History of composite materials

Composite material is a heterogeneous solid material of two or more components with a clear difference between them. The simplest example is plain plywood. But there are much more interesting technologies and materials used in the aircraft industry, automotive industry and other areas. Read more - under habrakatom.

Two or more inhomogeneous materials are used together to create a new unique material or to improve the characteristics of one of them. The first use of this method dates back to 1500 BC, when in Egypt and Mesopotamia they began to use clay and straw for the construction of buildings. Also straw was added to the composition to strengthen pottery and boats.

The bricks in which the scrapping was used are called "saman". The Egyptians did something like this:

')

The next milestone is 1200 AD. The Mongols tried: they created the first composite bow from materials such as wood, bone and animal glue. Mongolian onions were usually made from several layers of wood (mostly birch), which were glued together with animal glue. Horny plates were placed on the inside of the bow, securing veins.

There would be no modern composites, if scientists did not invent plastics. Prior to this, the only source of glue and binders were natural resins, which were obtained from animals or plants. And at the beginning of the 20th century, vinyl, polystyrene, phenol and polyester were developed. These materials were significantly superior to those previously used.

But the plastics could not provide sufficient strength. It was necessary to reinforce better, and in 1935 the company Owens / Corning has developed fiberglass. In combination with plastic polymers, it is an extremely strong and at the same time very light structure. This was the beginning of the reinforced polymer industry.

