A trip to the plant MZTO, the new 3D printer MZ3D-256 and the extruder MZTO E3Dv6

MZTO (Moscow Trade Equipment Factory) is known in narrow circles of 3D printing enthusiasts primarily for high-quality copies of E3D extruders (primarily V6 and Volcano):

When my Chinese hot end Geeetech at the end got me with corks and plastic leaking through the threads (yes, I compacted with a fum-tape, it still flows and is uncomfortable to disassemble when something gets stuck inside or the nozzle clogs up again), I decided to buy myself such a brilliant toy . As it turned out, it’s not so easy to find them in regular stores, I had to go to the factory ...

There is no shop in the factory to buy something - you need to go to the territory. They were greeted warmly and told that 3D printing is a new enough direction for the plant that is developing quite actively. They even made a separate website for it , I'm sure that you have not heard about it, like me.

')

In addition to the hot-houses and the steel frame, which I mentioned earlier (by the way, very inexpensive, I didn’t see anything like this on the market, aluminum was much more expensive), the plant presented its version of the printer . It turns out that July 14, there was his presentation, about which I have not seen any references anywhere. Probably, a few people came to it :) The printer is striking primarily with its compactness, compared with my Prusa i2, it is one and a half times less in all dimensions. True, the printing area is also not huge: 160x160x155 mm (x | y | z).

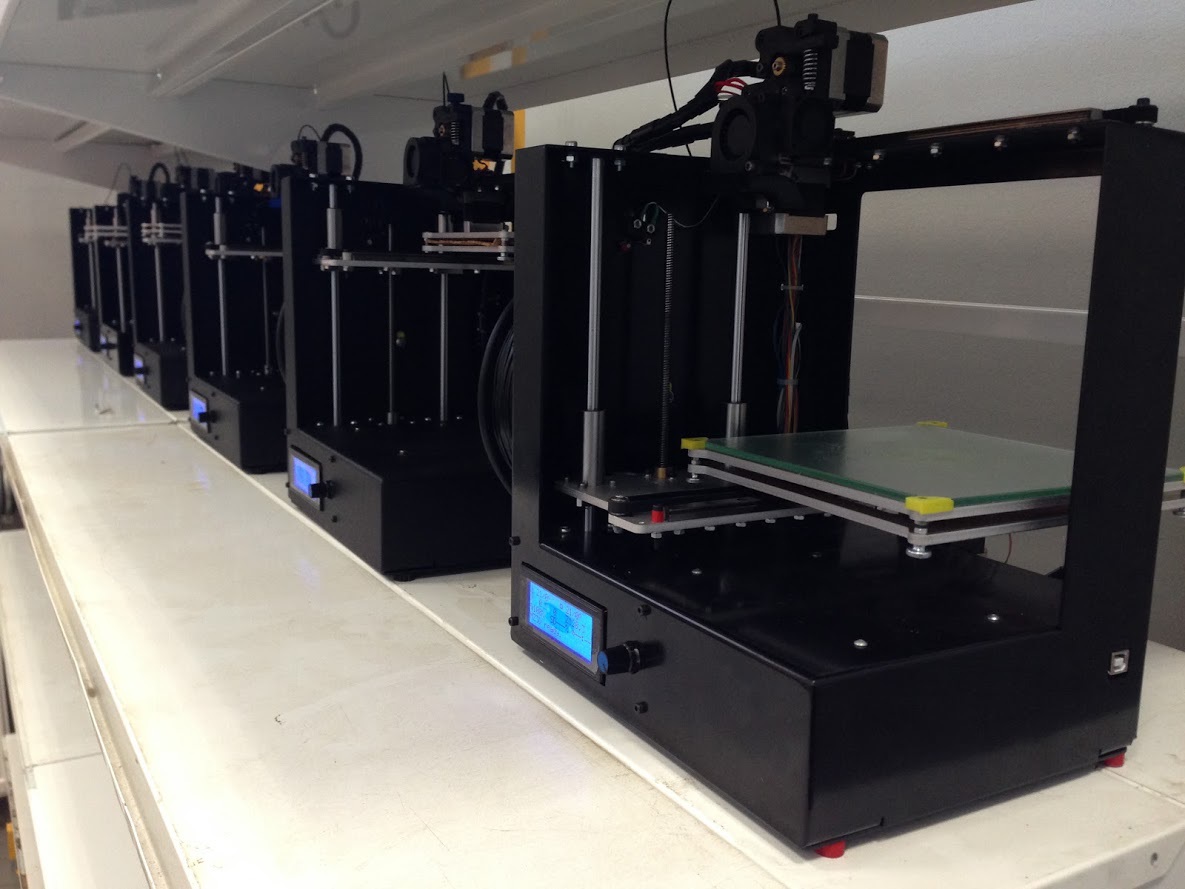

Ready printers in stock:

Printers willingly show visitors, I was invited to see how it prints, however, I was in a hurry, so I had to refuse. According to the representative of the plant, the aluminum table heats up to 120 degrees, the hot end up to 240. As for the hotend, I somehow doubted that it could not be heated more, since there is an E3D Volcano, which heats above 300 degrees without any problems. Probably, the operation of the printer has not yet been checked on high-temperature filaments.

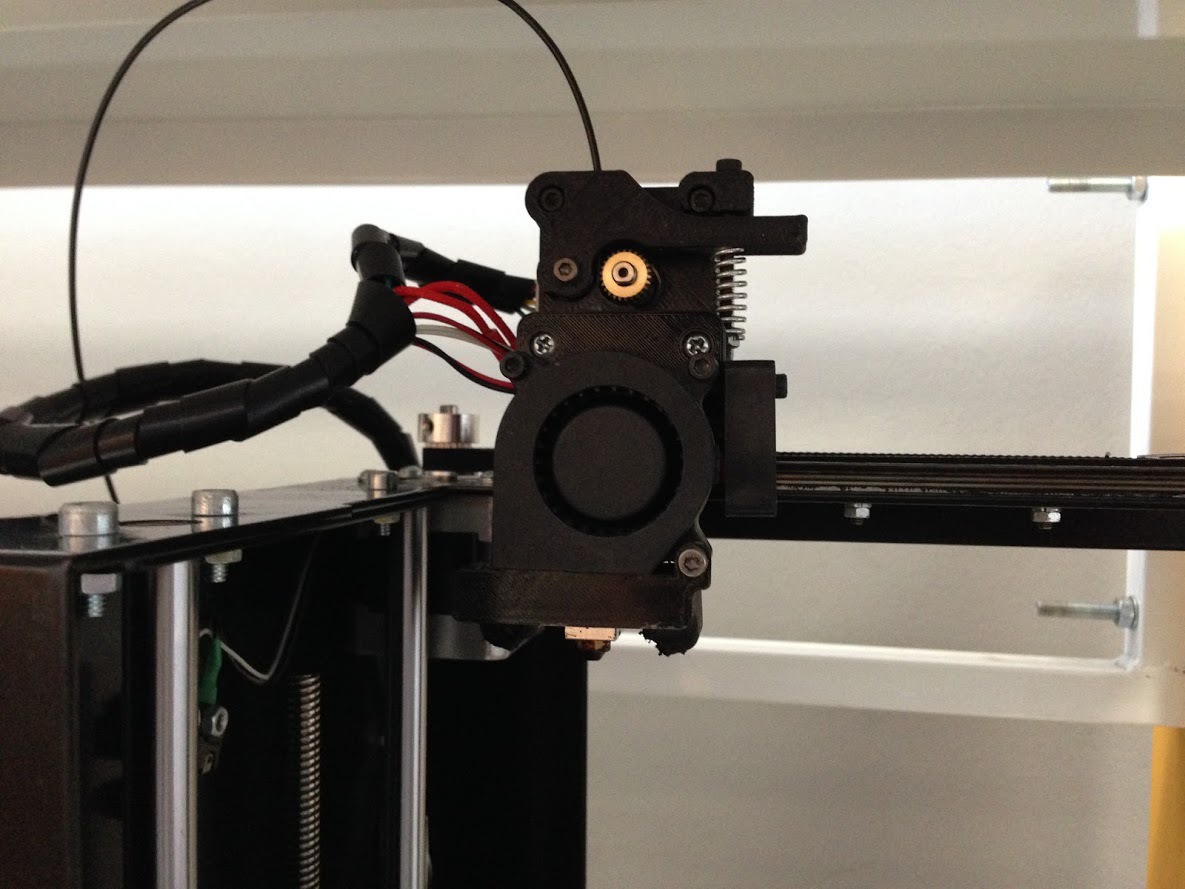

Extruder Construction:

