Saga of LED lamps. Part 3 - how it works

In the last article, we made a small comparison of the parameters of LED (and not only) lamps, during which we were convinced that lamps almost identical in appearance, color and touch could have very different characteristics, ranging from “very good” to “disgusting”, moreover, even lamps of the same manufacturer can show the most different quality. Now it's time to see what's inside these lamps and figure out what makes good lamps good and bad ones bad.

Of course, the author carried out all the manipulations at his own peril and risk, and therefore does not bear any responsibility for any possible consequences for those who want to repeat his feats.

')

Attention - a lot of photos.

For convenience, I will duplicate the comparison tables from the previous article:

With E27 socket:

With E14 socket:

The first thing that attracts attention is a wonderful ASD lamp with a ripple factor of about 100% and a measured power of more than 40% less than that claimed.

However, it is not dimmable, which could excuse a little such characteristics. Is it really inside there ... But no, let's take a look and see.

Oh. Is this glass or something? Why make a glass bulb in an LED lamp? One of the LED chips is insensitivity to shocks. A properly designed LED lamp can practically play football. The glass bottle, of course, negates this advantage. Is it really cheaper to manufacture glass? Well at least not cut. Well, okay, since it is so, let's approach differently.

Glass thin; in case of mechanical damage the balloon is broken into an unpleasant crumb. Inside there seems to be either a film, or a sputtering, but it somehow weakly helps. And what prevented to make a plastic cylinder?

Inside we see a board with an aluminum base (well, at least it's good) with a handful of LEDs on it. And what about the driver?

Yes, as I was afraid to assume at first, there is a classic circuit with a damping capacitor inside. Who does not know - there is such a way to power loads from the network, the history goes back to the depths of the fifties ( yes, yes ). Its principle is based on the fact that the capacitor in the AC circuit has a reactive resistance, which allows it to be used to limit the current. In fact, this is equivalent to turning on the resistor in series with the LED. Plus, this method has only one - simplicity and cheapness; the rest is minuses - absolutely no power factor, no galvanic isolation from the network (however, this is not so important here), a very conventional stabilization of the diode current (in our case), etc.

Spartan lamp circuit is simple.

It’s not quite clear about the high ripple ratio - the electrolytic capacitor at the output seems to be as it is (2.2 microfarad, 400 V). But either 2.2 microfarad is not enough for such power, or the capacitor is dry (although I took a new lamp), or the capacitor itself is not particularly good, but it does not help - that is a fact.

Something like this. But it is cheap, only about 200 p. retail. But I would not seriously buy it for such money. It is better to buy CFL for the same price, most likely it will be more decent.

Let’s, however, pick up something decent. It would be possible to take an eleven-watt lamp of the same ASD brand, by the way, leading in all respects, but we have already analyzed ASD. Therefore, for a change, I propose to dismantle the second lamp coming from the Gauss LED, especially since it lags behind only in terms of power factor, and only slightly.

I must say that this lamp from Gauss is unusually heavy, offhand three grams. It feels like a solid brick in his hand, which makes one think of some absolutely fantastic heat sink. In general, the instructions promise that the body is made of ceramics and aluminum. Well, let's see.

Taught by bitter experience with a lamp from ASD, I approached the removal of the cylinder very carefully here. Nevertheless, my fears were in vain - here it is plastic, as it should be.

In general, according to the magnitude of the case, it somehow does not look like ceramics. Although I do not know, maybe I did not understand something.

However, what do we see? The aluminum board with LEDs is attached to the case with screws and connected to the driver with a connector! Wow. Such a "disposable" devices like light bulbs, I have not seen. Not true. Is it possible, despite the warnings in the instructions, maintainable? If so, then this is just incredible!