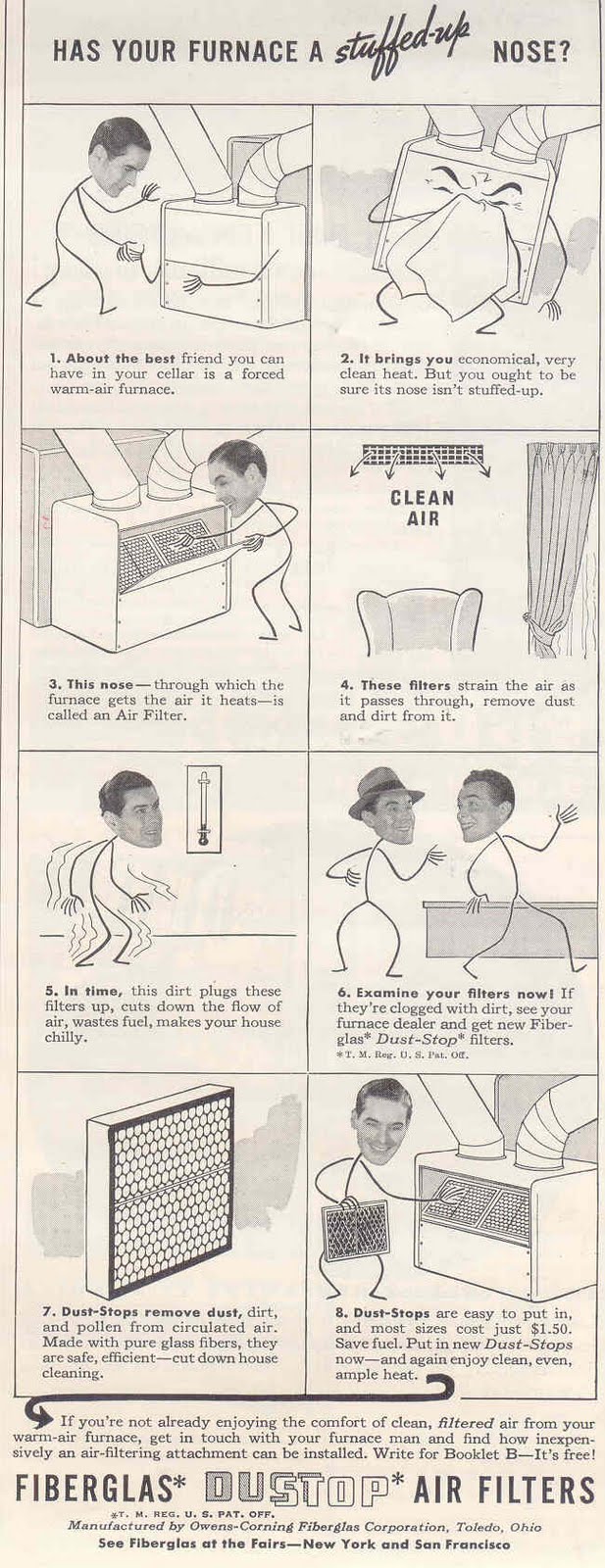

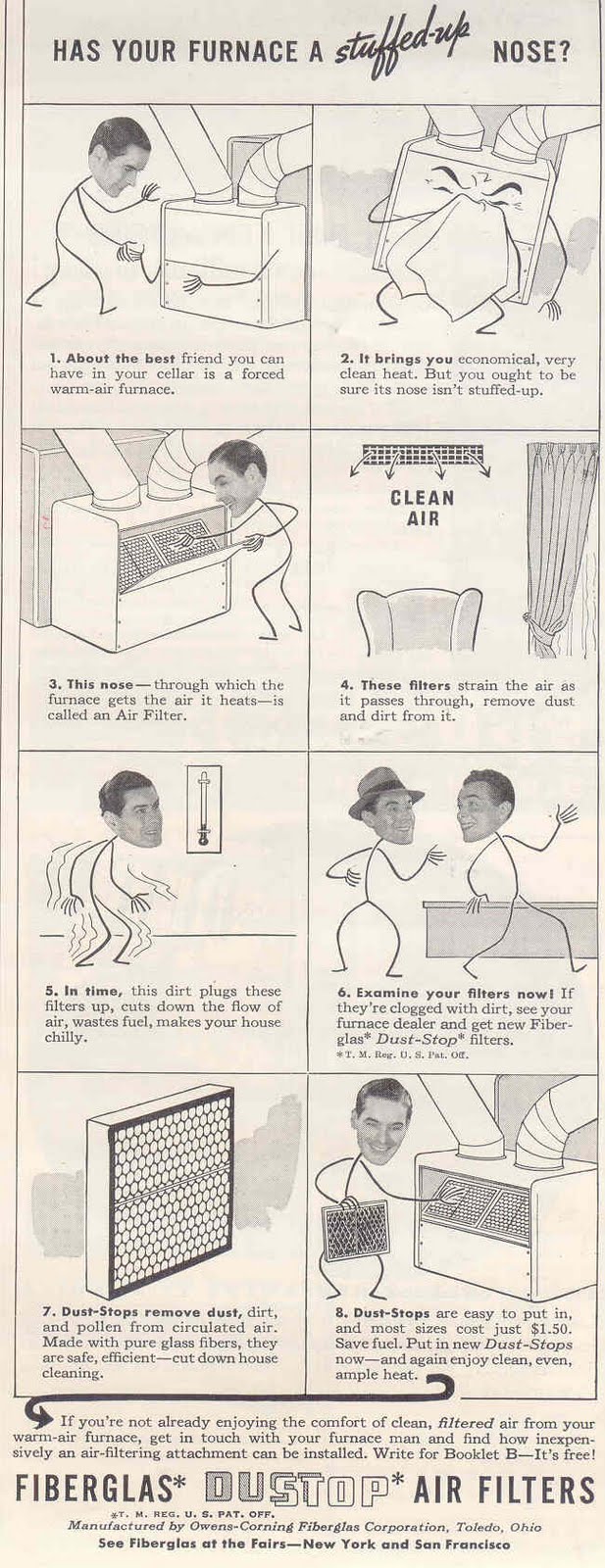

The first advertisement for a fiberglass product dates back to 1939. This is an Owens-Corning air filter.

In 1957, the company advertised fiberglass curtains with a print.

One more thing from 1970 - fiberglass panels for thermal insulation during construction.

Many inventions in this area were invented during the wars. As the Mongols created their compositional bow, so the Second World War allowed the reinforced polymers to migrate from the laboratories to the real world.

Alternative materials to reduce the weight of the final product were needed in military aircraft industry. Very quickly, engineers realized the advantages of composites in terms of their weight and strength.

Also, engineers have learned about the advantage of fiberglass composites, as radio permeability. And they began to use "fairings" to protect the radio modules from external factors, including wind.

During the war, Germany also tried to develop a stealth aircraft, long before Stealth in the United States. Then it was necessary to use a composite material in the case, where between the layers of plywood would be a filler of light balsa - a tree growing in South America. But in 1944 this material was unattainable for the Germans, so it was necessary to use a formholz ersatz composite: between layers of 1.5 mm plywood was a mixture of resin-impregnated sawdust and porous coal.

In general, by the end of the war a small niche of the composite industry was filled. And now there was a difficult task: how to switch from military orders to products for peaceful purposes.

Among the obvious options were boats. The first boat with a composite hull was presented in 1946. Around the same time, they made a fiberglass surfboard. And there was a method of “broach” - “pultrusion” used in the production of polymer composite materials.

For example, the dry pultrusion scheme. The method greatly simplified production.

Cars are another important area for polymer composites.

