Overview of the Russian DLP domestic 3D printer and interview with its creator

In the middle of 2014 in St. Petersburg, the development of a line of high-precision professional 3d-printers Starlight 3D and Russian DLP was completed .

Starlight 3D is a professional solution for jewelry, dentistry and other areas that require the highest precision of models, and Russian DLP is focused on learning, hobbies and 3D printing enthusiasts.

The stated characteristics are very ambitious: a layer thickness of 20 microns is sufficient for printing master models of jewelry, dental models, engineering prototypes with the highest precision. The maximum resolution on the X and Y axes has a solid figure of 45 microns.

')

We tested the Russian DLP 3D printer and interviewed its creator.

Equipment and specifications Russian DLP

Of the presented technical characteristics, the print area, which is 96x54x180mm, is not very impressive. Optionally, it can be increased to 144x81x180mm by installing an additional surface for building the part (substrate).

Russian DLP comes in a large, hard wooden box. Packed and securely fastened, so that no problems or damage during transport should arise.

The package bundle includes: the printer itself, cables for connecting the printer and the projector, a CD with software, a user manual and other useful trifles, a bath for the polymer and the photopolymer itself in a volume of 1 liter.

The printer comes with a Vivitek DLP projector with FullHD resolution and increased lamp life, which is a very important part for a 3D printer - models can take a very long time to expose, and a high lamp life will help reduce printer maintenance costs to a minimum.

In general, dry technical information is, of course, great, but much more interesting is how the printer behaves at work: how easy it is to use, reliable, stable, and most importantly, what is the quality of the parts produced.

Appearance

The design of the printer is as simple as possible - an open frame, in the lower part of which a projector is fixed on the movable frame, and in the upper part there is a working chamber, closed by a red transparent case. Substrate screw and logo illumination are made in red. All together it looks stylish and improves the impression of the uncomplicated design of the entire printer.

Guides, stepper motor, lift table are visible and open for maintenance and service.

Behind the working chamber there is a control electronics hidden in a solid case.