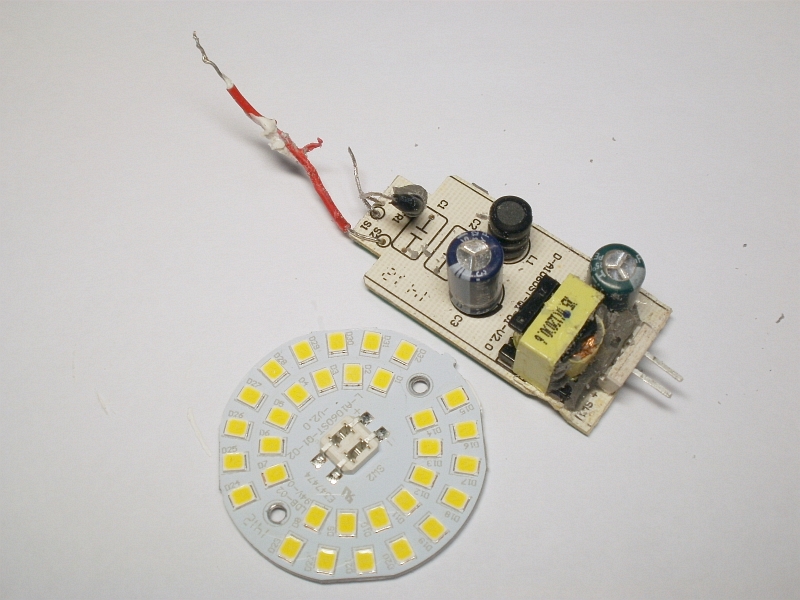

Oops, alas, no. The control circuit is tightly flooded with a compound (naturally, non-combustible - I specifically checked), so you can forget about maintainability. Fortunately, the compound was not an epoxy resin, which would reduce the prospects for further study to zero, but something of a porous rubber, which with some effort managed to remove and remove the driver.

Speaking of weight and heat sink. The heat sink is really a fairly weighty aluminum disc, pressed into what, according to what is written in the manual, is ceramics.

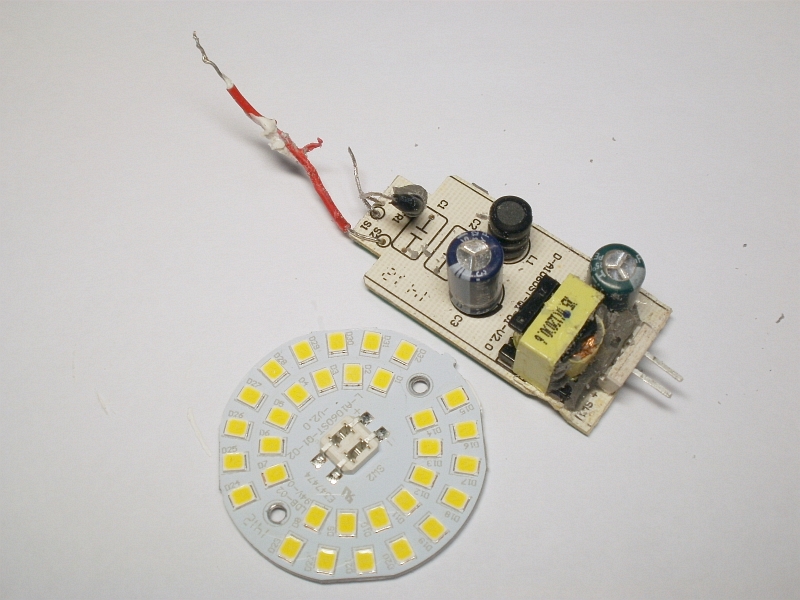

However, we finally got to the most interesting, quintessence of the LED bulb - its driver.

As it turned out, the driver of this bulb is built according to the classic transformerless step-down topology ( step-down / buck converter ). So the yellow product is a choke, not a return source transformer, as it might seem from the first sight. The solution is based on the MP4050 microcircuit from Monolithic Power Systems, incorporated according to a practically typical scheme .

If we talk about the differences, Varton engineers supplemented the typical circuit with a diode bridge and an electrolytic filtering capacitor at the input, however, they saved on capacitors labeled C1 and C2 in the typical circuit. This savings, apparently, leads to a not too high power factor (the section of the circuit with the coil is nothing more than a power factor correction node). However, as seen from the photos, there is a place for them. The coil itself is present and, as can be seen from measurements of parameters, does its good work.

So what do we have for this lamp as a whole? First of all, an excellent ripple factor is about 1%, which is in the region of the error of my measurement method. The light itself for my taste is very pleasant, without yellowness and blue, pure white. The atmosphere in the light of these lamps looks very natural, so the declared color rendition index of more than 92 can definitely be believed. In this sense, I like them even more than CFLs, and, of course, more frankly yellow incandescent bulbs.

Very decent design. In general, a tightly flooded driver gives us hope that this lamp can be used in humid places like a bathroom or in street lamps (by the way, there is something in the manual about sidewalk lamps). Nevertheless, the connection of the LED assembly and the driver, made in the form of a glamorous connector, although very impressive, but gives some concerns about how it behaves in the conditions of the systematic presence of moisture. It would definitely be calmer if the contacts were, for example, for loyalty, missed something like a conductive graphite grease or, at worst, just filled with sealant. So what about this question.

Plastic cylinder - thank God. As we have seen, this is far from the rule. So well, that in the case of Gauss, common sense prevailed.