In 1954, the first sports car with a fiberglass body appeared in the United States: the Kaiser-Darrin. This car accelerated to 60 miles per hour in 15.1 seconds. And the maximum speed is a little less than 100 miles per hour, that is, about 160 km / h.

These characteristics were achievable with a 90 horsepower engine due to the small weight of the car - about 2,200 pounds, or 997 kg.

In the 1970s, materials became even better and more complex. DuPont, one group led by Stephanie Quolec, developed aramid fibers known to us as Kevlar. Now it is a well-known material used in body armor. Kevlar is five times stronger than steel. Created his material for the reinforcement of automobile tires, it is now used for these purposes. They also reinforce copper and fiber-optic cables.

Car tire Wrangler using Kevlar.

Kevlar sleeve with dock for iPhone.

Kevlar is used in unmanned aircraft. For example, for additional protection of the unmanned aerial vehicle RQ-11 Raven.

In the production of aircraft parts, aluminum and other metals are replaced with low-density composites, which makes it possible to reduce the mass of aircraft. This, in turn, saves fuel. So composites are now widely used in civil aviation.

In the Boeing 787 DreamLiner, 50% of the fuselage elements are made of carbon-based composite materials. Thus, this aircraft is lighter and stronger than a conventional liner with an aluminum fuselage.

The Genx engine from General Electric also has composite materials: the body, turbine blades and nozzles that inject fuel into the combustion chamber are made from them.

Of course, composite materials are used to create weapons. For example, the intercontinental ballistic missile "Topol-M": it is 90% composed of composites, including engine designs and the head part.

Replacement barrel rifle Christensen Arms, made of carbon fiber. The rifle is built on the basis of the shutter group Remington-700.

Carabiner Carbon Custom R-93 with interchangeable trunks.

Butts for rifles made of composite materials. Presented at Open Innovations last year by Russian manufacturer HC Composite.

The most interesting group of composites is polymers. This is not plywood or straw in bricks, but materials difficult to manufacture, sometimes involving work even at the nano level (10 to -9 degrees).

A bit of theory this time. For reinforcement use:

carbon fabrics (carbon);

aramid fabrics (kevlar);

hybrid fabrics (carbon + kevlar);

unidirectional hybrid fabrics;

fiberglass;

multiaxial fabrics;

carbon tapes;

prepregs.

For the manufacture of carbon parts used as a simple carbon fiber with randomly located and fill the entire volume of material threads, and fabric (Carbon Fabric). The most common types of weaving, as Plain, Twill, Satin.

The density of the fabric, or specific gravity, expressed in g / m ^ 2, in addition to the type of weaving depends on the thickness of the fiber, which is determined by the amount of carbon. This characteristic is a multiple of a thousand. So, the abbreviation 1K means a thousand threads in the fiber.

Often we can hear from theboys in the area of motorists that they are “glued over with carbon-fiber cars”. Here we are actually talking more often not about polymer composites, but about the usual decorative film made under carbon. Such a film does not provide any advantage: the weight of parts will not become less, it will not win in strength either. So this is the pursuit of fashion and the desire to make your own car look like a racing car from Need For Speed.

In the construction of buildings and roads, for the reinforcement of concrete tanks and storages, carbon fiberglass and fiberglass reinforcement, inert to all aggressive media, possessing high strength and an expected service life of 75 years, is used.

Reinforcing during construction and after it is possible from the outside: using carbon tape impregnated with a two-component epoxy compound. The picture is better, unfortunately, not found.

Asphalt can be reinforced by adding fiber to it. Remember the straw and clay at the beginning of the post?

Polymer composites themselves can hardly be called nanotechnological if nanotechnology is defined as “a set of technological methods and techniques used in the study, design and production of materials, devices and systems, including targeted control and management of the structure, chemical composition and interaction of their individual nanoscale elements ( with dimensions of the order of 100 nm and less), which lead to improvement, or the appearance of additional operational and / or consumer characteristics ISTIC and properties of the resulting products. "

But recently, polymer resins have entered the market as a binder, which, based on the process of their production, quite falls under the definition of nanotechnology.

Of course, initially military developments very often turn into products of peacetime and are used also in medicine.

Let's start with dentistry. Seals you put? It was highly likely to be composite materials. Directly in front of you just before installation, the doctor mixes the components, then sets in place and then holds the UV lamp for several minutes. These are light-cured fillings.

There are chemical fillings. For example, glass ionomer cement from powder and liquid, in which the powder is alumino fluorosilicate glass with fluorine, and the liquid is an aqueous solution of polyacrylic acid.

