Embedded World 2015: what's new? What's interestnig?

Hello!

My colleagues and I were lucky to visit the next Embedded World 2015 exhibition. Exhibited, as usual, a huge number of companies. It’s just impossible to retell everything, so in this article I decided to write only about what seemed to me the most interesting and that I managed to analyze a little.

The exhibition is held at the Nurnberg Messe, usually exhibiting board developers, software and component manufacturers, as well as distribution companies. No mobile operators, no phone manufacturers - only embedded, only hardcore.

')

Who cares - I ask under the cat. There will be a lot of pictures and even video.

In a sense, we can say that the exhibition was held under the motto of IoT (Internet Of Things).

But the coherent picture did not work out; we can only say that everyone understood that the hardware (boards, controllers, etc.) was already done so much that nothing prevents them from stuffing any device with them and then connecting the devices to each other (and making an uprising of the machines). That is, by and large IoT is considered as the concept of creating software and protocols that can combine all existing developments.

The only thing I managed to fix was that many people were concerned about security in IoT.

One of the aspects is the rigid separation of a real-time kernel that performs some critical functions, and the rest of the application software, which currently has an infinite number of holes. For this, Intel is promoting the VT-X, VT-D technologies, under which GreenHills and WindRiver make their microkernels. And Xilinx is developing a chip (see below), in which Cortex-R5 (real-time) and Cortex-A53 (application) will work in parallel.

That's what else was interesting.

1. LPKF showed a technology that allows printing metallization on plastic, and 3d, that is, almost any kind of plastic can be used.

The technology is that a special varnish is applied to the plastic.

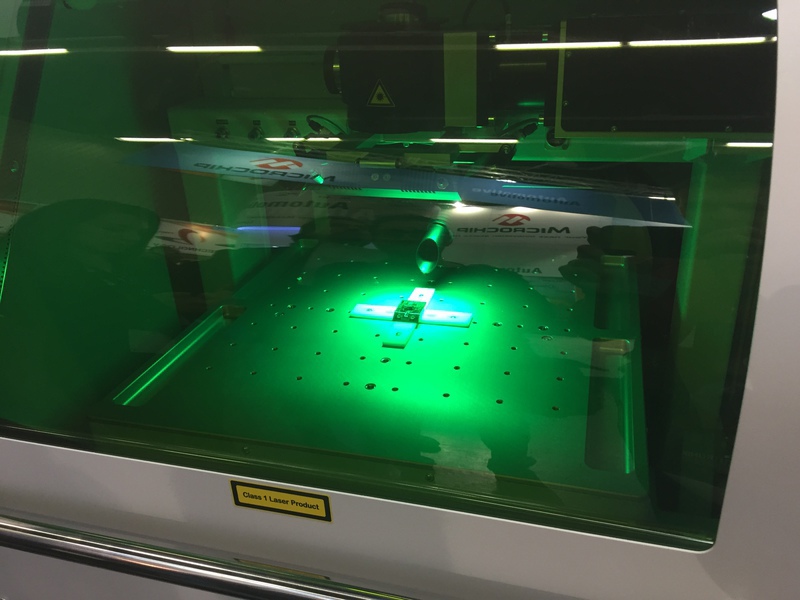

then the workpiece gets into a special printer, where tracks are applied to the varnish

then the workpiece is lowered into the chemical solution and metallization is obtained.

Unfortunately, the photo from the metallized part I have not survived. Fortunately, there is a video on their home site, which shows the process and the result:

www.lpkf.com/products/rapid-pcb-prototyping/lds/protoplate-lds.htm

Further, however, you need to unsolder the components without melting the plastic, but this is another technology.

2. Apacer showed a disk with a flash drive. The flash drive is connected from the outside and blocks the recording on the disk. While reading remains possible

By and large nonsense, but as protection against the fool is quite suitable.

3. Toradex continues to do processor-based SoM, i.e. while SoM on SoC should not be expected. The freshest shawls are made on the basis of tegra and can really work cool with video. NVidia knows its business.

In the meantime, we continue to use their old boards with the PXA320.

4. As I have already said, IoT was mentioned on the set of stands. Solution makers finally decided to cover the zoo with one umbrella. Smacks of marketing.

I really liked how IoT was shown at the Kontron booth

It turns out that if you plug a sensor (on the left) into the ground and water the plants based on its readings, then it will be better than if you evaluate the dryness of the earth by color (on the right). As much as 15 percent.