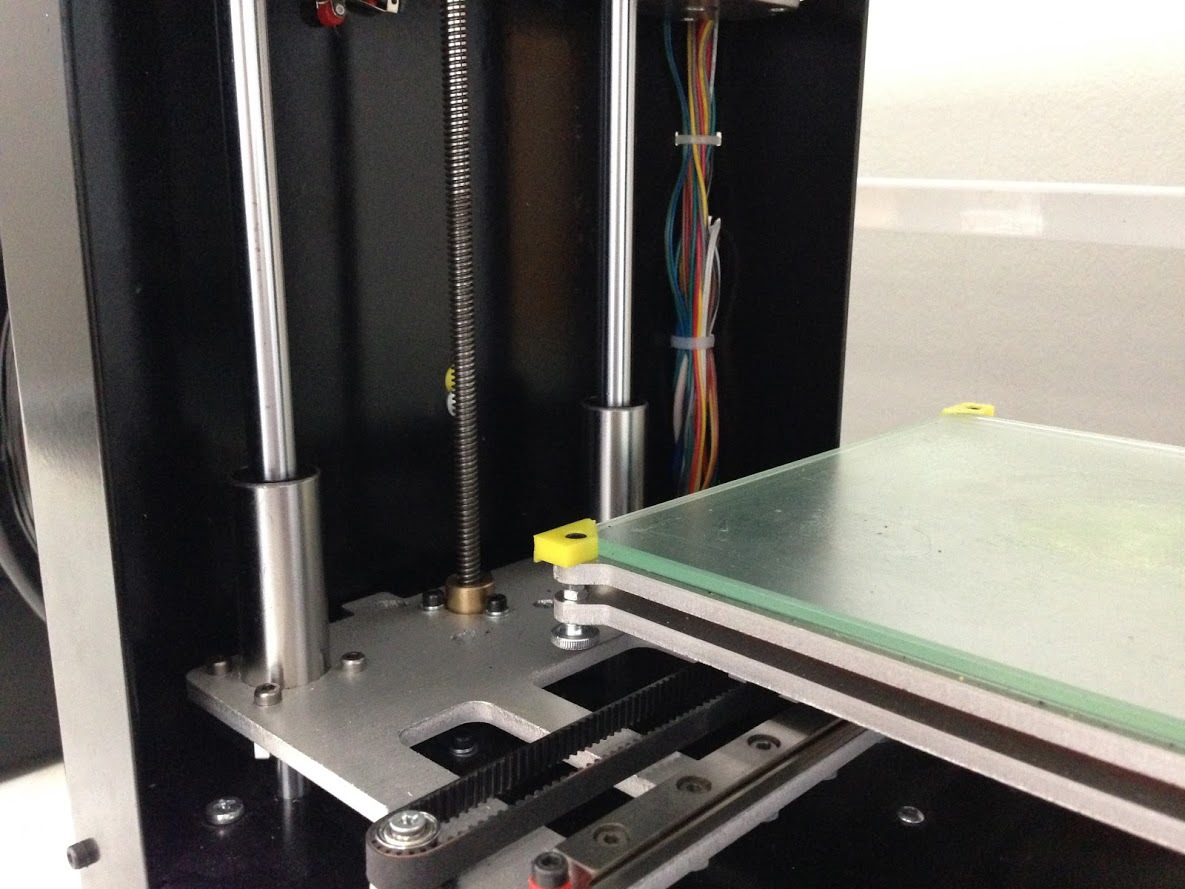

A direct-drive extruder, judging by the design, should normally press soft filament (Flex, Rubber), when I asked if it was heating up with fast nylon printing - again they didn’t answer, they probably didn’t check. Mechanics on ballscrews, GT2 belts, thick guides with plain bearings, Y-axis on rails:

I rolled the table on a semi-assembled printer, there are no backlash to the touch, it gives the impression of a rather rigid construction:

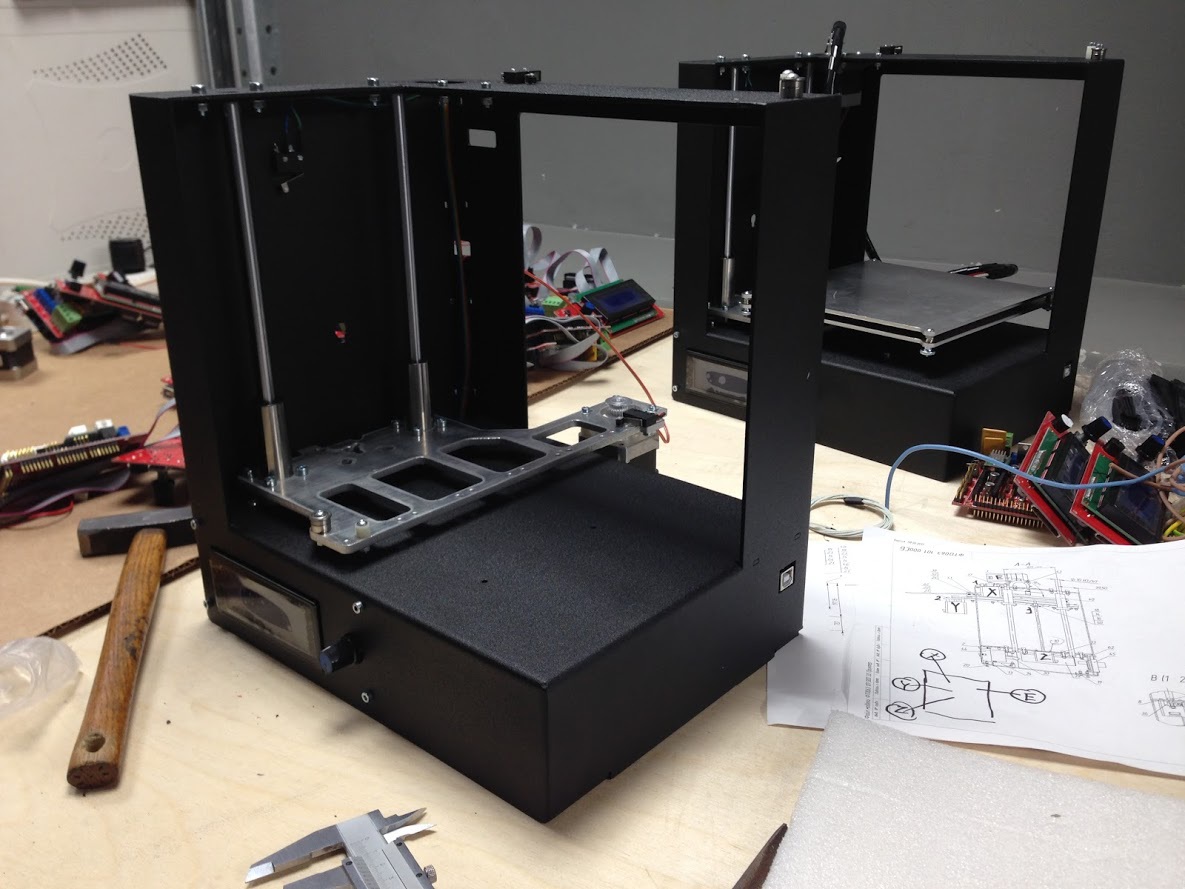

I don’t know what the hammer on the table is for :) At me the collector used only a caliper and a screwdriver :) Inside - the standard Arduino Mega and RAMPS (that means if there is a need to reflash, there will be no problems) and the power supply from the LED strip. Some doubts were caused by a small fan in the base of the printer; on my Prusa i2, a fan blows three times bigger in megu.

Of the main advantages of the printer - print speeds up to 150 mm / s. I was shown some details printed at this speed. The quality is not great, but for large parts is good. At lower speeds, the result is more positive. There are no reviews of this printer on the Internet, there is such an article about a pre-production sample.