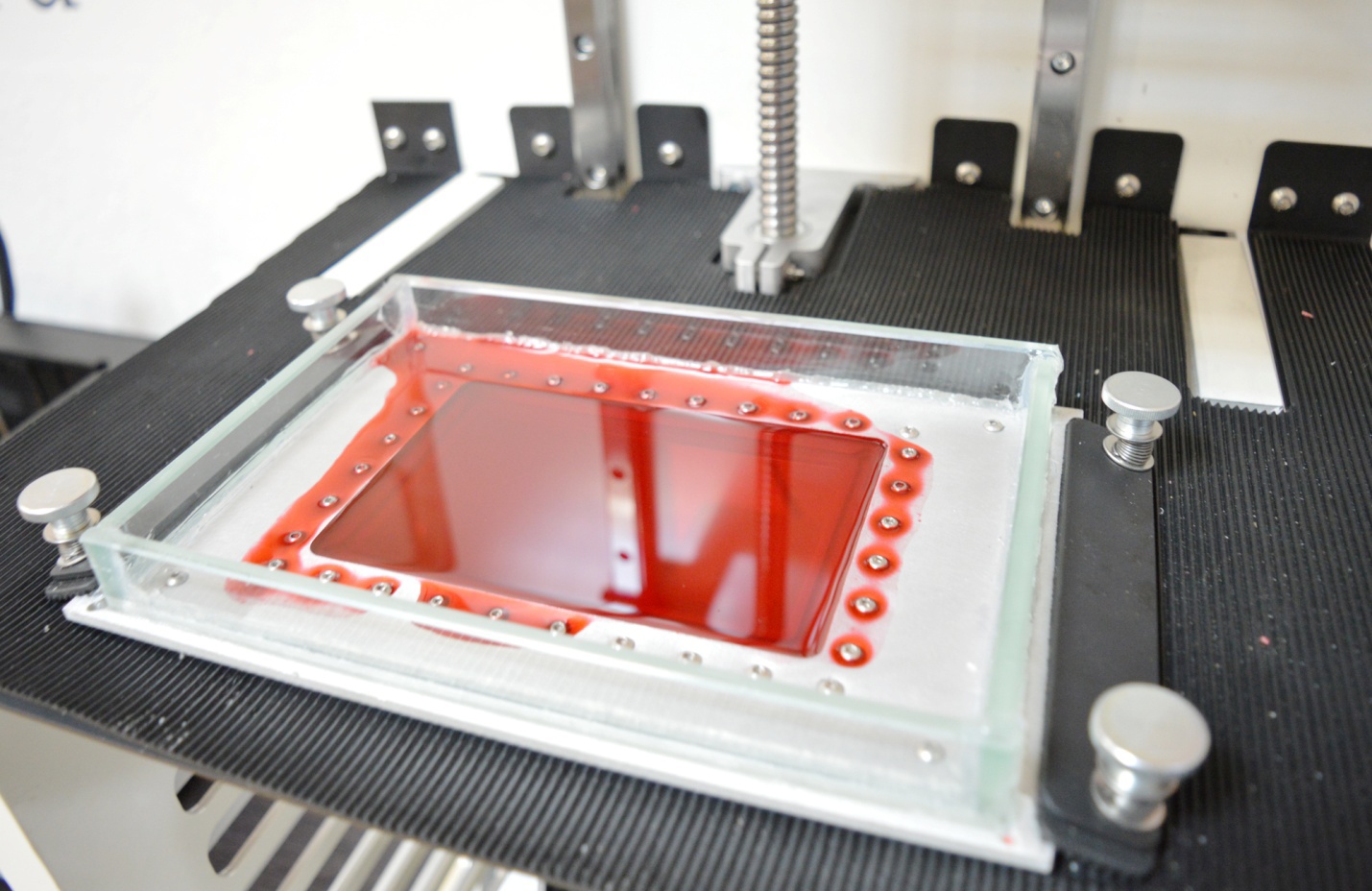

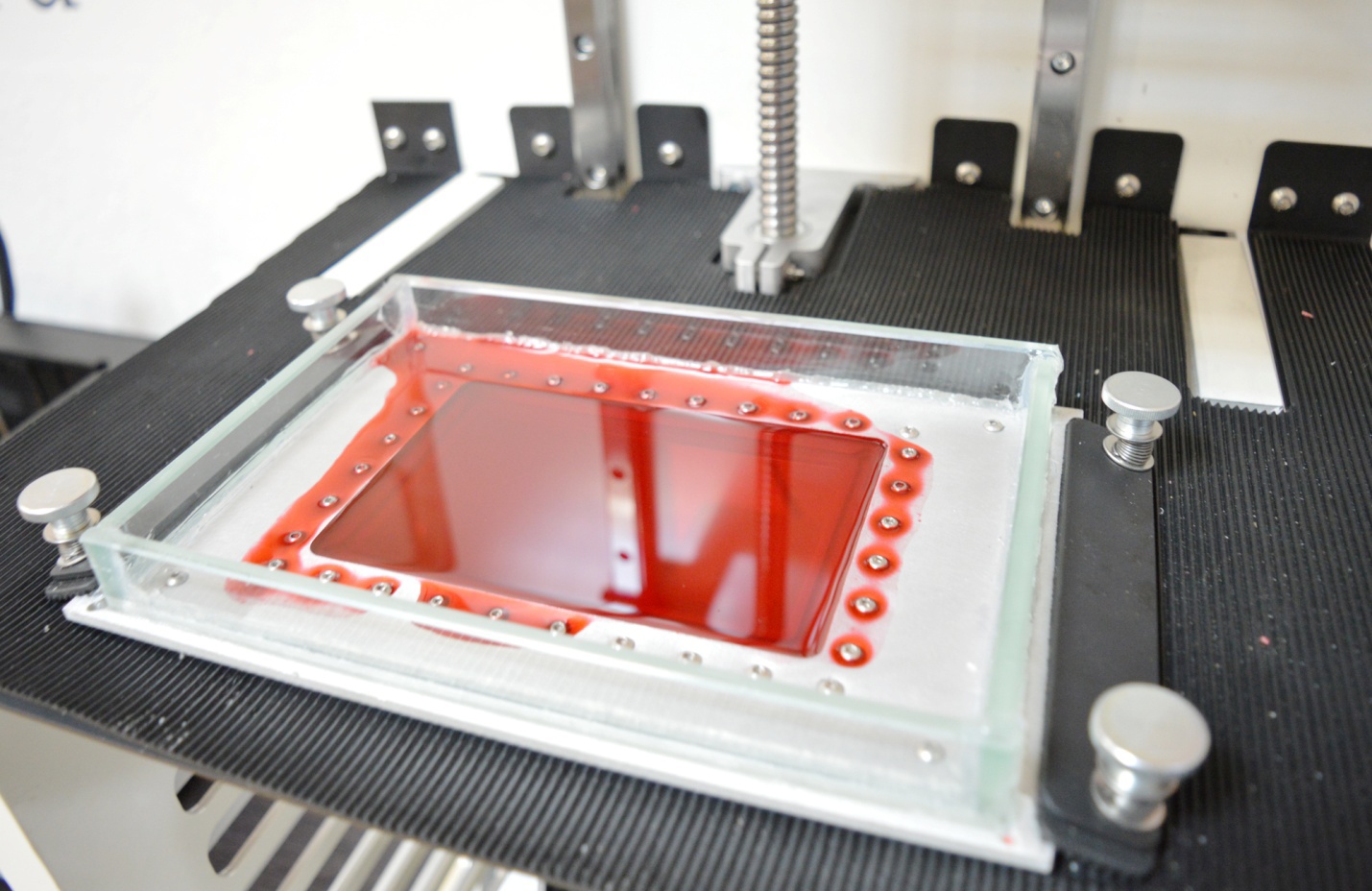

Perhaps one element that requires extremely careful handling is a bath for photopolymer. The film that is on its glass is rather thin, and its damage and the resin entering there will put a cross on your print. So when cleaning the bath you need to be very careful.

There are quite a few controls on the printer itself - the on / off, reset and platform height adjustment buttons. Everything else is controlled by a computer connected to the printer. Of course, there are still controls on the projector, but you can forget about them after the initial setup.

Software

The disk contains all the files and programs necessary for printing: a printer driver, sequences (a set of images for each layer) for cleaning, various support files, a user manual and two of the most important programs: Creation Workshop and RussianDLP Print Manager.

Creation Workshop is a slicer program for SLA and FDM printers. It features a convenient manual placement of various supports, setting up their shape. At the output, the model is exported as a sequence of images, which is transferred to RussianDLP Print Manager. All settings transmitted to the printer are set here - exposure time, layer thickness, lifting speed and others.

Overview of print quality and processes

Immediately, we note that out of the box the printer requires some configuration and calibration. Most of these settings are not required in the future, and the launch of printing will be much faster.

If the same photopolymer is used and the printer has not been transported, then before printing, no additional manipulations, except for slinting, will be required.

Each new type of photopolymer requires its own settings for the layer thickness, exposure time, time of exposure of the first layers. But the abundance of settings implies a large number of self-developed resins used:

- fully burnable jewelry photopolymer

- technical photopolymer

- ceramic photopolymer

By the way, a distinctive feature of these materials is that their value does not depend on currency fluctuations and they are all produced in the Russian Federation.

We decided to test it for work in jewelry as an area most demanding on the accuracy of models. Let's check it by printing two copies of rings that are quite complex in geometry. The model contains many holes of about 0.5 mm. It used the bundled resin of its own production Starlight red.

For printing, we used the following Russian DLP Print Manager program settings:

Connect to the printer and start printing. The first printing went without any problems: the model is perfectly attached to the substrate, it was printed successfully. Small holes are filled with resin, but this is solved by spraying the model with alcohol from a spray bottle. The holes are cleaned, we send the models for final polymerization to the ultraviolet camera, and evaluate the result.

