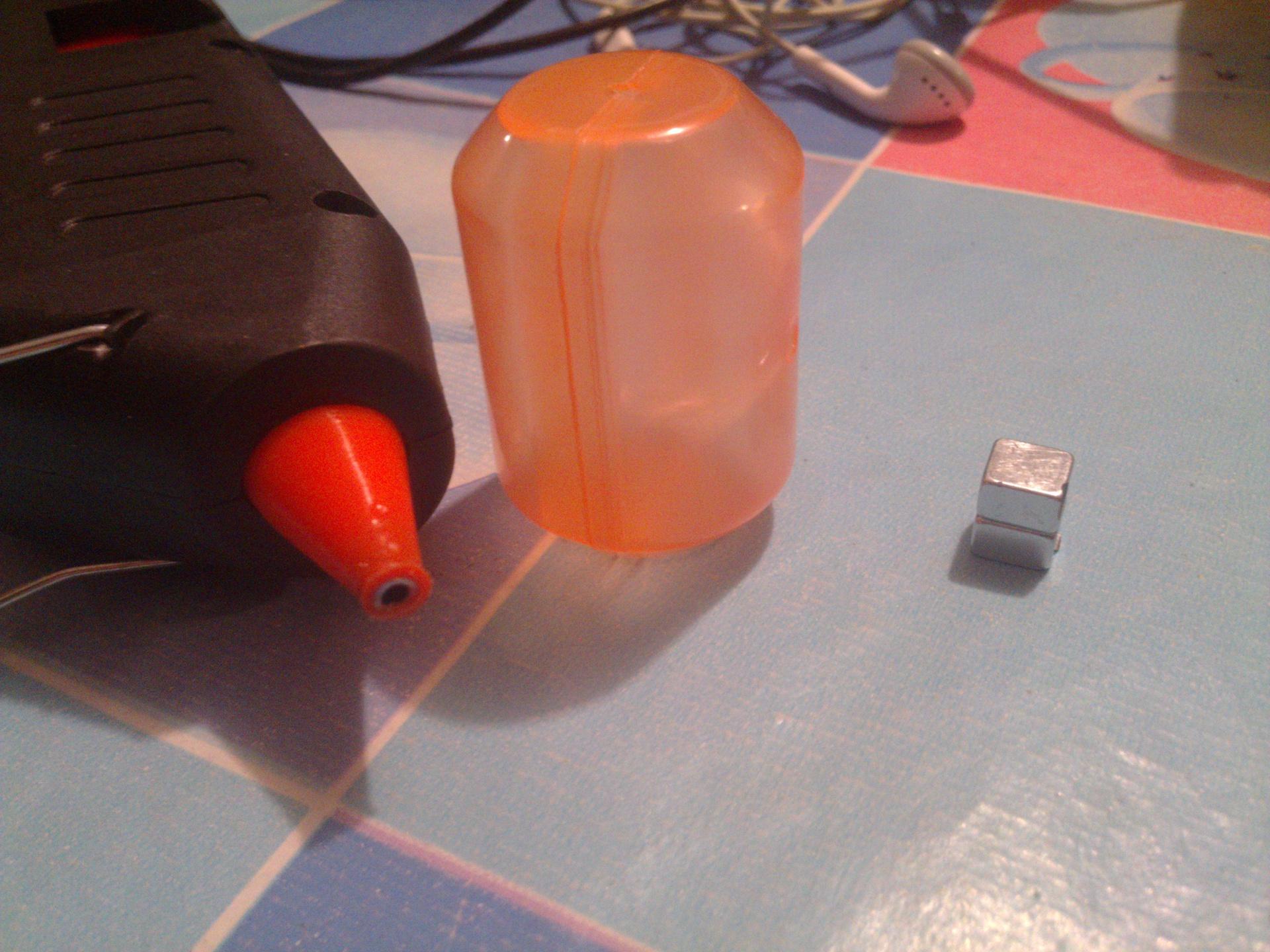

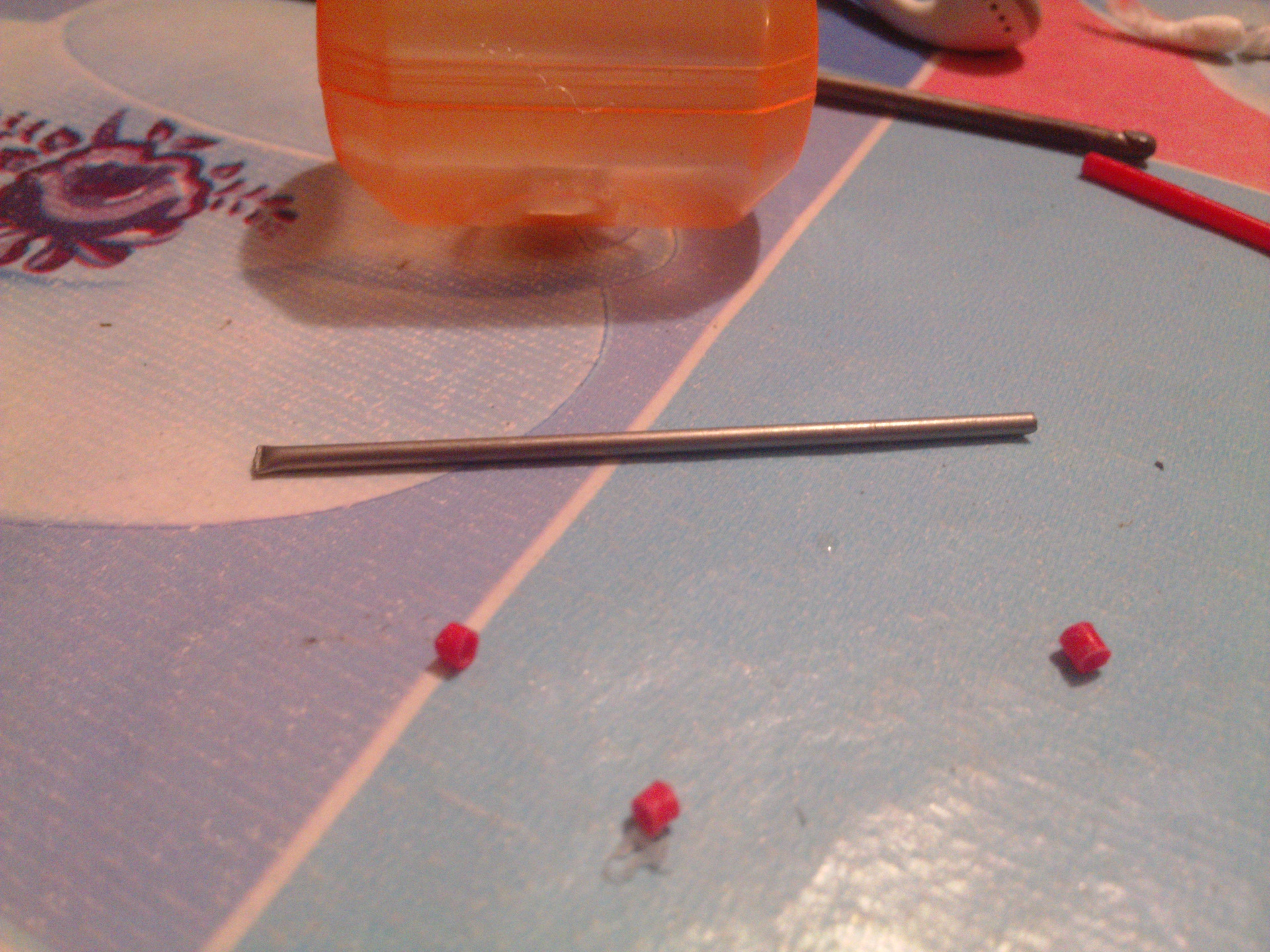

First, we define what we need (I used everything I could find in the room, so do not kick too much):

')

- Plastic case from Kinder, and I found one that opens across.

- 2 small magnets that are easy to place inside. I used neodymium 5x8x8mm, 35p piece.

