3D printing in microscale

The topic of 3D printing has long been called revolutionary, breakthrough. The possibilities of such a press were also discussed at the Open Innovations Forum this year and last. And now MIT Technology Review has introduced micro-scale 3D printing in the list of the 10 most breakthrough technologies.

Ink created from various materials, if properly combined, will expand the possibilities of 3D printing in the medical field. It's not about some covers for your favorite iPhone, not about printed clothes, but about saving people's lives, including through the testing of drugs.

It is necessary to immediately say about the printing of biological tissues with blood vessels - namely, blood vessels to this day are a “narrow” place that does not allow for the widespread use of artificial limbs. Creating biological materials with the desired functions will lead to the fact that we can implant a freshly printed organ to the patient, and not wait until the potential donor blows his head in a car accident.

')

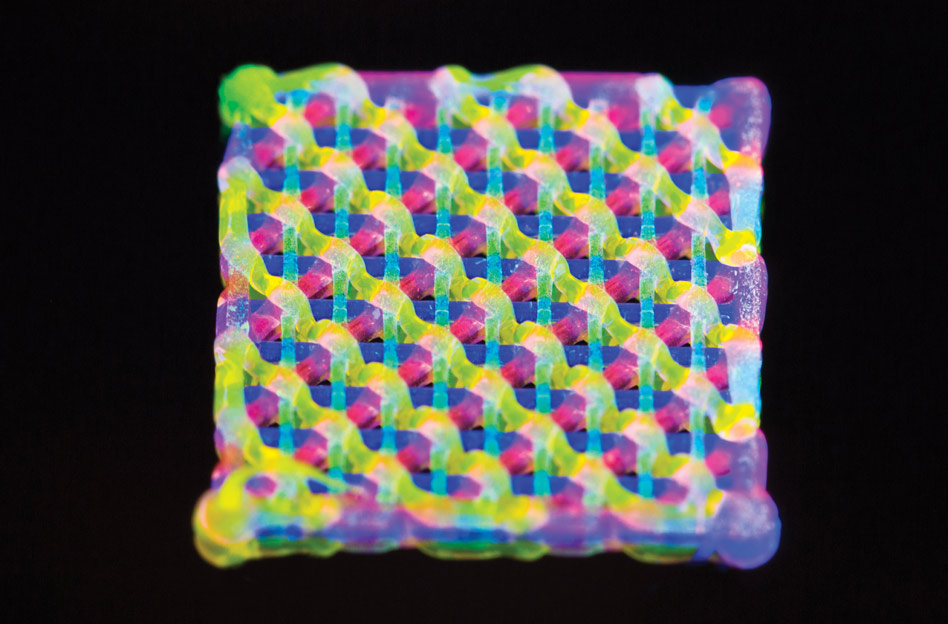

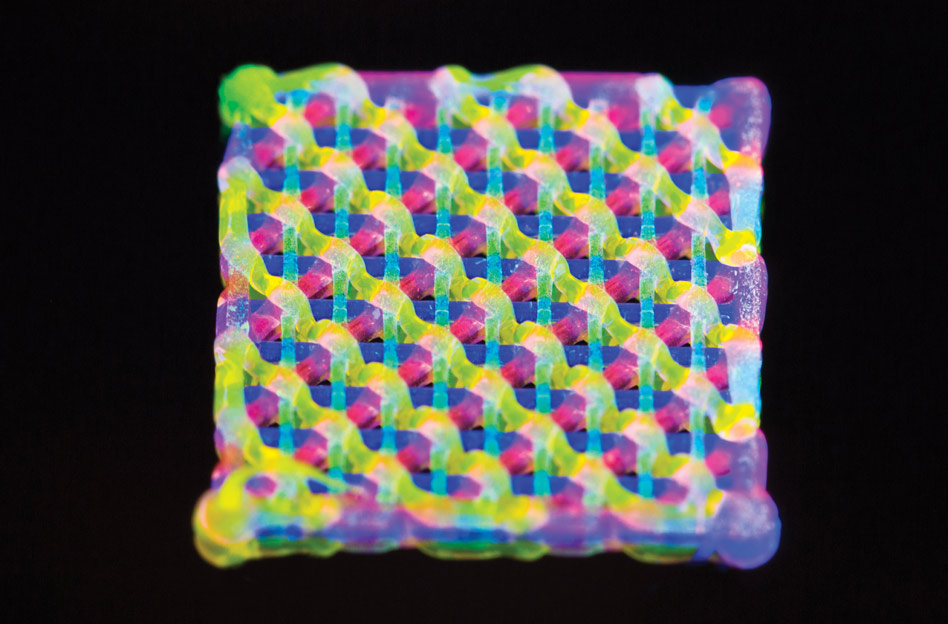

This multi-colored grille, made in the laboratory of Jennifer Lewis of Harvard University, clearly shows the possibilities of printing with several materials.

