Choosing a home printer - brief and to the point

All of us at least once used the printer at office, the copy center or somewhere else. But when it comes to buying a home printer, many are lost, they start reading countless articles, forums, increasingly confused, in the opinions of supporters of various technologies.

All of us at least once used the printer at office, the copy center or somewhere else. But when it comes to buying a home printer, many are lost, they start reading countless articles, forums, increasingly confused, in the opinions of supporters of various technologies.In this post we will try to help determine the choice of printing device, for which we consider the basic parameters of modern printers and compare them.

The basics

The first and most important thing to decide on is the printing technology. Most household and office printers are known to fall into two categories: laser and inkjet.

')

The basis of laser printing is static electricity. The laser projects on the negatively charged drum the desired image or text, creating neutral areas on it. Next, negatively charged powder toner particles are attracted to these areas, which are then transferred to positively charged paper. At the end of the process, the heating roller (it is often called the “stove”) secures the image on the carrier at temperatures up to 200 ° C — that is why the prints coming out of the laser printer are always warm.

Inkjet printing is done with liquid ink. The printhead moves across the sheet on the carriage (as in an old typewriter, but much faster) and distributes ink over the paper. At the time of production of a print from a set of holes (nozzles), microscopic ink droplets are ejected from the print head at different intervals. At the same time, inkjet printing technology is divided into two types - thermal jet (ink is pushed onto the carrier due to their heating and expansion) and piezoelectric (ink is pushed out using an electric pulse transmission). Piezoelectric technology (such as Epson Micro Piezo, for example) is considered to be more progressive, since it prevents the print head from deteriorating due to the absence of high temperatures, and also makes it possible to position drops more accurately, which means to print with higher quality.

Let's compare the devices based on different printing technologies by the main parameters.

At the start, attention, print!

Directly printing speed on a laser printer, as a rule, is higher than on an inkjet one, but at the same time the delay in the first sheet output is much greater. This is due to the fact that the laser printer takes time to warm up the engine and the “stove”. Therefore, after you send the document to print, it will take, on average, about 10-15 seconds before the appearance of the print. Inkjet printers, however, begin printing immediately after the job is sent, because it is not necessary to heat the ink.

Consumption

Consumables (toners) for laser printers are usually much more expensive than ink cartridges, especially if it is a set of color toners, but with a long resource. Powder toner cartridges can be recharged, but due to the fact that the drum cartridge wears out during printing, you can do this three or four times, after which you will have to change the drum. In addition, powder toner is very toxic. Anyway, “specially trained” people are engaged in filling the toner, so if the toner runs out at the wrong time, you will have to go to the store for a new one or for the purpose of refueling.

About ink cartridges to paint, in fact, nothing: bought, replaced. Filling such cartridges is almost always - messing around with syringes, ink cans, a lot of ink traces on clothes and furniture, as well as resetting counters in chips, etc ... You don't wish for anyone.

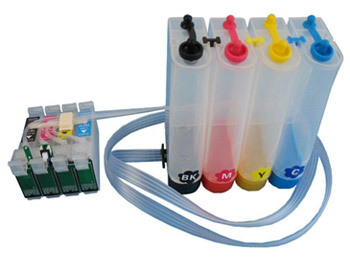

There is, and an alternative way of organizing the supply of ink to the device - the Continuous Ink Supply System (CISS). Such systems first appeared on the market in the form of self-made installations, representing a set of plastic bottles for ink and tubes connecting them to the print head. The main advantage of CISS is the low cost of printing (10-15 times cheaper than laser) and a large supply of ink combined with the absence of the need to buy cartridges, but the disadvantages often outweigh.

First, when installing a CISS and using third-party ink, any printer is automatically removed from warranty service. The process of "reworking" the printer requires a violation of the integrity of the body (filing, creating holes), changing the device structure. After such an intervention, no manufacturer will guarantee the quality of the result (the majority of installers of “handicraft” CISS, however, too).

Secondly, refilling such a device is as dirty and difficult as in the case of refilling ink cartridges. Most often, refilling is done with a large syringe, the ink gets past the bottle, and stains your hands and the table. To wash them then is quite problematic.

Thirdly, the ink tubes to the printhead are usually made of solid material, so they can crack and break off of the printhead. The ink cylinders themselves do not have pressure control systems and are not protected from the ingress of air. All this leads to private breakdowns, leaks and drying of ink in the tubes and elements of the print head, as well as to the uneven supply of ink of different colors on the paper when printing.

The best option

There are also factory printers with built-in ink tanks . At the moment, the only supplier of such devices on the Russian market is Epson, whose series of Epson Printing Factory devices perfectly solves the problems described above, while maintaining the main advantage of CISS — the extremely low cost of printing.

Ink containers are much cheaper than cartridges, they are easy to use, and they are free from the drawbacks of traditional CISS, while the life of containers is 10 to 15 times higher than that of ink cartridges. Ink does not stain your hands and furniture due to the special structure of the container's nose and the ink receiving port in the printer tank. The pressure control system allows you to adjust the flow of ink into the printhead, and the special structure of the tanks and ink paths virtually eliminates drying and breakage. All of the above allows you to significantly reduce the cost of printing. The initial set of ink supplied by the Factory is enough for 2-3 years of use (for more information, please visit Epson.ru ).

Print quality

If we compare the modern laser and inkjet printers in print quality , the appearance of the differences is almost not noticeable. It is believed that laser prints are more stable due to the fact that the toner "baked" on paper when printing. This is partly true. Indeed, most inks spread out when liquids come into contact with them and fade from direct sunlight. However, technology does not stand still: particles of modern pigment inks are protected by a polymer shell. They are fixed on the surface of the paper (as opposed to water-soluble, which penetrate into the sheet) and protected from exposure to water and light. Moreover, unlike laser toner, ink does not peel off from paper over time (this is a serious problem that makes itself felt when archival storage of documents!). Recall, for example, modern birth or marriage certificates: the inscriptions on them are showered and erased on the folds, if you fold the certificate in half. If you are planning to print black and white documents and want to save as much as possible - pay attention to monochrome printers of the Epson Print Factory series . They print with pigment ink, and the starter ink set will be enough for 11,000 prints!

What are you interested in?

The choice of a laser or inkjet printer also depends on the purpose of using the device. Laser printers are capable of printing with high resolution, but they do not reproduce a large number of semitones. Both options are suitable for printing documents, but inkjet technology is preferred for printing photos and high-quality images.

Laser and inkjet devices vary considerably in size . Due to the design features, most models of laser printers are bulky and take up a lot of space (especially color, which should fit four large toner cartridges). The paper tray in laser printers is usually located inside the case, which increases its height. Modern inkjet printers are usually more compact, and even MFPs with a built-in scanner will take up considerably less space.

Finally, we note that in terms of environmental friendliness, laser printers definitely lose to inkjet printers. Heating elements require a significant amount of electricity, and toner is toxic, its particles in the lungs face unpleasant consequences. In addition, in the process of printing ozone is released, detrimental effect on the atmosphere. Inkjet printers do not have these disadvantages.

In conclusion, we make a comparative table:

And now what?

Of course, most readers will find that the manufacturer of inkjet printing equipment will a priori try to engage any comparison of laser and inkjet technology in its favor at the earliest opportunity. We hurry to assure you that in this post there are no fabricated facts. If you wish, you can check any statement yourself and make sure that our goal is not to tread laser printing technology into the dirt, but to emphasize that the light does not come together with a wedge, and there are more advantageous solutions to the problem of home and office printing. Well, or ask a question in the comments to the post.

We thank you for your attention.

Source: https://habr.com/ru/post/366257/

All Articles