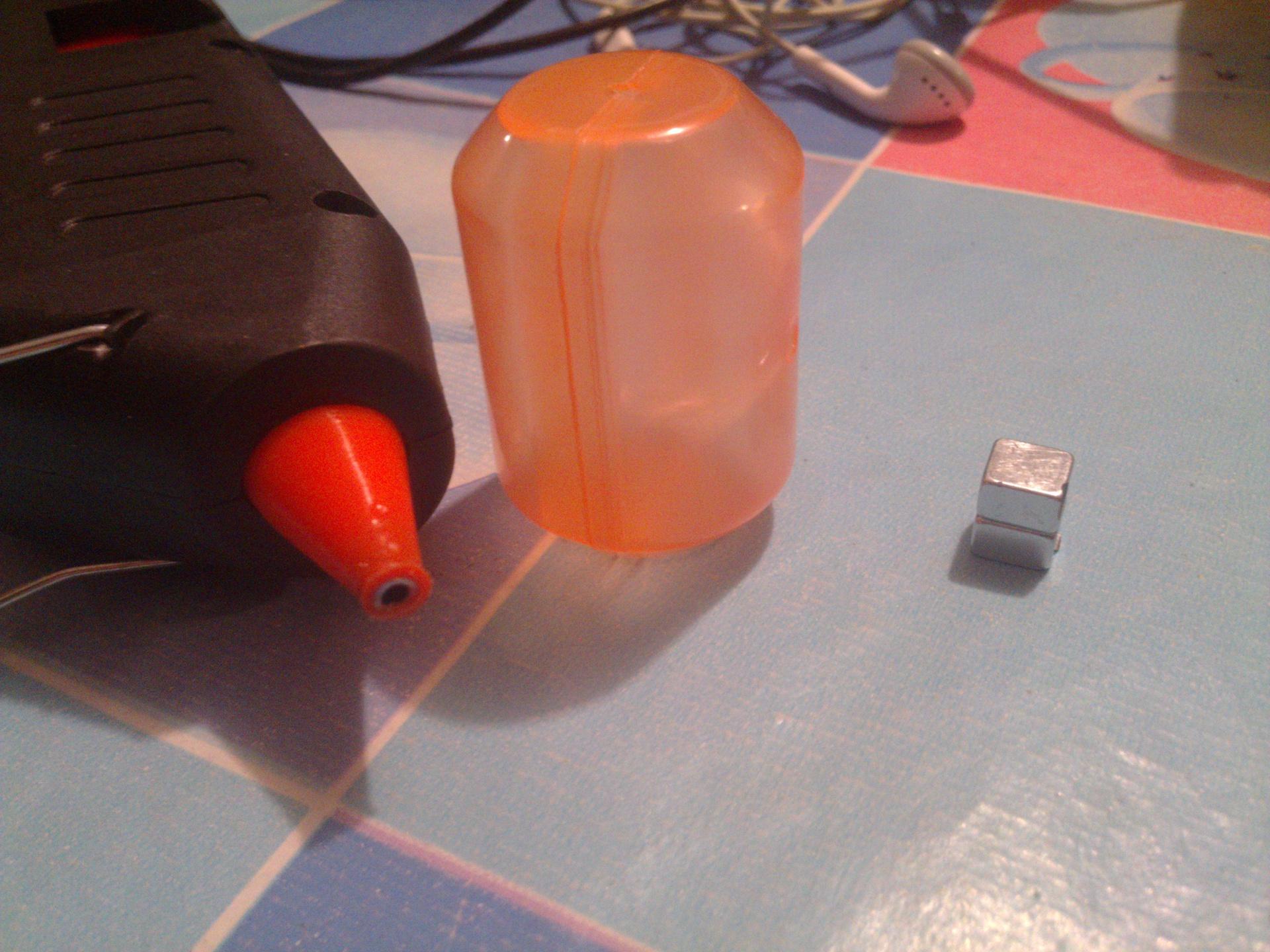

- Wire, nail or stick section 1-1.5 mm as the axis. I found a tube of similar diameter, at first I wanted a q-tip, but it turned out to be thick and soft.

- Glue. I used cyanoacrylate and hot melt.

- Wire for winding collector. I took from the headphones, she immediately lacquered and without isolation.

Wires, plates or other magnetics or ferromagnetics as a core.I took the nails on 30mm.- Brain, hands and good neighbors. if in a hostel, like me.

The list is not complete, the rest is small things and interchangeable.

