Will your hardware startup make a profit?

At least not in the case of the first 5000 units of production, and this is normal. Everyone wants to earn a lot, but you’ll probably have to wait a bit before you get your share.

We often have to deal with founders who underestimate how hard it is to profit from the production of consumer electronics, especially from the first batch of goods. If you spent $ 30 on the production of your product, and sold it for $ 99, then you get a profit, no?

')

Not certainly in that way.

Fictional Bluetooth Headphones Look Like a Motorola Model, Only Cooler

For clarity, consider a small example. Imagine that we need to make Bluetooth-headphones. To do this, we need to make several assumptions:

- Our headphones will be sold at a suggested price of $ 99.

- The first batch of our products will consist of 5000 copies.

- Product development will take 9 months.

- Production of the first batch of goods on an ongoing basis will be engaged in a small team of five people.

So, let's begin

Most companies spend a lot of time and money on developing their product. Usually it takes from 100 to 500 thousand dollars, and the process takes an average of 6-9 months. The creation of more complex products can take years, during which several million dollars will have to be spent.

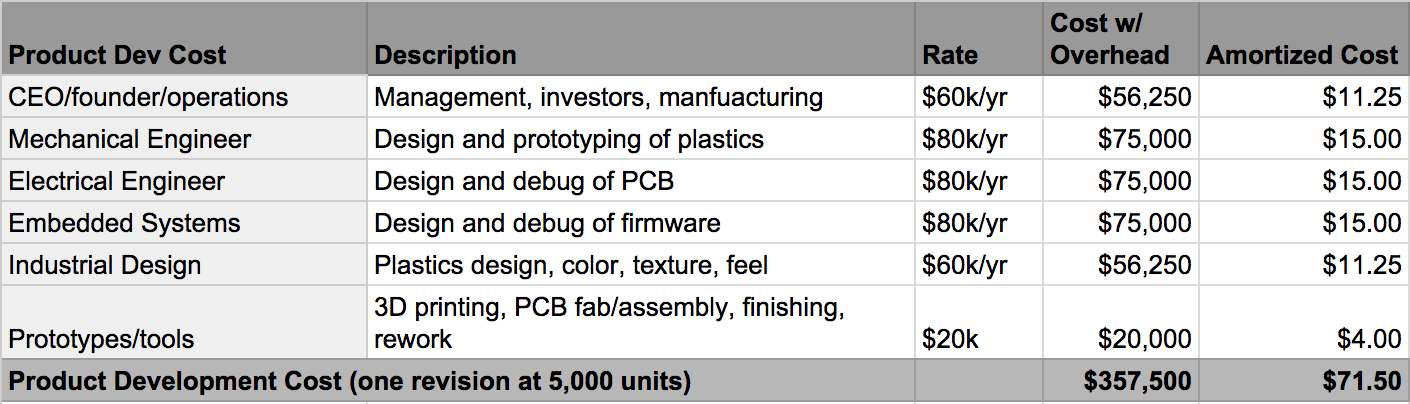

Before producing the headphones, we need to hire an electrical engineer, an industrial designer and an equipment operator. They have to spend 9 months to communicate with users, create prototypes and prepare for production. Production costs will be as follows:

This assessment can vary greatly depending on the complexity of the product, the composition of the team and other factors. In addition, it will have the most significant impact on profitability compared with other types of costs.

Product specification is just the beginning.