The driver's thermal mode causes some alarm - it is placed exactly in the warmest place, and is even filled with compound, which prevents any convection. It makes sense to recall the image in the infrared rays:

To warm electrolytic capacitors to 60 - 70 degrees (inside, of course, will be warmer than on the surface) - so-so idea. Of course, we must admit that in such a configuration to put the electronics more simply nowhere. I have already noted that the geometry of the incandescent lamp is alien to LEDs - this is one of the manifestations of this thesis. However, the applied capacitors are marked as certified for temperatures up to 125 ° C, and, judging by the small reviews on the Internet, the Aishi brand, which we see here, is not the worst thing that can be. Although, of course, Chemi-Con or at least something better known to science, like Jamicon, in such an application would inspire more confidence. However, the warranty period stated in the instructions is three years.

The type of driver itself is definitely chosen correctly. The step-down transformer topology is very good in the sense of a small ripple value, which we observe.

If we talk about such an important factor as the heatsink of LEDs, the uniform heating of the case visible on the IR image suggests that this is not bad in this sense.

In general, we can say that there is only one indisputable disadvantage of this lamp - the price, which is about 700 p. at retail according to Yandex.Market. Nevertheless, as you can see, this is a fairly high-quality device, which, although it costs space money for a light bulb, has every chance to justify trust.

That's all for today. In the following articles, we will continue the experimental study of light bulbs.

Of course, the author carried out all the manipulations at his own peril and risk, and therefore does not bear any responsibility for any possible consequences for those who want to repeat his feats.

')

Attention - a lot of photos.

For convenience, I will duplicate the comparison tables from the previous article:

With E27 socket:

| Lamp type | Measured power, W (cold start) | cos (φ) | K p | Generally |

| ASD 11W | 9 | 0.82 | one% | Very good |

| Gauss 12 W | 12 | 0.62 | one% | Good |

| Gauss 6.5 W | 6 | 0.50 | one% | Acceptable |

| SUPRA 11 W | 9 | 0.95 | 35% | poorly |

| ASD 7 W | four | 0.45 | 100% | Disgusting |

With E14 socket:

| Lamp type | Measured power, W (cold start) | cos (φ) | K p | Generally |

| Gauss 3W | 2 | 0.60 | one% | Good |

| Gauss 6.5W | 6 | 0.95 | 49% | Very bad |

| Wolta 5W | 2.2 | 0.40 | 68% | Disgusting |

The first thing that attracts attention is a wonderful ASD lamp with a ripple factor of about 100% and a measured power of more than 40% less than that claimed.

However, it is not dimmable, which could excuse a little such characteristics. Is it really inside there ... But no, let's take a look and see.

Oh. Is this glass or something? Why make a glass bulb in an LED lamp? One of the LED chips is insensitivity to shocks. A properly designed LED lamp can practically play football. The glass bottle, of course, negates this advantage. Is it really cheaper to manufacture glass? Well at least not cut. Well, okay, since it is so, let's approach differently.

Glass thin; in case of mechanical damage the balloon is broken into an unpleasant crumb. Inside there seems to be either a film, or a sputtering, but it somehow weakly helps. And what prevented to make a plastic cylinder?

Inside we see a board with an aluminum base (well, at least it's good) with a handful of LEDs on it. And what about the driver?

Yes, as I was afraid to assume at first, there is a classic circuit with a damping capacitor inside. Who does not know - there is such a way to power loads from the network, the history goes back to the depths of the fifties ( yes, yes ). Its principle is based on the fact that the capacitor in the AC circuit has a reactive resistance, which allows it to be used to limit the current. In fact, this is equivalent to turning on the resistor in series with the LED. Plus, this method has only one - simplicity and cheapness; the rest is minuses - absolutely no power factor, no galvanic isolation from the network (however, this is not so important here), a very conventional stabilization of the diode current (in our case), etc.

Spartan lamp circuit is simple.

It’s not quite clear about the high ripple ratio - the electrolytic capacitor at the output seems to be as it is (2.2 microfarad, 400 V). But either 2.2 microfarad is not enough for such power, or the capacitor is dry (although I took a new lamp), or the capacitor itself is not particularly good, but it does not help - that is a fact.

Something like this. But it is cheap, only about 200 p. retail. But I would not seriously buy it for such money. It is better to buy CFL for the same price, most likely it will be more decent.

Let’s, however, pick up something decent. It would be possible to take an eleven-watt lamp of the same ASD brand, by the way, leading in all respects, but we have already analyzed ASD. Therefore, for a change, I propose to dismantle the second lamp coming from the Gauss LED, especially since it lags behind only in terms of power factor, and only slightly.

