Sintering technology "turned inside out" can reduce the cost of metal 3D printers many times.

The University of Southern California ( USC ) has developed a new method for 3D printing of metal products. In September 2014, researchers Paymen Torabi, Matthew Petros and Beroh Hoshnevys presented an article describing their development.

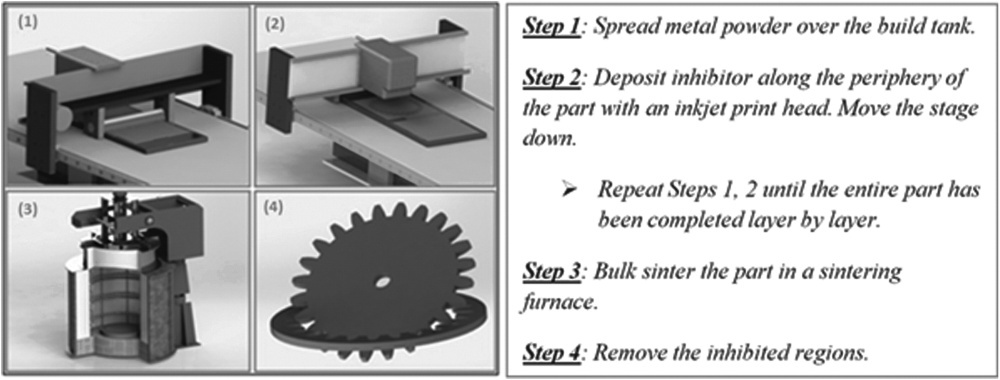

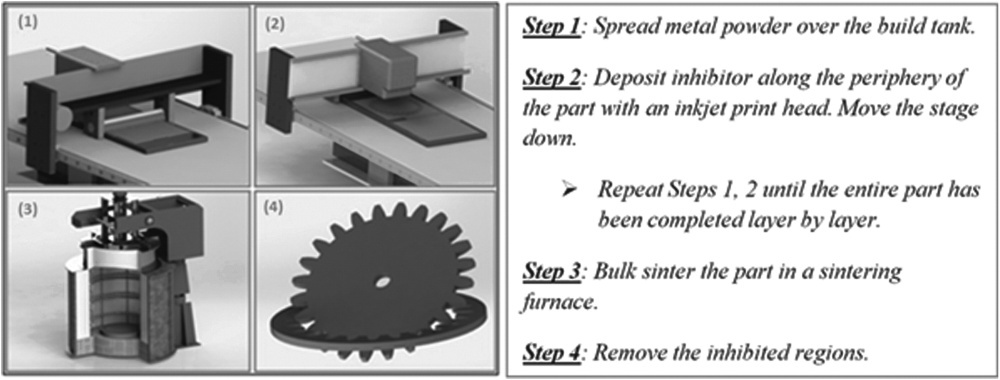

The idea is to use a special type of inkjet technology called “selective sinter suppression” (SIS).

')

Existing systems of low-cost home 3D-printers (printers that currently cost no more than $ 5000 are considered to be home-based) work on the principle of fusing , or, more rarely, laser stereolithography , but the speed of such printers is very low. In addition, home printers working with metal simply do not exist, since the use of high-power lasers for sintering metal powder dramatically increases the cost of the system.

Researchers, seeking to improve the performance of 3d-printers, work in two directions. You can try to make new materials suitable for existing technologies of the printers, and you can invent new technologies to work with existing materials.

Typically, printers using powder sintering tend to speed up this process in order to connect the layers with each other. SIS technology, on the contrary, delays this process. In a sense, this is the reverse of the traditional manufacturing of parts in 3d-printers. When using this technology, a special head places a liquid inhibitor substance around the perimeter of each layer of the future part, preventing the sintering process. Upon completion of the printing of all layers, the part is removed and brought to condition in a conventional oven. The inhibitor that separates the part, goes into a solid state and prevents sintering. After that, the part is removed from the resulting shell, as if from an ordinary casting mold.