5. A rather original solution is offered by Schroff - this is a metal case that is twisted with only two screws. It is very easy to break apart, almost like a children's designer (from that childhood, when the designers were metal). The technology is called Interscale M.

They already showed a similar decision last year, but when they tried to take a picture, they hid it. And now - promote in full growth, as they say.

The size of the case can be any, for example we were given a small cube, if it is interesting, I will shoot the video, how it is disassembled and assembled.

The body can be customized, for example, add guides:

It remains a pleasant impression, made wisely, technologically.

And here is a link to the manufacturer’s website (with video):

www.schroff.biz/InterscaleM

6. Avago at the stand of EBV showed transceivers that allow to form a connection between the boards on optics at any speed up to 14 gigabits per second. To do this, a special chip is attached to the board on the latches, to which an optics is already attached with a special connector. Each chip supports up to 12 links. The permissible length for optics is 100 meters. At the optical level, it looks like CWDM.

Here so mini and micro look:

These devices have a very interesting attachment to the board - it looks like a watchdog, i.e. just snap into place:

And then the optical part is attached to this thing. In fact, it is not only optical, but also electrical.

An interesting solution for those cases where high-speed signals do not want to pull with copper or need to throw signals to another card.

www.avagotech.com/pages/en/fiber_optics/parallel_optics/minipod_micropod

7. Altera showed a fee for 20 nm technology - Arria 10 is already loading and Linux is spinning on it!

This is still an engineering sample, but at the end of the year it will be possible to get normal chips.

8. Xilinx showed a prototype of the coolest chip (Zync UltraScale + MPSoC), which looks like this (prototype):

that is, for now it is six-seventh Virtex, and in the future there will be one chip that will combine the Quad-Core Cortex-A53 + Dual-Core ARM Cortex-R5. See more at Xilinx website.

www.xilinx.com/products/technology/ultrascale-mpsoc.html

9. I want to separately say about the design of stands. Almost all booths have any robots or devices that attract attention. This is the only way to lure someone from the crowd. Otherwise, with so many motherboards on offer, the eye simply has nothing to catch on. What is there just was not ...

A robot on the MathWorks (Matlab, Simulink) booth plays checkers:

As zavlekalova (guess what company) could drive on machines. It is really difficult, because there is no pondering machine. The cars are constantly falling on their side and go off the track.

Wurth lured by magic and powerful witchcraft:

Toradex is controlled by a robot from its Colibri board.

10. We also found a manufacturer of simple but cool plastic cases - the English company FSPT. The technology lies in the fact that the plastic plate is cut to the desired size, and then milled at the bend points. Then there is bending and it turns out a very good box. The cost in a batch of one hundred pieces is 5-7 euros. Production time - 1 week!

For one euro you can put the image on one side.

Surprisingly, with all the simplicity (perhaps seeming?) Of technology, the result is simply amazing! Shells are very well fitted, connect without screws, on the latches. And the boards are inserted into special slots:

And with the board it looks like this:

In short, almost unlimited scope for creativity for quite reasonable money.

UPD: I was wrong, the company is called Camdenboss . FSPT is a technology that stands for Flat Sheet Plastic Technology. Thank you maksfff

11 An interesting software is offered by the Dutch company verum. They invented their own language to describe systems, such as finite automata. By describing the behavior in this language, you can fully debug the automaton, generate test cases and monitor their execution, and then generate C / C ++ code. The program is distributed under the opensource license, but it seems to be paid for commercial use. The part is implemented as a plugin for Eclipse.

An example of using such a system is a console plus sirens plus a sensor. The relationship between the components is prescribed and the expected result from each action is described. After that, the automation performs a bunch of routine work, draws interaction diagrams for different input effects, creates test cases and drives them away.

The language is a bit like Verilog / VHDL, which uses a behavioral description.

I was hooked on a workflow in this product. Do not write the code, and then debug, retest and fix the bugs again, but describe the system, debug it, and then generate the code. It would be necessary to use. Maybe, who knows more similar projects?

This is called Model Based Design.

12. Cypress showed in the work capacitive touchscreen, which works directly under water. This is achieved with the help of tricks and software processing. For example, only two points work in such a touchscreen. Plus, this requires a special chip. We checked - it really works (there is an android inside).