I must say that this lamp from Gauss is unusually heavy, offhand three grams. It feels like a solid brick in his hand, which makes one think of some absolutely fantastic heat sink. In general, the instructions promise that the body is made of ceramics and aluminum. Well, let's see.

Taught by bitter experience with a lamp from ASD, I approached the removal of the cylinder very carefully here. Nevertheless, my fears were in vain - here it is plastic, as it should be.

In general, according to the magnitude of the case, it somehow does not look like ceramics. Although I do not know, maybe I did not understand something.

However, what do we see? The aluminum board with LEDs is attached to the case with screws and connected to the driver with a connector! Wow. Such a "disposable" devices like light bulbs, I have not seen. Not true. Is it possible, despite the warnings in the instructions, maintainable? If so, then this is just incredible!

Oops, alas, no. The control circuit is tightly flooded with a compound (naturally, non-combustible - I specifically checked), so you can forget about maintainability. Fortunately, the compound was not an epoxy resin, which would reduce the prospects for further study to zero, but something of a porous rubber, which with some effort managed to remove and remove the driver.

Speaking of weight and heat sink. The heat sink is really a fairly weighty aluminum disc, pressed into what, according to what is written in the manual, is ceramics.

However, we finally got to the most interesting, quintessence of the LED bulb - its driver.

As it turned out, the driver of this bulb is built according to the classic transformerless step-down topology ( step-down / buck converter ). So the yellow product is a choke, not a return source transformer, as it might seem from the first sight. The solution is based on the MP4050 microcircuit from Monolithic Power Systems, incorporated according to a practically typical scheme .

If we talk about the differences, Varton engineers supplemented the typical circuit with a diode bridge and an electrolytic filtering capacitor at the input, however, they saved on capacitors labeled C1 and C2 in the typical circuit. This savings, apparently, leads to a not too high power factor (the section of the circuit with the coil is nothing more than a power factor correction node). However, as seen from the photos, there is a place for them. The coil itself is present and, as can be seen from measurements of parameters, does its good work.

So what do we have for this lamp as a whole? First of all, an excellent ripple factor is about 1%, which is in the region of the error of my measurement method. The light itself for my taste is very pleasant, without yellowness and blue, pure white. The atmosphere in the light of these lamps looks very natural, so the declared color rendition index of more than 92 can definitely be believed. In this sense, I like them even more than CFLs, and, of course, more frankly yellow incandescent bulbs.

Very decent design. In general, a tightly flooded driver gives us hope that this lamp can be used in humid places like a bathroom or in street lamps (by the way, there is something in the manual about sidewalk lamps). Nevertheless, the connection of the LED assembly and the driver, made in the form of a glamorous connector, although very impressive, but gives some concerns about how it behaves in the conditions of the systematic presence of moisture. It would definitely be calmer if the contacts were, for example, for loyalty, missed something like a conductive graphite grease or, at worst, just filled with sealant. So what about this question.

Plastic cylinder - thank God. As we have seen, this is far from the rule. So well, that in the case of Gauss, common sense prevailed.

The driver's thermal mode causes some alarm - it is placed exactly in the warmest place, and is even filled with compound, which prevents any convection. It makes sense to recall the image in the infrared rays:

To warm electrolytic capacitors to 60 - 70 degrees (inside, of course, will be warmer than on the surface) - so-so idea. Of course, we must admit that in such a configuration to put the electronics more simply nowhere. I have already noted that the geometry of the incandescent lamp is alien to LEDs - this is one of the manifestations of this thesis. However, the applied capacitors are marked as certified for temperatures up to 125 ° C, and, judging by the small reviews on the Internet, the Aishi brand, which we see here, is not the worst thing that can be. Although, of course, Chemi-Con or at least something better known to science, like Jamicon, in such an application would inspire more confidence. However, the warranty period stated in the instructions is three years.

The type of driver itself is definitely chosen correctly. The step-down transformer topology is very good in the sense of a small ripple value, which we observe.

If we talk about such an important factor as the heatsink of LEDs, the uniform heating of the case visible on the IR image suggests that this is not bad in this sense.

In general, we can say that there is only one indisputable disadvantage of this lamp - the price, which is about 700 p. at retail according to Yandex.Market. Nevertheless, as you can see, this is a fairly high-quality device, which, although it costs space money for a light bulb, has every chance to justify trust.

That's all for today. In the following articles, we will continue the experimental study of light bulbs.

Source: https://habr.com/ru/post/363271/

All Articles