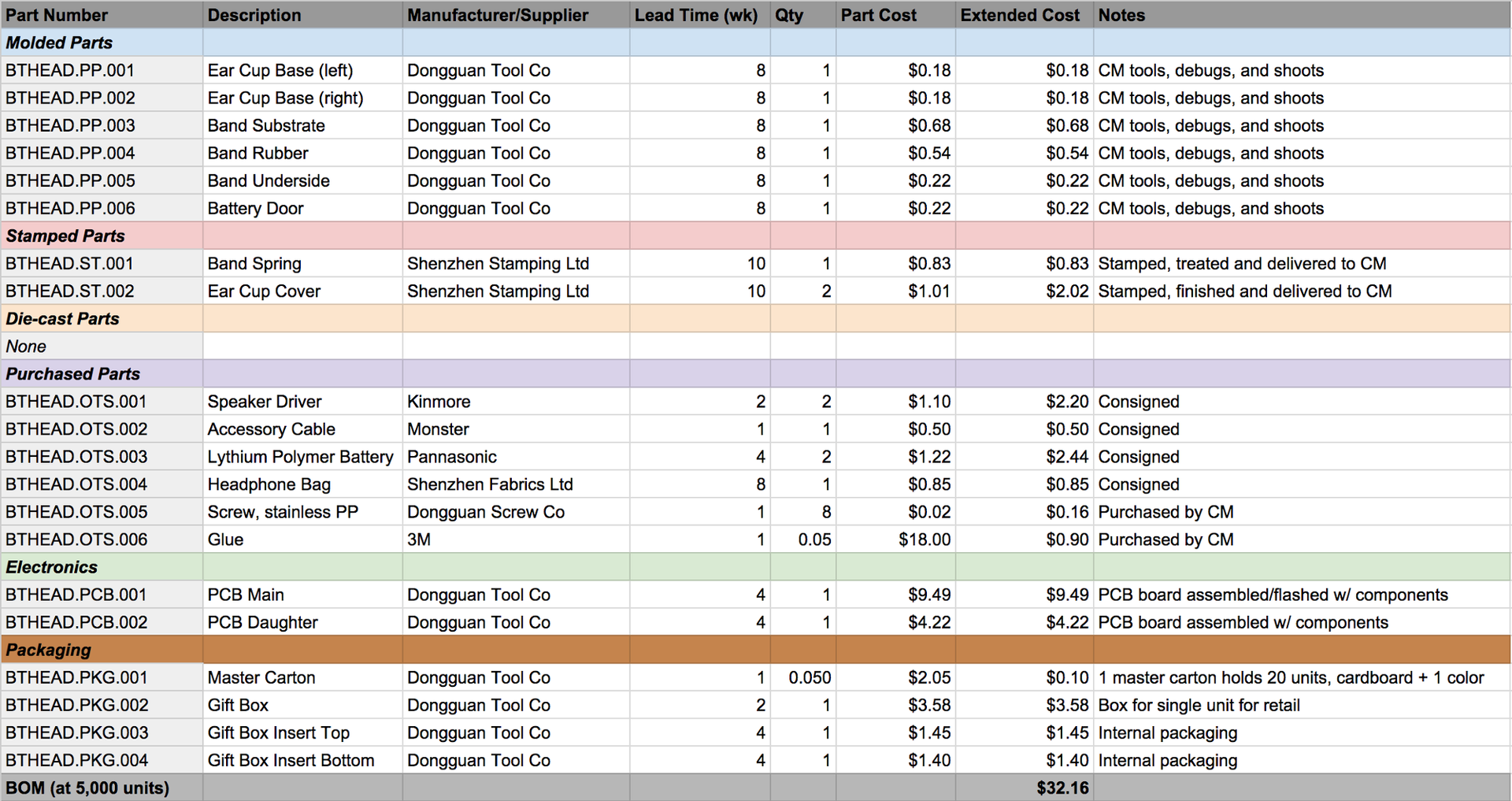

At the end of the development process, we will receive a final list of parts required for the production of our headphones. This list is commonly referred to as a specification [eng. Bill of materials, BOM]. This is one of the main stages of costing, which must be taken into account by a consumer electronics manufacturer. We will not be able to attract funding or launch a fundraising campaign if we do not have a clear idea of the cost of our product.

We included plastic parts, a printed circuit board with the components necessary for it, glue for plastic fastening and packaging, in which our headphones will be supplied. Each part is recorded in the table along with all the information needed to produce one instance of headphones: the part number, the number of parts per unit of production, the name of the supplier, the time of execution, the cost of manufacture, and additional information about the part.

Do not forget to consider the cost price

The specification does not take into account a number of very important economic indicators of every single detail. For the assembly of each pair of headphones hired workers from China spend some time. In addition, we need to deliver goods worldwide. These and some other types of costs are reflected in the cost of goods sold [eng. Cost of goods sold, COGS].