Assembly

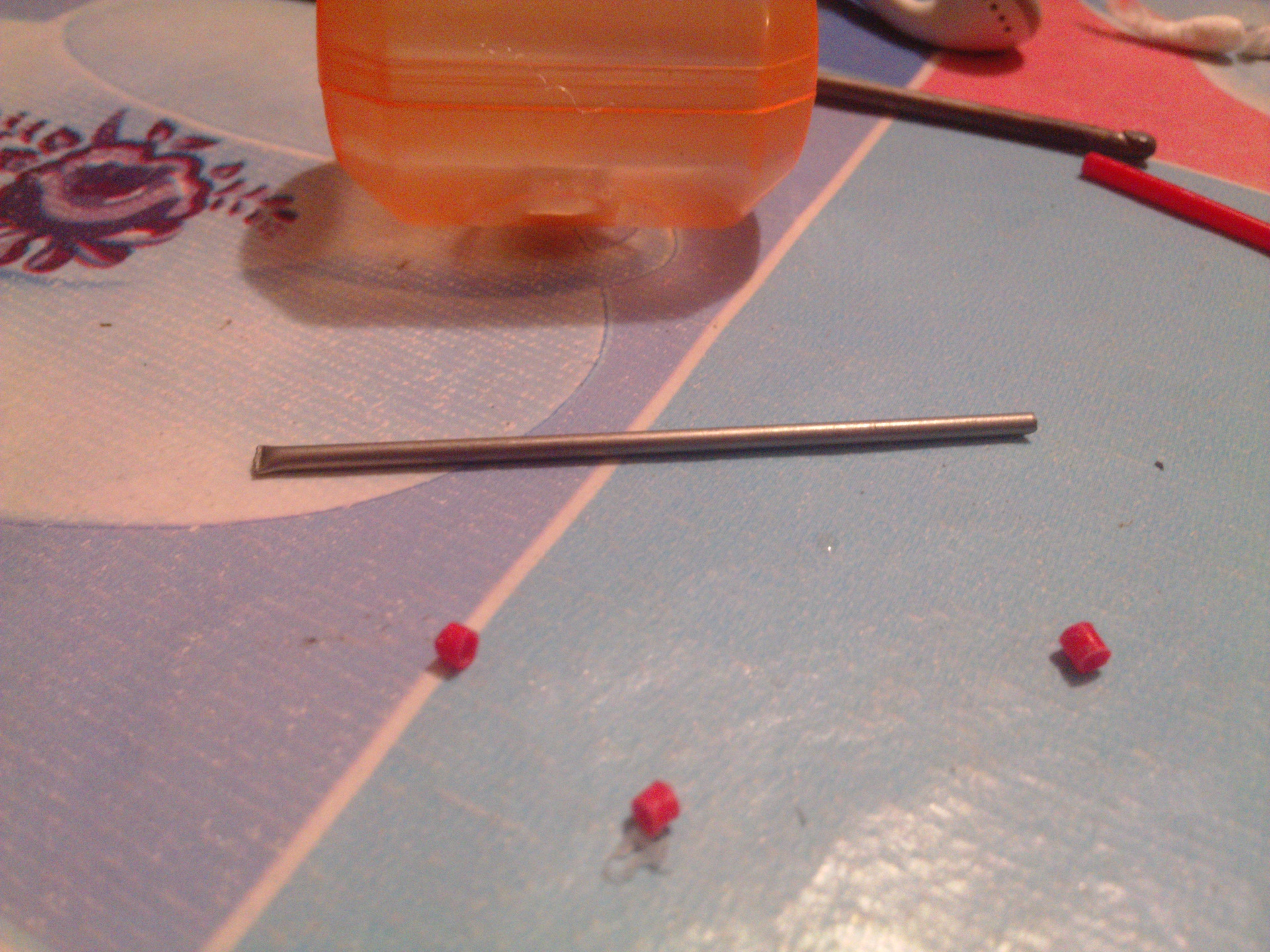

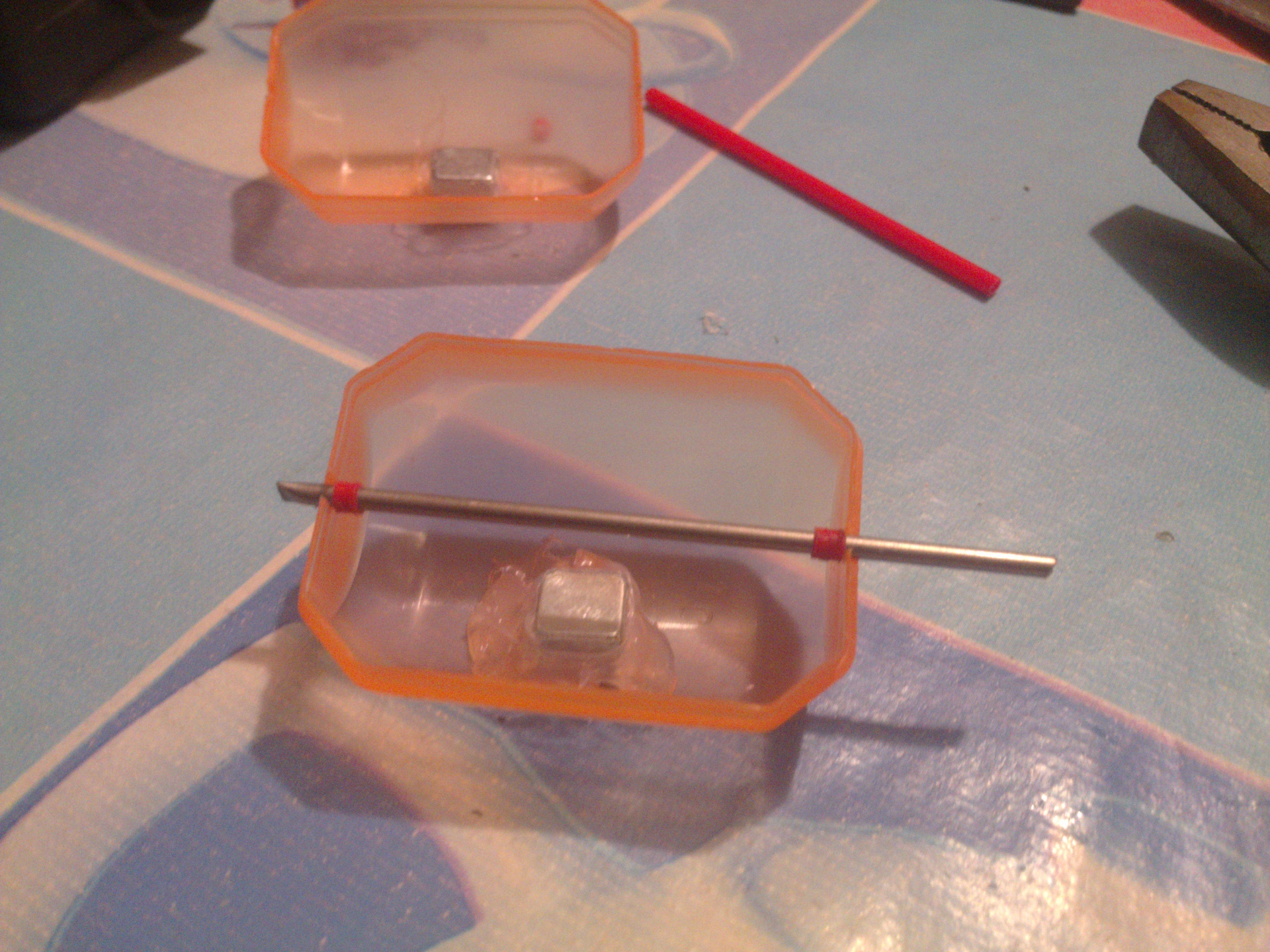

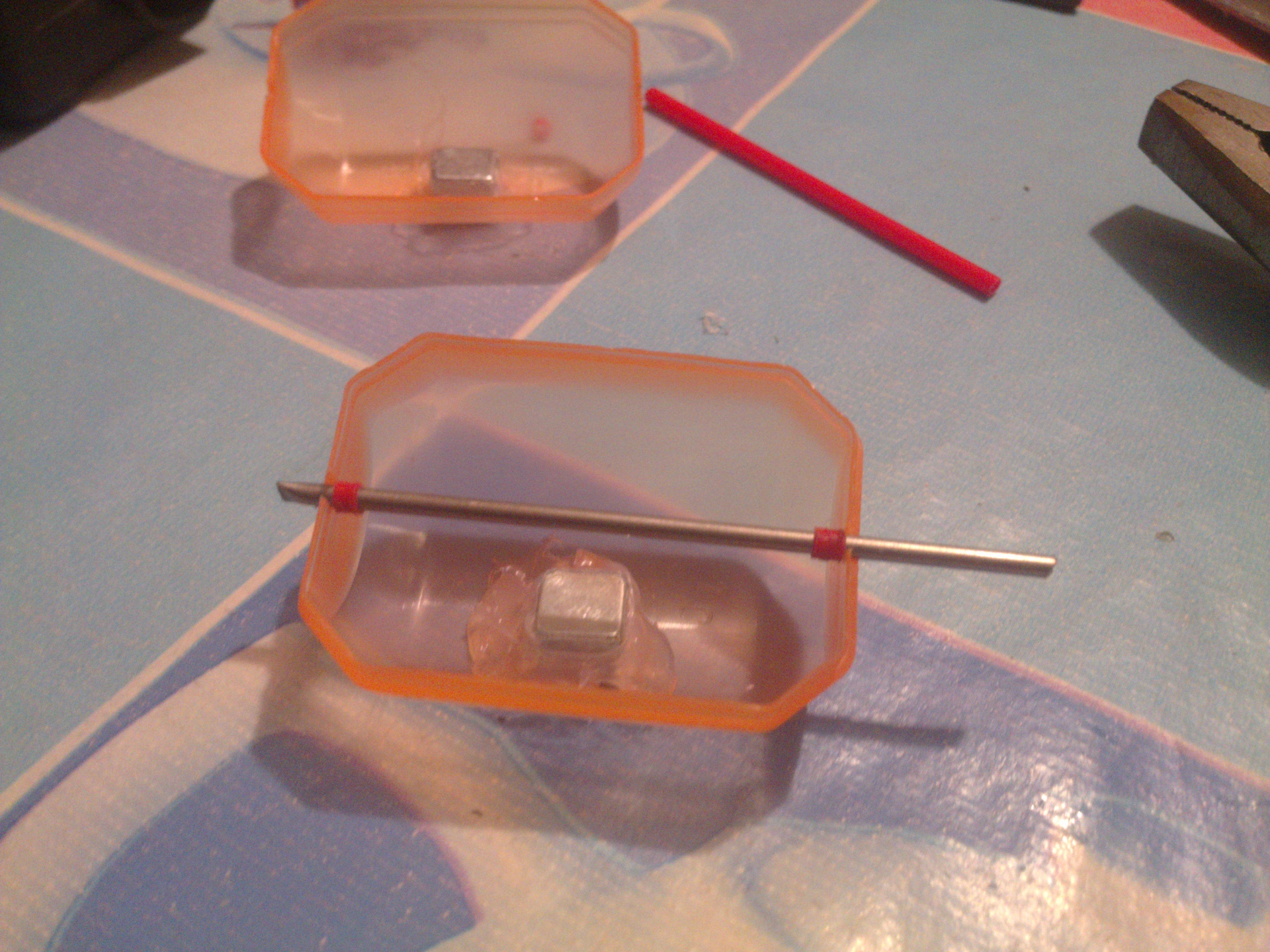

At first, I glued the magnets to the case, since the pips were at the bottom of the halves, I shifted them. Glue hot melt, but since they are very strong, after n closing / opening the case, they crawled out (I even plastered around - it did not help), and I poured superglue to the bottom.

Installation of magnets

Next you need an axis. I took the steel tube (I don’t know what it was from, I found it in the box) and put stop rings on it from a cotton swab, the holes were already in the case and the axis fit perfectly. It turned out quite nicely:

Make an axis

It all takes no more than 5 minutes, the fun begins with the manufacture of the rotor. There were as many as 3 variants of the rotor: non-magnetic core, steel, steel with a wire of 0.5 mm. For the first one, I took a wand from Ikea and made 2 pieces of 2 cm each. In the center