Composite fibers are used in the manufacture of orthoses. An orthosis is a special device designed to unload, fix, activate or correct the functions of a joint or limb. There are Cortesa, bandages, shoes and other products.

Of course, prostheses are also made from composite materials. In the case of samples for runners, this is simply necessary, since other materials cannot provide similar flexibility and strength.

The most ancient method, which helped to make bricks and bows stronger, combined with modern materials provides invaluable advantages in various fields. Among them are aviation and automobile manufacturing, astronautics, medicine, including dentistry and prosthetics, and construction. Even such a simple thing, as reinforcement in concrete structures, has now become more technological, made of fiberglass and carbon fiber. Seals at the dentist, as I wrote above, also apply to composite materials. Composite materials have firmly entered our lives, sometimes completely unnoticed by us.

Moreover, the use of this method is possible even at home. I mentioned in one of the past publications that I plan to make new fashions for my quadrocopter. As soon as I achieve success in this - I will write.

Ancient discoverers

Two or more inhomogeneous materials are used together to create a new unique material or to improve the characteristics of one of them. The first use of this method dates back to 1500 BC, when in Egypt and Mesopotamia they began to use clay and straw for the construction of buildings. Also straw was added to the composition to strengthen pottery and boats.

The bricks in which the scrapping was used are called "saman". The Egyptians did something like this:

')

The next milestone is 1200 AD. The Mongols tried: they created the first composite bow from materials such as wood, bone and animal glue. Mongolian onions were usually made from several layers of wood (mostly birch), which were glued together with animal glue. Horny plates were placed on the inside of the bow, securing veins.

Plastic era

There would be no modern composites, if scientists did not invent plastics. Prior to this, the only source of glue and binders were natural resins, which were obtained from animals or plants. And at the beginning of the 20th century, vinyl, polystyrene, phenol and polyester were developed. These materials were significantly superior to those previously used.

But the plastics could not provide sufficient strength. It was necessary to reinforce better, and in 1935 the company Owens / Corning has developed fiberglass. In combination with plastic polymers, it is an extremely strong and at the same time very light structure. This was the beginning of the reinforced polymer industry.

The first advertisement for a fiberglass product dates back to 1939. This is an Owens-Corning air filter.

In 1957, the company advertised fiberglass curtains with a print.

One more thing from 1970 - fiberglass panels for thermal insulation during construction.

Early innovations in composite materials: World War II

Many inventions in this area were invented during the wars. As the Mongols created their compositional bow, so the Second World War allowed the reinforced polymers to migrate from the laboratories to the real world.

Alternative materials to reduce the weight of the final product were needed in military aircraft industry. Very quickly, engineers realized the advantages of composites in terms of their weight and strength.

Also, engineers have learned about the advantage of fiberglass composites, as radio permeability. And they began to use "fairings" to protect the radio modules from external factors, including wind.

During the war, Germany also tried to develop a stealth aircraft, long before Stealth in the United States. Then it was necessary to use a composite material in the case, where between the layers of plywood would be a filler of light balsa - a tree growing in South America. But in 1944 this material was unattainable for the Germans, so it was necessary to use a formholz ersatz composite: between layers of 1.5 mm plywood was a mixture of resin-impregnated sawdust and porous coal.

Adaptation of composites

In general, by the end of the war a small niche of the composite industry was filled. And now there was a difficult task: how to switch from military orders to products for peaceful purposes.

Among the obvious options were boats. The first boat with a composite hull was presented in 1946. Around the same time, they made a fiberglass surfboard. And there was a method of “broach” - “pultrusion” used in the production of polymer composite materials.

For example, the dry pultrusion scheme. The method greatly simplified production.

Cars are another important area for polymer composites.

In 1954, the first sports car with a fiberglass body appeared in the United States: the Kaiser-Darrin. This car accelerated to 60 miles per hour in 15.1 seconds. And the maximum speed is a little less than 100 miles per hour, that is, about 160 km / h.

These characteristics were achievable with a 90 horsepower engine due to the small weight of the car - about 2,200 pounds, or 997 kg.

In the 1970s, materials became even better and more complex. DuPont, one group led by Stephanie Quolec, developed aramid fibers known to us as Kevlar. Now it is a well-known material used in body armor. Kevlar is five times stronger than steel. Created his material for the reinforcement of automobile tires, it is now used for these purposes. They also reinforce copper and fiber-optic cables.

Car tire Wrangler using Kevlar.

Kevlar sleeve with dock for iPhone.