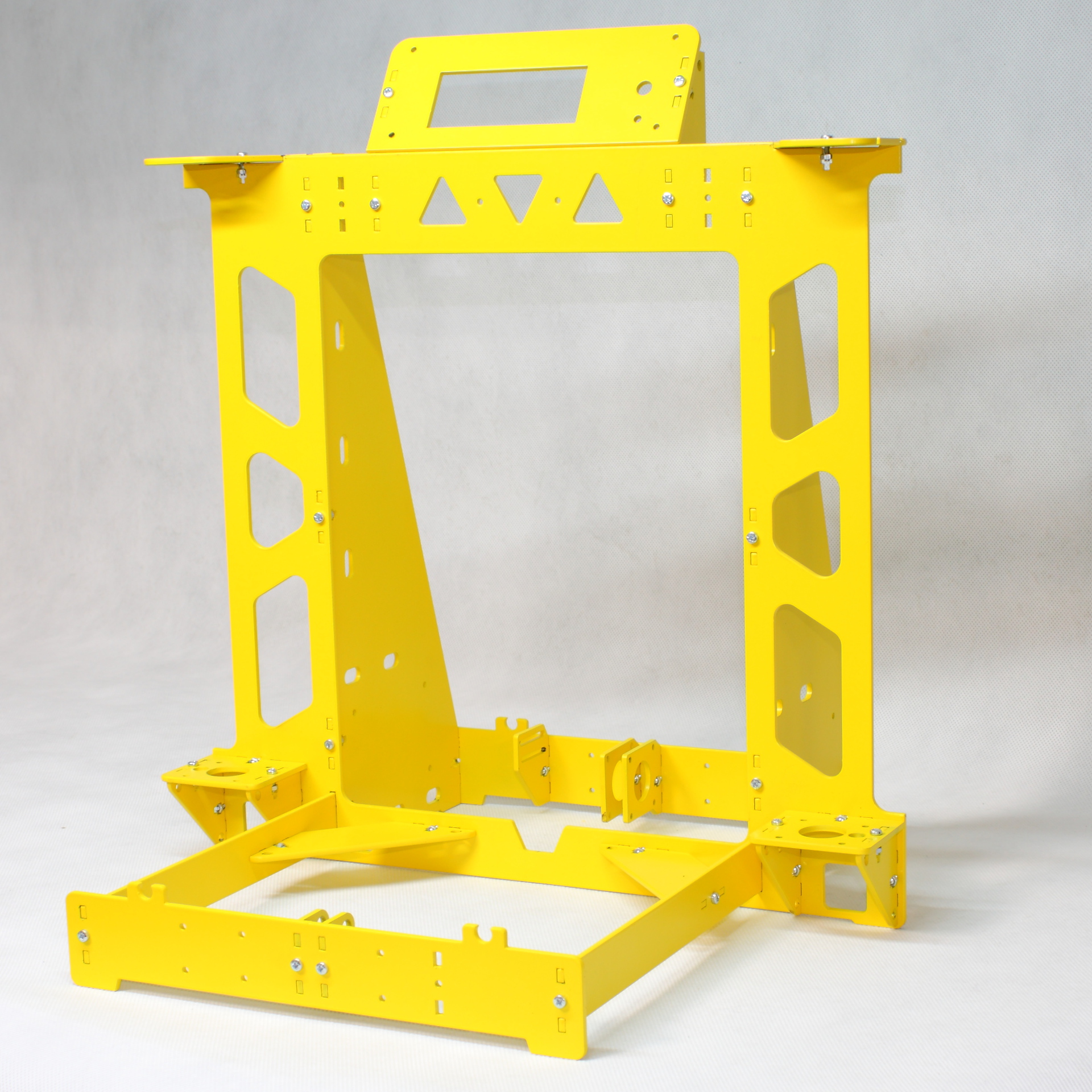

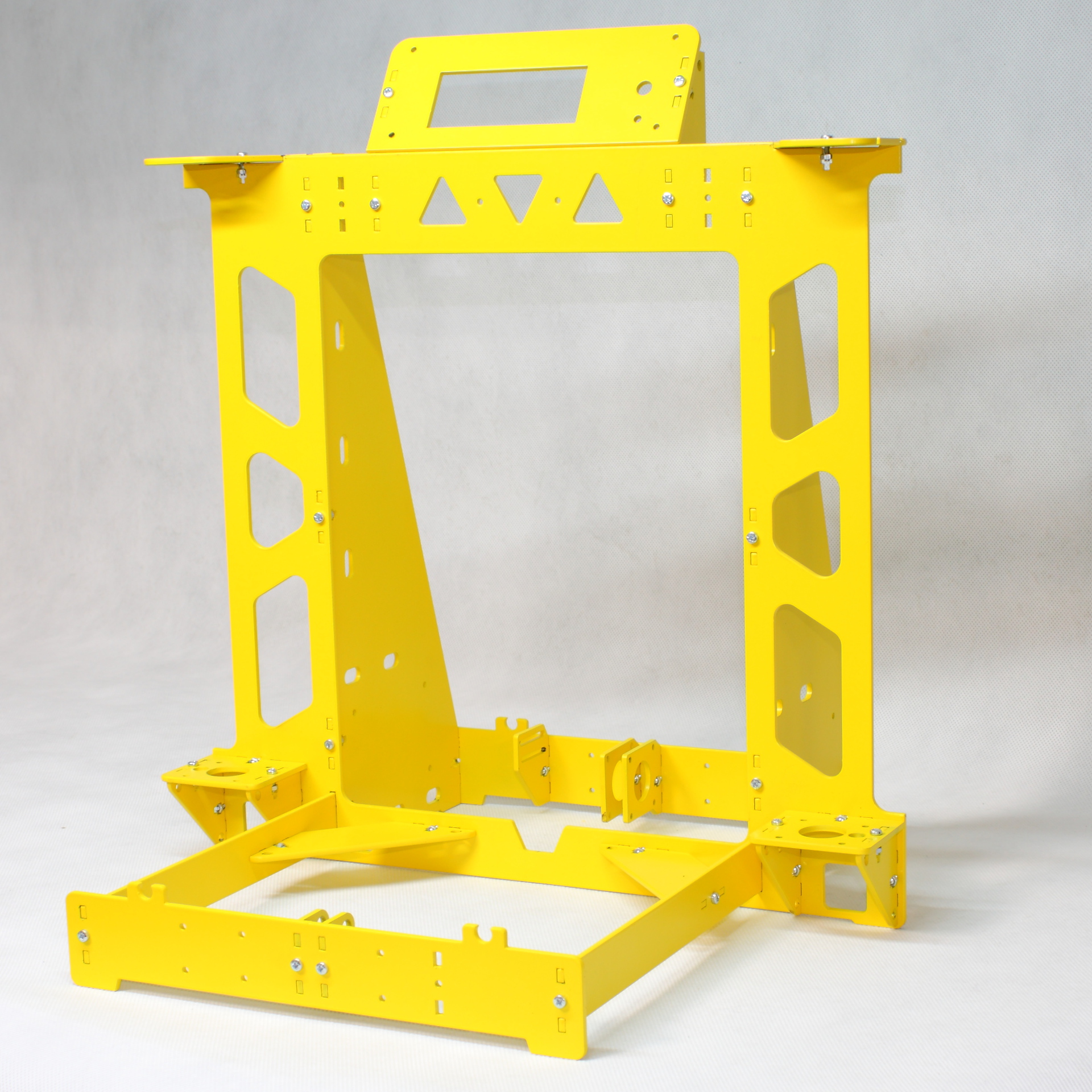

And finally, awesome positive yellow frame for Prusa i3:

MZTO employee is not :)

When my Chinese hot end Geeetech at the end got me with corks and plastic leaking through the threads (yes, I compacted with a fum-tape, it still flows and is uncomfortable to disassemble when something gets stuck inside or the nozzle clogs up again), I decided to buy myself such a brilliant toy . As it turned out, it’s not so easy to find them in regular stores, I had to go to the factory ...

There is no shop in the factory to buy something - you need to go to the territory. They were greeted warmly and told that 3D printing is a new enough direction for the plant that is developing quite actively. They even made a separate website for it , I'm sure that you have not heard about it, like me.

')

In addition to the hot-houses and the steel frame, which I mentioned earlier (by the way, very inexpensive, I didn’t see anything like this on the market, aluminum was much more expensive), the plant presented its version of the printer . It turns out that July 14, there was his presentation, about which I have not seen any references anywhere. Probably, a few people came to it :) The printer is striking primarily with its compactness, compared with my Prusa i2, it is one and a half times less in all dimensions. True, the printing area is also not huge: 160x160x155 mm (x | y | z).

Ready printers in stock:

Printers willingly show visitors, I was invited to see how it prints, however, I was in a hurry, so I had to refuse. According to the representative of the plant, the aluminum table heats up to 120 degrees, the hot end up to 240. As for the hotend, I somehow doubted that it could not be heated more, since there is an E3D Volcano, which heats above 300 degrees without any problems. Probably, the operation of the printer has not yet been checked on high-temperature filaments.

Extruder Construction:

A direct-drive extruder, judging by the design, should normally press soft filament (Flex, Rubber), when I asked if it was heating up with fast nylon printing - again they didn’t answer, they probably didn’t check. Mechanics on ballscrews, GT2 belts, thick guides with plain bearings, Y-axis on rails:

I rolled the table on a semi-assembled printer, there are no backlash to the touch, it gives the impression of a rather rigid construction:

I don’t know what the hammer on the table is for :) At me the collector used only a caliper and a screwdriver :) Inside - the standard Arduino Mega and RAMPS (that means if there is a need to reflash, there will be no problems) and the power supply from the LED strip. Some doubts were caused by a small fan in the base of the printer; on my Prusa i2, a fan blows three times bigger in megu.

Of the main advantages of the printer - print speeds up to 150 mm / s. I was shown some details printed at this speed. The quality is not great, but for large parts is good. At lower speeds, the result is more positive. There are no reviews of this printer on the Internet, there is such an article about a pre-production sample.

And finally, awesome positive yellow frame for Prusa i3:

MZTO employee is not :)

Source: https://habr.com/ru/post/365825/

All Articles