From a financial point of view, the cost of sales is calculated based on the list of storage costs, but it is easier for a startup to consider it as an “extended version of the specification”. In it, I included all marginal costs per unit of production needed to launch a product, such as the size of the duty, the reject rate and the frequency of return of goods, which are calculated as a certain percentage of the cost price:

Everyone has fixed costs.

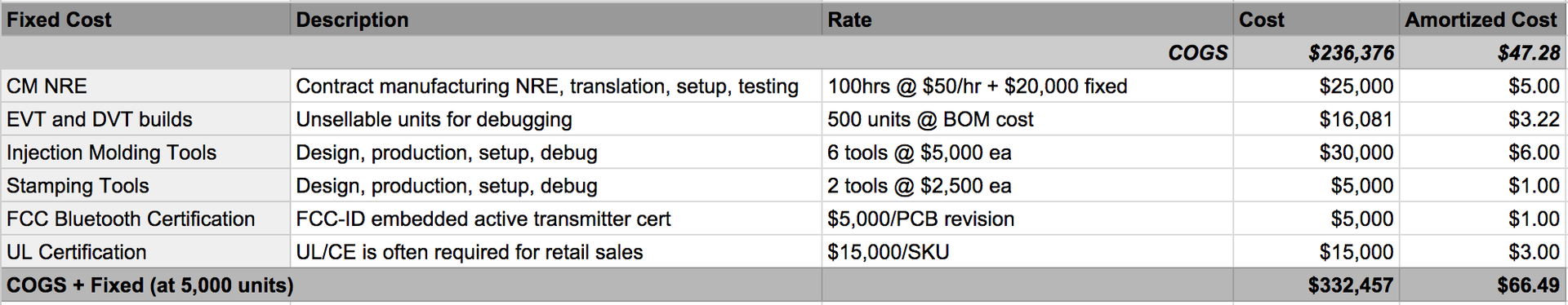

In addition, from the first batch of products we will incur fixed costs. At an early stage of a company's development, when it has a relatively small amount of cash, fixed costs can seriously affect its economic performance. A fixed fee is levied on each new batch of goods: this may be the processing of plastic parts, taxes on the use of certain technologies and payment for certification of the product.

Fixed costs should be considered separately, since they can be quite a substantial amount. Also, it does not hurt to separately allocate depreciation deductions from the production of 5,000 units of products. All this is written in the table:

After 9 months spent on the development of the prototype, production and logistics, we eventually produced 5,000 units of products. We spent about 690 thousand dollars on this (360 thousand on the development of a prototype and 330 thousand on production) and are ready to supply customers with their long-awaited headphones.