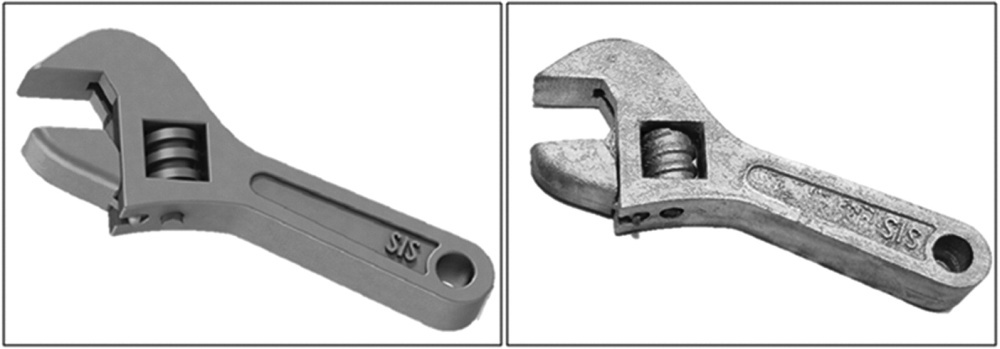

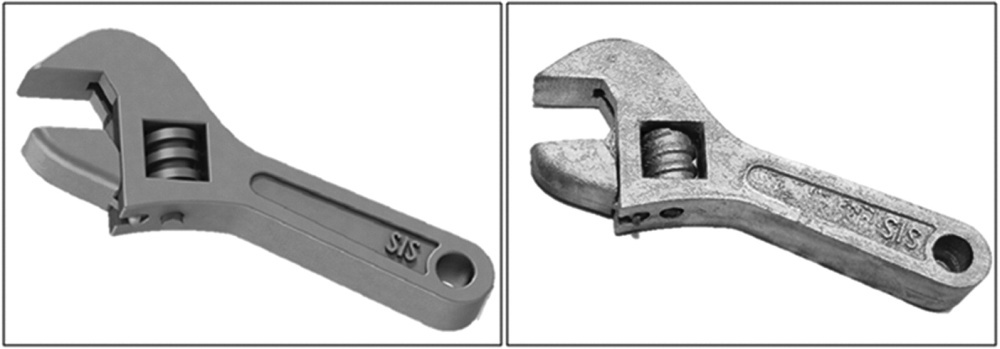

Thus, instead of expensive and complex laser sintering, print heads are used, resembling ordinary jet heads. At the moment, the authors have built a working prototype of the printer and are experimenting with various inhibitors. They successfully managed to create parts from different metals, including bronze. Among the interesting examples of details is an adjustable wrench, all four components of which were printed and then assembled by hand.

The idea is to use a special type of inkjet technology called “selective sinter suppression” (SIS).

')

Existing systems of low-cost home 3D-printers (printers that currently cost no more than $ 5000 are considered to be home-based) work on the principle of fusing , or, more rarely, laser stereolithography , but the speed of such printers is very low. In addition, home printers working with metal simply do not exist, since the use of high-power lasers for sintering metal powder dramatically increases the cost of the system.

Researchers, seeking to improve the performance of 3d-printers, work in two directions. You can try to make new materials suitable for existing technologies of the printers, and you can invent new technologies to work with existing materials.

Typically, printers using powder sintering tend to speed up this process in order to connect the layers with each other. SIS technology, on the contrary, delays this process. In a sense, this is the reverse of the traditional manufacturing of parts in 3d-printers. When using this technology, a special head places a liquid inhibitor substance around the perimeter of each layer of the future part, preventing the sintering process. Upon completion of the printing of all layers, the part is removed and brought to condition in a conventional oven. The inhibitor that separates the part, goes into a solid state and prevents sintering. After that, the part is removed from the resulting shell, as if from an ordinary casting mold.

Thus, instead of expensive and complex laser sintering, print heads are used, resembling ordinary jet heads. At the moment, the authors have built a working prototype of the printer and are experimenting with various inhibitors. They successfully managed to create parts from different metals, including bronze. Among the interesting examples of details is an adjustable wrench, all four components of which were printed and then assembled by hand.

Source: https://habr.com/ru/post/362821/

All Articles