The calculation of the payback period of solar panels

By writing this article inspired a reservation in the report from the MegaFon company about a solar-powered base station. The reservation was that the payback period of the power system on solar panels was 2-3 years. I am engaged in the installation and commissioning of alternative energy systems, and, as I see it, the authors of articles on this subject underestimate the time during which the system pays for itself, and several times.

I do not pretend to absolute accuracy, but the figures are not taken from the ceiling, but from the specific object on which the installation was made by the crew - the Myasko Simferopol production and warehouse complex. The calculations include the main most expensive items.

At the time of our work, this plant already had a farm for 300+ panels assembled according to a modular system. We added six more contours on twenty panels. (Circuit - combining a certain number of panels into one energy source, thus recruiting the circuit required for the inverter voltage).

')

Now a little to the numbers, all calculations are carried out with the cost of delivery to the Crimea from the territory of Germany.

Total:

A farm with 120 panels costs $ 59,000. These calculations have not yet included compensation for the designer, engineer, and installer. In sum, everything will translate into a budget aspiring to $ 65,000.

Theoretically, under ideal conditions, one panel should produce about 220-230 W per hour (in terms of the 220 volts we are used to). Below are the graphs that the control unit maintains in the inverter, and you can monitor them remotely.

Sunny day :

Partly cloudy :

