The technology of introducing sensors into the glass of a smartphone

Despite the abundance of all kinds of "sense organs" in smartphones, developers are trying to introduce new sensors, expanding the capabilities of devices. For obvious reasons, the protective glass displays are practically not used to accommodate the sensors, except for touch screen films.

But recently, a technology has been made public , thanks to which the glass of a smartphone can perform not only the functions of mechanical protection and recognition of user contacts. It was developed by researchers from the Polytechnic School of the University of Montreal, Canada, and specialists from Corning.

In the vast majority of modern smartphones, there is a certain set of sensors that has become the de facto standard. For example, in YotaPhone built-in:

')

• a three-axis electronic compass, which is a collection of sensors measuring the Earth’s magnetic field, and an output data converter;

• proximity and illumination sensor with built-in infrared LED, used during a telephone conversation to determine the distance to the user's face;

• gyroscope / accelerometer, designed to determine the position of the smartphone in space and use in entertainment applications;

• touchscreen sensors.

This set allows you to meet the needs of the vast majority of users. But this seemed a little to the Canadian-American group of scientists, and as a result, the above-mentioned idea of embedding sensors in glass was born and worked out in the laboratory.

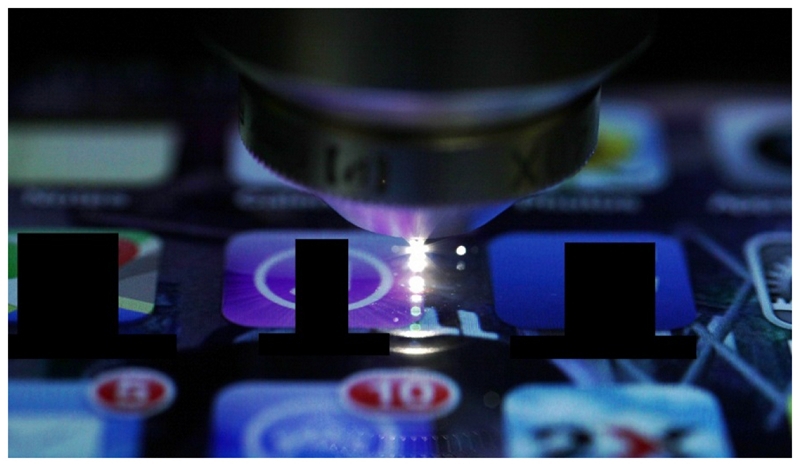

It consists in introducing various sensors into the glass, which transmit not a electric, but a photon signal. To do this, using a laser in a protective glass (the developers used Gorilla Glass), a system of the thinnest channels-waveguides, invisible to the naked eye and not distorting the image, is formed.

To demonstrate the performance of the idea, the authors created two laboratory samples. The first is a thermal sensor based on the Mach-Zehnder interferometer, consisting of direct and curved waveguides. When heated, the glass expands, thereby increasing the length of the waveguides. The smartphone measures how much the wavelength of the light passing through the waveguides changes, and based on this determines the temperature of the glass .

The second sample received an embedded authentication system . For this, a waveguide system was formed with transversely “drilled” holes in different places.

Light is lost at these holes. And for each device it turns out its own unique pattern of light “breakouts”, like a fingerprint. For the user, they are invisible. As a result, the smartphone can be used as one of the levels in the security system during transactions. To do this, it will be enough to “show” the display to an infrared detector, which counts the unique location of the holes. In particular, this method is somewhat more secure compared to radio frequency confirmation, which is easier to intercept. And infrared waves are blocked by most materials, so nobody will scan your smartphone in your pocket.

Of course, this is not the first case when waveguides are “cut out” in a glass by a laser. But no one has ever done this with Gorilla Glass. The fact is that high internal stress is inherent in this glass, due to which it is distinguished by high mechanical strength . Therefore, the developers feared that the glass could just burst during processing.

According to the authors of the project, the waveguides created by them are of the highest quality. The fact is that even the use of a laser usually does not give an ideal flatness of the channel walls, which leads to the inevitable loss of light at various defects. However, in this work, the signal loss is about 10 times less than usual. This is precisely the result of internal tension in Gorilla Glass and its high homogeneity. Also, these properties of glass made it possible to use a low-power laser that operated with ultrashort pulses at a high frequency, which made the walls of the waveguides even more even.

In contrast to the same photolithography, laser waveguide formation has a number of advantages:

• Cheap and easy.

• Ability to create waveguides not only on the glass surface, but also in its volume.

• The ability to create multiple layers of waveguides, which allows to reduce the size of the devices themselves.

In addition to the two types of applications described above, technology developers see a number of other areas where photon sensors embedded in protective glass can be used. For example, in medicine: it will be possible to determine the level of sugar in the blood, or even carry out DNA analysis.

Also, the developers believe that, in addition to embedding sensors, this technology can eventually be used to introduce computational modules, creating transparent touch screens like the ones we saw in Avatar and Iron Man films.

How do you think, how can this technology be useful and in demand?

Source: https://habr.com/ru/post/362371/

All Articles