13. At the EBV stand, On Semi showed that it can take CCDs at a frequency of about 14,000 frames per second. That is, about 70 microseconds per frame! The matrix can be of various sizes, while the mount allows you to install almost any lens - from cheap to expensive.

As proof of the rate of fire, an example was shown in which a circle was spinning with a frequency not visible to the eye, that is, the image on the circle was eroded. At the same time, adjusting the frame rate can achieve a visible image (using a stroboscopic effect). In this example, the circle was doing about 115 revolutions per second.

In the second photo you can see that the sensitivity of the sensor is enough even with short exposures and the absence of a bright light source:

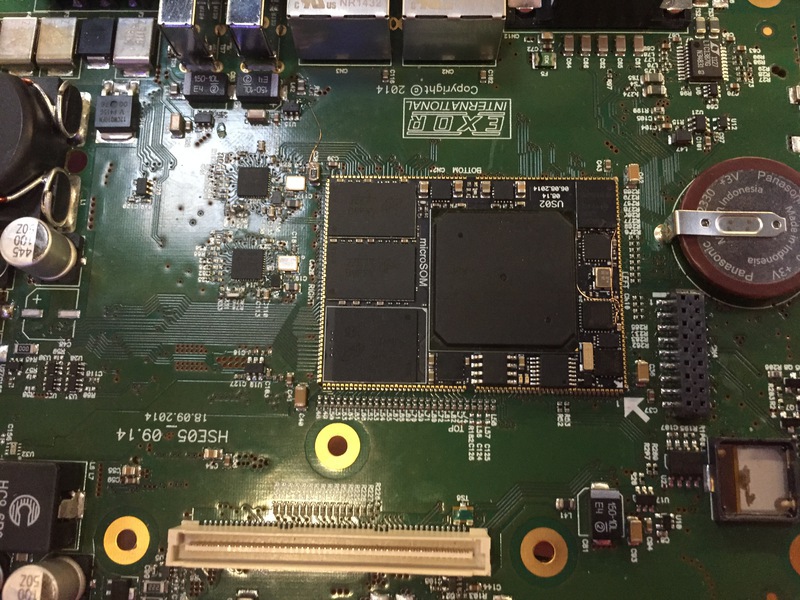

14. EXOR showed a microSOM based on Altera Cyclone V (this is with ARM on board).

www.ultilogic.com/webpage?ReadForm&wPageName=products&t=Product&p=microSOM

He was interested in mounting to the board: this is not a connector. It is soldered onto the board almost like a microcircuit.

And ultimately looks in its place

15. FTDIchip holds brand. They showed a new family of microcontrollers - F90X. Now IP-camera can be done on a single chip. On the one hand the camera, on the other Ethernet, what else is needed? Display? You are welcome!

www.ftdichip.com/Products/ICs/FT90X.html

16. Another rather curious product is Wyliodrin. This is a service that allows

program and manage devbords from the browser. Supported: Malinka, Intel & Edison, Beaglebone Black. In this case, the board itself is, as they say, in the cloud, that is, somewhere else.

www.wyliodrin.com

I took a dozen promotional codes for a month of free use. Who cares, write, share.

17. In the evening, at the EBV stand, live music was played and beer was poured. Where do without him, after all, Bavaria!

At this endless party of IT-Schnick we captured ourselves

Everyone who read to the end, thank you! I hope it was interesting and I managed to at least a little convey the atmosphere that usually hovers at such events.

I would like to express special thanks to our company, which in this difficult time gave us the opportunity to visit the exhibition. And also - Konstantin Dobrosoltsu (EBV), thanks to which we always learn about all the new trends first: he did not let us get bored at the exhibition.

My colleagues and I were lucky to visit the next Embedded World 2015 exhibition. Exhibited, as usual, a huge number of companies. It’s just impossible to retell everything, so in this article I decided to write only about what seemed to me the most interesting and that I managed to analyze a little.

The exhibition is held at the Nurnberg Messe, usually exhibiting board developers, software and component manufacturers, as well as distribution companies. No mobile operators, no phone manufacturers - only embedded, only hardcore.

')

Who cares - I ask under the cat. There will be a lot of pictures and even video.

In a sense, we can say that the exhibition was held under the motto of IoT (Internet Of Things).

But the coherent picture did not work out; we can only say that everyone understood that the hardware (boards, controllers, etc.) was already done so much that nothing prevents them from stuffing any device with them and then connecting the devices to each other (and making an uprising of the machines). That is, by and large IoT is considered as the concept of creating software and protocols that can combine all existing developments.