Kevlar is used in unmanned aircraft. For example, for additional protection of the unmanned aerial vehicle RQ-11 Raven.

Space and Aviation

In the production of aircraft parts, aluminum and other metals are replaced with low-density composites, which makes it possible to reduce the mass of aircraft. This, in turn, saves fuel. So composites are now widely used in civil aviation.

In the Boeing 787 DreamLiner, 50% of the fuselage elements are made of carbon-based composite materials. Thus, this aircraft is lighter and stronger than a conventional liner with an aluminum fuselage.

The Genx engine from General Electric also has composite materials: the body, turbine blades and nozzles that inject fuel into the combustion chamber are made from them.

Weapons

Of course, composite materials are used to create weapons. For example, the intercontinental ballistic missile "Topol-M": it is 90% composed of composites, including engine designs and the head part.

Replacement barrel rifle Christensen Arms, made of carbon fiber. The rifle is built on the basis of the shutter group Remington-700.

Carabiner Carbon Custom R-93 with interchangeable trunks.

Butts for rifles made of composite materials. Presented at Open Innovations last year by Russian manufacturer HC Composite.

Modern polymer composite materials

The most interesting group of composites is polymers. This is not plywood or straw in bricks, but materials difficult to manufacture, sometimes involving work even at the nano level (10 to -9 degrees).

A bit of theory this time. For reinforcement use:

carbon fabrics (carbon);

aramid fabrics (kevlar);

hybrid fabrics (carbon + kevlar);

unidirectional hybrid fabrics;

fiberglass;

multiaxial fabrics;

carbon tapes;

prepregs.

How are carbon fabrics used?

For the manufacture of carbon parts used as a simple carbon fiber with randomly located and fill the entire volume of material threads, and fabric (Carbon Fabric). The most common types of weaving, as Plain, Twill, Satin.

The density of the fabric, or specific gravity, expressed in g / m ^ 2, in addition to the type of weaving depends on the thickness of the fiber, which is determined by the amount of carbon. This characteristic is a multiple of a thousand. So, the abbreviation 1K means a thousand threads in the fiber.

Often we can hear from the

In the construction of buildings and roads, for the reinforcement of concrete tanks and storages, carbon fiberglass and fiberglass reinforcement, inert to all aggressive media, possessing high strength and an expected service life of 75 years, is used.

Reinforcing during construction and after it is possible from the outside: using carbon tape impregnated with a two-component epoxy compound. The picture is better, unfortunately, not found.

Asphalt can be reinforced by adding fiber to it. Remember the straw and clay at the beginning of the post?

Nanotechnology

Polymer composites themselves can hardly be called nanotechnological if nanotechnology is defined as “a set of technological methods and techniques used in the study, design and production of materials, devices and systems, including targeted control and management of the structure, chemical composition and interaction of their individual nanoscale elements ( with dimensions of the order of 100 nm and less), which lead to improvement, or the appearance of additional operational and / or consumer characteristics ISTIC and properties of the resulting products. "

But recently, polymer resins have entered the market as a binder, which, based on the process of their production, quite falls under the definition of nanotechnology.

The medicine

Of course, initially military developments very often turn into products of peacetime and are used also in medicine.

Let's start with dentistry. Seals you put? It was highly likely to be composite materials. Directly in front of you just before installation, the doctor mixes the components, then sets in place and then holds the UV lamp for several minutes. These are light-cured fillings.

There are chemical fillings. For example, glass ionomer cement from powder and liquid, in which the powder is alumino fluorosilicate glass with fluorine, and the liquid is an aqueous solution of polyacrylic acid.

Composite fibers are used in the manufacture of orthoses. An orthosis is a special device designed to unload, fix, activate or correct the functions of a joint or limb. There are Cortesa, bandages, shoes and other products.

Of course, prostheses are also made from composite materials. In the case of samples for runners, this is simply necessary, since other materials cannot provide similar flexibility and strength.

Conclusion

The most ancient method, which helped to make bricks and bows stronger, combined with modern materials provides invaluable advantages in various fields. Among them are aviation and automobile manufacturing, astronautics, medicine, including dentistry and prosthetics, and construction. Even such a simple thing, as reinforcement in concrete structures, has now become more technological, made of fiberglass and carbon fiber. Seals at the dentist, as I wrote above, also apply to composite materials. Composite materials have firmly entered our lives, sometimes completely unnoticed by us.

Moreover, the use of this method is possible even at home. I mentioned in one of the past publications that I plan to make new fashions for my quadrocopter. As soon as I achieve success in this - I will write.

Source: https://habr.com/ru/post/362189/

All Articles