Sell directly first

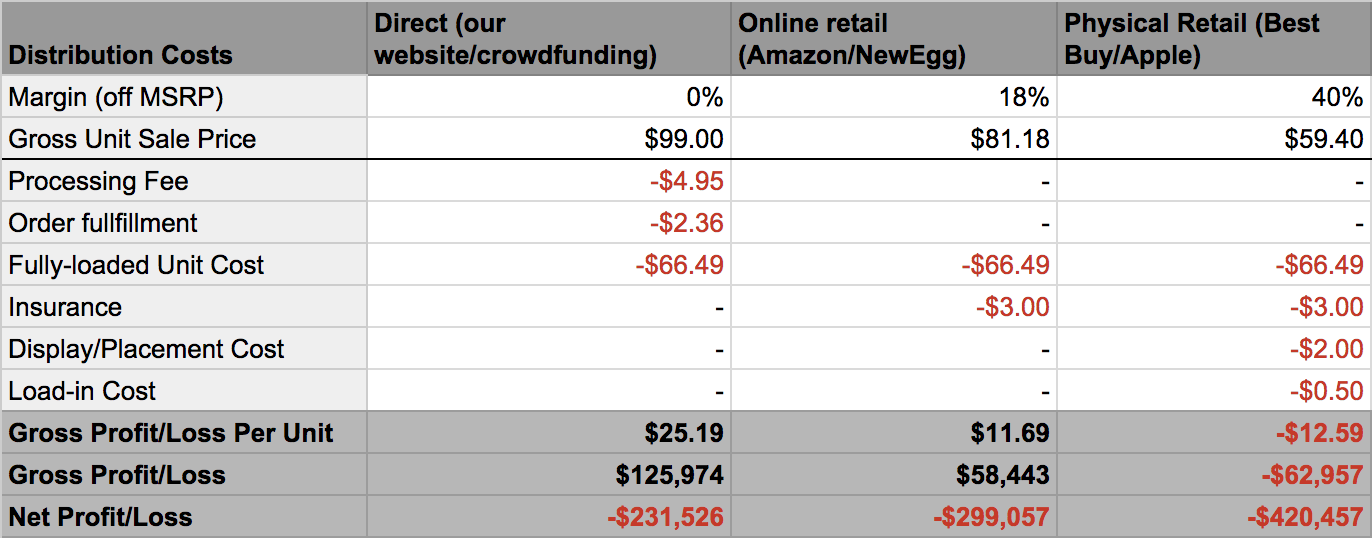

Initially, we believed that the cost value of $ 32.16 suggests that we can make a profit if we sell our product for $ 99, regardless of how it is sold. But as soon as all other costs were taken into account, the number of methods for selling goods was sharply reduced. Usually, any company has three options for marketing its products:

- Directly (trading through your own website without additional payments, however, you will have to make all payments, as well as pay for the optimization of certain business processes);

- Through an online store / third-party e-commerce site (trading is handled by an outside seller who does not have physical premises and charges a modest fee for his services);

- According to traditional retail channels (the sale is conducted through a retail distribution network, as a result of which a standard fee is charged as a seller’s markup).

The amount of profit received from the sale of a unit of production can vary dramatically depending on the method of sale of goods:

Please note that with each product sold through a retail network, we actually lose money. That is why a small company, which does not have much money in the bank, is very difficult to sell the first batch of goods in this way. Be prepared for the fact that you will have to work at a loss if you are going to sell the first batch of goods through a retail network.