The only thing I managed to fix was that many people were concerned about security in IoT.

One of the aspects is the rigid separation of a real-time kernel that performs some critical functions, and the rest of the application software, which currently has an infinite number of holes. For this, Intel is promoting the VT-X, VT-D technologies, under which GreenHills and WindRiver make their microkernels. And Xilinx is developing a chip (see below), in which Cortex-R5 (real-time) and Cortex-A53 (application) will work in parallel.

That's what else was interesting.

1. LPKF showed a technology that allows printing metallization on plastic, and 3d, that is, almost any kind of plastic can be used.

The technology is that a special varnish is applied to the plastic.

then the workpiece gets into a special printer, where tracks are applied to the varnish

then the workpiece is lowered into the chemical solution and metallization is obtained.

Unfortunately, the photo from the metallized part I have not survived. Fortunately, there is a video on their home site, which shows the process and the result:

www.lpkf.com/products/rapid-pcb-prototyping/lds/protoplate-lds.htm

Further, however, you need to unsolder the components without melting the plastic, but this is another technology.

2. Apacer showed a disk with a flash drive. The flash drive is connected from the outside and blocks the recording on the disk. While reading remains possible

By and large nonsense, but as protection against the fool is quite suitable.

3. Toradex continues to do processor-based SoM, i.e. while SoM on SoC should not be expected. The freshest shawls are made on the basis of tegra and can really work cool with video. NVidia knows its business.

In the meantime, we continue to use their old boards with the PXA320.

4. As I have already said, IoT was mentioned on the set of stands. Solution makers finally decided to cover the zoo with one umbrella. Smacks of marketing.

I really liked how IoT was shown at the Kontron booth

It turns out that if you plug a sensor (on the left) into the ground and water the plants based on its readings, then it will be better than if you evaluate the dryness of the earth by color (on the right). As much as 15 percent.

5. A rather original solution is offered by Schroff - this is a metal case that is twisted with only two screws. It is very easy to break apart, almost like a children's designer (from that childhood, when the designers were metal). The technology is called Interscale M.

They already showed a similar decision last year, but when they tried to take a picture, they hid it. And now - promote in full growth, as they say.

The size of the case can be any, for example we were given a small cube, if it is interesting, I will shoot the video, how it is disassembled and assembled.

The body can be customized, for example, add guides:

It remains a pleasant impression, made wisely, technologically.

And here is a link to the manufacturer’s website (with video):