Despite all the excitement and expectations of bulk printing, endless discussions and plans - the possibilities of technology are still extremely limited. About this very well written in this habraposte : the problem is in dimension, I advise you to look and read more. At the moment, printers can print complex shapes, but most often from plastic or from several types of metal alloys. But what if it becomes possible to use different materials, from living cells to semiconductors, so that the printer can mix such inks with the highest precision?

This issue deals with Jennifer Lewis of Harvard University . It prints objects of complex shape, adding to them materials useful for the mechanical properties of the object, its electrical conductivity or optical characteristics. This will allow technology to move to a new level: the level of creation of objects capable of responding to the environment.

For the demonstration, four types of polymer inks of different colors were used. Multi-colored inks are placed in standard printheads.

Consistently and accurately the car has created a colorful grid. Special software was used.

As you may remember, a bionic ear was printed at Princeton, and retinal cells for eye surgery were printed at Cambridge. But the Lewis lab has now surpassed everyone.

Last year, Lewis with students printed microscopic electrodes and other components for a miniature lithium-ion battery. Another project was sensors on a plastic backing capable of detecting athlete's concussion.

More recently, they printed biological tissue with a complex network of blood vessels interwoven in it. For this, the inks were made from various types of cells and materials that form the matrix supporting them. What for? For more effective testing of drugs on living tissue, or perhaps to create artificial organs for humans.

Silver nanoparticles inks are used to print electrodes smaller than a few micrometers. The process is controlled by special software.

Left - Jennifer Lewis. On the right are gloves with a strain sensor, created by imprinting electronics into an elastomer.

The secret of Lewis is that all ink can be used during the process. Although inks are made from different materials, they can all be used at room temperature. It is also worth saying that problems arise when working with different materials: for example, the cells are too thin and can be destroyed at the nozzle exit. Therefore, you need to think about how to “squeeze” them to the right place. Work continues.

Ink created from various materials, if properly combined, will expand the possibilities of 3D printing in the medical field. It's not about some covers for your favorite iPhone, not about printed clothes, but about saving people's lives, including through the testing of drugs.

It is necessary to immediately say about the printing of biological tissues with blood vessels - namely, blood vessels to this day are a “narrow” place that does not allow for the widespread use of artificial limbs. Creating biological materials with the desired functions will lead to the fact that we can implant a freshly printed organ to the patient, and not wait until the potential donor blows his head in a car accident.

')

This multi-colored grille, made in the laboratory of Jennifer Lewis of Harvard University, clearly shows the possibilities of printing with several materials.

Despite all the excitement and expectations of bulk printing, endless discussions and plans - the possibilities of technology are still extremely limited. About this very well written in this habraposte : the problem is in dimension, I advise you to look and read more. At the moment, printers can print complex shapes, but most often from plastic or from several types of metal alloys. But what if it becomes possible to use different materials, from living cells to semiconductors, so that the printer can mix such inks with the highest precision?

This issue deals with Jennifer Lewis of Harvard University . It prints objects of complex shape, adding to them materials useful for the mechanical properties of the object, its electrical conductivity or optical characteristics. This will allow technology to move to a new level: the level of creation of objects capable of responding to the environment.

For the demonstration, four types of polymer inks of different colors were used. Multi-colored inks are placed in standard printheads.

Consistently and accurately the car has created a colorful grid. Special software was used.

As you may remember, a bionic ear was printed at Princeton, and retinal cells for eye surgery were printed at Cambridge. But the Lewis lab has now surpassed everyone.

Last year, Lewis with students printed microscopic electrodes and other components for a miniature lithium-ion battery. Another project was sensors on a plastic backing capable of detecting athlete's concussion.

More recently, they printed biological tissue with a complex network of blood vessels interwoven in it. For this, the inks were made from various types of cells and materials that form the matrix supporting them. What for? For more effective testing of drugs on living tissue, or perhaps to create artificial organs for humans.

Silver nanoparticles inks are used to print electrodes smaller than a few micrometers. The process is controlled by special software.

Left - Jennifer Lewis. On the right are gloves with a strain sensor, created by imprinting electronics into an elastomer.

The secret of Lewis is that all ink can be used during the process. Although inks are made from different materials, they can all be used at room temperature. It is also worth saying that problems arise when working with different materials: for example, the cells are too thin and can be destroyed at the nozzle exit. Therefore, you need to think about how to “squeeze” them to the right place. Work continues.

Source: https://habr.com/ru/post/362839/

All Articles