of them I cut the grooves under the axis, so that it would go in tight, and then glued it together. Do you think this design fit and rotate? No, it turned out that the magnets stand a bit at different heights, and the pieces of the rods themselves were long. For 20 minutes I had to adjust a piece of grinding stone so that the rotor would not touch the magnets. Winding it was carried out residential from the headphone cable, I do not know exactly how such wires are called. The winding itself in the original version consisted of 24 turns in 2 layers - how long the wire lasted.

The trouble with this type of electromagnet is a small inductance, and therefore a small magnetic field. I understood this when I tried to measure the intensity of such a rotor.

Initial rotor

I made the second version of the rotor from studs - 2 rows of 4 pieces in a checkerboard pattern. I connected them with hot melt, it turned out something in the form of chokopayki, but instead of soufflé - hot melt glue. This rotor had the same problem as the first one - no matter how I measured it, it touched the magnets. The same grinding disc helped, but it took longer to grind the edges. The winding was made with the same wire, and the wire from the twisted pair is 0.5 mm copper, although I wrapped 0.5 mm of wire only 1 row of 6 turns on the shoulder, since it is thicker and smaller.

Nail Tiles

It was a bad idea. Since I had quite strong magnets, and the clearance between the magnet and the core was about or less than 1mm: the rotor could not be turned over the shaft - the shaft was spinning, and the rotor remained between the magnets. Since I could not even manually turn the steel rotor, my electromagnets could not force the magnetic field between the magnets with their field, and when the power was connected (such polarity that the magnetic induction would be opposite to the induction between the poles of the magnets), theory is not correct, correct).