Rings turned out just perfect. The smallest details are worked out, the drawing on them is also very detailed, the layers are not felt at all, neither by touch nor visually. The printer justified all the declared characteristics completely. The resin is quite flexible, the surface is glossy. By the way, the cost of each ring for the polymer was about eight rubles.

For comparison, we printed the same ring on a printer of the same price category Formlabs Form 1+ and compared the result.

Here Russian DLP won in print quality: a thin mesh turned out much better, unlike Form 1+. Another advantage is the number of supports: the Form 1+ slicer has generated them in huge quantities, which will cause problems during the post-processing. In CreationWorkshop, which uses Russian DLP, support can be set manually, and you need a lot less. And one more plus to the Russian DLP - thanks to the substrate of a special form, the required substrate thickness is much less, which significantly saves the photopolymer and reduces the cost of printing.

During the preparation of this article, the manufacturer managed to print and cast a ring on the Starlight photopolymer just released a few days ago and showed the quality of its burning.

The result of the casting is simply excellent, the model's detailed model is the highest and the metal cast ring looks great. It can be said that even the youngest model in the line confidently provides high-quality execution of models for jewelry.

Conclusion

The printer definitely deserves attention. Being one of the cheapest models in its class, it provides print quality that is not inferior to competitors.

Of course, we need preliminary preparation, readiness for experiments and knowledge of 3D printing methods, but you will get the corresponding result. At the same time, the printer is reliable, all elements subject to wear are made soundly and, if necessary, are easily serviced.

We could not help but take advantage of the incident and interviewed the creator of the domestic 3D printers Starlight 3D and Russian DLP about his developments and plans for the future:

Starlight 3D is a professional solution for jewelry, dentistry and other areas that require the highest precision of models, and Russian DLP is focused on learning, hobbies and 3D printing enthusiasts.

The stated characteristics are very ambitious: a layer thickness of 20 microns is sufficient for printing master models of jewelry, dental models, engineering prototypes with the highest precision. The maximum resolution on the X and Y axes has a solid figure of 45 microns.

')

We tested the Russian DLP 3D printer and interviewed its creator.

Equipment and specifications Russian DLP

| Printing technology | SLA (DLP) |

| Maximum print quality, micron | 20 |

| Construction area, mm | 96x54x180 |

| Interfaces | USB; HDMI; VGA |

| System requirements | Windows 64 bit; 8 GB RAM |

| Resolution in X and Y axis (micron) | > 45 |

| Print speed | from 12 mm / h |

| File formats | .stl, .obj, .3ds, .amf, .png, .tiff, .jpg, .bmp |

| Supported materials | Visijet FTI; technical polymer Starlight ; burnable polymer Starlight, 3DINK |

Of the presented technical characteristics, the print area, which is 96x54x180mm, is not very impressive. Optionally, it can be increased to 144x81x180mm by installing an additional surface for building the part (substrate).

Russian DLP comes in a large, hard wooden box. Packed and securely fastened, so that no problems or damage during transport should arise.

The package bundle includes: the printer itself, cables for connecting the printer and the projector, a CD with software, a user manual and other useful trifles, a bath for the polymer and the photopolymer itself in a volume of 1 liter.

The printer comes with a Vivitek DLP projector with FullHD resolution and increased lamp life, which is a very important part for a 3D printer - models can take a very long time to expose, and a high lamp life will help reduce printer maintenance costs to a minimum.

In general, dry technical information is, of course, great, but much more interesting is how the printer behaves at work: how easy it is to use, reliable, stable, and most importantly, what is the quality of the parts produced.

Appearance

The design of the printer is as simple as possible - an open frame, in the lower part of which a projector is fixed on the movable frame, and in the upper part there is a working chamber, closed by a red transparent case. Substrate screw and logo illumination are made in red. All together it looks stylish and improves the impression of the uncomplicated design of the entire printer.