www.schroff.biz/InterscaleM

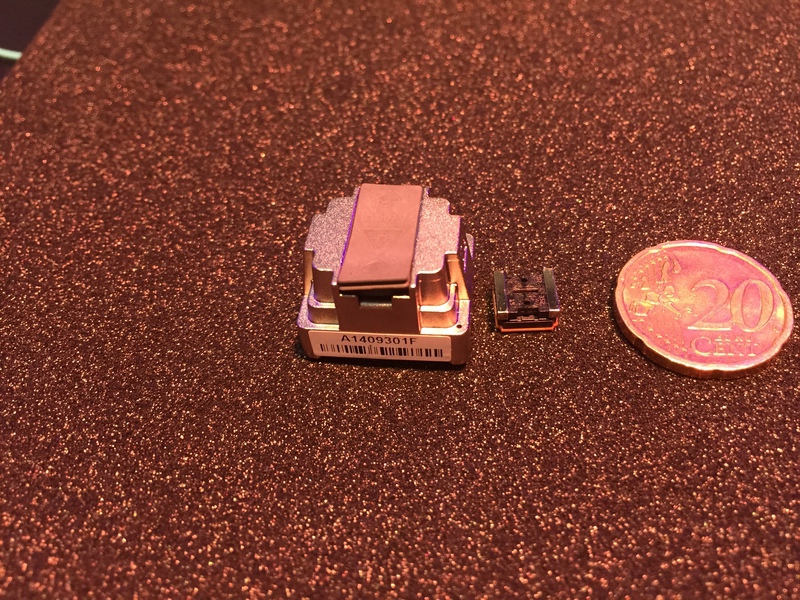

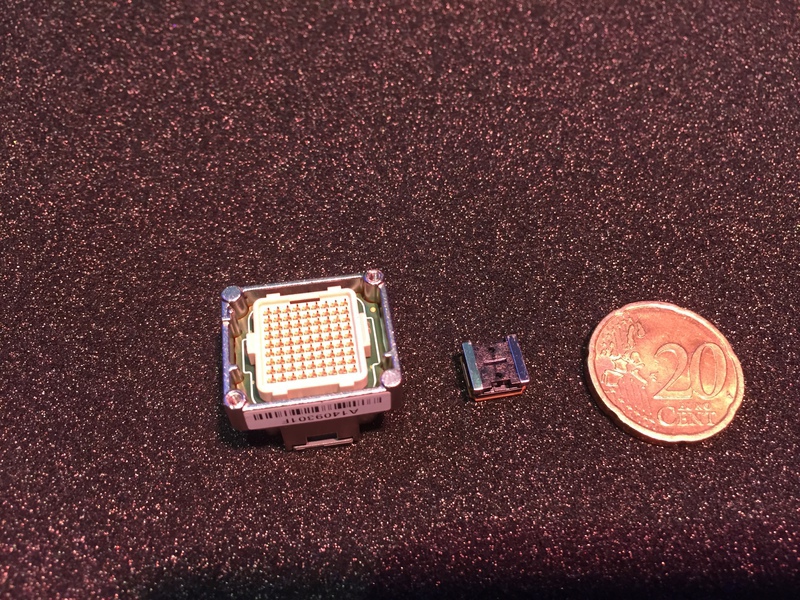

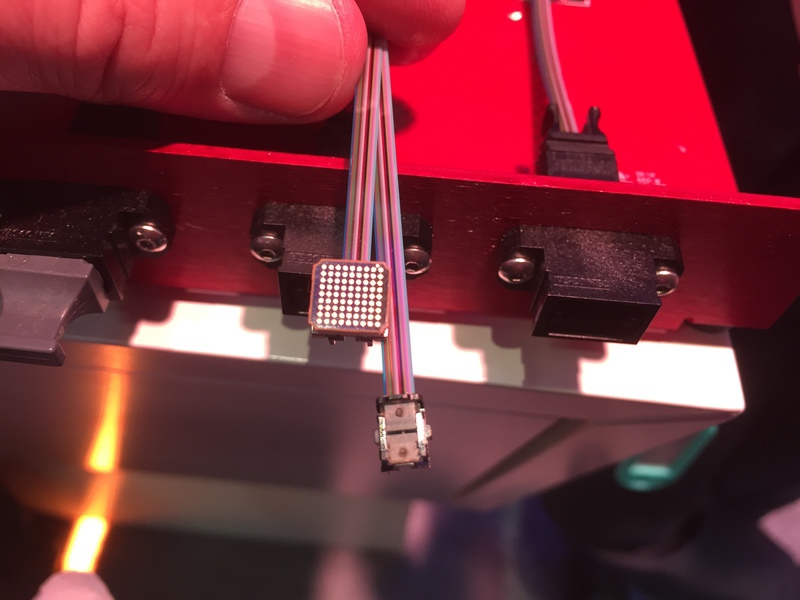

6. Avago at the stand of EBV showed transceivers that allow to form a connection between the boards on optics at any speed up to 14 gigabits per second. To do this, a special chip is attached to the board on the latches, to which an optics is already attached with a special connector. Each chip supports up to 12 links. The permissible length for optics is 100 meters. At the optical level, it looks like CWDM.

Here so mini and micro look:

These devices have a very interesting attachment to the board - it looks like a watchdog, i.e. just snap into place:

And then the optical part is attached to this thing. In fact, it is not only optical, but also electrical.

An interesting solution for those cases where high-speed signals do not want to pull with copper or need to throw signals to another card.

www.avagotech.com/pages/en/fiber_optics/parallel_optics/minipod_micropod

7. Altera showed a fee for 20 nm technology - Arria 10 is already loading and Linux is spinning on it!

This is still an engineering sample, but at the end of the year it will be possible to get normal chips.

8. Xilinx showed a prototype of the coolest chip (Zync UltraScale + MPSoC), which looks like this (prototype):

that is, for now it is six-seventh Virtex, and in the future there will be one chip that will combine the Quad-Core Cortex-A53 + Dual-Core ARM Cortex-R5. See more at Xilinx website.

www.xilinx.com/products/technology/ultrascale-mpsoc.html

9. I want to separately say about the design of stands. Almost all booths have any robots or devices that attract attention. This is the only way to lure someone from the crowd. Otherwise, with so many motherboards on offer, the eye simply has nothing to catch on. What is there just was not ...