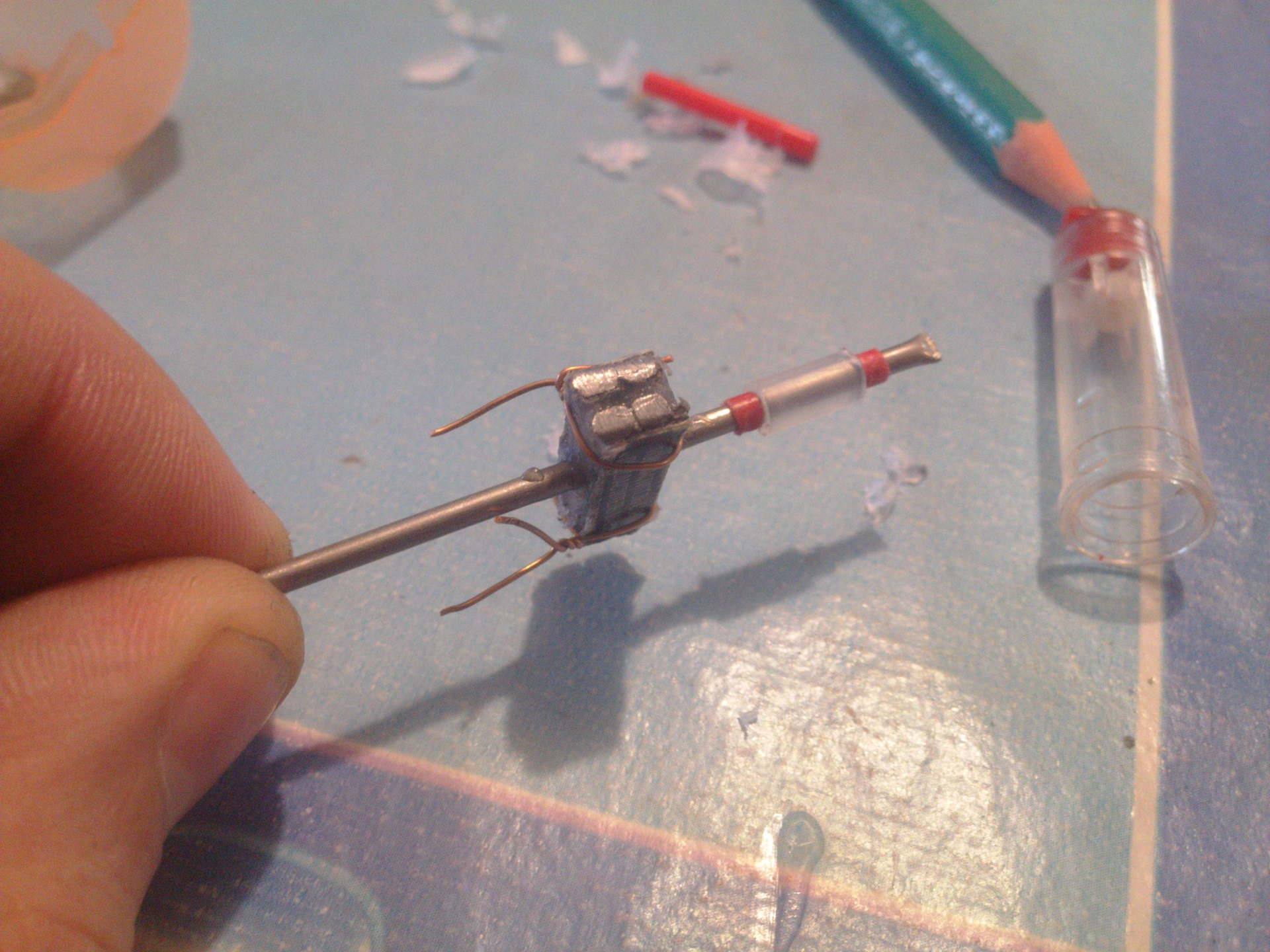

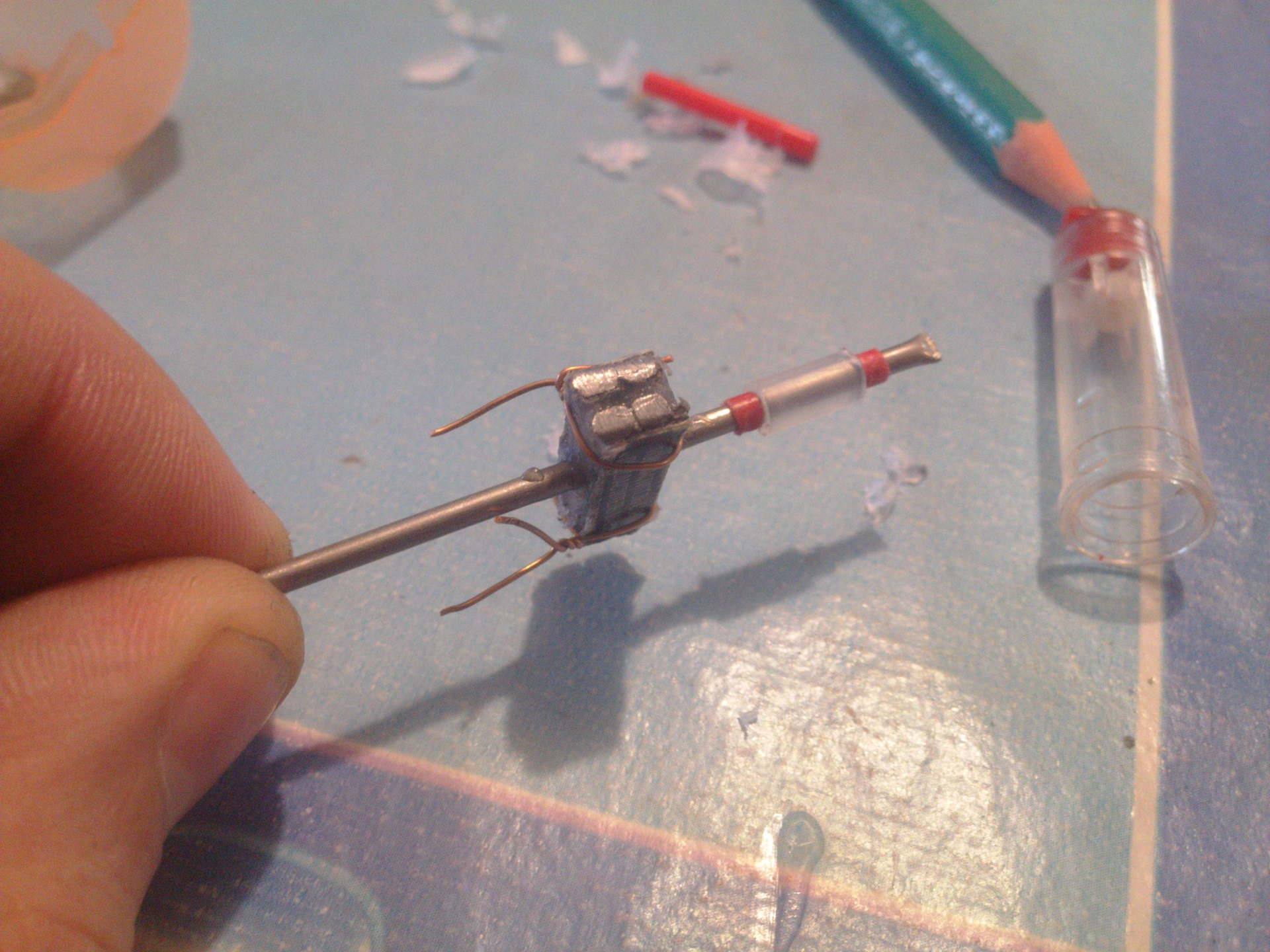

So the decision was to stay on the rotor of the first type, without a magnetic conductive material, but with an increased number of turns 2 times (winding is crooked, since I fastened the ends with superglue, and the winding on the droplets sprawled, and then I just scored for evenness).

The old is once again in fashion

To check for workability, I stuffed this rotor into the case, hooked it to the wires. When connected to a battery, it cranked and stood perpendicular to the axis of the magnets.

Current collectors

According to the scheme of the motor, we need to make current-collecting contacts.

I decided not to worry too much about this, took a 0.5mm wire from the former unsuccessful rotor, bent it several times and stuck it perpendicularly to the tube and the rotor itself, as in the figure. Then he cleaned it with the same grindstone and soldered the leads of the rotor coil. It turned out pretty.

Rotor with current collectors

Everything, for good on this all, it remains only to make a brush, that would bring the current to the current collectors, but I decided not to think much, and tried to do as shown:

Just threw one stripped at the contact point of the wire under the current collector, and one over it, and clamped the edges of the case. It seems the idea is good, but if you strongly pull, then the shaft brakes strongly.

Motor assembly

Start

Gathered, picked up the battery and ... nothing, I decided to turn the shaft - tugovato. I relaxed a little wire-brush, picked it up again - nothing, just a squeak in certain positions, if you turn the shaft by hand, and a rotor slip through when it is near the magnet.

Then I decided to honestly do it: I balanced the rotor so that the beats would become minimal, lubricate the shaft with lithologic in places of contact and make normal brushes. After that, he earned, but not without problems, he still had to be powered by + 5V 1A, as he advised ftp27 , just as he wrote to the radiolok , such a motor has dead zones, or rather, one when the rotor is across the axis of the magnets, for this, I had to start the motor manually, slightly turning it (in my design, the angle when the brushes do not touch is more due to the large inaccuracy in the manufacture of brushes and current collectors).

File editing

Thank you for reading my post, this is complete, but if you want to hunt, then I can try to check some characteristics, such as: rotation speed, moment of force and maybe anything else.

Source: https://habr.com/ru/post/366525/

All Articles