Guides, stepper motor, lift table are visible and open for maintenance and service.

Behind the working chamber there is a control electronics hidden in a solid case.

Perhaps one element that requires extremely careful handling is a bath for photopolymer. The film that is on its glass is rather thin, and its damage and the resin entering there will put a cross on your print. So when cleaning the bath you need to be very careful.

There are quite a few controls on the printer itself - the on / off, reset and platform height adjustment buttons. Everything else is controlled by a computer connected to the printer. Of course, there are still controls on the projector, but you can forget about them after the initial setup.

Software

The disk contains all the files and programs necessary for printing: a printer driver, sequences (a set of images for each layer) for cleaning, various support files, a user manual and two of the most important programs: Creation Workshop and RussianDLP Print Manager.

Creation Workshop is a slicer program for SLA and FDM printers. It features a convenient manual placement of various supports, setting up their shape. At the output, the model is exported as a sequence of images, which is transferred to RussianDLP Print Manager. All settings transmitted to the printer are set here - exposure time, layer thickness, lifting speed and others.

Overview of print quality and processes

Immediately, we note that out of the box the printer requires some configuration and calibration. Most of these settings are not required in the future, and the launch of printing will be much faster.

If the same photopolymer is used and the printer has not been transported, then before printing, no additional manipulations, except for slinting, will be required.

Each new type of photopolymer requires its own settings for the layer thickness, exposure time, time of exposure of the first layers. But the abundance of settings implies a large number of self-developed resins used:

- fully burnable jewelry photopolymer

- technical photopolymer

- ceramic photopolymer

By the way, a distinctive feature of these materials is that their value does not depend on currency fluctuations and they are all produced in the Russian Federation.

We decided to test it for work in jewelry as an area most demanding on the accuracy of models. Let's check it by printing two copies of rings that are quite complex in geometry. The model contains many holes of about 0.5 mm. It used the bundled resin of its own production Starlight red.

For printing, we used the following Russian DLP Print Manager program settings:

Connect to the printer and start printing. The first printing went without any problems: the model is perfectly attached to the substrate, it was printed successfully. Small holes are filled with resin, but this is solved by spraying the model with alcohol from a spray bottle. The holes are cleaned, we send the models for final polymerization to the ultraviolet camera, and evaluate the result.

Rings turned out just perfect. The smallest details are worked out, the drawing on them is also very detailed, the layers are not felt at all, neither by touch nor visually. The printer justified all the declared characteristics completely. The resin is quite flexible, the surface is glossy. By the way, the cost of each ring for the polymer was about eight rubles.

For comparison, we printed the same ring on a printer of the same price category Formlabs Form 1+ and compared the result.

Here Russian DLP won in print quality: a thin mesh turned out much better, unlike Form 1+. Another advantage is the number of supports: the Form 1+ slicer has generated them in huge quantities, which will cause problems during the post-processing. In CreationWorkshop, which uses Russian DLP, support can be set manually, and you need a lot less. And one more plus to the Russian DLP - thanks to the substrate of a special form, the required substrate thickness is much less, which significantly saves the photopolymer and reduces the cost of printing.

During the preparation of this article, the manufacturer managed to print and cast a ring on the Starlight photopolymer just released a few days ago and showed the quality of its burning.

The result of the casting is simply excellent, the model's detailed model is the highest and the metal cast ring looks great. It can be said that even the youngest model in the line confidently provides high-quality execution of models for jewelry.

Conclusion

The printer definitely deserves attention. Being one of the cheapest models in its class, it provides print quality that is not inferior to competitors.

Of course, we need preliminary preparation, readiness for experiments and knowledge of 3D printing methods, but you will get the corresponding result. At the same time, the printer is reliable, all elements subject to wear are made soundly and, if necessary, are easily serviced.

We could not help but take advantage of the incident and interviewed the creator of the domestic 3D printers Starlight 3D and Russian DLP about his developments and plans for the future:

Source: https://habr.com/ru/post/366413/

All Articles