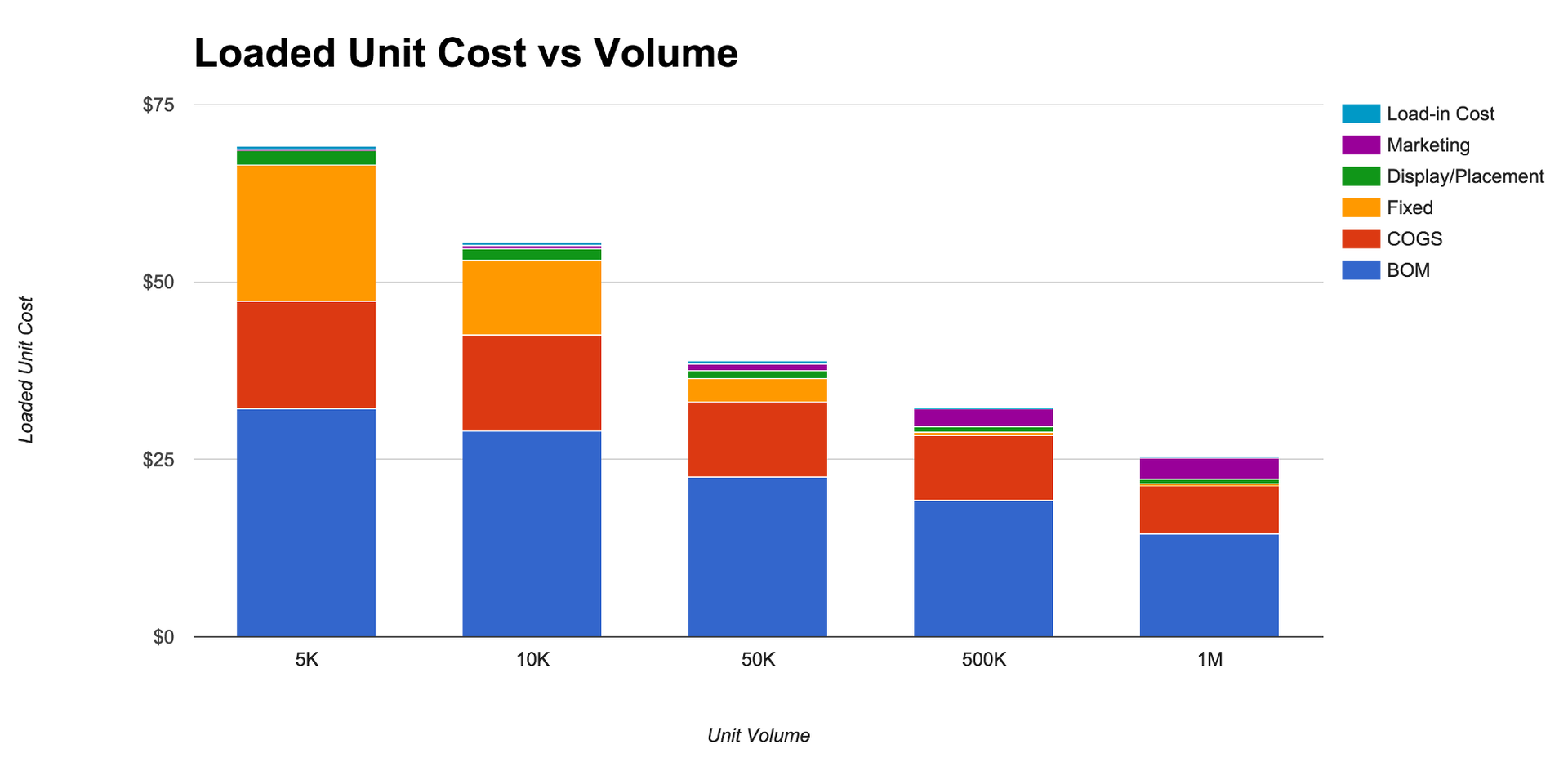

Scaling trends

Selling a batch of 5,000 units of production can discourage inexperienced founders, but all this is minor compared to truly successful consumer products. Real success comes from selling huge volumes of products, usually due to effective scaling. In the production and marketing of large volumes of products:

- Fixed depreciation charges tend to zero with a growing volume of finished products.

- It is easier to negotiate with retailers for lower margins. Retailers make sure that customers visit their stores more often for their products, therefore, the more famous your product is, the more often customers will ask it in stores.

- It is easier to negotiate with suppliers about lower prices for the supply of materials.

- Certification companies provide better loan offers for reliable customers, allowing you to pay for certification services after the release of your products (sometimes 90-120 days after the release, and this significantly speeds up cash flow).

- Reduction of scrap rate and the frequency of return of goods, as the level of permissible production deviations decreases and customer technical support improves.

The total cost of one instance of headphones will change dramatically if the volume of production increases. Notice how each type of costs is greatly reduced, with the exception of marketing costs, which are increasing each time:

In addition, given the reduction in unit cost of production, as well as the ability to reduce prices for the supply of goods, the company's profitability varies greatly:

Despite the fact that the delivery of 5,000 units of any product is already a good achievement, this table shows how hard it is to get a decent profit at an early stage of development of a hardware startup. Even the most successful crowdfunding campaigns, as was the case with Canary, Pebble, Oculus, Ouya and other projects, often do not help make enough money on the first batch of goods.

A truly profitable and fast-growing company, such as Fitbit (its value is estimated at about $ 9 billion), is forced to carry out large-scale production. The same Fitbit for 2014 was able to sell 10.9 million units of its products. But do not despair! Selling 10.9 million units seemed to James and Eric a pipe dream when they just launched Fitbit in 2007.

Notes:

Marketing costs, or costs to attract customers, depending on the situation may vary greatly. Some products, in particular, GoPro products, actually sell themselves, as the content of the company is created by the users themselves. Others, such as, for example, Nest products, need additional help, as people rarely think about replacing their thermostats.

When delivering a small batch of goods (5,000 units or less), there are small problems due to the fact that many suppliers of components set the minimum amount of their orders in the amount of more than 5,000 units. For example, many startups are forced to buy more than 6,000 units of a certain type of component for printed circuit boards, even if they only need 5,000 units of finished goods. In these calculations, such factors were not taken into account.

Announcement:

Announcement:We (FRII) have launched a platform for searching for co-founders of startups CoFoundIt.ru .

The project aims to resolve the situation with a shortage of qualified employees and potential partners for startups.

While the service is in beta testing.

Source: https://habr.com/ru/post/366501/

All Articles