A robot on the MathWorks (Matlab, Simulink) booth plays checkers:

As zavlekalova (guess what company) could drive on machines. It is really difficult, because there is no pondering machine. The cars are constantly falling on their side and go off the track.

Wurth lured by magic and powerful witchcraft:

Toradex is controlled by a robot from its Colibri board.

10. We also found a manufacturer of simple but cool plastic cases - the English company FSPT. The technology lies in the fact that the plastic plate is cut to the desired size, and then milled at the bend points. Then there is bending and it turns out a very good box. The cost in a batch of one hundred pieces is 5-7 euros. Production time - 1 week!

For one euro you can put the image on one side.

Surprisingly, with all the simplicity (perhaps seeming?) Of technology, the result is simply amazing! Shells are very well fitted, connect without screws, on the latches. And the boards are inserted into special slots:

And with the board it looks like this:

In short, almost unlimited scope for creativity for quite reasonable money.

UPD: I was wrong, the company is called Camdenboss . FSPT is a technology that stands for Flat Sheet Plastic Technology. Thank you maksfff

11 An interesting software is offered by the Dutch company verum. They invented their own language to describe systems, such as finite automata. By describing the behavior in this language, you can fully debug the automaton, generate test cases and monitor their execution, and then generate C / C ++ code. The program is distributed under the opensource license, but it seems to be paid for commercial use. The part is implemented as a plugin for Eclipse.

An example of using such a system is a console plus sirens plus a sensor. The relationship between the components is prescribed and the expected result from each action is described. After that, the automation performs a bunch of routine work, draws interaction diagrams for different input effects, creates test cases and drives them away.

The language is a bit like Verilog / VHDL, which uses a behavioral description.

I was hooked on a workflow in this product. Do not write the code, and then debug, retest and fix the bugs again, but describe the system, debug it, and then generate the code. It would be necessary to use. Maybe, who knows more similar projects?

This is called Model Based Design.

12. Cypress showed in the work capacitive touchscreen, which works directly under water. This is achieved with the help of tricks and software processing. For example, only two points work in such a touchscreen. Plus, this requires a special chip. We checked - it really works (there is an android inside).

13. At the EBV stand, On Semi showed that it can take CCDs at a frequency of about 14,000 frames per second. That is, about 70 microseconds per frame! The matrix can be of various sizes, while the mount allows you to install almost any lens - from cheap to expensive.

As proof of the rate of fire, an example was shown in which a circle was spinning with a frequency not visible to the eye, that is, the image on the circle was eroded. At the same time, adjusting the frame rate can achieve a visible image (using a stroboscopic effect). In this example, the circle was doing about 115 revolutions per second.

In the second photo you can see that the sensitivity of the sensor is enough even with short exposures and the absence of a bright light source:

14. EXOR showed a microSOM based on Altera Cyclone V (this is with ARM on board).

www.ultilogic.com/webpage?ReadForm&wPageName=products&t=Product&p=microSOM

He was interested in mounting to the board: this is not a connector. It is soldered onto the board almost like a microcircuit.

And ultimately looks in its place

15. FTDIchip holds brand. They showed a new family of microcontrollers - F90X. Now IP-camera can be done on a single chip. On the one hand the camera, on the other Ethernet, what else is needed? Display? You are welcome!

www.ftdichip.com/Products/ICs/FT90X.html

16. Another rather curious product is Wyliodrin. This is a service that allows

program and manage devbords from the browser. Supported: Malinka, Intel & Edison, Beaglebone Black. In this case, the board itself is, as they say, in the cloud, that is, somewhere else.

www.wyliodrin.com

I took a dozen promotional codes for a month of free use. Who cares, write, share.

17. In the evening, at the EBV stand, live music was played and beer was poured. Where do without him, after all, Bavaria!

At this endless party of IT-Schnick we captured ourselves

Everyone who read to the end, thank you! I hope it was interesting and I managed to at least a little convey the atmosphere that usually hovers at such events.

I would like to express special thanks to our company, which in this difficult time gave us the opportunity to visit the exhibition. And also - Konstantin Dobrosoltsu (EBV), thanks to which we always learn about all the new trends first: he did not let us get bored at the exhibition.

Source: https://habr.com/ru/post/366405/

All Articles