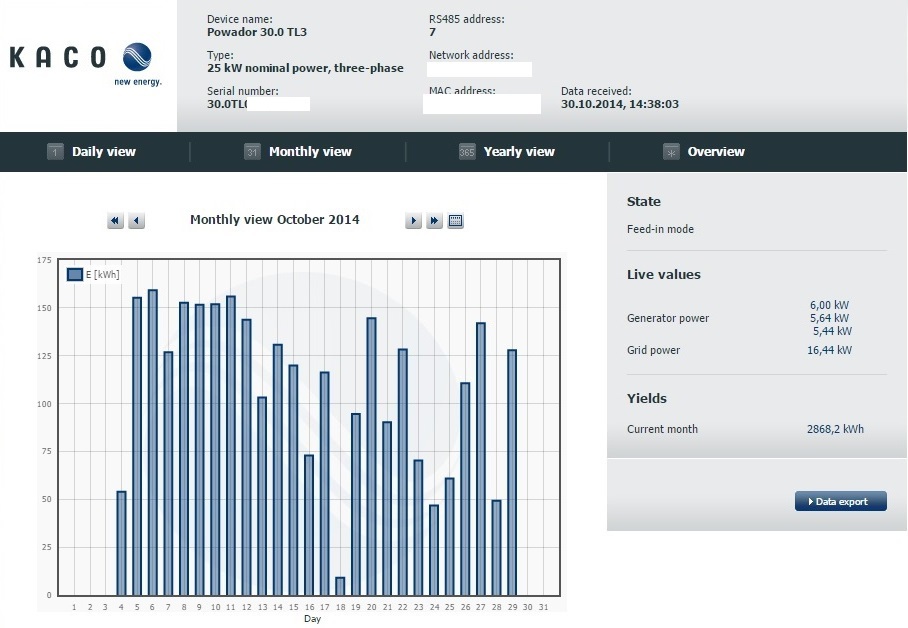

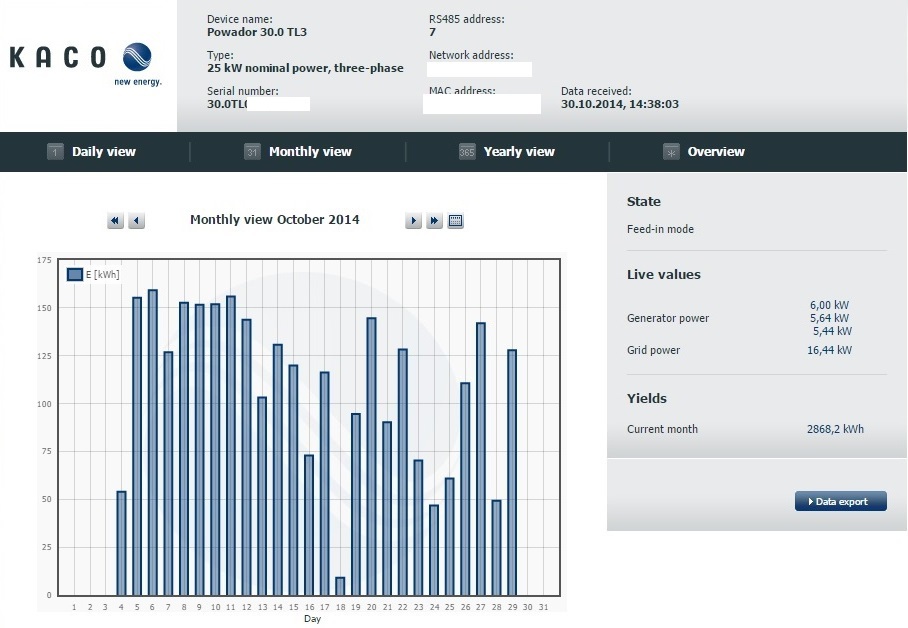

Monthly schedule :

In the last chart, it should be noted that for two days the system was turned off for a while, and the first three days of the month and the last two were missing.

In a consistently sunny summer month, with a long daylight hours, such a farm will produce a maximum of 4,500-4700 kW-h. Knowing these numbers, you can calculate the profitability of the system, taking into account the tariffs for electricity.

It should be noted that the farm is assembled without batteries, their presence would increase the total cost of the system, the payback time, respectively, too.

Thus, I can’t get a return on investment in 2-3 years. 10 years is a more or less real term.

I do not pretend to absolute accuracy, but the figures are not taken from the ceiling, but from the specific object on which the installation was made by the crew - the Myasko Simferopol production and warehouse complex. The calculations include the main most expensive items.

At the time of our work, this plant already had a farm for 300+ panels assembled according to a modular system. We added six more contours on twenty panels. (Circuit - combining a certain number of panels into one energy source, thus recruiting the circuit required for the inverter voltage).

')

Dry calculations

Now a little to the numbers, all calculations are carried out with the cost of delivery to the Crimea from the territory of Germany.

- The panels. When ordering from the manufacturer (SolarWorld, Germany), one panel costs $ 350.

120 panels * $ 350 = $ 42,000 - Fasteners. Usually, when mounted on a tin roof, guide rails are used and the designer is aluminum alloy, bolts are stainless steel. In terms of one panel consumes 3 meters of rails, 10 bolts with a gasket, 4 bolts with a semi-thin barrel. The cost of fasteners - $ 6.000

- Cable. The price for a hundred-meter bay seeks to $ 500. Suppose that the panels are placed optimally close to the inverter, in this case 200m will suffice (in our case, 350m is gone). $ 1,000

- Inverter is a converter from a high-voltage input DC to a switch that is familiar to us. Usually they are three-phase, in our case it was an inverter from KACO Powador 30.0 TL3, the cost is $ 10,000.

Total:

A farm with 120 panels costs $ 59,000. These calculations have not yet included compensation for the designer, engineer, and installer. In sum, everything will translate into a budget aspiring to $ 65,000.

Actual power generation

Theoretically, under ideal conditions, one panel should produce about 220-230 W per hour (in terms of the 220 volts we are used to). Below are the graphs that the control unit maintains in the inverter, and you can monitor them remotely.

Sunny day :

Partly cloudy :

Monthly schedule :

In the last chart, it should be noted that for two days the system was turned off for a while, and the first three days of the month and the last two were missing.

In a consistently sunny summer month, with a long daylight hours, such a farm will produce a maximum of 4,500-4700 kW-h. Knowing these numbers, you can calculate the profitability of the system, taking into account the tariffs for electricity.

It should be noted that the farm is assembled without batteries, their presence would increase the total cost of the system, the payback time, respectively, too.

Thus, I can’t get a return on investment in 2-3 years. 10 years is a more or less real term.

Source: https://habr.com/ru/post/362443/

All Articles