Electric boost for auto on Arduino: myth or is everything possible?

I want to begin my story with a quote: “a car is not a luxury, but a means of transportation.” And indeed, on the roads of our country every year there are more and more cars, their generations are replaced by generations, models by models. In this variety it is very easy to get confused, but on the contrary, it becomes more and more difficult to stand out from the general flow.

In this article I want to talk about my thoughts on changing the internal appearance of the car, and help me in this, as in many other things - microelectronics, represented by the well-known Arduino controller.

So, during my driving experience (about 8 years), I managed to try on myself a considerable number of car models that were either in my personal property or in possession of relatives or friends: VAZ 2109, 21099, 2112, Honda Accord, Honda Civic, Volkswagen Jetta, Mitsubishi Lancer X, Skoda Oktavia, BMW E34 and many others. Of all the cars, perhaps, the Honda Accord of 1993 was the most memorable for me, with the legendary H22A engine replaced with a non-native 200-horsepower engine, which I have been in this configuration for 2 long years. What I liked about her was her character, the motor easily spun up to 7500 rpm and had a pronounced pickup from exactly 4000 rpm. However, the basement was not at all!

')

Today I drive on another car, the Suzuki SX4, this problem is even more pronounced because of 1600 cubic meters of a total of 112 strong engines and a considerable mass of 1,330 kg (together with the driver).

Lack of traction at low and medium speeds - the problem of almost all modern small-capacity engines, on average up to 3000 rpm, they do not “go” at all - there is no acceleration, which is undoubtedly inconvenient neither in the city nor on the highway.

Apparently, such dynamics settings are introduced by auto manufacturers in order to reduce exhaust emissions, fuel consumption and increase engine reliability (artificially low power at low revs prolongs the life of all rubbing parts in the engine).

This problem is fundamentally solved by several methods:

- replacement of the motor for a larger one;

- installation of a small turbine with an early spool (quite a popular method, gives the effect of a more spacious engine with 1500-2000 rpm);

- installation of a volumetric compressor driven by a crankshaft of the engine (gives the effect of a more volumetric engine almost from idle but takes a lot of space in the engine compartment, the method is practically not popular).

One day, an idea came to my mind - what if we took the cold part of the turbine (centrifugal compressor) and rotated its impeller with waste exhaust gases and not with the help of a belt from the engine crankshaft, but with a powerful electric motor, whose speed can be changed electronically and exhibit exactly what you need to maintain the required level of boost, and therefore the power and torque of the car at any (!) rpm:

This idea is not new - the first mentions that I managed to find about such systems relate to 2009 - the year of development of auxiliary electric boost by the Audi concern; “Turboleague” - poor responsiveness of a powerful turbocharged engine at low revs. The system was demonstrated on the Audi RS5 model in 2012, but did not hit the conveyor. Similar systems are planned to be developed by other auto manufacturers - approximately such systems will be released on production cars in 2017-2019.

And what if we do not limit ourselves to 3000 rpm and turn the electric motor further, to 4000 - 5000 rpm? Thus, it is possible to cover almost the entire daily rpm range used when driving a car in 90% of cases.

Yes, it will take quite a lot of power - according to my calculations, with a crankshaft rotational speed of 4000 rpm for an internal combustion engine of 1600 cc and the required boost of 0.4 bar (the maximum level of boost, supported by most full-time ECU cars without flashing ) - the selected power to drive the impeller of the compressor will be about 4.5 kW (taking into account the average statistical efficiency of a centrifugal compressor is 50%).

In the free market now there are quite powerful and at the same time small in size auto / model aircraft brushless electric motors, develop power up to a maximum of 10-15 kW and having a supply voltage of 50-70 volts:

Without thinking, the diagnostic adapter was purchased - ELM 327 bluetooth mini:

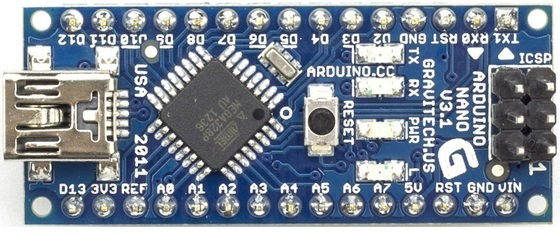

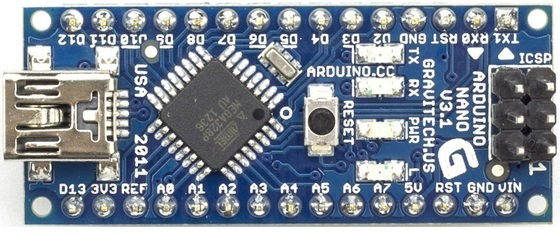

And on its basis, a reader is made of data about the revolutions and position of the engine throttle valve. In the photo in order: diagnostic adapter, arduino uno, a simple brushless motor and a regulator to it.

A small sketch for arduino is written:

Sketch earned immediately - when the engine started, the motor began to rotate at a speed proportional to the engine speed:

Now it remains the case for "small" - to assemble a prototype of the device, which will inject air into the engine based on data from the current position of the throttle valve and engine speed.

Thank you all for your attention.

Waiting for your comments!

For questions, suggestions, comments, please write to frimen3 at gmail.com.

In this article I want to talk about my thoughts on changing the internal appearance of the car, and help me in this, as in many other things - microelectronics, represented by the well-known Arduino controller.

So, during my driving experience (about 8 years), I managed to try on myself a considerable number of car models that were either in my personal property or in possession of relatives or friends: VAZ 2109, 21099, 2112, Honda Accord, Honda Civic, Volkswagen Jetta, Mitsubishi Lancer X, Skoda Oktavia, BMW E34 and many others. Of all the cars, perhaps, the Honda Accord of 1993 was the most memorable for me, with the legendary H22A engine replaced with a non-native 200-horsepower engine, which I have been in this configuration for 2 long years. What I liked about her was her character, the motor easily spun up to 7500 rpm and had a pronounced pickup from exactly 4000 rpm. However, the basement was not at all!

')

Today I drive on another car, the Suzuki SX4, this problem is even more pronounced because of 1600 cubic meters of a total of 112 strong engines and a considerable mass of 1,330 kg (together with the driver).

Lack of traction at low and medium speeds - the problem of almost all modern small-capacity engines, on average up to 3000 rpm, they do not “go” at all - there is no acceleration, which is undoubtedly inconvenient neither in the city nor on the highway.

Apparently, such dynamics settings are introduced by auto manufacturers in order to reduce exhaust emissions, fuel consumption and increase engine reliability (artificially low power at low revs prolongs the life of all rubbing parts in the engine).

This problem is fundamentally solved by several methods:

- replacement of the motor for a larger one;

- installation of a small turbine with an early spool (quite a popular method, gives the effect of a more spacious engine with 1500-2000 rpm);

- installation of a volumetric compressor driven by a crankshaft of the engine (gives the effect of a more volumetric engine almost from idle but takes a lot of space in the engine compartment, the method is practically not popular).

One day, an idea came to my mind - what if we took the cold part of the turbine (centrifugal compressor) and rotated its impeller with waste exhaust gases and not with the help of a belt from the engine crankshaft, but with a powerful electric motor, whose speed can be changed electronically and exhibit exactly what you need to maintain the required level of boost, and therefore the power and torque of the car at any (!) rpm:

This idea is not new - the first mentions that I managed to find about such systems relate to 2009 - the year of development of auxiliary electric boost by the Audi concern; “Turboleague” - poor responsiveness of a powerful turbocharged engine at low revs. The system was demonstrated on the Audi RS5 model in 2012, but did not hit the conveyor. Similar systems are planned to be developed by other auto manufacturers - approximately such systems will be released on production cars in 2017-2019.

And what if we do not limit ourselves to 3000 rpm and turn the electric motor further, to 4000 - 5000 rpm? Thus, it is possible to cover almost the entire daily rpm range used when driving a car in 90% of cases.

Yes, it will take quite a lot of power - according to my calculations, with a crankshaft rotational speed of 4000 rpm for an internal combustion engine of 1600 cc and the required boost of 0.4 bar (the maximum level of boost, supported by most full-time ECU cars without flashing ) - the selected power to drive the impeller of the compressor will be about 4.5 kW (taking into account the average statistical efficiency of a centrifugal compressor is 50%).

In the free market now there are quite powerful and at the same time small in size auto / model aircraft brushless electric motors, develop power up to a maximum of 10-15 kW and having a supply voltage of 50-70 volts:

Without thinking, the diagnostic adapter was purchased - ELM 327 bluetooth mini:

And on its basis, a reader is made of data about the revolutions and position of the engine throttle valve. In the photo in order: diagnostic adapter, arduino uno, a simple brushless motor and a regulator to it.

A small sketch for arduino is written:

#include <Servo.h> #include <SoftwareSerial.h> #define RxD 2 #define TxD 3 SoftwareSerial ELM327Serial(RxD,TxD); int motor_value = 0; Servo firstESC; int engine_on_rpm=500; char rxData[30]; char rxIndex=0; double rpm , drossel; void setup() { pinMode(RxD, INPUT); pinMode(TxD, OUTPUT); ELM327Serial.flush(); ELM327Serial.begin(38400); ELM327Serial.println("ATZ"); delay(900); ELM327Serial.println("ATSP0"); delay(100); firstESC.attach(2); // attached to pin 2 I just do this with 1 Servo Serial.begin(9600); // start serial at 9600 baud firstESC.writeMicroseconds(700); delay(1000); } void loop() { rpm = Get_Rpm(); drossel = Get_drossel(); // if (rpm_var>engine_on_rpm) { motor_value = map(rpm,1000,6000,860,2000); } else motor_value = 700; if (rpm_var<1000) motor_value = 700; firstESC.writeMicroseconds(motor_value); } Sketch earned immediately - when the engine started, the motor began to rotate at a speed proportional to the engine speed:

Now it remains the case for "small" - to assemble a prototype of the device, which will inject air into the engine based on data from the current position of the throttle valve and engine speed.

Thank you all for your attention.

Waiting for your comments!

For questions, suggestions, comments, please write to frimen3 at gmail.com.

Source: https://habr.com/ru/post/365675/

All Articles